| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

Warning

This product contains a chemical or chemicals known to the State of California to cause cancer, birth defects, or reproductive harm.

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

This spark ignition system complies with Canadian ICES-002.

The enclosed Engine Owner's Manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely. Keep for future reference.

You may contact Toro directly at www.Toro.com for product and accessory information, help finding a dealer, or to register your product.

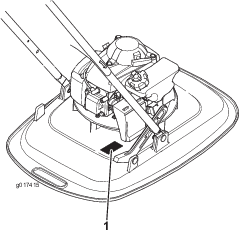

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product.

Write the product model and serial numbers in the space below:

This manual identifies potential hazards and has safety messages identified by the safety alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

For models with stated engine horsepower, the gross horsepower of the engine was laboratory rated by the engine manufacturer in accordance with SAE J1349. As configured to meet safety, emission, and operating requirements, the actual engine horsepower on this class machine will be significantly lower.

Safety

This cutting machine can amputate hands and feet and throw objects. Failure to observe the following safety instructions could result in serious injury or death.

The following safety section is adapted from ANSI B71.4–2012 and EN 14910.

General Operation

-

Read the Operator’s Manual and other training material. If the operator(s) or mechanic(s) cannot read English it is the owners responsibility to explain this material to them.

-

Become familiar with the safe operation of the equipment, operator controls, and the safety signs.

-

All operators and mechanics should be trained. The owner is responsible for training the users.

-

Never let children or untrained people operate or service the equipment. Local regulations may restrict the age of the operator.

-

The owner/user can prevent and is responsible for accidents or injuries occurring to themselves, other people, or property.

-

Do not put hands or feet near or under the machine.

-

Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Only use accessories and attachments approved by the manufacturer.

-

Clear the area of objects such as rocks, wire, toys, etc., which could be thrown by the cutting line. Stay behind the handle when the engine is running.

-

Be sure the area is clear of bystanders before operating. Stop machine if anyone enters the area.

-

Always wear substantial, slip-resistant footwear and long pants.

-

Wear appropriate clothing including hard hat, safety glasses, and hearing protection. Tie back long hair. Do not wear jewelry.

-

Do not pull machine backward unless absolutely necessary. Always look down and behind before and while moving backward.

-

slow down and use caution when making turns and crossing roads and sidewalks. Stop cutting element if not mowing.

-

Never direct discharged material toward anyone. Avoid discharging material against a wall or obstruction. Material may ricochet back toward the operator. Stop the cutting line when crossing gravel surfaces.

-

Check that the operator’s presence controls, safety switches, and shields are attached and functioning properly. do not operate unless they are functioning properly.

-

Never leave a running machine unattended.

-

Stop the engine and wait until the cutting line comes to a complete stop, and remove the spark plug wire before cleaning or unclogging the machine.

-

Operate machine only in daylight or good artificial light.

-

Do not operate machine while tired, ill, or under the influence of alcohol or drugs.

-

Never operate machine in wet grass. Always be sure of your footing; walk; never run.

-

Never raise the deck with the engine running.

-

If the machine should start to vibrate abnormally, stop the engine and check for the cause immediately. Vibration is generally a warning of trouble.

-

Use care when loading or unloading the machine into a trailer or truck.

Slope Operation

Slopes are a major factor related to slip and fall accidents, which can result in severe injury. Operation on all slopes require extra caution. If you feel uneasy on a slope, do not mow it.

-

Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven terrain could cause a slip and fall accident. Tall grass can hide obstacles.

-

Do not mow on wet grass or excessively steep slopes. Poor footing could cause a slip and fall accident.

-

Do not mow near drop-offs, ditches, or embankments. You could lose your footing or balance.

-

When using the machine, always keep both hands on the handlebar.

-

When cutting steep slopes from the top of the slope and a longer reach is needed, never tie the HoverPro to a rope; use the extended handlebar kit option.

Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the machine and the mowing activity. Never assume that children will remain where you last saw them.

-

Keep children out of the mowing area and under the watchful care of a responsible adult other than the operator.

