Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Servicing the Bedbar

Removing the Bedbar

-

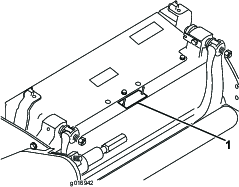

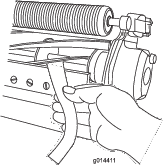

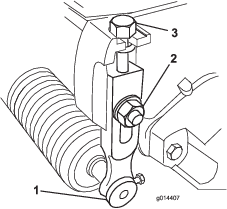

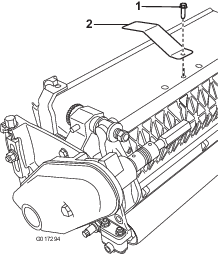

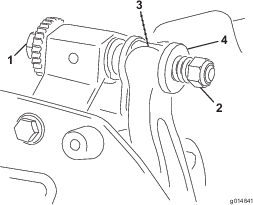

Turn the bedbar-adjusting screw, counterclockwise, to back the bedknife away from the reel (Figure 19).

-

Back out the spring-tension nut until the washer is no longer tensioned against the bedbar (Figure 19).

-

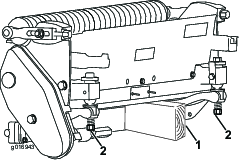

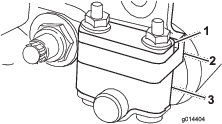

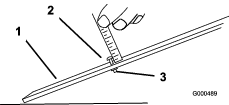

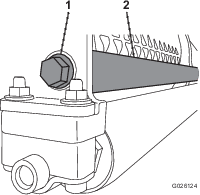

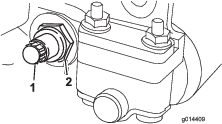

On each side of the machine, loosen the locknut securing the bedbar bolt (Figure 20).

-

Remove each bedbar bolt allowing the bedbar to be pulled downward and removed from the machine bolt (Figure 20).

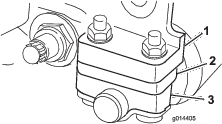

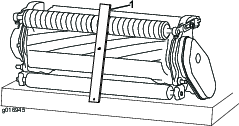

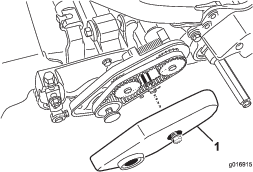

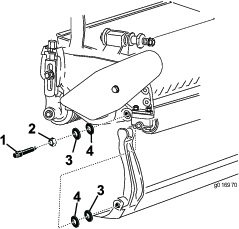

Account for the 2 nylon and 2 stamped steel washers on each end of the bedbar (Figure 21).

Assembling the Bedbar

-

Install the bedbar, positioning the mounting ears between the washer and bedbar adjuster.

-

Secure the bedbar to each side plate with the bedbar bolts (nuts on bolts) and 4 washers (8 total).

-

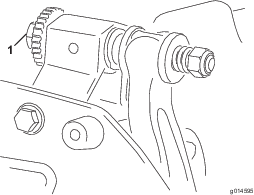

Position a nylon washer on each side of the side plate boss. Place a steel washer outside each of the nylon washers (Figure 21).

-

Torque the bedbar bolts to 27 to 36 N-m (240 to 320 inch-lb). Tighten the locknuts by hand until the outside steel washer stops rotating and there is no end play. The washers on the inside may have a gap.

Important: Do not overtighten the locknuts or they will deflect the side plates.

-

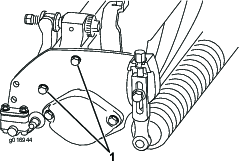

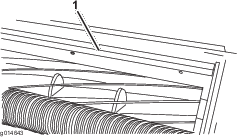

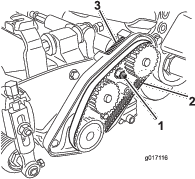

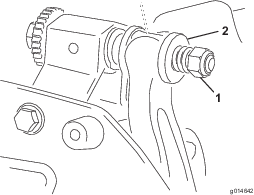

Tighten the spring tension nut until the spring is collapsed, then back it off 1/2 turn (Figure 22).

Backlapping the Reel

Danger

Contact with the reel or other moving parts can result in personal injury.

Keep your fingers, hands, and clothing away from the reels or other moving parts.

-

Stay away from the reel while backlapping.

-

Never use a short handled paint brush for backlapping. Handle assembly parts are available from your local authorized Toro distributor.

You can backlap the reels either by leaving the cutting unit on the traction unit or removing the cutting unit completely from the traction unit. If the cutting unit is left on the traction unit, move the hex coupler between the main drive and cutting unit drive to the decoupled position to prevent excessive wear to the reel brake.

-

Position the machine on a clean, level surface.

-

Shut off the machine as follows:

-

Gasoline units: shut off the engine and disconnect the spark-plug wire.

-

Electric units: turn off the machine and disconnect the battery connector (T-handle).

-

-

Engage the parking brake.

-

Connect the backlapping machine to the cutting unit by connecting a 1/2 inch hex socket to the reel pulley output shaft on the left side of the cutting unit.

Note: Additional instructions and procedures on Backlapping are available in the Toro Sharpening Reel and Rotary Mowers Manual (Form No. 80-300PT).

Note: For a better cutting edge, run a file across the front face of the bedknife when the lapping operation is completed. This removes any burrs or rough edges that may have built up on the cutting edge. A very light file touch may be necessary on the top edge to break the burr off completely from the cutting edge.

Note: If the cutting unit was left attached to the machine during backlapping, couple the hex shaft of the machine back to the cutting unit.