| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

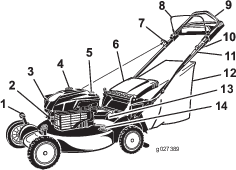

This rotary-blade, walk-behind lawn mower is intended to be used by residential homeowners. It is designed primarily for cutting grass on well-maintained lawns on residential properties. It is not designed for cutting brush or for agricultural uses.

Read this information carefully to learn how to operate and maintain your machine properly and to avoid injury and equipment damage. You are responsible for operating the machine properly and safely.

You may contact Toro directly at www.Toro.com for product and accessory information, help finding a dealer, or to register your product.

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your machine ready. Figure 1 identifies the location of the model and serial numbers on the product.

Write the product model and serial numbers in the following space:

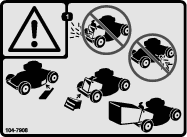

This manual identifies potential hazards and has safety messages identified by the safety alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This product complies with all relevant European directives. For details, see the separate product-specific Declaration of Conformity (DOC) sheet.

Net Torque: The gross or net torque of this engine was laboratory rated by the engine manufacturer in accordance with the Society of Automotive Engineers (SAE) J1940. As configured to meet safety, emission, and operating requirements, the actual engine torque on this class of mower will be significantly lower. Go to www.Toro.com to view specifications on your mower model.

Do not tamper with the engine controls or alter the governor speed; doing so may create an unsafe condition resulting in personal injury.

Safety

This machine has been designed in accordance with EN ISO 5395:2013.

Improperly using or maintaining this mower can result in injury. To reduce the potential for injury, comply with these safety instructions.

To ensure maximum safety, best performance, and to gain knowledge of the product, it is essential that you and any other operator of the mower read and understand the contents of this manual before the engine is ever started. Pay particular attention to the safety alert symbol (Figure 2), which means Caution, Warning, or Danger—“personal safety instruction.” Read and understand the instruction because it has to do with safety. Failure to comply with the instruction may result in personal injury.

General Lawn Mower Safety

This cutting machine is capable of amputating hands and feet and of throwing objects. Failure to observe the following safety instructions could result in serious injury or death.

Training

-

Read the instructions carefully. Be familiar with the controls and the proper use of the equipment.

-

Never allow children or people unfamiliar with these instructions to use the machine. Local regulations can restrict the age of the operator.

-

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their property.

-

Understand explanations for all pictograms used on the machine or in the instructions.

Gasoline

WARNING-Gasoline is highly flammable. Take the following precautions.

-

Store fuel in containers specifically designed for this purpose.

-

Refuel outdoors only and do not smoke while refueling.

-

Add fuel before starting the engine. Never remove the cap of the fuel tank or add gasoline while the engine is running or when the engine is hot.

-

If gasoline is spilled, do not attempt to start the engine but move the machine away from the area of spillage and avoid creating any source of ignition until gasoline vapors have dissipated.

-

Replace all fuel tank and container caps securely.

Preparation

-

While mowing, always wear substantial, slip-resistant footwear and long trousers. Do not operate the equipment when barefoot or wearing open sandals.

-

Thoroughly inspect the area where the equipment is to be used and remove all stones, sticks, wires, bones and other foreign objects.

-

Before using, always visually inspect to see that guards and safety devices, such as deflectors and/or grass catchers, are in place and working correctly.

-

Before using, always visually inspect to see that the blades, blade bolts and cutter assembly are not worn or damaged. Replace worn or damaged blades and bolts in sets to preserve balance.

Starting

-

Do not tilt the machine when starting the engine unless the machine must be tilted for starting. In this case, do not tilt it more than absolutely necessary and lift only the part which is away from the operator.

-

Start the engine carefully according to instructions and with feet well away from the blade(s) and not in front of the discharge chute.

Operation

-

Never mow while people, especially children, or pets are nearby.

-

Mow only in daylight or in good artificial light.

-

Stay alert for holes in the terrain and other hidden hazards.

-

Do not put hands or feet near or under rotating parts. Keep clear of the discharge opening at all times.

