CALIFORNIA

Proposition 65 Warning

Note: Determine the left and right sides of the machine from the normal operating position.

Note: If you have a bagger attached to your machine, this kit will not fit.

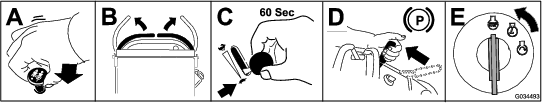

Disengage the PTO.

Move the motion-control levers to the NEUTRAL-LOCK position.

Move the throttle control to the SLOW position.

Engage the parking brake.

Shut off the engine and remove the key.

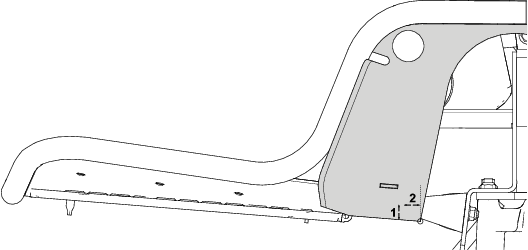

Using the measurements shown in Figure 2, drill a 9.5 mm (3/8 inch) hole into each side of the platform gussets.

Note: Only drill holes into the platform gussets, if necessary. Some models already have the holes.

Parts needed for this procedure:

| Left striper-mount bracket | 1 |

| Right striper-mount bracket | 1 |

| Flat washer | 4 |

| Hex-head bolt (3/8 x 4 inches) | 4 |

Jack up the rear of the machine.

Use jack stands to support the rear of the machine.

Remove the jack used in step 1.

Remove the wheels from the rear of the machine.

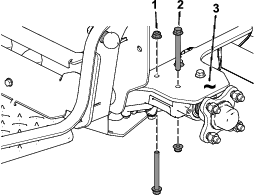

Remove the existing 2 flange-head bolts (3/8 x 3-1/2 inches) and 2 flange nuts (3/8 inch) from the rear of the transmission mount on each side (Figure 3).

Retain the 4 flange nuts (3/8 inch).

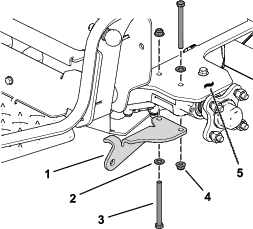

Loosely install a striper-mount bracket to the transmission mount using 2 hex-head bolts (3/8 x 4 inches), previously removed 2 flange nuts (3/8 inch), and 2 flat washers on each side (Figure 4).

Parts needed for this procedure:

| Roller assembly | 1 |

| Left torsion spring | 1 |

| Right torsion spring | 1 |

| Pivot rod | 1 |

| Pivot tube | 1 |

| Pivot washer | 2 |

| Hairpin cotter | 2 |

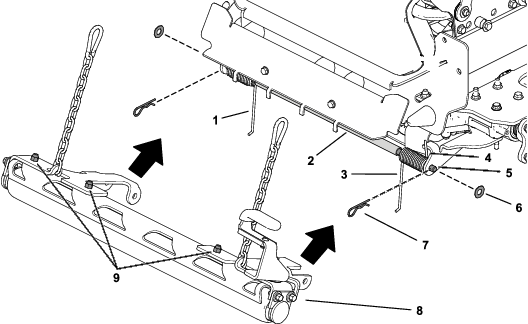

Position the springs into the striper-mount brackets (Figure 5).

Ensure that the short, outside fingers on the springs are under the striper-mount brackets (Figure 5).

Loosen the 4 nuts on top of the roller assembly and align the holes in the roller assembly with the holes in the striper-mount brackets (Figure 5).

While holding the pivot tube in place, insert the pivot rod through the pivot tube, springs, and striper-mount brackets and secure it with 2 pivot washers and 2 hairpin cotters (Figure 5).

Tighten the fasteners on the striper-mount brackets and roller assembly (Figure 4 and Figure 5).

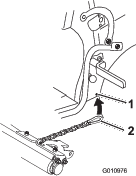

Pull the inside spring finger up over the roller mount (Figure 6).

Hold the operator platform while releasing the platform latch.

Lower the platform down completely.

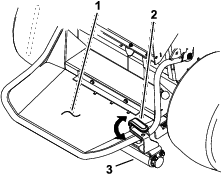

With the platform down, raise the roller up, and rotate the lift handle over the platform (Figure 7).

Snap the chain end into the hole in the lower, front side plate of the platform (Figure 8).

Repeat this procedure on the other side.

