| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| After each use |

|

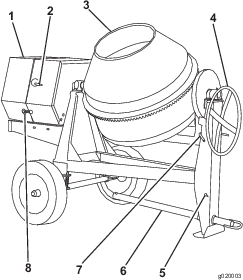

Introduction

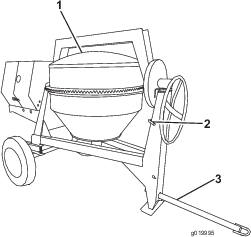

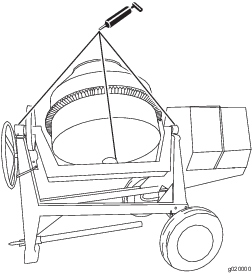

This machine is designed to mix concrete, plaster, fireproofing material, grout, and other small-grained concrete products. You can tow the machine behind a vehicle equipped with a hitch appropriate for the type of tow pole your machine has (ball, pintle, or pin hitch).

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

You may contact Toro directly at www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready.Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Warning

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Tire Information—The DOT tire information is located on the side of each tire. This information gives load and speed ratings. Replacement tires should have the same or better ratings; refer to Specifications to ensure that the tires on your machine meet or exceed the weight requirements of your machine.

Safety

Improper use or maintenance by the operator or owner can result in injury. To reduce the potential for injury, comply with these safety instructions and always pay attention to the safety-alert symbol (Figure 2), which means: Caution, Warning, or Danger—personal safety instruction. Failure to comply with the instruction may result in personal injury or death.

Safe Operating Practices

This product is capable of amputating hands. Always follow all safety instructions to avoid serious injury or death.

Warning

Machining or handling stone, masonry, concrete, metal, and other materials can generate dust, mists, and fumes containing chemicals, such as silica, known to cause serious or fatal injury or illness, such as respiratory disease, silicosis, cancer, birth defects, or other reproductive harm.

-

Control dust, mist, and fumes at the source where possible. Use water for dust suppression when feasible.

-

Use good work practices and follow the recommendations of the manufacturer or suppliers, OSHA, and other occupational and trade associations.

-

Always follow respiratory precautions.

-

When you cannot eliminate the hazards from inhalation, you and any bystanders should wear a respirator approved by OSHA for the material being handled.

Warning

Engine exhaust contains carbon monoxide, an odorless, deadly poison that can kill you.

Do not run the engine indoors or in an enclosed area.

Training

-

Read the Operator's Manual and other training material. If the operator(s) or mechanic(s) cannot read or understand the information, it is the owner's responsibility to explain this material to them.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

All operators and mechanics should be trained. The owner is responsible for training the users.

-

Never let children or untrained people operate or service the equipment. Local regulations may restrict the age of the operator.

-

The owner/user can prevent and is responsible for accidents or injuries to people or damage to property.

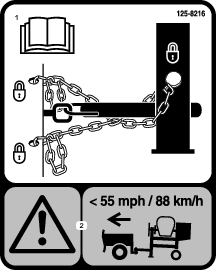

Towing

Check with your local county or state towing safety regulations before towing the machine.

-

To reduce the possibility of an accident while transporting the machine on public roads, ensure that the towing vehicle is mechanically sound and in good operating condition.

-

Shut off the engine before transporting the machine.

-

When towing with a ball hitch, ensure that the ball hitch you are using is the proper size for the hitch coupler on the machine.

-

When towing with a pintle hitch, ensure that the eye of the tow pole is the correct dimension for the pintle hook.

-

Do not tow without the safety pin inserted into the top of the receiver.

-

Inspect the hitch and coupling for wear. Never tow the machine with damaged or defective hitches, couplings, chains, or other components.

-

Check the tire air pressure on the towing vehicle and the machine.

-

Check the tire tread and sidewall for damage and wear.

-

Properly attach the safety chains to the towing vehicle.

-

Ensure that the directional and brake lights are working properly (if the machine is equipped with the light kit).

-

Ensure that the directional, backup, and brake lights of the tow vehicle are working properly (if equipped).

-

Before towing, ensure that your machine is correctly and securely attached to the towing vehicle.

-

Ensure that the safety chains are properly secured to the vehicle, and leave enough slack for turning.

-

Do not carry any material in the machine when towing.

-

Avoid sudden stops and starts. This can cause skidding, or jackknifing. Smooth, gradual starts and stops will improve towing.

-

Avoid sharp turns to prevent rolling. Tow only with a vehicle that has a hitch designed for towing. Do not attach towed equipment except at the hitch point.

-

Do not tow the machine faster than 88 km/h (55 mph).

-

Use caution when backing up; use a spotter outside the vehicle to guide you.

-

Do not allow anyone to sit or ride on the machine.

-

Disconnect the machine from the tow vehicle before using it.

-

Secure the machine from movement before you tow it.

-

Place chock blocks underneath the tires to prevent them from rolling while the machine is parked.

Preparation

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Use only accessories and attachments approved by the manufacturer.

-

Wear personal protective equipment (PPE) and appropriate clothing, including the following:

-

Hard hat

-

Respirator or dust mask

-

Face shield

-

Safety glasses

-

Hearing protection

-

Substantial, slip-resistant footwear

-

Long pants

-

Shirt with long sleeves that are tight at the wrists

-

Tight-fitting gloves without drawstrings or loose cuffs

-

-

Secure loose clothing, tie back long hair, and do not wear loose jewelry.

-

Use extra care when handling fuels. They are flammable and the vapors are explosive. Use the following practices when handling fuel:

-

Use only an approved fuel container.

-

Never remove the fuel cap or add fuel with the engine running.

-

Allow the engine to cool before refueling.

-

Do not smoke.

-

Never refuel or drain the machine indoors.

-

Install the fuel cap and tighten it securely.

-

Keep the container nozzle in contact with the tank during filling.

-

Never fill a container while it is inside a vehicle, trunk, pickup bed, or any surface other than the ground.

-

Never store the machine or fuel container inside where there is an open flame, such as near a water heater or furnace.

-

If you spill fuel, wipe it off the engine and equipment.

-

-

Ensure that the machine is on a level surface before operating the machine.

-

Chock the tires of the machine to prevent unintended movement.

-

Before every use, do the following:

-

Inspect the coupler, ball, and hitch.

-

Ensure that all lights are functioning properly (if equipped).