-

Be alert and turn machine off if a child enters the area.

-

Never allow children to operate the machine.

-

Use extra care when approaching blind corners, shrubs, trees, or other objects that may block your view of a child.

Service

Safe Handling of Gasoline

To avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive.

-

Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

-

Use only an approved gasoline container.

-

Never remove gas cap or add fuel with the engine running. Allow engine to cool before refueling.

-

Never refuel or drain the machine indoors.

-

Never store the machine or fuel container where there is an open flame, spark, or pilot light such as on a water heater or on other appliances.

-

Never fill containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always place containers on the ground away from your vehicle before filling.

-

Remove gas-powered equipment from the truck or trailer and refuel it on the ground. If this is not possible, then refuel such equipment with a portable container, rather than from a gasoline dispenser nozzle.

-

Keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete. Do not use a nozzle lock-open device.

-

If fuel is spilled on clothing, change clothing immediately.

-

Never overfill fuel tank. Replace gas cap and tighten securely.

Warning

Exhaust contains carbon monoxide, an odorless, deadly poison that can kill you.

Do not run the engine indoors or in an enclosed area.

General Service

-

Never operate machine in a closed area.

-

Keep all nuts and bolts tight to be sure the equipment is in safe working condition.

-

Never tamper with safety devices. Check their proper operation regularly.

-

Keep machine free of grass, leaves, or other debris build-up. Clean up oil or fuel spillage and remove any fuel-soaked debris. Allow machine to cool before storing in an enclosed space.

-

Never make any adjustments or repairs with the engine running. Disconnect the spark plug wire and ground against engine to prevent unintended starting.

-

Do not change the engine governor setting or overspeed the engine.

-

Maintain or replace safety and instruction labels, as necessary.

-

If gasoline is spilled, do not attempt to start the engine but move the machine away from the area of spillage and avoid creating any source of ignition until the gasoline vapor has dissipated.

-

Replace faulty silencers.

-

Before using, always visually inspect to see that the cutting line, bolts and cutter assembly are not worn or damaged. Replace worn or damaged cutting lines in sets to preserve balance.

-

Stop the cutting line if the machine has to be tilted for transportation when crossing surfaces other than grass, and when transporting the machine to and from the area to be mowed.

-

Never pick up or carry a machine while the engine is running.

-

Stop the engine and disconnect the spark plug wire, make sure that all moving parts have come to a complete stop:

-

Before clearing blockages.

-

Before checking, cleaning, or working on the machine.

-

After striking a foreign object. Inspect the machine for damage and make repairs before restarting and operating the machine.

-

If the machine starts to vibrate abnormally.

-

Whenever you leave the machine.

-

Before refueling.

-

-

Ensure the engine and fuel tank are empty of fuel before rotating the machine beyond a 25 degree angle.

-

Use care when checking the cutting line. Wrap the cutting line or wear gloves, and use caution when servicing them. Only replace the cutting line.

-

Keep hands and feet away from moving parts. If possible, do not make adjustments with the engine running.

-

Shut off the fuel while storing or transporting the machine. Do not fuel near open flames, and do not drain fuel indoors.

-

Park the machine on level ground. Never allow untrained personnel to service the machine.

-

Allow the engine to cool before storing in any enclosure.

-

Replace worn or damaged parts for safety.

-

If the fuel tank has to be drained, this should be done outdoors. The drained fuel should be stored in a container specifically designed for fuel storage or it should be disposed of carefully.

-

Start the engine carefully according to the Operator’s Manual and with feet away from the cutting elements.

-

Do not tilt the trimmer when starting the engine, except if the trimmer has to be tilted for starting. In this case do not tilt it more than absolutely necessary and lift only the part which is away from the operator.

-

Examine the trimmer regularly and replace worn or damaged parts for safety. Never replace the cutting unit with metal parts and only use cutting heads and cutting elements which are suitable for use at the operating speed of the trimmer;

Sound Pressure

This machine has a sound pressure level at the operator’s ear of 88 dBA, which includes an Uncertainty Value (K) of 2 dBA. The sound pressure level was determined according to the procedures outlined in EN ISO 11201.

