Maintenance

Replacing the Pressurizer Air Filter

Note: Change the engine oil and filter more frequently when the operating conditions are extremely dusty or sandy.

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

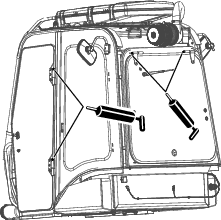

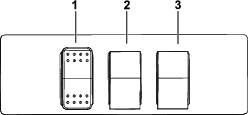

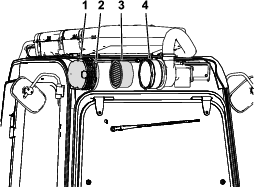

Remove the pressurizer precleaner; lift the tab and rotate the precleaner counterclockwise (Figure 4).

-

Clean the precleaner and inspect for any damage.

-

Pull the pressurizer air filter out of the pressurizer body; inspect for any damage or blockage.

Important: Replace a blocked or damaged air filter immediately; do not attempt to clean the filter.

Important: Do not operate the engine without the air filter and precleaner installed.

-

Install the air filter to the pressurizer body and rotate the precleaner onto the pressurizer body.

Greasing the Machine

Grease type: General-purpose grease.

-

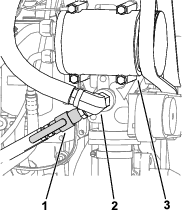

Clean the grease fittings with a rag.

-

Connect a grease gun to each fitting.

-

Pump grease into the fittings until grease begins to ooze out of the bearings (approximately 3 pumps).

-

Wipe up any excess grease.