-

Ensure that the tires are properly inflated as recommended.

-

Ensure that the wheel lug nuts are tight and torqued properly.

-

Ensure that the machine is properly secured.

-

Operation

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Never run the engine in an enclosed or poorly ventilated area.

-

Operate the machine only in good lighting conditions.

-

Before starting the machine, ensure that there are no persons or obstacles near or under the machine.

-

Shut off the engine before leaving the machine for any reason.

Never leave a running machine unattended. Always shut off the engine and verify that all moving parts have stopped.

-

Chock the tires of the machine or keep it attached to the towing vehicle when it is not in use, to prevent it from rolling.

-

Avoid prolonged breathing of exhaust fumes. Engine exhaust fumes can cause sickness or death.

-

Keep your hands away from any moving parts. Keep your feet away from the tires and the front post.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Keep bystanders, especially small children, out of the operating area. Stop the machine if anyone enters the area.

-

Never place your hands or any solid object into the drum when the machine is in operation.

-

Do not touch parts which may be hot from operation. Allow them to cool before attempting to maintain, adjust, or service the machine.

-

Never move the machine while the engine is running.

-

Keep the cowl closed and latched during operation.

-

Ensure that all the guards and shields are securely in place before operating the machine.

-

If the mixing paddles strike a foreign object or if the machine should start making an unusual noise or vibration, shut off the engine and empty the drum. Wait for all moving parts to come to a complete stop and cool. Vibration is generally a warning of trouble. Inspect for clogging or damage. Clean and repair and/or replace damaged parts.

-

Do not change the engine governor setting or overspeed the engine.

-

Lightning can cause severe injury or death. If you see lightning or hear thunder in the area, do not operate the machine; seek shelter.

Maintenance and Storage

-

Before performing maintenance, do the following:

-

Park the machine on a level surface.

-

Shut off the engine. Wait for all movement to stop and remove the spark plug wire before adjusting, cleaning, or repairing.

-

Allow the engine to cool before performing maintenance or storing.

-

Disengage all power and operation controls before making any repairs.

-

-

Never lubricate, service, repair, or adjust the machine while it is running.

-

Keep equipment materials clear from the muffler and engine to help prevent fires. Wipe up any spilled oil or fuel.

-

Never allow untrained personnel to service the machine.

-

Keep your hands, feet, and clothing away from moving parts. If possible, do not make adjustments with the engine running.

-

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

-

Remove any buildup of grease, oil, or debris from the machine.

-

Stop the machine, shut off the engine, and inspect the machine if a foreign object enters the drum or causes another obstruction. Make any necessary repairs before starting the machine.

-

Do not tamper with safety devices.

-

Secure the machine from movement and chock the tires when storing the machine.

-

Keep all nuts, bolts, screws, and hose clamps securely tightened. Keep the machine in good condition.

-

Use only genuine Toro replacement parts to ensure that the original standards are maintained.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

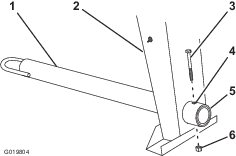

Installing the Tow Pole

Parts needed for this procedure:

| Tow pole kit (sold separately) | 1 |

Installing the Tow Pole to the Machine

Note: The tow pole is purchased separately and includes the nut and bolt needed for installation.

The machine has the following tow pole options:

| Hitch Type | Length |

|---|---|

| 50 mm (2 inch) ball—stamped | 127 cm (50 inches) |

| 50 mm (2 inch) ball—forged | 127 cm (50 inches) |

| Pintle | 127 cm (50 inches) |

-

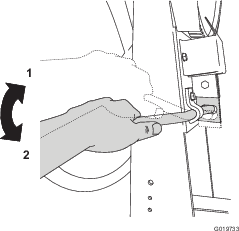

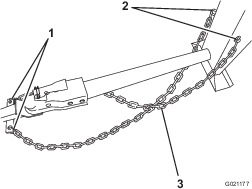

Remove the bolt and nut from the tow pole (Figure 3).

-

Slide the tow pole forward and align the hole in the pole with the hole in the frame fitting (Figure 3).

-

Insert the bolt through the holes in the fitting and the pole (Figure 3).

-

Thread the nut onto the bolt and tighten them until they are tight against the frame fitting (Figure 3).

Note: If the self-locking nylon insert in the locknut wears with use, replace the nut with a new Grade 5 or Grade 8 locknut.

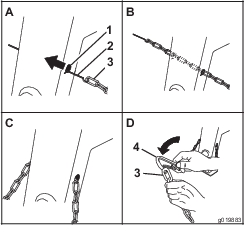

Installing the Safety Chain

Parts needed for this procedure:

| Safety chain | 1 |

| Connecting link | 2 |

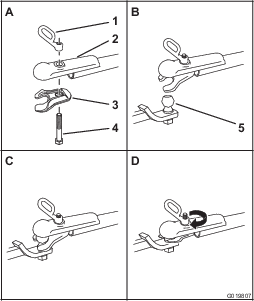

Installing the Safety Chain

-

Form a hook on the end of a bendable piece of rod or stiff wire (not included), and insert it through both keyholes in the front post of the machine (Figure 4A).

-

Attach the safety chain to the length of rod or wire (Figure 4A).

-

Pull the rod, or wire, and the safety chain through both keyholes (Figure 4B).

Note: Ensure that approximately equal lengths of safety chain extend from either side of the front post.

Installing the Connecting Links

-

Align the connecting link to the last link in one end of the safety chain (Figure 4D).

-

Insert the connecting link through the chain link until the connecting link snaps closed.

-

Repeat steps 1 and 2 to install the other connecting link in the other end of the safety chain.

Product Overview

Become familiar with all of the controls before you start the engine and operate the machine.

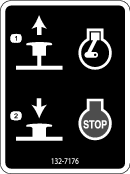

Handwheel

The handwheel controls the tilt of the drum.

Drum-Tilt Brake

The drum-tilt brake locks the drum into position.

