Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.For all maintenance procedures, park the machine on a level surface, shut off the engine, and remove the key.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 50 hours |

|

| Every 250 hours |

|

| Every 500 hours |

|

| Every 2 years |

|

Warning

Working on the machine without the safety support bracket increases your risk of injury.

Before carrying out maintenance underneath the operator platform and cab, ensure that the safety support bracket is installed.

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the ignition before you do any maintenance.

Important: Maintenance or repairs on the heating system should be carried out by an Authorized Toro Distributor or a specialist in vehicle heating systems.

Important: All work on the refrigerant part of the air-conditioning system should be carried out by fully qualified personnel.

-

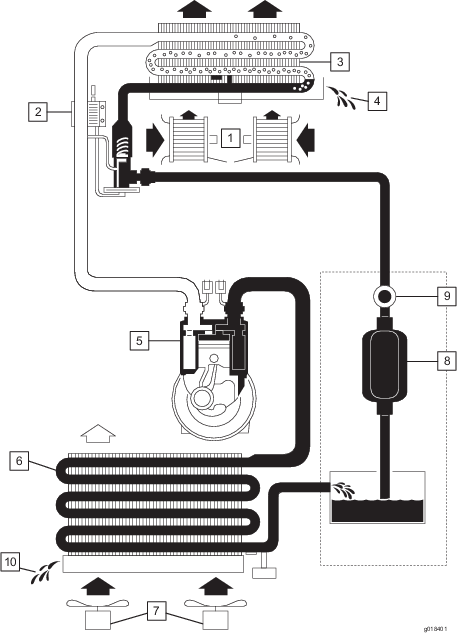

You can use the air-conditioning system for many months of the cutting season. Follow the regular prescribed maintenance to prolong the life of the system and ensure efficient operation. Failure to carry out the prescribed and documented maintenance could invalidate the warranty on the system and its components.

-

Even if the air-conditioning system is used infrequently, follow the maintenance schedule, as aging and refrigerant loss can occur with time.

-

Clean the condenser and evaporator fins with compressed air in the opposite direction of the normal air flow. If there is any buildup of greasy deposits, clean it with a non-abrasive soap solution.

-

Low levels of refrigerant can reduce the efficiency of the air-conditioning unit.

-

Extremely low levels can cause the low-pressure switch to shut down the system.

-

To check the refrigerant level, there is an integrated sight glass in the collecting tank. After filling, run the system for 5 minutes to allow all air bubbles to be purged from the system. Check the level after this period and top up is necessary. The occasional air bubble can be accepted.

Important: Do not spill compressor oil on the vehicle surface. It can cause discoloration of vehicle paint and deterioration of acrylic or ABS plastic components.

-

When attaching the climatic hoses, oil the sealing rings with refrigerator oil.

-

After removal of climatic hoses from the air-conditioner system, always replace the O-rings with new ones specified for refrigerant 134A.

-

When tightening or loosening fittings, always use 2 wrenches to prevent the tubes from twisting.

Checking the Refrigerant Pressure

When using the air-conditioning system the operating pressure is different on the suction side and the pressure side of the compressor.

This pressure difference is influenced by the speed of the compressor, the inside temperature of the vehicle, the outside air temperature and the relative air humidity.

Pressures that differ from those in the table below indicate a possible fault in the system.

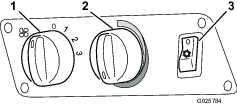

To check the pressures, set the compressor speed to 2000 rpm with an air temperature between 20 and 40 degrees C (68 and 104 degrees F). Operate the blower at position 3 (fastest speed setting).

| Outside Temperature | Low-Pressure Side | High-Pressure Side |

| 20° C (68° F) | 1.7 to 2.1 bar (24.7 to 30.5 psi) | 10 to 14 bar (145 to 203 psi) |

| 25° C (77° F) | 1.8 to 2.2 bar (26.1 to 31.9 psi) | 12 to 16 bar (174 to 232 psi) |

| 30° C (86° F) | 1.9 to 2.3 bar (27.6 to 33.4 psi) | 14 to 18 bar (203 to 261 psi) |

Troubleshooting the Pressure Readings

During the compression test, deviations from the values in the table may be measured. Locating the cause can determine whether a part requires repair or replacement.

The following is a short list of some pressure deviation that may be measured and some possible causes.

-

Pressure on high-pressure manometer too high

-

The air volume in the condenser is too small.

-

Refrigerant quantity is too high

-

The dryer/filter is blocked.

-

-

Pressure on high-pressure manometer is too low

-

The refrigerant quantity is too low (check the sight glass).

-

The compressor speed is too low (check the drive belt for slip/tension).

-

There is a fault with the compressor.

-

-

Pressure on low-pressure manometer too high

-

The expansion valve is incorrect.

-

The compressor speed is too low (check the drive belt for slip/tension).

-

There is a fault with the compressor.

-

-

Pressure on low-pressure manometer too low

-

There is restriction in the suction or pressure hoses.

-

The expansion valve is incorrect.

-

The refrigerant quantity is too low (examine the sediment bowl).

-

The air volume in the evaporator is too small.

Have a qualified person examine and repair all deviations in pressure from the values in the table.

-

Important: Do not allow refrigerant to discharge into the atmosphere. Before opening or disconnecting parts from the refrigerant circuit, empty the refrigerant into a specified recycling bottle, and dispose of it correctly.

Always use genuine Toro spare parts when repairing or servicing the air-conditioning system.

