Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first hour |

|

| After the first 2 hours |

|

| Before each use or daily |

|

| Every 100 hours |

|

| Yearly |

|

| Yearly or before storage |

|

Maintenance Safety

Read the following safety precautions before performing any maintenance on the machine:

-

Before performing any maintenance, service, or adjustment, shut off the engine and remove the key. If major repairs are ever needed, contact an Authorized Service Dealer.

-

Check all fasteners at frequent intervals for proper tightness to ensure that the machine is in safe working condition.

-

Do not change the governor settings on the engine.

-

Purchase only genuine Toro replacement parts and accessories.

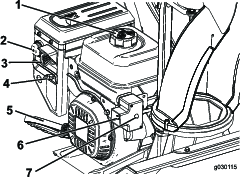

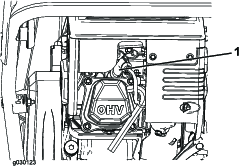

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

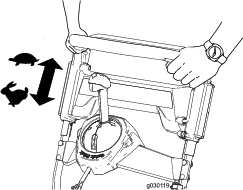

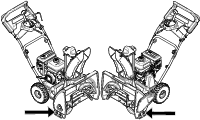

Checking and Adjusting the Skids

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

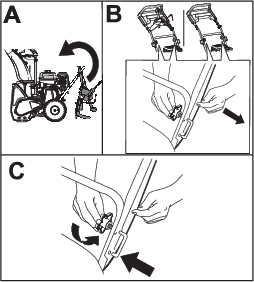

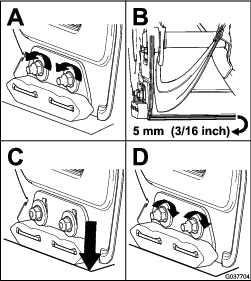

Check the skids to ensure that the auger does not contact the paved surface. Adjust the skids as needed to compensate for wear (Figure 17).

-

Loosen the skid bolts.

-

Slide a 5 mm (3/16 inch) board underneath the scraper.

Note: Using a thinner board results in a more aggressive scraper; using a thicker board results in a less aggressive scraper.

-

Lower the skids to the ground.

Note: Ensure that the skids are flat on the ground.

-

Tighten the skid bolts.

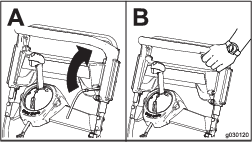

Inspecting the Throwing Edges

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

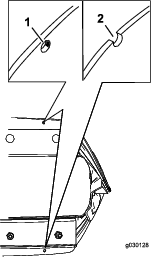

Before each session, inspect the throwing edges for wear. When a throwing edge has worn down to the wear-indicator hole, have an Authorized Service Dealer replace the throwing edges (Figure 18).

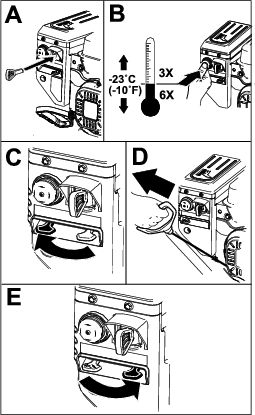

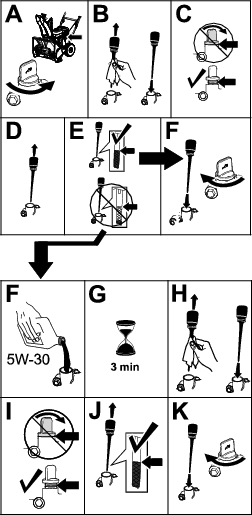

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

If possible, run the engine for a few minutes before changing the oil to warm it. Warm oil flows better and carries more contaminants.

| Engine oil capacity | Model 36002: 0.50 L (17 fl oz); Model 36003: 0.59 L (20 fl oz) |

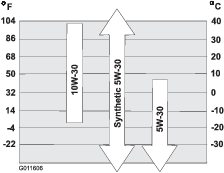

| Oil viscosity | Refer to Figure 20. |

| API service classification | SJ or higher |

-

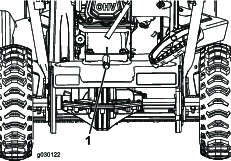

Move the machine to a level surface.