Engine Controls

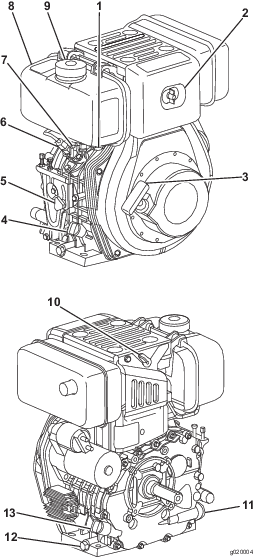

Engine Speed Control Handle

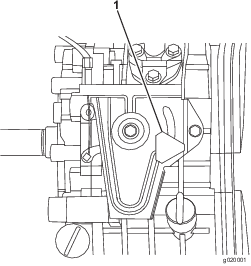

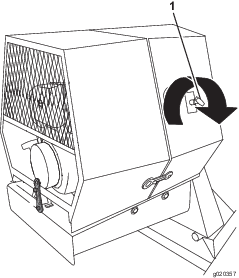

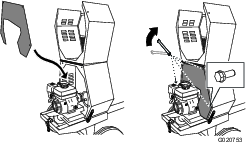

The engine-speed-control handle (Figure 7) allows the operator to start and shut off the engine. It is located on the engine cowl, and is connected to the engine-speed-control knob, which is located on the engine (Figure 8). To control the engine-speed-control handle:

-

Rotate the engine-speed-control handle counterclockwise to unlock it.

-

Pull it all the way out and lock it by rotating it clockwise.

-

Rotate it counterclockwise and push it in to stop the engine.

Note: The speed-control knob on the engine must be loose (rotated counterclockwise) for the cowl-mounted speed-control handle to work.

Fuel-Shutoff Lever

The fuel-shutoff lever is located underneath the fuel tank. Move the fuel-shutoff lever to the ON position before attempting to start the engine. Once you have finished using the machine and you have shut off the engine, move the fuel-shutoff lever to the OFF position.

Recoil-Start Handle

To start the engine, pull the recoil-start handle (Figure 6) quickly to turn the engine over. The engine controls described above must all be set correctly for the engine to start.

Note: Specifications and design are subject to change without notice.

| Batch Capacity | 0.34 m3(12 ft3) |

| Total Volume | 0.56 m3(19.8 ft3) |

| Length | 241 cm(95 inches) |

| Width | 142 cm(56 inches) |

| Height | 178 cm(70 inches) |

| Weight | 407 kg (897 lb) |

Operation

Important: Before operating the machine, check the fuel and oil levels and remove debris from the machine. Ensure that the area is clear of people.

Preparing to Tow the Machine

Important: Ensure that your tow vehicle has towing capacity for the weight of the machine.

Important: Use a Class 2 or larger receiver.

Note: Ensure that your tow vehicle has the appropriate hitch to tow the machine; options include a 50 mm (2 inch) ball hitch or a pintle hitch.

Note: If the machine is equipped with a trailer-light kit, ensure that the electrical connector of the tow vehicle is compatible with the electrical connector of the machine. If your tow vehicle has a different type of plug, obtain an adapter from an automotive parts store.

-

Ensure that the engine is stopped, the fuel-shutoff lever is off, and the drum is empty.

-

Using the handwheel, position the drum so that it is pointing down toward the ground (Figure 10).

-

Lock the drum into position by pushing down on the drum-tilt brake handle (Figure 11).

-

Ensure that the engine cowl is closed and latched; refer to Closing the Cowl.

-

Inspect the tires and wheels; refer to Checking the Tires and Wheels.

Checking the Tires and Wheels

Warning

Failure to maintain correct tire pressure may result in tire failure and loss of control, resulting in property damage and serious injury or death.

-

Check the tire pressure frequently to ensure proper inflation. If the tires are not inflated to the correct pressure, they will wear prematurely.

-

Inspect the tire condition before towing and after any operating accident.

The DOT tire information is located on the side of each tire. This information gives load and speed ratings. Replacement tires should have the same or better ratings. For more information go to http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note: Refer to Specifications and ensure that all replacement tires meet or exceed the ratings for this machine.

-

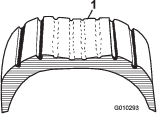

Visually inspect the tires for damage and wear (Figure 12 and Figure 13).

-

Ensure that the tires are inflated to the correct air-pressure. The following rating indicates the appropriate air pressure for the tires as installed at the factory.

Important: Always check the information on the actual tires for the correct air pressure requirement.

Important: The most common cause of tire trouble is underinflation. Maintain full air pressure.

Air Pressure: Max 241 kPa (35 psi)

-

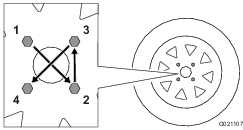

Ensure that the wheel lug nuts are torqued to 108 to 122 N-m (80 to 90 ft-lb).

Note: Check the torque of the wheel lug nuts initially and after towing.

Note: Torque the lug nuts in the sequence shown in Figure 14.

Hitching a Machine with a Stamped Ball Coupler

-

Apply chassis grease to the socket of the coupler and the area of the clamp that contacts the ball.

-

Oil the pivot points and sliding surfaces of the coupler with SAE 30 motor oil.

-

Open the coupler latch (Figure 15).

-

Position the coupler on top of the hitch ball (Figure 15A).

-

Close the coupler latch (Figure 15B).

-

Open the bail on the safety pin and insert the pin through the hole in the latch (Figure 15B).

-

Rotate the free end of the bail over the end of the safety pin that is protruding through the latch (Figure 15C).

-

If the machine is equipped with a trailer-light kit, connect the wire plug of the tow vehicle to the wire plug of the machine.

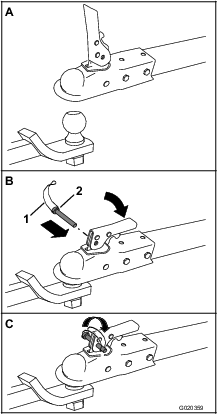

Hitching a Machine with a Forged Ball Coupler

-

Apply removable thread-locking compound to the threads of the coupler bolt to prevent the coupler handle from coming loose (Figure 16).

Important: Apply thread-locking compound as needed in the future.

-

Apply chassis grease to the socket of the coupler and the area of the clamp that contacts the ball.

-

Push the coupler bolt up through the coupler clamp and the coupler top, and connect the coupler handle to the bolt (Figure 16A).

-

Position the coupler so that the socket is on top of the hitch ball and the clamp is under the ball (Figure 16C).

-

Turn the coupler handle clockwise to thread it onto the bolt until it is secure (Figure 16D).