Sound Power

This machine has a guaranteed sound power level of 98 dBA, which includes an Uncertainty Value (K) of 2 dBA. The sound power level was determined according to the procedures outlined in EN ISO 3744.

Vibration

Measured vibration level for the left hand = 3.4 m/s2.

Measured vibration level for the right hand = 4.4 m/s2.

Uncertainty Value (K) = 2 m/s2.

The measured values were determined according to the procedures outlined in EN ISO 20643.

Safety and Instructional Decals

Important: Safety and instruction decals are located near areas of potential danger. Replace damaged decals.

Setup

Note: Determine right and left side of the machine from normal operating position.

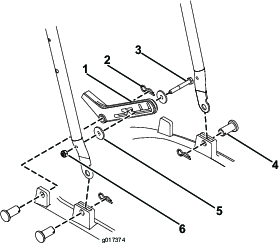

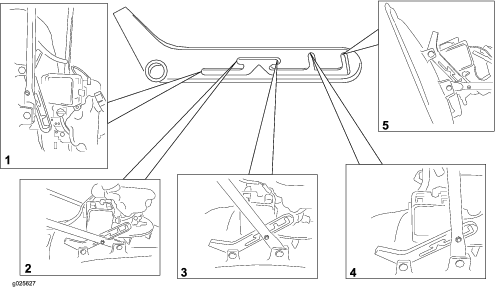

Assembling the Handle

-

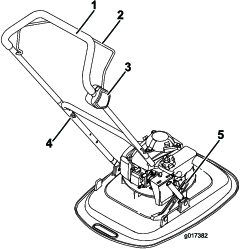

Slide the lower handle into the frame (Figure 3).

-

Secure each side with a retaining pin and a haripin (Figure 3).

-

Secure the footstop to the right side of the lower handle using an M6 nut, and M6 bolt, and 2 washers (Figure 3).

-

Attach the footstop to the frame with a retaining pin and a hairpin (Figure 3).

-

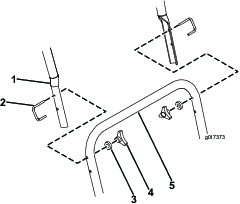

Connect the upper handle to the lower handle by securing each side with a U bolt, an M6 washer, and a handwheel (Figure 4).

Filling the Engine with Oil

Important: Your machine does not come with oil in the engine. Before starting the engine, fill the engine with oil.

Max. fill: 0.59 L (20 oz), type: Multigrade Mineral 10W-30 oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

-

Move the machine to a level surface.

-

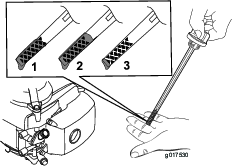

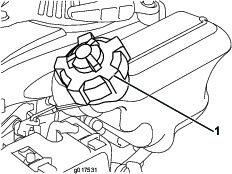

Remove the dipstick (Figure 5).

-

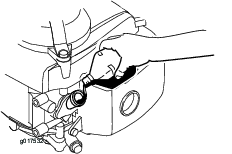

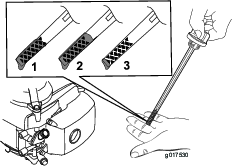

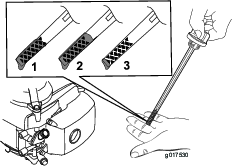

Slowly pour oil into the oil fill hole, wait 3 minutes, and check the oil level on the dipstick by wiping the dipstick clean and then inserting, but not screwing in, the oil fill cap into the hole (Figure 6).

Note: Fill the engine crankcase with oil until the dipstick indicates that the engine oil level is correct as shown in Figure 5. If you overfill the engine with oil, remove the excess oil as directed in Changing the Engine Oil.

-

Install the dipstick and hand tighten it securely.

Important: Change the engine oil after the first 5 operating hours; change it yearly thereafter. Refer to Changing the Engine Oil.