-

Never pick up or carry a lawn mower while the engine is running.

-

Use extreme caution when reversing or pulling a pedestrian-controlled mower toward you.

-

Walk, never run.

-

Slopes:

-

Do not mow excessively steep slopes.

-

Exercise extreme caution when on slopes.

-

Mow across the face of slopes, never up and down, and exercise extreme caution when changing direction on slopes.

-

Always be sure of your footing on slopes.

-

-

Reduce speed on slopes and in sharp turns to prevent overturning or loss of control.

-

Stop the blade if the machine must be tilted for transportation when crossing surfaces other than grass and when transporting the machine to and from the area to be mowed.

-

Do not operate the engine in a confined space where dangerous carbon monoxide and other exhaust gasses can collect.

-

Stop the engine

-

whenever you leave the machine.

-

before refueling.

-

before removing the grass catcher.

-

before making height adjustment unless adjustment can be made from the operating position.

-

-

Stop the engine and disconnect the spark-plug wire.

-

before clearing blockages or unclogging chute.

-

before checking, cleaning or working on the machine.

-

after striking a foreign object, inspect the machine for damage and make repairs before restarting and operating the machine.

-

if the machine starts to vibrate abnormally (check immediately).

-

-

Lightning can cause severe injury or death. If you see lightning or hear thunder in the area, do not operate the machine; seek shelter.

-

Watch out for traffic when crossing or near roadways.

Maintenance and Storage

-

Keep all nuts, bolts, and screws tight to be sure that the equipment is in safe working condition.

-

Do not use pressure-cleaning equipment on the machine.

-

Never store the equipment with gasoline in the tank and inside a building where fumes can reach an open flame or spark.

-

Allow the engine to cool before storing in any enclosure.

-

To reduce the fire hazard, keep the engine, silencer, battery compartment and gasoline storage area free of grass, leaves, or excessive grease.

-

Check grass catcher components and the discharge guard frequently and replace with manufacturer's recommended parts, when necessary.

-

Replace worn or damaged parts for safety.

-

Replace faulty silencers.

-

If the fuel tank has to be drained, do this outdoors.

-

Do not change the engine governor settings or overspeed the engine. Operating an engine at excessive speed can increase the hazard of personal injury.

-

Be careful while adjusting the machine to prevent entrapment of the fingers between moving blades and fixed parts of the machine.

-

To ensure the best performance and safety, purchase only genuine Toro replacement parts and accessories. Do not use will fit parts and accessories; they may cause a safety hazard.

Hauling

-

Use care when loading or unloading the machine into a trailer or a truck.

-

Use full-width ramps for loading the machine into a trailer or a truck.

-

Tie the machine down securely using straps, chains, cable, or ropes. Both the front and the rear straps should be directed down and outward from the machine.

Sound Pressure

This unit has a sound pressure level at the operator’s ear of 90 dBA, which includes an Uncertainty Value (K) of 1 dBA.

The sound pressure level was determined according to the procedures outlined in EN ISO 5395-1:2013.

Sound Power

This unit has a guaranteed sound power level of 98 dBA, which includes an Uncertainty Value (K) of 1 dBA.

The sound power level was determined according to the procedures outlined in ISO 11094.

Caution

Long-term exposure to noise while operating the machine may cause some hearing loss.

Wear adequate hearing protection whenever you operate the machine for an extended period of time.

Hand/Arm Vibration

Measured vibration level for right hand = 4.7 m/s2

Measured vibration level for left hand = 3.6 m/s2

Uncertainty Value (K) = 2.4 m/s2

Measured values were determined according to the procedures outlined in EN ISO 5395-1:2013.

Caution

Long-term exposure to vibration while operating the machine may cause some numbness in the hands and wrists.

Wear gloves that dampen the vibration whenever you operate the machine for an extended period of time.

Safety and Instructional Decals

Important: Safety and instruction decals are located near areas of potential danger. Replace damaged decals.