Note: Use a wrench to keep the bolt from spinning.

-

If the machine is equipped with a trailer-light kit, connect the wire plug of the tow vehicle to the wire plug of the machine.

Hitching a Machine with a Pintle Hitch Tow Pole

-

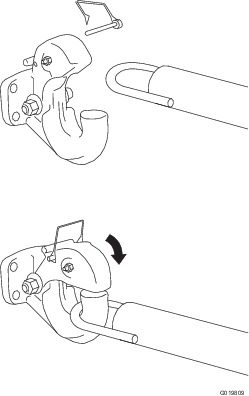

Remove the pin from the pintle hitch and open it (Figure 17).

-

Position the ring on the tow pole onto the hook of the pintle hitch (Figure 17).

-

Close the top of the pintle hitch and secure it with the pin (Figure 17).

-

If the machine is equipped with a trailer-light kit, connect the wire plug of the tow vehicle to the wire plug of the machine.

Connecting the Safety Chains to the Tow Vehicle

Connect the safety chain to the machine and the tow vehicle as follows:

-

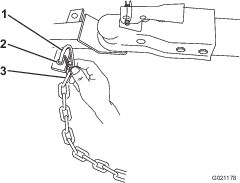

Pull the safety chain through the slots in the keyholes located in the front post of the machine, so that there is just enough slack on each side for turning around corners when towing the machine Figure 18).

Note: Stow the excess chain inside the bottom of the front post by pushing it into the keyholes and latching the appropriate links into the keyhole slots.

-

Cross both lengths of chain under the tow pole.

Note: Crossing the chains decreases the chances of the front of the machine dropping to the ground if the hitch does not hold the connection.

-

Connect each length of chain to the safety chain mounting point on the tow vehicle with the connecting links (Figure 19).

Towing the Machine

Warning

Towing the machine at high speed increases the risk of a hitch malfunction and tire failure. Higher speeds also increase the momentum of the machine and braking distance. If the machine becomes detached from the tow vehicle at high speed, it could cause damage to property, or injury or death to bystanders.

Do not exceed 88 km/h (55 mph) when towing the machine. For poor road conditions or inclement weather, reduce speed accordingly.

Warning

Towing the machine with material in the drum increases the risk of a hitch malfunction and tire failure. In addition, material could bounce out of the drum and hit other vehicles and/or people. Material in the drum increases the weight, which affects momentum and braking distance.

Do not tow the machine with material in the drum.

-

Review and understand Safe Operating Practices.

-

Test the brakes of the tow vehicle before towing.

-

Avoid sudden starts and stops while towing the machine.

Preparing to Use the Machine

-

Review all of the safety decals on the machine.

-

Use a hard-hat, hearing protection, a shirt with long sleeves that are tight at the wrists, tight-fitting gloves without draw strings or loose cuffs, eye protection, and a dust mask or respirator. A mesh visor alone does not provide sufficient eye protection; supplement with protective glasses.

-

Ensure that you are familiar with the safety regulations and shutdown procedures described in the Operator’s Manual and Engine Owner’s Manual.

-

Ensure that all guards are in place and in good condition.

-

Ensure that the paddles are in place and in good condition.

-

Check the fuel and oil levels of the engine.

-

When preparing to mix material:

-

Move the machine to a level job-site surface.

-

Remove the machine from the tow vehicle.

-

Chock the front and back of the tires to prevent the machine from moving.

-

Ensure that the drum is in the mix position (upright).

-

Ensure that the drum-tilt brake is engaged and that the drum does not rotate toward the dump position.

-

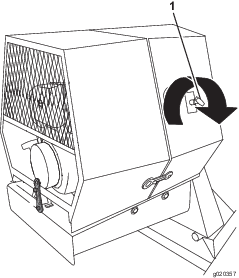

Opening and Closing the Cowl

Opening the Cowl

-

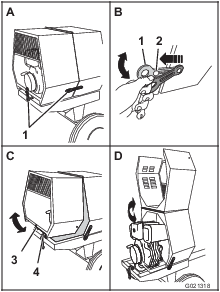

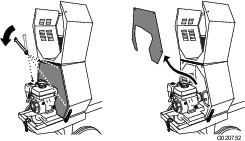

At the side of the machine where the front cowl and rear cowl meet, grasp the ring of the latch and pull it off from the latch anchor on the rear cowl (Figure 20).

-

Repeat 1 on the opposite side of the machine.

-

At the back of the machine where the rear cowl meets the frame of the machine, grasp the ring of the latch and pull it off from the latch anchor on the cowl (Figure 20).

-

Rotate the rear cowl up and forward until it is fully positioned on top of the front cowl (Figure 20).

Closing the Cowl

-

Rotate the rear cowl rearward and down until the receiver at the bottom center of the cowl is aligned with the V-fitting and flush on the frame of the machine (Figure 20).

-

At the back of the machine, grasp the ring of the latch and pull it on to the latch anchor on the rear cowl.

-

At the side of the machine, grasp the ring of the latch and pull it onto the latch anchor on the rear cowl.

-

Repeat step 3 on the opposite side of the machine (Figure 20).

Adding Fuel

-

Use only ultra-low sulfur (< 15 ppm) diesel fuel.

-

Purchase fuel in quantities that can be used within 30 days to ensure fuel freshness.

-

Use summer-grade diesel fuel (Number 2-D) at temperatures above -7°C (20°F) and winter-grade diesel fuel (Number 1-D or Number 1-D/2-D blend) below -7°C (20°F ).

-

Never mix kerosene, used engine oil, or residual fuels with the diesel fuel.

-

Do not store fuel either in the fuel tank or fuel containers over the winter.

-

Fuel additives are not recommended. Some fuel additives may cause poor engine performance.

Danger

In certain conditions, diesel fuel is extremely flammable and highly explosive. A fire or explosion from diesel can burn you and others and can damage property.

Use only diesel fuel. Filling the fuel tank with gasoline may result in a fire.

-

Fill the fuel tank and store fuel in a well-ventilated area.

-

Do not refuel the fuel tank while the engine is running.

-

Do not fill the fuel tank completely full. Add fuel until it is at the same level as the red ring. This empty space in the tank allows fuel to expand.

-

Never smoke when handling fuel, and stay away from an open flame or where fuel may be ignited by a spark.

