Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 1,000 hours |

|

| Monthly |

|

| Yearly |

|

| Every 2 years |

|

Removing the Doors

Tilting the Cab

You can tilt the cab for access under the operator platform for cleaning and maintenance.

The cab and the operator platform tilt together as a single unit. The angle of tilt is less than that of a platform without a cab. This is to ensure that, owing to the weight and position of the tilted cab, the machine has sufficient stability when the cab is tilted.

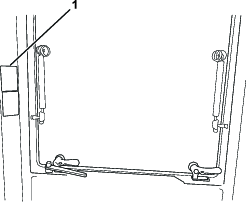

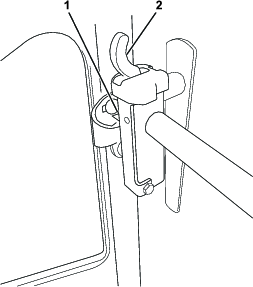

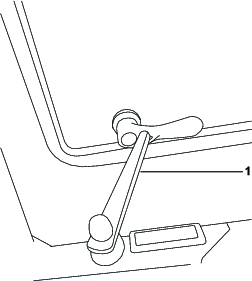

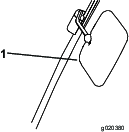

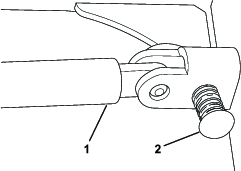

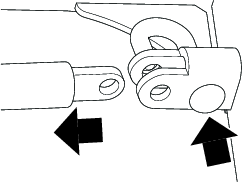

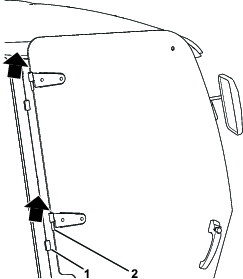

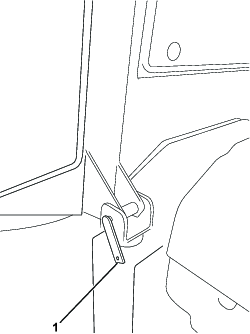

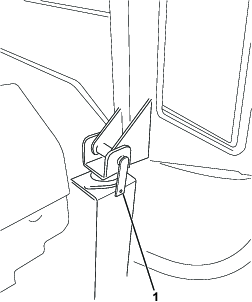

To tilt a cab without the optional tilt kit, release the 2 pins and use lifting equipment with a lifting capacity of at least 250 kg (550 lb); refer to Figure 15 and Figure 16.

If your machine has the optional tilt kit, refer to the instructions for that kit.

Filling the Windshield-Washer Fluid Reservoir

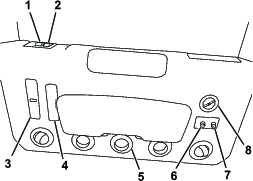

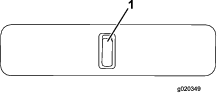

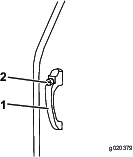

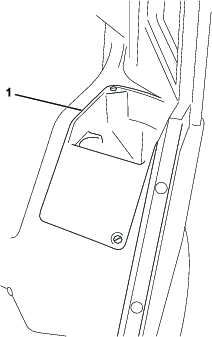

To access the windshield-washer fluid reservoir, remove the tool tray (Figure 17).

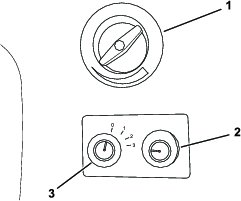

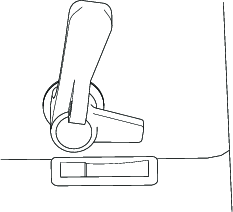

Fill the reservoir with clean water plus the recommended quantity of proprietary windshield-washer fluid (Figure 18).

Warning

Failure to use washer fluid with antifreeze protection in cold weather could result in impaired vision and increase the risk of injury or accident.

If you operate your machine in temperatures below 5°C (40°F), use washer fluid with antifreeze protection.

Accessing the Fuses

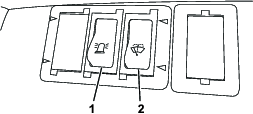

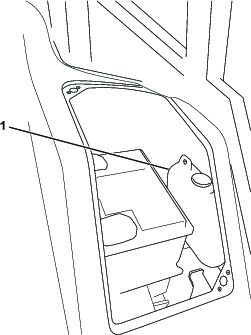

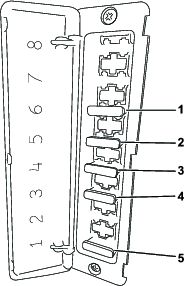

The cab fuses are located in the fuse box in the cab headliner (Figure 19).

Checking the Air-Conditioner System

Check the air-conditioner system to ensure that everything is in good working condition.

Washing the Machine and Cab

When washing the machine and the cab, do not direct water into the roof area.