Setup

Important: Remove and discard the protective plastic sheet that covers the engine.

Assembling and Unfolding the Handle

Warning

Assembling and unfolding the handle improperly can damage the cables, causing an unsafe operating condition.

-

Do not damage the cables when assembling and unfolding the handle.

-

If a cable is damaged, contact an Authorized Service Dealer.

-

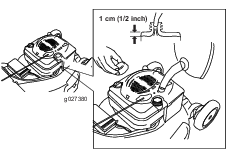

Raise the rear of the machine housing to its highest cutting-height setting by moving the 2 rear cutting-height levers all the way forward. Refer to Adjusting the Cutting Height.

-

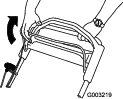

Attach the handle ends to the machine housing with 2 washers and 2 handle bolts (Figure 3), but do not tighten the handle bolts.

-

Rotate the handle rearward (Figure 4).

-

Lock the handle at your desired height; refer to Adjusting the Handle Height.

-

Torque the handle bolts to 120 to 160 in-lb (14 to 17 N-m).

-

Adjust the cutting height; refer to Adjusting the Cutting Height.

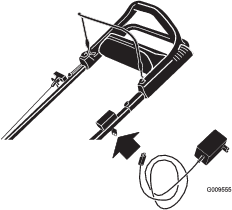

Installing the Recoil-Starter Rope in the Rope Guide

Important: You must install the recoil-starter rope in the rope guide.

Hold the blade-control bar to the upper handle and pull the recoil-starter rope through the rope guide on the handle (Figure 5).

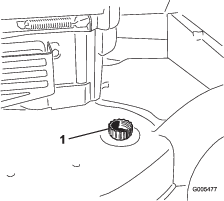

Filling the Engine with Oil

Important: This machine does not come with oil in the engine. Before starting the engine, fill the engine with oil.

Important: Change the engine oil after the first 5 operating hours; change it yearly thereafter. Refer to Changing the Engine Oil.

-

Move the machine to a level surface.

-

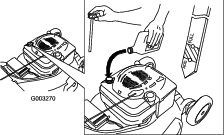

Remove the dipstick (Figure 6) and pour about 3/4 of the crankcase capacity of oil into the oil-fill tube.

Note: Max. fill: 0.59 L (20 oz.), type: SAE 30 detergent oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

-

Wipe off the dipstick end with a clean cloth.

-

Insert the dipstick into the oil-fill tube, and screw it in until it stops.

-

Remove the dipstick and read the oil level on the dipstick; refer to Figure 6.

-

If the oil level is too low, add a small amount of oil slowly to the oil-fill tube, and then repeat steps 3 through 5 until the oil level is correct as shown in Figure 6.

-

If the oil level is too high, drain the excess oil until you obtain the correct oil level on the dipstick. To drain the excess oil, refer to Changing the Engine Oil.

Important: If the oil level in the crankcase is too low or too high and you run the engine, you may damage the engine.

-

-

Install the dipstick securely by hand.

Charging the Battery

Refer to Charging the Battery.

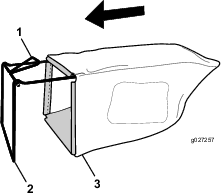

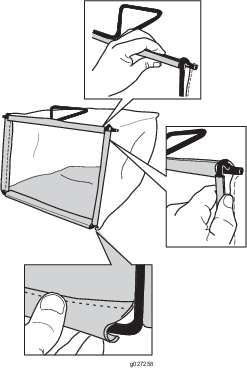

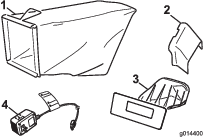

Assembling the Grass Bag

Product Overview

| Model | Weight | Length | Width | Height |

| 20797 | 42 kg (92 lb) | 165 cm (65 inches) | 56 cm (22 inches) | 104 cm (41 inches) |

Operation

Filling the Fuel Tank

Danger

Gasoline is extremely flammable and explosive. A fire or explosion from gasoline can burn you and others.