-

Store diesel in an approved container and keep it out of the reach of children. Do not buy more than a 30-day supply of fuel.

-

Do not operate without the entire exhaust system in place and in proper working condition.

Danger

In certain conditions during fueling, static electricity can be released, causing a spark which can ignite the fuel vapors. A fire or explosion from fuel can burn you and others and can damage property.

-

Always place fuel containers on the ground away from your vehicle before filling.

-

Do not fill fuel containers inside a vehicle or on a truck or trailer bed because interior carpets or plastic truck bed liners may insulate the container and slow the loss of any static charge.

-

When practical, remove fuel-powered equipment from the truck or trailer and fuel the equipment with the wheels on the ground.

-

If this is not possible, then refuel such equipment on a truck or trailer from a portable container rather than from a fuel-dispenser nozzle.

-

If you must use a fuel dispenser nozzle, keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

Warning

Fuel is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious injury and illness.

-

Avoid prolonged breathing of vapors.

-

Keep your face away from the nozzle and the fuel tank or conditioner opening.

-

Keep fuel away from your eyes and skin.

Diesel Fuel Specifications

Important: Do not mix oil with diesel.

Diesel fuel should comply with the following specification. The table lists 7 worldwide specifications for diesel fuels.

| Diesel Fuel Specifications | Location |

|---|---|

| Number 2-D, Number 1-D, ASTM D975-94 Ultra-low Sulfur (< 15 ppm) | USA |

| EN590:96 | European Union |

| ISO 8217 DMX | International |

| BS 2869-A1 or A2 | United Kingdom |

| JIS K2204 Grade Number 2 | Japan |

| KSM-2610 | Korea |

| GB252 | China |

Using Fuel Stabilizer/Conditioner

Use a diesel fuel stabilizer/conditioner in the machine to keep the fuel fresh during storage of 90 days or less. If you are storing the machine for longer, drain the fuel tank; refer to Draining the Fuel Tank and Replacing the Outlet Fuel Filter.

Important: Do not use fuel additives containing methanol or ethanol.

Add the correct amount of fuel stabilizer/conditioner to the fuel, and follow the directions of the manufacturer.

Note: Fuel stabilizer/conditioner is most effective when mixed with fresh fuel.

Filling the Fuel Tank

Capacity: 4.7 L (1.25 US gallons)

-

Park the machine on a level surface, stop the engine, and allow the engine to cool.

-

Clean around the fuel cap and remove it (Figure 21).

Important: Keep the inlet-fuel screen and the red ring in the fuel tank while pouring the fuel.

-

Add fuel to the fuel tank until the level is up to the red ring (Figure 22).

Important: This space in the tank allows the fuel to expand. Do not fill the fuel tank completely full.

-

Securely install the fuel cap (Figure 21).

-

Wipe up any fuel that may have spilled.

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Toro Premium Engine Oil is available from your Authorized Toro Dealer.

Important: Use 4-cycle engine oil that meets or exceeds the following guidelines and classifications:

-

API Service Categories CH-4, CI-4, CJ-4 or higher

-

ACEA Service Categories E-3, E-4, and E-5

-

JASO Service Category DH-1

Crankcase capacity: 1.6 L (1.7 US qt)

Important: If the oil level in the crankcase is too low or too high and you run the engine, you may damage the engine. This type of damage is not covered by the warranty.

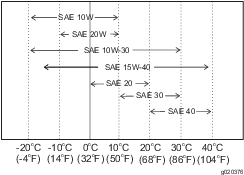

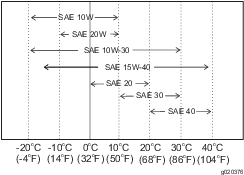

Viscosity: Refer to Figure 23.

Important: Ensure that the engine oil, engine oil storage containers, and engine oil filling equipment are free of sediments and water.

-

Place the machine on a flat, level surface, and stop the engine.

-

Allow the engine to cool.

-

Clean around the dipstick.

-

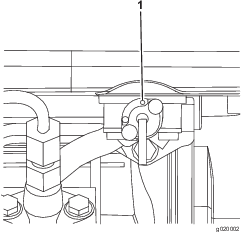

Remove the dipstick and wipe the end clean (Figure 24).

-

Slide the dipstick fully into the fill port without threading it into the port (Figure 24).

-

Remove the dipstick and look at the end. If the engine oil level is below the halfway point on the hatchmarks, slowly pour only enough oil into the fill port to raise the level to the halfway point on the dipstick.

-

Install and secure the dipstick (Figure 24).

Starting the Engine

-

Read Safe Operating Practices and understand the Controls before attempting to start the machine.

-

Make sure that the fuel-shutoff lever is in the ONposition.

-

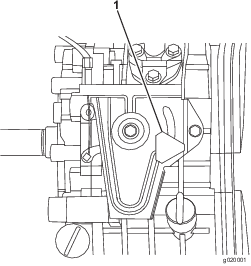

Ensure that the engine-speed-control knob on the engine is loose by rotating it counterclockwise (Figure 26).

-

Rotate the engine-speed-control handle counterclockwise to unlock it, pull it all the way out, and lock it by rotating it clockwise (Figure 27).

-

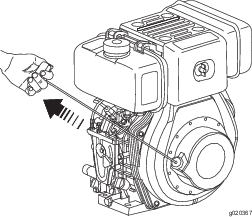

Push the decompression lever to the left (Figure 6).

Note: The decompression lever stays cocked to the left and automatically returns to the original position when the you pull the recoil-starter handle again.

-

Grasp the recoil-start handle, pull it out slowly until you feel resistance, then pull it all the way out with a strong and even motion (Figure 28).

Note: Use 2 hands if necessary.

-

Slowly return the recoil-start handle to the initial position.

-

If the engine does not start, repeat steps 2 through 7.

Shutting Off the Engine

-

Unlock the engine-speed-control handle by rotating it counterclockwise, and push it in slightly, to the idle setting.

-

Run the engine at low idle speed and without a load for at least 5 minutes to allow engine components that operate at a high temperature to cool down.

-

Push the engine-speed-control handle the rest of the way in to shut off the engine.

-

Move the fuel-shutoff lever to the CLOSED position after the engine stops.

Note: If the engine does not stop after you push the engine-speed-control handle all the way in, stop the engine by moving the fuel-shutoff lever to the CLOSED position.

