Maintenance

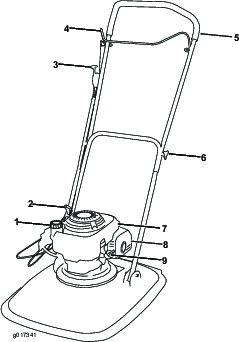

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 operating hours |

|

| Before each use or daily |

|

| Every 100 hours |

|

| Before storage |

|

| Yearly |

|

Preparing for Maintenance

-

Stop the engine and wait for all moving parts to stop.

-

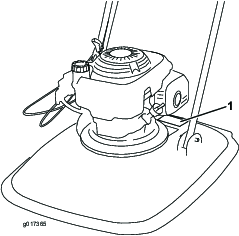

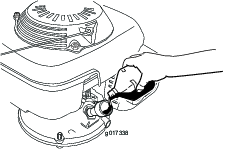

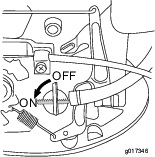

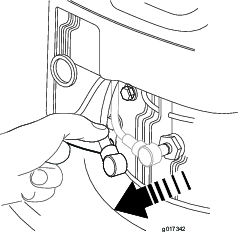

Disconnect the spark plug wire from the spark plug (Figure 19) before performing any maintenance procedure.

-

After performing the maintenance procedure(s), connect the spark plug wire to the spark plug.

Warning

Tipping the machine may cause the fuel to leak. Gasoline is flammable, explosive and can cause personal injury.

Run the engine dry or remove the gasoline with a hand pump; never siphon.

Important: Always tip the machine onto its side with the dipstick down.

Replacing the Air Cleaner

-

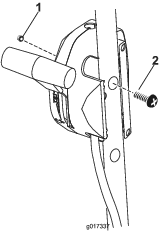

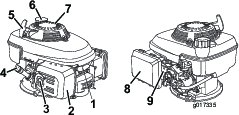

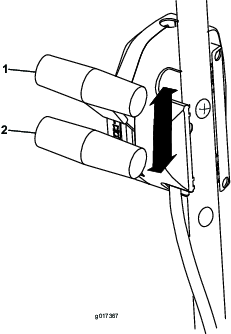

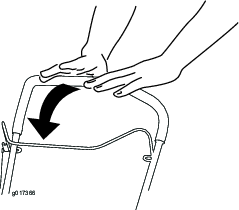

Press down on the latch tabs on top of the air cleaner cover (Figure 20).

-

Open the cover.

-

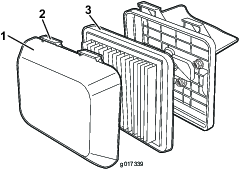

Remove the filter (Figure 20).

-

Inspect the filter, and replace it if it is damaged or excessively dirty.

-

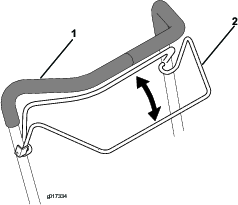

Inspect the paper air filter.

-

If the filter is damaged or is wet with oil or fuel, replace it.

-

If the filter is dirty, tap it on a hard surface several times or blow compressed air less than 207 kPa (30 psi) through the side of the filter that faces the engine.

Note: Do not brush the dirt off the filter; brushing forces dirt into the fibers.

-

-

Remove dirt from the air cleaner body and cover using a moist rag. Do not wipe dirt into the air duct.

-

Insert the filter into the air cleaner.

-

Install the cover.

Changing the Engine Oil

-

Ensure that the fuel tank contains little or no fuel so that fuel does not leak out when you tip the machine onto its side.

-

Run the engine a few minutes before changing the oil to warm it.

Note: Warm oil flows better and carries more contaminants.

-

Disconnect the wire from the spark plug. Refer to Preparing for Maintenance.

-

Remove the dipstick.

-

Tip the machine onto its side, with the dipstick down, to drain the used oil out through the oil fill tube.

-

Return the machine to the operating position.