-

To prevent a static charge from igniting the gasoline, place the container and/or machine directly on the ground before filling, not in a vehicle or on an object.

-

Fill the tank outdoors when the engine is cold. Wipe up spills.

-

Do not handle gasoline when smoking or around an open flame or sparks.

-

Store gasoline in an approved fuel container, out of the reach of children.

-

For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method).

-

Oxygenated fuel with up to 10% ethanol or 15% MTBE by volume is acceptable.

-

Ethanol: Gasoline with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. Ethanol and MTBE are not the same. Gasoline with 15% ethanol (E15) by volume is not approved for use. Never use gasoline that contains more than 10% ethanol by volume, such as E15 (contains 15% ethanol), E20 (contains 20% ethanol), or E85 (contains up to 85% ethanol). Using unapproved gasoline may cause performance problems and/or engine damage which may not be covered under warranty.

-

Do not use gasoline containing methanol.

-

Do not store fuel either in the fuel tank or in fuel containers over the winter unless a fuel stabilizer is used.

-

Do not add oil to gasoline.

Fill the fuel tank with fresh unleaded regular gasoline from a major name-brand service station (Figure 11).

Important: To reduce starting problems, add fuel stabilizer to the fuel all season, mixing it with gasoline less than 30 days old.

Checking the Engine-Oil Level

Max. fill: 0.59 L (20 oz), type: SAE 30 detergent oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

-

Move the machine to a level surface.

-

Remove the dipstick (Figure 12).

-

Wipe off the dipstick end with a clean cloth.

-

Insert the dipstick into the oil-fill tube and screw it in until it stops.

-

Remove the dipstick and read the oil level; refer to Figure 12.

-

If the oil level is below the Add mark on the dipstick, slowly add a small amount of oil to the oil-fill tube, and then repeat steps 3 through 5 until the oil level is at the Full mark on the dipstick.

-

If the oil level is above the Full mark on the dipstick, drain the excess oil until the oil level is at the Full mark on the dipstick. To drain the excess oil, refer to Changing the Engine Oil.

Important: If the oil level in the crankcase is too low or too high and you run the engine, you may damage the engine.

-

-

Install the dipstick securely by hand.

Adjusting the Cutting Height

Warning

Adjusting the cutting height may bring you into contact with the moving blade, causing serious injury.

-

Stop the engine and wait for all moving parts to stop.

-

Do not put your fingers under the housing when adjusting the cutting height.

Caution

If the engine has been running, the muffler will be hot and can severely burn you. Keep away from the hot muffler.

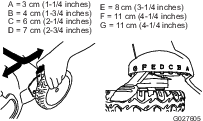

Adjust the cutting height as desired. Set all 4 wheels to the same height.

Note: To raise the machine, move all 4 cutting height levers forward; to lower the machine, move them all rearward (Figure 13).

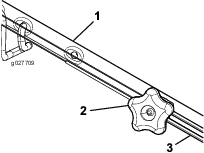

Adjusting the Handle Height

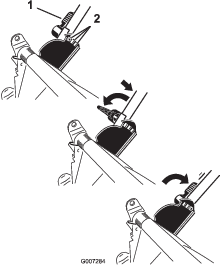

You may raise or lower the upper handle to a position comfortable for you.

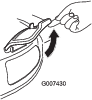

Rotate the handle lock, move the handle to 1 of 3 positions, and lock the handle into position (Figure 14).

Starting the Engine

-

Pull the blade-control bar to the handle (Figure 15).

-

Turn the ignition key (Figure 16) or pull the recoil-start handle (Figure 17).

Note: When you pull the recoil-start handle, pull it lightly until you feel resistance, then pull it sharply (Figure 17). Allow the rope to return to the handle slowly.

Note: If the machine does not start after several attempts, contact an Authorized Service Dealer.

Using the Self-Propel Drive

To operate the self-propel drive, simply walk with your hands on the upper handle and your elbows at your sides, and the machine will automatically keep pace with you (Figure 18).