Product Overview

| Model | Cutting width | Product width |

| 02615 | 400 mm (15-3/4 inches) | 500 mm (19-11/16 inches) |

Operation

Filling the Fuel Tank

Danger

Gasoline is extremely flammable and explosive. A fire or explosion from gasoline can burn you and others.

-

To prevent a static charge from igniting the gasoline, place the container and/or machine directly on the ground before filling, not in a vehicle or on an object.

-

Fill the tank outdoors when the engine is cold. Wipe up spills.

-

Do not handle gasoline when smoking or around an open flame or sparks.

-

Store gasoline in an approved fuel container, out of the reach of children.

Fill the fuel tank with fresh unleaded regular gasoline having an octane rating at or near 87 from a major name-brand service station (Figure 9).

Important: Do not use any fuel that contains more than 10% ethanol. Alternative fuels with high alcohol content can cause hard starting, poor engine performance, and may cause internal engine damage.

Important: To reduce starting problems, add fuel stabilizer to the fuel all season, mixing it with gasoline less than 30 days old.

Checking the Engine Oil Level

-

Move the machine to a level surface.

-

Remove the dipstick and wipe it with a clean cloth.

-

Insert, but do not screw in, the dipstick into the oil fill hole.

-

Remove the dipstick and check it.

-

To determine the proper oil level on the dipstick, refer to Figure 10).

-

If the oil level is low, slowly pour oil into the oil fill hole, wait 3 minutes, and check the oil level on the dipstick by wiping the dipstick clean and then inserting, but not screwing in, the oil fill cap into the hole.

Note: Max. fill: 20 oz. (0.59 l), Multigrade Mineral 10W-30 oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

Note: Fill the engine crankcase with oil until the dipstick indicates that the engine oil level is correct as shown in Figure 10. If you overfill the engine with oil, remove the excess oil as directed in Changing the Engine Oil.

-

Install the dipstick and hand tighten it securely.

Important: Change the engine oil after the first 5 operating hours; change it yearly thereafter. Refer to Changing the Engine Oil.

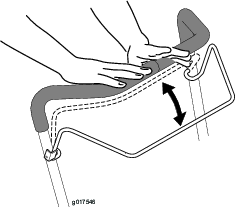

Adjusting the Cutting Height

Warning

Adjusting the cutting height may bring you into contact with the moving cutting unit, causing serious injury.

-

Stop the engine and wait for all moving parts to stop.

-

Wear gloves while handling the cutting unit.

Caution

If the engine has been running, the muffler will be hot and can severely burn you. Keep away from the hot muffler.

Adjust the cutting height as desired.

-

Turn the fuel switch to the off position.

-

Disconnect the wire from the spark plug.

-

Tilt the machine on its left side.

-

Wearing protective gloves, remove the nylon cutting line.

-

Reposition the spacers to the desired height, then reinstall the nylon cutting line.

Starting the Engine

-

Open the fuel tank vent by turning the vent knob at least 2 or 3 turns counterclockwise.

-

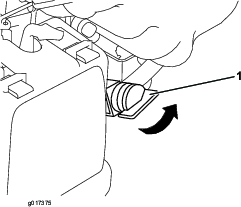

Turn the fuel valve to the On position (Figure 12).

-

Place your foot on the deck and tilt the machine towards you (Figure 13).

-

Pull the recoil-start handle.

Note: Do not allow the starter grip to snap back against the engine. Return it gently to prevent damage to the starter.

Note: If the machine does not start after several attempts, contact an Authorized Service Dealer.

Adjusting the Handle Position

Refer to Figure 14 for the different handle positions.

Note: For proper storage procedure, refer to Before storage.

Stopping the Engine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

To stop the engine, release the engine stop handle (Figure 15).

Important: When you release the engine control bar, both the engine and cutting line should stop within 5 seconds. If they do not stop properly, stop using your machine immediately and contact an Authorized Service Dealer.

Hauling

-

Use care when loading or unloading the machine into a trailer or a truck.

-

Tie the machine down securely using straps, chains, cable, or ropes. Both the front and the rear straps should be directed down and outward from the machine.