-

Place an oil-drain pan under the oil-drain plug, remove the oil-drain plug, and tip the machine backward and drain the used oil in the oil-drain pan (Figure 19).

-

After draining the used oil, return the machine to the operating position.

-

Install the oil-drain plug and tighten it securely.

-

Clean around the oil-fill cap.

-

Use Figure 20 to select the best oil viscosity for the outdoor temperature range expected:

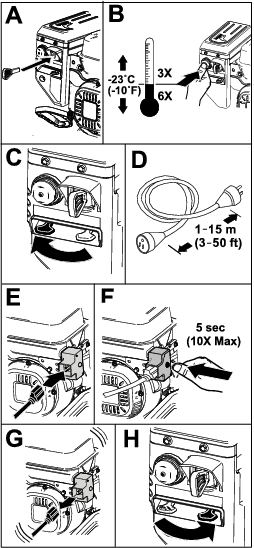

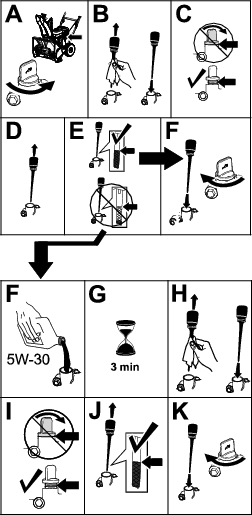

Replacing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Warning

Replacing the spark plug while the engine is hot can result in burns.

Wait until the engine is cool to replace the spark plug.

Use a Toro spark plug or equivalent (Champion® RN9YC or NGK BPR6ES).

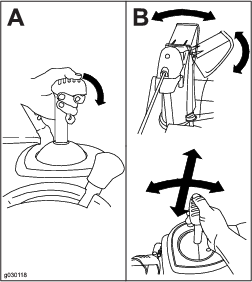

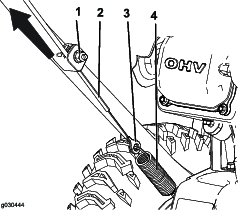

Adjusting the Auger Cable

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

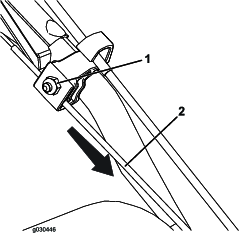

If the drive belt slips or squeals under a heavy load, adjust the auger cable.

-

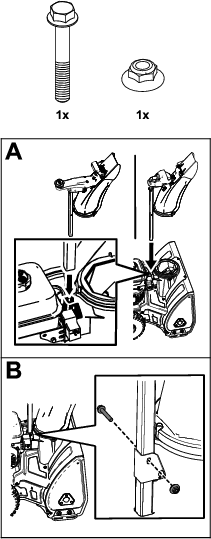

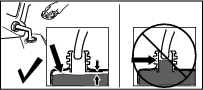

Loosen the nut on the lower cable clamp, but do not remove it (Figure 24).

-

Pull the cable up to remove some slack (Figure 24).

Important: Do not remove all the slack from the cable. Removing all the slack from the cable prevents the auger from stopping properly.

-

Hold the cable in place and tighten the nut (Figure 24).

Adjusting the Transmission Cable

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

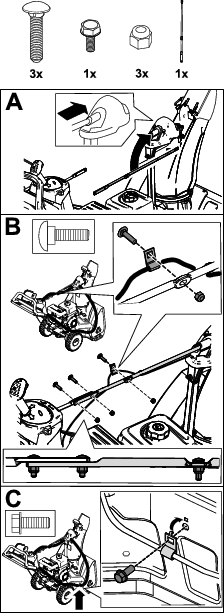

If the wheels easily stall out, or if the wheels drive without engaging the self-propel handle, adjust the transmission cable.

-

Loosen the nut on the upper cable clamp, but do not remove it (Figure 25).

-

Pull the cable down to remove most of the slack in the cable (Figure 25).

Important: Do not remove all the slack from the cable. Removing all the slack from the cable may cause the wheels to engage without engaging the self-propel handle.

-

Tighten the nut (Figure 25).