Stopping the Engine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

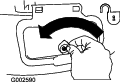

To stop the engine, release the blade-control bar (Figure 19).

Important: When you release the blade-control bar, both the engine and blade should stop within 3 seconds. If they do not stop properly, stop using your machine immediately and contact an Authorized Service Dealer.

Recycling the Clippings

Your machine comes from the factory ready to recycle the grass and leaf clippings back into the lawn.

If the side-discharge chute is on the machine, remove it and lock the side discharge door; refer to Removing the Side-Discharge Chute before recycling the clippings.

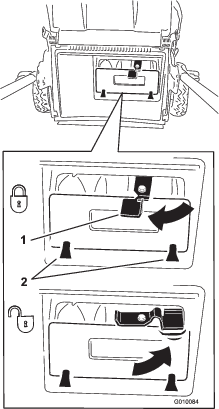

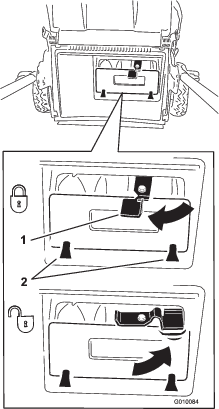

Important: Ensure that the rear-discharge plug is locked in place. To lock the plug: Raise the rear-discharge deflector (Figure 20), firmly push the plug in until it snaps into place behind the tabs, and rotate the lever on the plug to the left (Figure 21).

Note: To unlock the plug, rotate the lever on the plug to the right (Figure 21).

Bagging the Clippings

Use the grass bag when you want to collect grass and leaf clippings from the lawn.

Warning

A worn grass bag could allow small stones and other similar debris to be thrown toward you or bystanders, resulting in serious personal injury or death.

Check the grass bag frequently. If it is damaged, install a new Toro replacement bag.

If the side-discharge chute is on the machine, remove it and lock the side-discharge door; refer to Removing the Side-Discharge Chute before bagging the clippings.

Warning

The blade is sharp; contacting the blade can result in serious personal injury.

Stop the engine and wait for all moving parts to stop before leaving the operating position.

Installing the Grass Bag

-

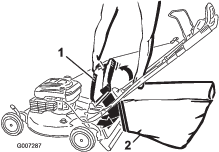

Route the starter rope around the lower-rope guide (Figure 22).

Note: The lower-rope guide releases the starter rope when you pull the recoil-start handle.

-

Raise and hold up the rear-discharge deflector (Figure 23).

-

Pull out the rear-discharge plug (Figure 23).

-

Hang the upper front edge of the bag on the notches (Figure 24).

-

Lower the rear-discharge deflector.

Removing the Grass Bag

-

Route the starter rope around the lower-rope guide (Figure 25).

Note: The lower-rope guide releases the starter rope when you pull the recoil-start handle.

-

Raise and hold up the rear-discharge deflector.

-

Lift the grass bag up by the handle off the notches.

-

Install the rear-discharge plug (Figure 23).

Important: Ensure that the rear-discharge plug is locked in place. To lock the plug, firmly push the plug in until it snaps into place behind the tabs, and rotate the lever on the plug to the left (Figure 27).

Note: To unlock the plug, rotate the lever on the plug to the right (Figure 27).

-

Lower the rear-discharge deflector.

Side-Discharging the Clippings

Use the side discharge for cutting very tall grass.

If the bag is on the machine, remove it and insert the rear-discharge plug; refer toRemoving the Grass Bag before side-discharging the clippings.

Important: Ensure that the rear-discharge plug is locked in place. To lock the plug: Raise the rear-discharge deflector (Figure 28), firmly push the plug in until it snaps into place behind the tabs, and rotate the lever on the plug to the left (Figure 27).

Note: To unlock the plug, rotate the lever on the plug to the right (Figure 27).

Warning

The blade is sharp; contacting the blade can result in serious personal injury.

Stop the engine and wait for all moving parts to stop before leaving the operating position.

Installing the Side-Discharge Chute

Removing the Side-Discharge Chute

To remove the side discharge chute, reverse the steps above.

