Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

| Before storage |

|

| Yearly or before storage |

|

Caution

If you leave the key in the switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the switch before you perform any maintenance.

Greasing the Auger Bearing

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

Grease the fitting immediately after every washing.

Grease Type: General-purpose grease

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

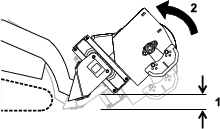

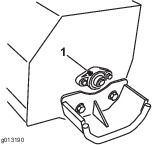

Clean the grease fitting with a rag (Figure 6).

-

Connect a grease gun to the fitting.

-

Pump grease into the fitting until grease begins to ooze out of the auger bearing.

-

Wipe up any excess grease.

Adjusting the Skids

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly or before storage |

|

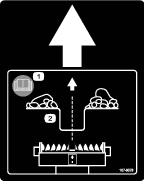

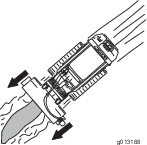

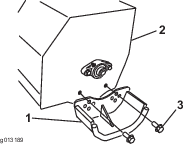

The distance between the auger blade and the ground is controlled by skids on each side of the housing. Adjust the height so that the auger flighting does not catch on uneven surfaces.

-

Park the machine on a level surface, engage the parking brake, and lower the attachment until it is just above the ground.

-

Shut off the engine and remove the key.

-

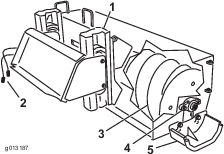

Remove the bolts that secure the skids to the housing (Figure 7).

-

Position the skids equally on both sides and secure them with the bolts (Figure 7).

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.