-

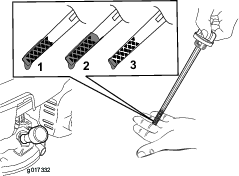

Slowly pour oil into the oil fill hole, wait 3 minutes, and check the oil level on the dipstick by wiping the dipstick clean and then inserting, but not screwing in, the oil fill cap into the hole.

Note: Max. fill: 0.59 l (20 oz.), type: Multigrade Mineral 10W-30 oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

Note: Fill the engine crankcase with oil until the dipstick indicates that the engine oil level is correct as shown in (Figure 21). If you overfill the engine with oil, remove the excess oil as directed in 5.

-

Install the dipstick and hand tighten it securely.

-

Dispose of the used oil properly at a local recycling center.

Servicing the Spark Plug

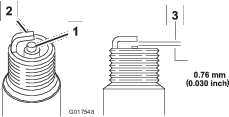

Check the spark plug after every 100 operating hours. Use an Champion RN9YC spark plug or equivalent.

-

Stop the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Clean around the spark plug.

-

Remove the spark plug from the cylinder head.

Important: Replace a cracked, fouled, or dirty spark plug. Do not clean the electrodes because grit entering the cylinder can damage the engine.

-

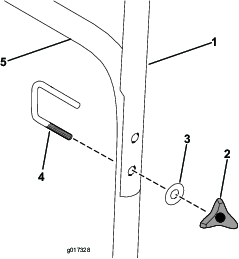

Set the gap on the plug to 0.76 mm (0.030 inch) (Figure 22).

-

Install the spark plug and the gasket seal.

-

Torque the plug to 20 N-m (15 ft-lb).

-

Connect the wire to the spark plug.

Replacing the Flexiblade/Cutterbar

Important: You will need a torque wrench to install the blade properly. If you do not have a torque wrench or are uncomfortable performing this procedure, contact an Authorized Service Dealer.

Examine the blade whenever you run out of gasoline. If the blade is damaged or cracked, replace it immediately. If the blade edge is dull or nicked, have it sharpened or replace it.

Warning

The blade is sharp; contacting the blade can result in serious personal injury.

-

Disconnect the wire from the spark plug.

-

Wear gloves when servicing the blade.

-

Disconnect the spark plug wire from the spark plug. Refer to Preparing for Maintenance.

-

Tip the machine onto its side, with the air filter up.

-

Use a block of wood to hold the blade steady.

-

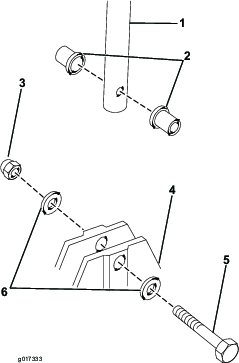

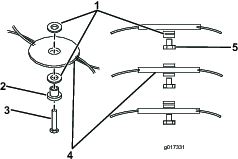

Remove the blade (turn the blade bolt counterclockwise), saving all the mounting hardware.

-

Install the new blade (turn the blade bolt clockwise) and all mounting hardware.

Important: Position the curved ends of the blade to point toward the machine housing.

-

Use a torque wrench to tighten the blade bolt to 25 N-m (18 ft-lb).

Important: A bolt torqued to 25 N-m (18 ft-lb) is very tight. While holding the blade with a block of wood, put your weight behind the ratchet or wrench and tighten the bolt securely. This bolt is very difficult to overtighten.

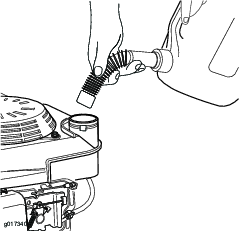

Cleaning the Machine

Warning

The machine may dislodge material from under the machine housing.

-

Wear eye protection.

-

Stay in the operating position (behind the handle).

-

Do not allow bystanders in the area.

-

Tip the machine on its side.

-

Use a brush or compressed air to remove grass and debris from the exhaust guard, the top cowl, and the surrounding deck areas.