Important: Lock the side-discharge door after you close it (Figure 32).

Operating Tips

General Mowing Tips

-

Clear the area of sticks, stones, wire, branches, and other debris that the blade could hit.

-

Avoid striking solid objects with the blade. Never deliberately mow over any object.

-

If the machine strikes an object or starts to vibrate, immediately stop the engine, disconnect the wire from the spark plug, and examine the machine for damage.

-

For best performance, install a new blade before the cutting season begins.

-

Replace the blade when necessary with a Toro replacement blade.

Cutting Grass

-

Cut only about a third of the grass blade at a time. Do not cut below the 51 mm (2 inch) setting unless the grass is sparse or it is late fall when grass growth begins to slow down. Refer to Adjusting the Cutting Height.

-

When cutting grass over 15 cm (6 inches) tall, mow at the highest cutting-height setting and walk slower; then mow again at a lower setting for the best lawn appearance. If the grass is too long, the machine may plug and cause the engine to stall.

-

Mow only dry grass or leaves. Wet grass and leaves tend to clump on the yard and can cause the machine to plug or the engine to stall.

Warning

Wet grass or leaves can cause serious injury if you slip and contact the blade. Mow only in dry conditions.

-

Alternate the mowing direction. This helps disperse the clippings over the lawn for even fertilization.

-

If the finished lawn appearance is unsatisfactory, try 1 or more of the following:

-

Replace the blade or have it sharpened.

-

Walk at a slower pace while mowing.

-

Raise the cutting height on your machine.

-

Cut the grass more frequently.

-

Overlap cutting swaths instead of cutting a full swath with each pass.

-

Set the cutting height on the front wheels a notch lower than the rear wheels. For example, set the front wheels at 51 mm (2 inches) and the rear wheels at 64 mm (2-1/2 inches).

-

Cutting Leaves

-

After cutting the lawn, ensure that half of the lawn shows through the cut leaf cover. You may need to make more than a single pass over the leaves.

-

If there are more than 13 cm (5 inches) of leaves on the lawn, set the front cutting height 1 or 2 notches higher than the rear cutting height.

-

Slow down your mowing speed if the machine does not cut the leaves finely enough.

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Every 50 hours |

|

| Before storage |

|

| Yearly |

|

Important: Refer to your engine owner's manual for additional maintenance procedures.

Preparing for Maintenance

-

Stop the engine and wait for all moving parts to stop.

-

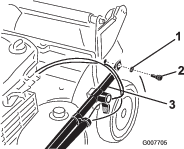

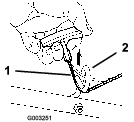

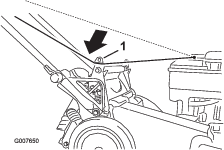

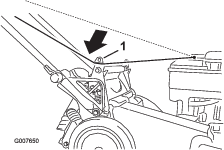

Disconnect the spark-plug wire from the spark plug (Figure 33) before performing any maintenance procedure.

-

After performing the maintenance procedure(s), connect the spark-plug wire to the spark plug.

Important: Before tipping the machine to change the oil or replace the blade, allow the fuel tank to run dry through normal usage. If you must tip the machine prior to running out of fuel, use a hand fuel pump to remove the fuel. Always tip the machine onto its side with the dipstick down.

Warning

Tipping the machine may cause the fuel to leak. Gasoline is flammable and explosive and can cause personal injury.

Run the engine dry or remove the gasoline with a hand pump; never siphon.

Replacing the Air Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Perform the pre-maintenance procedures; refer to Preparing for Maintenance.

-

Use a screw driver to open the air-filter cover (Figure 34).

-

Replace the air filter (Figure 35).

-

Install the air-filter cover.

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 50 hours |

|

Note: Max. fill: 0.59 L (20 oz), type: SAE 30 detergent oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

-

Move the machine to a level surface.

-

Ensure that the fuel tank contains little or no fuel so that fuel does not leak out when you tip the machine onto its side.

-

Run the engine a few minutes before changing the oil to warm it.

