Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 100 hours |

|

| Every 250 hours |

|

Checking the Hydraulic Fluid

Hydraulic Fluid Type: Toro® HYPR-OIL ™ 500 hydraulic oil

Hydraulic Fluid Capacity: 4.7 L (1.25 US gallons)

-

Park the machine on a level surface, disengage the PTO, engage the parking brake, and move the motion-control levers outward to the NEUTRAL-LOCK position.

-

Shut off the engine and remove the key. Allow the machine to cool.

-

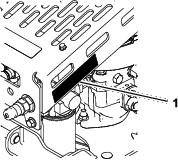

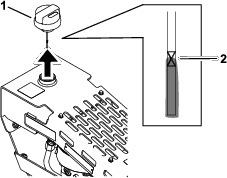

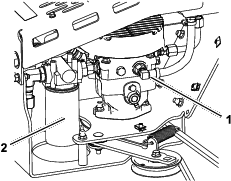

Remove the breather cap and wipe off the dipstick with a clean rag (Figure 10).

-

Insert the dipstick into the tank, but do not thread the cap; then remove it and check the fluid level (Figure 10).

Note: The fluid level should be between the upper and lower lines on the dipstick.

-

If the fluid level is low, add hydraulic fluid to the tank until the level is between the upper and lower lines on the dipstick (Figure 10).

-

Install the breather cap.

Changing the Hydraulic Fluid, Filter, and Screen Fitting

-

Park the machine on a level surface, disengage the PTO, engage the parking brake, and move the motion-control levers outward to the NEUTRAL-LOCK position.

-

Shut off the engine and remove the key. Allow the machine to cool.

Warning

Hot hydraulic fluid can cause severe burns.

Allow the hydraulic fluid to cool before performing any maintenance on the hydraulic system.

-

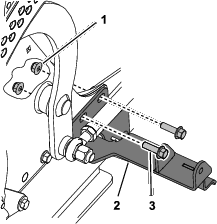

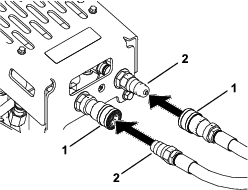

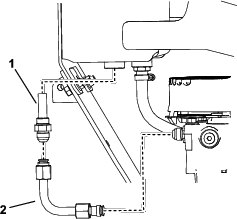

Place a drain pan under the 90-degree fitting (Figure 11).

-

Remove the hose from the fitting and allow the fluid to drain.

-

Install the hose to the fitting.

-

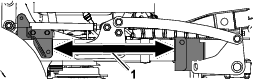

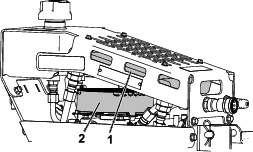

Remove the tube and screen fitting from the tank and pump (Figure 12). Discard the screen fitting.

-

Install the new screen fitting to the tank (Figure 12). Torque the fitting to 79 to 98 N∙m (58 to 72 ft-lb)

-

Install the tube to the screen fitting and pump (Figure 12).

-

Torque the ends of the tube to 45 to 56 N∙m (33 to 41 ft-lb).

-

Remove the hydraulic filter (Figure 11).

-

Lubricate the new filter gasket and fill the filter with hydraulic fluid.

-

Ensure that the filter-mounting area is clean and screw the filter on until the gasket contacts the mounting plate; then tighten the filter an additional 1/10 to 1/4 turn (Figure 11).

-

Fill the hydraulic tank with fluid; refer to Checking the Hydraulic Fluid.

-

Start the engine and let it run with an attachment connected for about 2 minutes to purge air from the system.

-

Shut off the engine and check for leaks.

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury; otherwise, gangrene may result.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

-

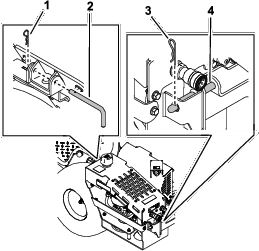

Cleaning Debris from the Hydraulic Cooler

-

Park the machine on a level surface, disengage the PTO, engage the parking brake, and move the motion-control levers outward to the NEUTRAL-LOCK position.

-

Shut off the engine and remove the key.

-

Remove any debris buildup from the hydraulic cooler and pump fan shroud (Figure 13).

Note: You may use pressurized air to help remove debris that are difficult to reach.

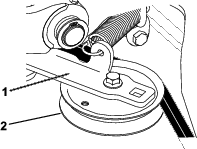

Replacing the Belt

Signs of a worn belt include squeaking when the belt is rotating, a frayed belt edge, burn marks, and cracks. Replace the deck belt if any of these conditions are evident.

-

Park the machine on a level surface, disengage the PTO, engage the parking brake, and move the motion-control levers outward to the NEUTRAL-LOCK position.

-

Shut off the engine and remove the key.

-

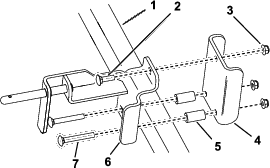

Remove the belt from the pulleys (Figure 14).

-

Install the new belt around the machine clutch pulley, idler pulley, and high-flow pump pulley (Figure 14).

Note: Use care not to cut or twist the belt as you slide it under the pump pulley and frame. You do not need to remove the spring from the idler pulley.