Operating Tips

General Mowing Tips

Warning

Operating the engine on a slope greater than 25° will severely damage the engine because of a lack of lubrication. Potential damage includes stuck valves, scored pistons, or burned crank bearings.

-

Before operating the machine on a slope, complete a site survey to measure the slope where you will operate the machine.

-

Do not operate the 4-cycle Honda engine on this machine on slopes greater than 25°.

-

Clear the area of sticks, stones, wire, branches, and other debris that the cutting line could hit.

-

Avoid striking solid objects with the cutting line. Never deliberately mow over any object.

-

If the machine strikes an object or starts to vibrate, immediately stop the engine, disconnect the wire from the spark plug, and examine the machine for damage.

-

For best performance, install a new cutting line before the cutting season begins.

-

Replace the cutting line when necessary with a Toro replacement cutting line.

Cutting Grass

-

Cut only about a third of the grass blade at a time. Do not cut below the 51 mm (2 inch) setting unless the grass is sparse or it is late fall when grass growth begins to slow down. Refer to Adjusting the Cutting Height.

-

Mow only dry grass or leaves. Wet grass and leaves tend to clump on the yard and can cause the machine to plug or the engine to stall.

Warning

Wet grass or leaves can cause serious injury if you slip and contact the cutting line. Mow only in dry conditions.

-

Alternate the mowing direction. This helps disperse the clippings over the lawn for even fertilization.

-

If the finished lawn appearance is unsatisfactory, try one or more of the following:

-

Replace the cutting line.

-

Walk at a slower pace while mowing.

-

Raise the cutting height on your machine.

-

Cut the grass more frequently.

-

Overlap cutting swaths instead of cutting a full swath with each pass.

-

Cutting Leaves

-

After cutting the lawn, ensure that half of the lawn shows through the cut leaf cover. You may need to make more than one pass over the leaves.

-

Slow down your mowing speed if the machine does not cut the leaves finely enough.

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Before each use or daily |

|

| After each use |

|

| Every 100 hours |

|

| Before storage |

|

| Yearly |

|

Preparing for Maintenance

-

Shut off the engine and wait for all moving parts to stop.

-

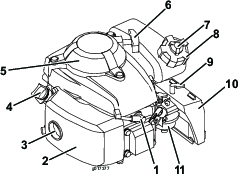

Disconnect the spark-plug wire from the spark plug (Figure 16) before performing any maintenance procedure.

-

After performing the maintenance procedure(s), connect the spark-plug wire to the spark plug.

Warning

Tipping the machine may cause the fuel to leak. Gasoline is flammable, explosive and can cause personal injury.

Run the engine dry or remove the gasoline with a hand pump; never siphon.

Important: Always tip the machine onto its side with the dipstick down.

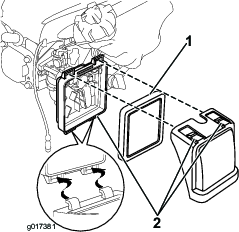

Replacing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Press down on the latch tabs on top of the air cleaner cover (Figure 17).

-

Open the cover (Figure 17).

-

Remove the filter (Figure 17).

-

Inspect the air filter.

-

If the filter is damaged or is wet with oil or fuel, replace it.

-

If the filter is dirty, tap it on a hard surface several times or blow compressed air less than 207 kPa (30 psi) through the side of the filter that faces the engine.

Note: Do not brush the dirt off the filter; brushing forces dirt into the fibers.

-

-

Remove dirt from the air cleaner body and cover using a moist rag. Do not wipe dirt into the air duct.

-

Insert the filter into the air cleaner (Figure 17).

-

Install the cover (Figure 17).

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Yearly |

|

-

Ensure that the fuel tank contains little or no fuel so that fuel does not leak out when you tip the machine onto its side.

-

Run the engine a few minutes before changing the oil to warm it.

Note: Warm oil flows better and carries more contaminants.

-

Disconnect the wire from the spark plug. Refer to Preparing for Maintenance.