Note: Warm oil flows better and carries more contaminants.

-

Disconnect the wire from the spark plug; refer to Preparing for Maintenance.

-

Set an oil-drain pan beside the machine on the side of the dipstick.

-

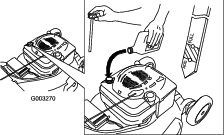

Remove the dipstick from the oil-fill tube (Figure 36).

-

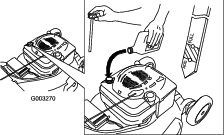

Tip the machine onto its side, with the oil-fill tube down, to drain the used oil out through the oil-fill tube into the oil-drain pan (Figure 37).

-

After draining the used oil, return the machine to the operating position.

-

Pour about 3/4 of the crankcase capacity of oil into the oil-fill tube.

Note: Max. fill: 0.59 L (20 oz), type: SAE 30 detergent oil with an API service classification of SF, SG, SH, SJ, SL, or higher.

-

Wipe off the dipstick end with a clean cloth.

-

Insert the dipstick into the oil-fill tube and screw it in until it stops.

-

Remove the dipstick and read the oil level; refer to Figure 38.

-

If the oil level is below the Add mark on the dipstick, slowly add a small amount of oil to the oil-fill tube, and then repeat steps 10 through 12 until the oil level is at the Full mark on the dipstick.

-

If the oil level is above the Full mark on the dipstick, drain the excess oil until the oil level is at the Full mark on the dipstick.

Important: If the oil level in the crankcase is too low or too high and you run the engine, you may damage the engine.

-

-

Install the dipstick securely.

-

Recycle the used oil at a local recycling center.

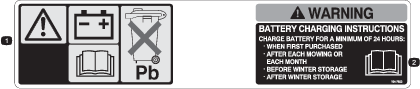

Charging the Battery

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

| Before storage |

|

Charge the battery for 24 hours initially, then monthly (every 25 starts) or as needed. Always use the charger in a sheltered area and charge the battery at room temperature (22°C or 70°F) whenever possible.

-

Connect the charger to the machine wire harness located below the ignition key (Figure 39).

-

Plug the charger into a wall outlet.

Note: When the battery no longer holds a charge, recycle or dispose of the lead-acid battery according to local codes.

Note: Your battery charger may have a 2-color LED display that indicates the following states of charging:

-

A red light indicates that the charger is charging the battery.

-

A green light indicates that the charger is fully charged or the charger is disconnected from the battery.

-

A flashing light that alternates between red and green indicates that the battery is nearly fully charged. This state lasts only a few minutes until the battery is fully charged.

Replacing the Fuse

If the battery does not charge or the engine does not turn with the electric starter, the fuse may be blown. Replace it with a 40-amp plug-in type fuse.

Important: You cannot start the machine with the electric starter or charge the battery unless you install the fuse.

Adjusting the Self-Propel Drive

Whenever you install a new self-propel cable or if the self-propel drive is out of adjustment, adjust the self-propel drive.

-

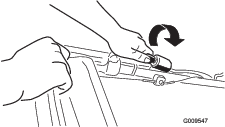

Turn the adjustment knob counterclockwise to loosen the cable adjustment (Figure 42).

-

Adjust the tension on the cable (Figure 42) by pulling it back or pushing it forward and holding that position.

Note: Push the cable toward the engine to increase the traction; pull the cable away from the engine to decrease the traction.

-

Turn the adjustment knob clockwise to tighten the cable adjustment.

Note: Tighten the knob firmly by hand.

Lubricating the Wheel Gears

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Wipe the grease fittings just inside the rear wheels with a clean rag (Figure 43).

-

Install a grease gun onto each fitting and gently apply 2 or 3 pumps of #2 multi-purpose, lithium-base grease.

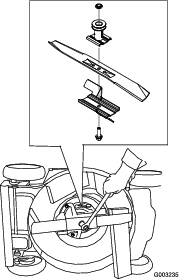

Replacing the Blade

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

Important: You will need a torque wrench to install the blade properly. If you do not have a torque wrench or are uncomfortable performing this procedure, contact an Authorized Service Dealer.