Install the wheels on the rear of the machine, and torque the lug nuts to 104 to 126 N∙m (77 to 93 ft-lb).

Jack up the machine, remove the jack stands, and lower the machine.

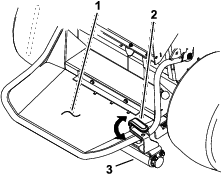

With the platform down, raise the roller up, and rotate the lift handle over the platform (Figure 9).

Rotate the lift handle off the platform to lower the roller.

Raise the platform, which also raises the roller by the chains.

Verify that the latch engages to hold the platform and the roller up.

Release the chain end from the platform.

Raise the platform up.

Release the tension on the springs by rotating the long spring fingers off the roller mounts.

Remove the clevis hairpin cotters.

Remove the roller from the machine.

Install the springs and hairpin cotters onto the roller assembly for later use.

Limp grass where wheel tracks are very visible is usually good for striping.

Stiff grass where wheel tracks are less visible usually produces poor striping.

Cool-season grass types found in northern areas are usually good for striping.

Warm-season grass types found in southern areas usually produce less pronounced striping.

Transition-zone grasses found in the narrow-belt region can produce good striping in some areas, and some portions of the growing season, while producing poor striping in other areas or portions of the season.

Some grass types produce better striping contrast when mowing short. Other grass types or moisture content of the grass can provide better contrast when mowing at a tall height of cut. Experiment with what works best in your situation.

This is how light reflects on the grass.

Mowing patterns that generally run east-west have a greater contrast than north-south patterns.

The striping pattern contrast is less visible around noon and is more visible in mornings and afternoons.

Grass bent toward you appears darker; grass bent away from you appears lighter.

Mowing patterns that generally run along a road has greater contrast when viewed approaching or leaving the property. The contrast of striping is less visible when looking across the mowing direction.

If the property has a focal point, or a viewing location, mow in a pattern that is generally to and from the observation point.

Avoid operating in wet conditions on slopes, if possible.

Large, flat areas usually provide better striping contrast than on slopes or areas with a lot of trimming and edging.

Mowing in morning dew can produce good striping contrast.

Double-cut mowing and mowing a second pass at a 13 mm (1/2 inch) lower height of cut may produce good striping contrast.

Side-dispersal of clippings can hide striping, reducing the contrast effect.

Bagging can display heavy wheel tracks, reducing the effect of striping.

Mulching often displays excellent contrast, enhancing the effect of striping.

The mowing area size has an effect on the final appearance. Large areas may look better when mowed with a large mower. Small areas may not look right when cut with a large mower.

Large areas with occasional trees or other obstructions often look best when the mowing pattern appears to go through the obstruction. For example, it looks best for a pattern to match and continue on the far side of a small pond. A different cross-cut pattern on the far side of a pond may not be visible.

Some areas look best with long, straight lines of a striped-mowing pattern, aligned with the property edge. Some areas look best with a diamond pattern, where neither straight line is aligned with the property edge. Properties with rolling hillsides or ponds look best with a flowing-curves striping pattern. You can highlight and enhance a distinctive feature like a small pond by mowing in a radial or a ring pattern.

On a new property during the first 2 weeks, you may need to follow the exact same pattern and direction in the same wheel tracks. This begins “training the grass to bend in the desired direction.

During the third week, use a cross-grain striping pattern.

During the fourth and fifth weeks, follow with repeating the original pattern. After you establish the primary striping pattern grain, you may alternate the pattern each week to establish a checkerboard or a plaid-style pattern.

Do not mow in the same pattern every week. This causes compaction in the wheel tracks and may produce ruts or depressions along the wheel tracks.

Raise the roller when turning; striping is generally not enhanced by end turns.

Raising the roller reduces confusing the pattern at the ends of the pattern.

Raise the roller and deck, and drive along a previous path to transport from one area of the property to another section.

Do not drive across a striped pattern.

It is usually best to first mow the perimeter to establish a boundary.

When side-discharging, direct the clippings away from walks, drives, flower beds, buildings, and vehicles. If the discharge throws clippings a long distance, mow additional passes to avoid unwanted cleanup of clippings.

Avoid driving backward excessively. Driving back and forth or frequent forward and reverse maneuvers around an obstacle compresses the grass and disturbs the professional appearance of a nice job.

Avoid close trimming with the striping kit installed to reduce damage to landscaping and the roller.

Follow all safe mowing practices as described in the Operator’s Manual. Do not let the striping pattern cause you to mow in a hazardous manner.