Using the Machine

Danger

This machine is capable of amputating hands.

-

Stay in the operator’s position while the machine is running.

-

Keep all bystanders a safe distance from the machine.

-

Stop the machine immediately if any people or animals enter the work area.

-

Never place any part of your body into a position that causes an unsafe operating condition.

-

Ensure that the machine is on level ground and that the surrounding area is clear of obstacles.

Note: Disconnect the machine from the tow vehicle and chock the front and back of both tires to prevent any movement.

-

Make sure that you read all the recommendations from the Safety section; refer to Safe Operating Practices before using the machine.

-

Start the engine and close the engine cowl. Allow the engine to warm up at idle for 2 minutes; refer to Starting the Engine.

-

Use the handwheel to move the drum into an upright, slightly tilted position to allow access for pouring materials into the drum.

Note: This position also allows the mixing paddles to mix the materials more effectively.

-

Push the drum-tilt brake down to lock the drum into position and avoid accidentally dumping the material.

Important: If you need to stop the machine, use the engine-speed-control handle located on the cowl; refer to Engine Speed Control Handle.

Mixing the Material

Danger

Eye and skin contact with concrete materials and breathing the dust involved is hazardous to your health.

-

Ensure that there is adequate air ventilation.

-

Wear a dust mask to prevent inhalation of dust while using the machine; refer to Safe Operating Practices.

-

Avoid direct contact of cement and concrete materials with skin and eyes.

Important: Do not add more material than the batch capacity of the machine; refer to Specifications.

Note: Follow the manufacturer’s instructions that are printed on the packaging of the product.

Concrete has the following 4 basic ingredients:

-

Sand

-

Gravel

-

Portland cement

-

Water

Depending on the application, you can use different ratios of these 4 ingredients.

There are many variations of concrete mix recipes, depending on the application. It is important to use the appropriate quantity of water. Using too little water results in dry areas in the mix, but using too much water will result in weaker concrete. The amount of water needed varies depending on the moisture content of the sand and gravel. The mix should have a thickness similar that of peanut butter.

Keep the poured concrete damp for several days to obtain proper curing. Evaporation results in weaker concrete. Concrete cures through hydration, a reaction between water and cement.

Mixing Pre-Mix Concrete

-

Ensure that the tilt brake is fully engaged and that the drum is operating at full speed.

-

Pour water into the drum.

-

Add the required amount of dry pre-mix.

-

Allow the drum to turn while the mix reaches the appropriate consistency.

Mixing Sand, Gravel, and Cement

The typical ratio for mixing concrete is 1 part Portland cement, 2 parts sand, and 3 parts gravel.

-

Ensure that the tilt brake is fully engaged and that the drum is operating at full speed.

-

Pour water into the drum.

-

Add the required amount of gravel.

-

Add the required amount of Portland cement.

-

Add the required amount of sand.

-

Allow the drum to turn while the mix reaches the appropriate consistency.

Note: Adding water and gravel before cement and sand allows the mix left in the drum from the previous batch to be tumbled off the drum and paddles and into the next batch.

Using the Drum

Danger

Contact with the mixing paddles could cause damage or injury.

Never put your hands inside the drum at any time.

Dumping the Drum

Note: When dumping a batch of material, leave the engine running so that the rotating drum helps dump the material.

-

Align a wheelbarrow or similar container of adequate capacity in the path of the drum opening.

-

While the drum is turning, firmly grasp the handwheel with one hand.

-

Using your other hand, pull up on the drum-tilt brake handle to release the brake.

-

Using both hands, slowly turn the handwheel, allowing the drum to tilt in the desired direction and dump the desired amount of material.

-

Turn the handwheel in the opposite direction to return the drum into an upright position.

-

Push down on the drum-tilt brake to lock the drum into position, avoiding accidental discharging of concrete mix.

-

After dumping a batch of material, clean the drum; refer to Cleaning the Drum.

Note: This step will clean the paddles and drum between batches and prevent dried material from forming and contaminating the next batch of material.

Cleaning the Drum

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

Important: Do not strike the drum with a shovel, hammer, or any other device to loosen accumulation of dried materials.

-

While the machine is running, use the handwheel to tilt the drum slightly.

-

Engage the drum-tilt brake to prevent the drum from tilting further and discharging the water.

-

As the drum is rotating, spray it thoroughly with water before the material dries.

-

Allow the drum to rotate and tumble the loose material and water, further loosening the rest of the material.

-

Continue to spray the drum with water to remove all of the material from the drum and mixing paddles.

-

When all the material has been removed from the surfaces of the drum and mixing paddles, disengage the drum-tilt brake and use the handwheel to tilt the drum and dump the water from the drum.

-

If some material still remains in the drum, spray the drum with water while it is tilted downward, allowing the water and material to run out.

Maintenance

Important: Before performing any maintenance procedures, stop the engine and wait 5 minutes to allow all moving parts to come to a complete stop and cool.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 25 hours |

|

| After the first 50 hours |

|

| Before each use or daily |

|

| After each use |

|

| Every 20 hours |

|

| Every 40 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 400 hours |

|

| Every 1,000 hours |

|

| Monthly |

|

Pre-Maintenance Procedures

Preparing the Machine for Maintenance

-

Park the machine on a level surface.

-

Remove the machine from the tow vehicle.

-

Chock the tires.

-

Open the rear cowl; refer to Opening the Cowl.

-

Ensure that the engine and muffler are cool.

Removing and Installing the Divider Plate

You need to remove the divider plate to provide access before performing some maintenance procedures.

Removing the Divider Plate

-

Unlatch and open the cowl; refer to Opening the Cowl.

-

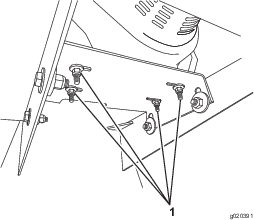

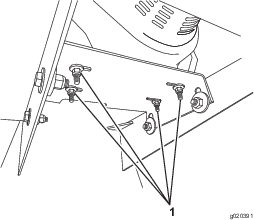

Use a wrench to remove the 4 bolts that secure the divider plate to the front cowl.

Note: Keep the bolts for installing the divider plate.

-

To remove the divider plate, lift it upward and rotate it counterclockwise so that it clears various engine components.

Installing the Divider Plate

-

Guide the divider plate into position against the front cowl.