Examine the blade whenever you run out of gasoline. If the blade is damaged or cracked, replace it immediately. If the blade edge is dull or nicked, have it sharpened or replace it.

-

Disconnect the spark-plug wire from the spark plug; refer to Preparing for Maintenance.

-

Tip the machine onto the side with the dipstick down.

-

Use a block of wood to hold the blade steady (Figure 44).

-

Remove the blade, saving all mounting hardware.

-

Install the new blade and all mounting hardware.

Important: Position the curved ends of the blade to point toward the machine housing.

-

Use a torque wrench to tighten the blade bolt to 82 N-m (60 ft-lb).

Important: A bolt torqued to 82 N-m (60 ft-lb) is very tight. While holding the blade with a block of wood, put your weight behind the ratchet or wrench and tighten the bolt securely. This bolt is very difficult to overtighten.

Cleaning under the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Warning

The machine may dislodge material from under the machine.

-

Wear eye protection.

-

Stay in the operating position (behind the handle).

-

Do not allow bystanders in the area.

Note: For best results, clean the machine soon after you have completed mowing.

-

Lower the machine to its lowest cutting-height setting; refer to Adjusting the Cutting Height.

-

Move the machine onto a flat paved surface.

-

Attach a garden hose that is connected to a water supply to the washout port (Figure 45).

-

Turn the water on.

-

Start the engine and run it until there are no more clippings that come out from under the machine.

-

Stop the engine.

-

Shut off the water and disconnect the garden hose from the machine.

-

Start the engine and run it for a few minutes to dry the underside of the machine.

Storage

Preparing the Machine for Storage

Warning

Gasoline vapors can explode.

-

Do not store gasoline more than 30 days.

-

Do not store the machine in an enclosure near an open flame.

-

Allow the engine to cool before storing it.

-

On the last refueling of the year, add fuel stabilizer to the fuel as directed by the engine manufacturer.

-

Run the machine until the engine stops from running out of fuel.

-

Allow the engine to run until it stops. When you can no longer start the engine, it is sufficiently dry.

-

Disconnect the wire from the spark plug.

-

Remove the spark plug, add 30 ml (1 oz) of oil through the spark plug hole, and pull the starter rope slowly several times to distribute oil throughout the cylinder to prevent cylinder corrosion during the off-season.

-

Loosely install the spark plug.

-

Tighten all nuts, bolts, and screws.

-

Charge the battery for 24 hours, then unplug the battery charger and store the machine in an unheated area. If you must store the machine in a heated area, you must charge the battery every 90 days.

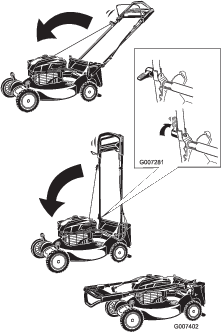

Folding the Handle

Warning

Folding or unfolding the handle improperly can damage the cables, causing an unsafe operating condition.

-

Do not damage the cables when folding or unfolding the handle.

-

If a cable is damaged, contact an Authorized Service Dealer.

-

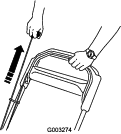

Rotate the handle forward (Figure 46).

Important: Route the cables to the outside of the handle knobs as you fold the upper handle.

-

To unfold the handle, refer to Assembling and Unfolding the Handle.

Removing the Machine from Storage

-

Check and tighten all fasteners.

-

Remove the spark plug and spin the engine rapidly using the starter to blow the excess oil from the cylinder.

-

Install the spark plug and tighten it with a torque wrench to 20 N-m (15 ft-lb).

-

Perform any needed maintenance procedures; refer to .

-

Check the engine-oil level; refer to Checking the Engine-Oil Level.

-

Fill the fuel tank with fresh gasoline; refer to Filling the Fuel Tank.

-

Connect the wire to the spark plug.

-

Charge the battery; refer to Charging the Battery.