-

Remove the dipstick.

-

Tip the machine onto its side, with the dipstick down, to drain the used oil out through the oil fill tube.

-

Return the machine to the operating position.

-

Slowly pour oil into the oil fill hole, wait 3 minutes, and check the oil level on the dipstick by wiping the dipstick clean and then inserting, but not screwing in, the oil fill cap into the hole.

Note: Max. fill: 0.59 L (20 oz), type: Multigrade Mineral 10W-30 oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

Note: Fill the engine crankcase with oil until the dipstick indicates that the engine oil level is correct as shown in (Figure 18). If you overfill the engine with oil, remove the excess oil as directed in 5.

-

Install the dipstick and hand tighten it securely.

-

Dispose of the used oil properly at a local recycling center.

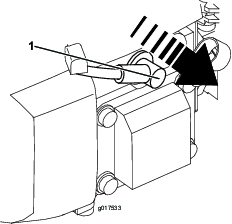

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

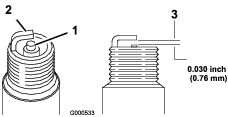

Use a Champion RN9YC spark plug or equivalent.

-

Stop the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Clean around the spark plug.

-

Remove the spark plug from the cylinder head.

Important: Replace a cracked, fouled, or dirty spark plug. Do not clean the electrodes because grit entering the cylinder can damage the engine.

-

Set the gap on the plug to 0.76 mm (0.030 inch) as shown in Figure 19.

-

Install the spark plug and the gasket seal.

-

Torque the plug to 20 N-m (15 ft-lb).

-

Connect the wire to the spark plug.

Replacing the Nylon Cutting String

-

Turn the fuel tap to the OFF position and close the vent knob.

-

Disconnect the wire from the spark plug.

-

Turn the machine on its left side, with the carburetor facing upwards.

-

Wearing protective gloves, remove the nylon cutting line.

-

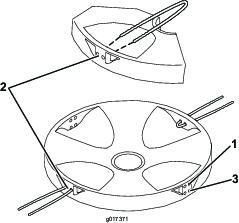

Place one length of nylon cutting line into the desired cutting height setting. Ensure that a second length is placed in the corresponding cutting height on the opposite side of the cutting disc.

Note: If using a spare reel, cut the line to a length of 200 mm (7-7/8 inches).

Cleaning the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| After each use |

|

Warning

The machine may dislodge material from under the machine housing.

-

Wear eye protection.

-

Stay in the operating position (behind the handle).

-

Do not allow bystanders in the area.

-

Tip the machine on its side.

-

Use a brush or compressed air to remove grass and debris from the exhaust guard, the top cowl, and the surrounding deck areas.

Storage

Store the machine in a cool, clean, dry place.

Preparing the Machine for Storage

Warning

Gasoline vapors can explode.

-

Do not store gasoline more than 30 days.

-

Do not store the machine in an enclosure near an open flame.

-

Allow the engine to cool before storing it.

-

On the last refueling of the year, add fuel stabilizer to the fuel as directed by the engine manufacturer.

-

Run the machine until the engine stops from running out of fuel.

-

Prime the engine and start it again.

-

Allow the engine to run until it stops. When you can no longer start the engine, it is sufficiently dry.

-

If you are storing the machine hanging on a wall, switch the fuel tap off and close the vent of the fuel cap.

-

Disconnect the wire from the spark plug.

-

Remove the spark plug, add 30 ml (1 oz.) of oil through the spark plug hole, and pull the starter rope slowly several times to distribute oil throughout the cylinder to prevent cylinder corrosion during the off-season.

-

Install the spark plug and tighten it with a torque wrench to 20 N-m (15 ft-lb).

-

Tighten all nuts, bolts, and screws.

Troubleshooting

| Problem | Possible Cause | Corrective Action |

|---|---|---|

| The engine does not start. |

|

|

| The engine starts hard or loses power. |

|

|

| The engine runs rough. |

|

|

| The machine or engine vibrates excessively. |

|

|

| There is an uneven cutting pattern. |

|

|