Note: Start with the divider plate rotated slightly counterclockwise, and then rotate it clockwise while lowering it into position.Ensure that the divider plate is not backward.

-

Align the bolt holes in the divider plate and the front cowl.

-

Install each of the 4 bolts, and hand-tighten them to prevent cross-threading.

-

Tighten the bolts with a wrench until they are secure.

Lubrication

Lubricating the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Monthly |

|

-

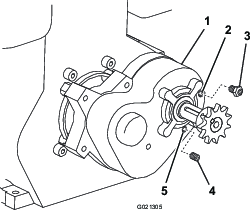

Clean around each grease fitting with a rag and lift the plastic cap off the grease fitting (Figure 31).

-

Use a grease gun to lubricate the grease fittings of both trunnions and the drum spindle with general-purpose lithium grease (Figure 31).

-

Wipe up any excess grease.

Important: Do not lubricate the pinion gear and ring gear. Lubrication will cause them to collect abrasive materials and accelerate wear.

Lubricating the Drive Chain

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 40 hours |

|

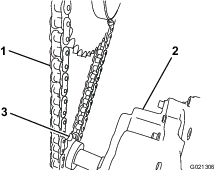

Apply a chain lubricant that is non-sticky to help prevent dirt and abrasive particles from sticking to the chain (Figure 32).

Engine Maintenance

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 200 hours |

|

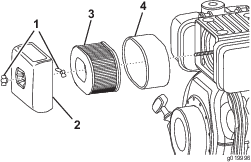

Important: Do not operate the engine without the air filter assembly; extreme engine damage will occur.

-

Stop the engine and wait for all moving parts to stop.

-

Turn the fuel-shutoff lever to the OFF position.

-

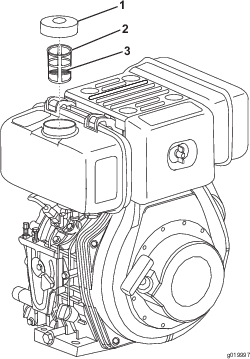

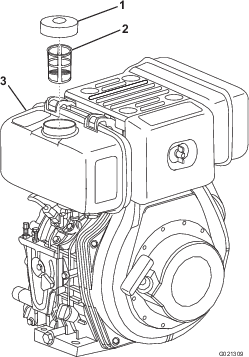

Remove the wing nut that secures the air-cleaner cover ().

-

Remove the air-cleaner cover.

-

Remove the internal wing nut.

-

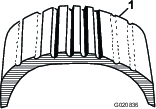

Remove the foam and paper elements from the base ().

-

Remove the foam element from the paper element ().

-

Inspect the foam and paper elements, and replace them if they are damaged or excessively dirty.

Note: Never try to brush dirt off the paper element; brushing forces the dirt into the fibers.

-

Wipe dirt from the base and the cover with a moist rag.

Note: Be careful to prevent dirt and debris from entering the air duct inside the air-cleaner housing.

-

Slide the outer foam element over the paper element.

-

Install the air cleaner elements and ensure that they are properly positioned.

-

Install the internal wing nut

-

Securely install the cover with the other wing nut.

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 25 hours |

|

| Every 100 hours |

|

Toro Premium Engine Oil is available from your Authorized Toro Dealer.

Important: Use 4-cycle engine oil that meets or exceeds the following guidelines and classifications:

-

API Service Categories CH-4, CI-4, CJ-4 or higher

-

ACEA Service Categories E-3, E-4, and E-5

-

JASO Service Category DH-1

Crankcase capacity: 1.6 L (1.7 US qt)

Important: If the oil level in the crankcase is too low or too high and you run the engine, you may damage the engine. This type of damage is not covered by the warranty.

Viscosity: Refer to Figure 34.

Draining the Engine Oil

Warning

Oil may be hot after the engine has been run, and contact with hot oil can cause severe personal injury.

Avoid contacting the hot engine oil when you drain it.

-

Stop the engine and wait for all moving parts to stop.

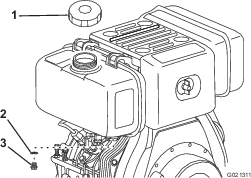

-

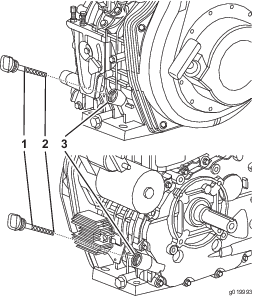

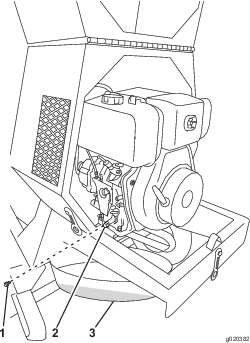

Place a oil-drain pan under the oil-drain hole of the engine (Figure 35).

-

Remove the drain plug and catch the oil in the oil-drain pan (Figure 35).

-

When the oil has drained completely, install the drain plug with a new washer (Figure 35).

Note: Dispose of the used oil at a certified recycling center.

Filling the Engine Crankcase with Oil

-

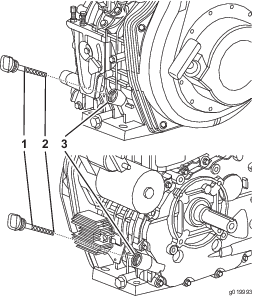

Remove the dipstick (Figure 36) and slowly pour oil into the fill hole until the oil is between the upper and lower limit on the dipstick.

-

Install and secure the dipstick.

-

Wipe up any spilled oil.

Servicing the Engine-Oil Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 400 hours |

|

Inspecting and Cleaning the Engine-Oil Filter

-

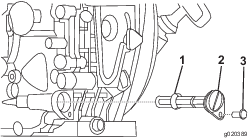

Remove the oil-filter retaining bolt.

-

Pull the oil-filter cap out and remove the oil filter.

-

Clean the oil filter or replace it if it is damaged.

-

Install the oil filter.

-

Make sure that the oil-filter cap is fully seated.

-

Install and tighten the oil-filter-retaining bolt.

-

Add new engine oil; refer toFilling the Engine Crankcase with Oil.

-

Warm up the engine by running it for 5 minutes, and check for any engine oil leaks.

-

After the engine is warm, turn it off and let it sit for 10 minutes.

-

Check the engine oil level by fully inserting, but not screwing in, the dipstick.

-

Add engine oil as needed; refer to Checking the Engine-Oil Level

Removing and Installing the Engine

Removing the Engine

-

Open the rear cowl; refer to Opening the Cowl.

-

Remove the 4 nuts and bolts that secure the engine to the engine-mounting plate (Figure 38).

-

Slide the engine to the right, and move the drive chain away from the engine sprocket.

-

Carefully lift the engine up and off the engine-mounting plate.

Installing the Engine

-

Set the engine on the engine-mounting plate, and align the bolt holes (Figure 38).

-

Install the 4 bolts and secure them with the nuts torqued to 24 N-m (18 ft-lb).

-

Check the drive chain tension, and adjust it if necessary; refer to Checking the Drive Chain Tension and Adjusting the Drive Chain Tension.

-

Close the rear cowl; refer to Closing the Cowl.

Fuel System Maintenance

Servicing the Fuel System

Cleaning the Inlet-Fuel Screen

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

Clean the area around the fuel cap.

-

Remove the fuel cap.

-

Lift the inlet-fuel screen out of the fuel tank.

-

Clean the inlet-fuel screen or replace it if it is damaged.

-

Install the inlet-fuel screen.

-

Install the fuel cap and hand tighten it.

Note: Overtightening the fuel cap will damage it.

Draining the Fuel Tank and Replacing the Outlet Fuel Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

-

Stop the engine and wait for all moving parts to stop.

-

Place an approved container under the fuel tank to collect the fuel.

-

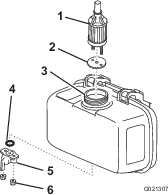

Remove the fuel cap (Figure 40).

-

Remove the drain plug and gasket to drain the fuel (Figure 40).

-

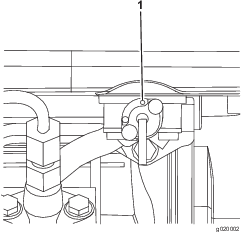

Loosen the nuts under the fuel-shutoff lever (Figure 41).

-

Remove and discard the O-ring (Figure 41).

-

Pull the outlet-fuel filter and gasket out of the filler port (Figure 41).

-

Install a new outlet-fuel filter and gasket through the filler port, and seat them in the fuel tank (Figure 41).

-

Install a new O-ring on the fuel-shutoff lever, and install the assembly to the fuel tank using the nuts under the fuel-shutoff lever (Figure 41).

-

Install the drain plug with a new gasket (Figure 40).

-

Install the fuel cap and hand tighten it.

Note: Overtightening the fuel cap will damage it.

Drive System Maintenance

Servicing the Reduction Case

Changing the Reduction Case Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 1,000 hours |

|

Oil type:non-detergent motor oil with a viscosity of SAE 50 or less

Capacity: 0.24 L (8.0 fl oz)

-

Remove the engine; refer to Removing the Engine.

-

Remove the drain plug and the vented-filler bolt on the reduction case.

-

Tip the engine so that the oil drains completely, to avoid mixing different types of oil.

Important: To avoid damaging parts of the engine or the reduction case, be careful when tipping the engine.

-

Install the drain plug into the drain hole.

-

Ensure that the engine is level, and pour 0.24 L (8.0 oz) of oil into the fill hole.

-

Install the vented-filler bolt into the fill hole.

-

Install the engine; refer toInstalling the Engine.

Servicing the Drive Chain

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 20 hours |

|

Checking the Drive Chain

-

Stop the engine and lock the engine-speed-control handle to the Stop position; refer toShutting Off the Engine, and move the fuel-shutoff lever to the OFF position.

-

Using a flashlight, carefully inspect the chain. If rust and debris are present, remove them with a brush.

Checking the Drive Chain Tension

-

Lay a straightedge along the drive chain from one sprocket to the other.

-

Push on the chain with 6.8 kg (15 lb) of pressure, midway between the sprockets.

-

Measure the distance from the chain to the straightedge. The distance should be approximately 2.5 cm (1 inch).

-

If the chain tension needs adjustment, refer to Adjusting the Drive Chain Tension.

Adjusting the Drive Chain Tension

-

Stop the engine and wait for all moving parts to stop.

-

Loosen the 4 nuts and bolts that secure the engine to the engine-mounting plate (Figure 43).

-

Slide the engine left to increase tension on the drive chain or right to decrease tension.

-

When the chain has the appropriate amount of tension; refer to Checking the Drive Chain Tension, torque the 4 nuts and bolts to 24 N•m (18 ft-lb) each.

Cleaning

Cleaning the Machine

Regular cleaning and washing with mild detergent and water will increase the life span of the machine. Clean the machine after each use before the dirt hardens.

Remove dirt and grime from the external parts of the entire machine, especially the engine. Clean dirt and concrete materials from the outside of the engine.

Ensure that the fuel cap and oil-fill cap/dipstick are secure to avoid getting water in the engine.

Use care when using a high-pressure sprayer, because it can damage safety decals, instruction signs, and the engine.

Storage

Storing the Machine

Whenever you store the machine over 30 days, prepare it as follows:

-

Clean the machine; refer to Cleaning the Machine.

-

Start the engine. Allow the engine to idle for 3 minutes and then stop the engine.

-

Drain the engine oil while the engine is still warm, and fill the engine with new oil; refer toChanging the Engine Oil.

-

Push the decompression lever down and hold it while slowly pulling the recoil starter 2 or 3 times.

Note: Do not start the engine.

-

Drain the fuel tank by unscrewing fuel drain plug and collecting fuel in a fuel container.

Note: Dispose of the fuel properly; recycle it according to local codes.

-

Check and tighten all bolts, nuts, and screws. Repair or replace any part that is damaged.

-

Paint all scratched or bare metal surfaces with paint available from your Authorized Service Dealer.

-

Store the machine in a clean, dry garage or storage area.

-

Cover the machine to protect it and keep it clean.

Troubleshooting

| Problem | Possible Cause | Corrective Action |

|---|---|---|

| The engine does not start. |

|

|

| The engine runs rough. |

|

|

| There is white or black exhaust smoke. |

|

|

| The drum does not turn. |

|

|

| The drum does not tilt. |

|

|

| The drum chatters or turns erratically. |

|

|

| The machine vibrates excessively. |

|

|