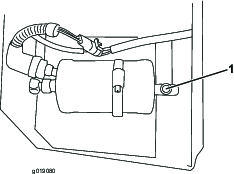

Checking the Refrigerant Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

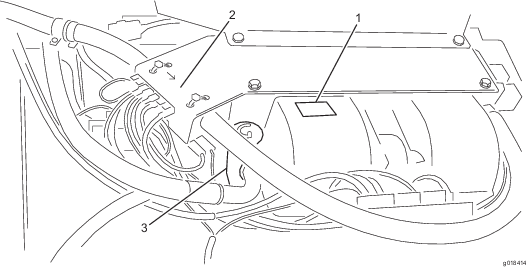

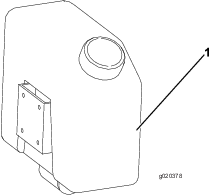

Check the refrigerant to assure it is at the correct level for operation. As the level of the refrigerant lowers, more air bubbles can be seen passing through the sight glass. Low levels of refrigerant can reduce the efficiency of the air-conditioning unit. Extremely low levels can cause the low-pressure switch to shut down the system.

-

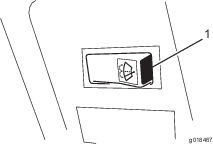

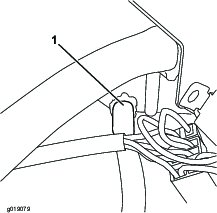

Using the sight gauge in the collecting tank, check on refrigerant level (Figure 15).

-

After filling, run the system for 5 minutes to allow all air bubbles to be purged from the system.

-

Check the level after this period and top up is necessary.

Note: The occasional air bubble is acceptable.

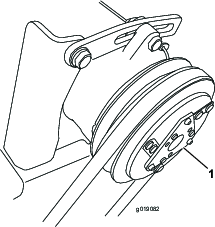

Checking the Compressor Magnetic Clutch

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 250 hours |

|

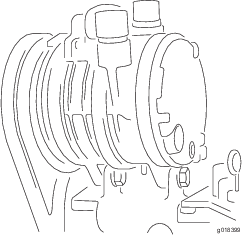

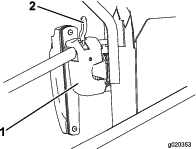

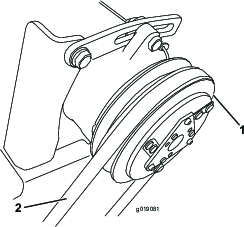

The compressor magnetic clutch is operating correctly if it clicks when it is turned on (Figure 16).

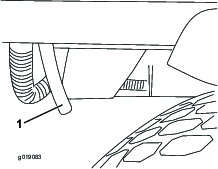

Checking the Drain Tube

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 250 hours |

|

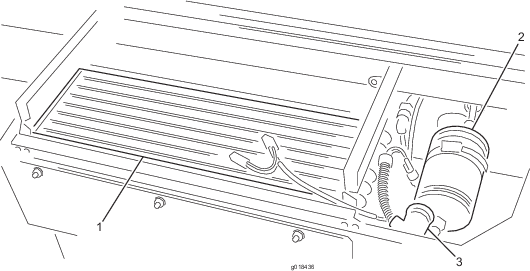

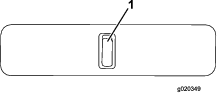

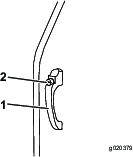

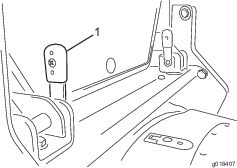

The water drain is the clear plastic tube connected to the condenser. It runs from the condenser through the cab structure to below the front of the cab (Figure 17). Check the water drain for blockages and clean as necessary.

If the tube is blocked, use a flexible unblocking tool (pipe cleaner) or disconnect the tube and blow it out with compressed air.

Note: If the blockage is not reachable with a flexible unblocking tool, the other end of the tube can be disconnected and blown out with compressed air (Figure 18).

Checking the Compressor-Fan Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 500 hours |

|

-

Proper tension allows 10 mm (3/8 inch) deflection when applying a force of 40 N (9 lb) on the belt, midway between the pulleys.

-

If the deflection is not 10 mm (3/8 inch), loosen the upper and lower compressor-mounting bolts.

-

Increase or decrease the compressor-belt tension and tighten the bolts.

-

Check the deflection of the belt again to ensure that the tension is correct.

Tilting the Cab

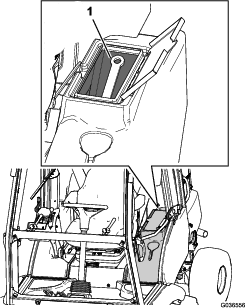

You can tilt the cab for access under the operator platform for cleaning and maintenance.

The cab and the operator platform tilt together as a single unit. The angle of tilt is less than that of a platform without a cab. This is to ensure that, owing to the weight and position of the tilted cab, the machine has sufficient stability when the cab is tilted.

Tilting the Cab Upward

-

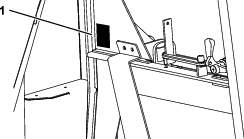

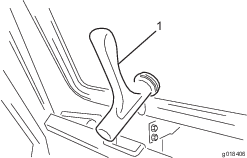

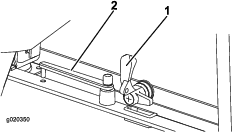

Remove the R-clips and rotate the 2 locking levers, located on the cross beam at the rear of the cab, so that they point upward (Figure 20).

-

Slide the levers inward to remove them from the brackets.

Note: If the levers are difficult to remove, align the locking pegs with the slots in the bracket and then remove the levers.

-

On both sides of the cab, on the rear corner post, there is a grab handle for raising the cab from either side. Lift up on 1 of these handles.

Note: The built-in gas springs assist in raising the cab in a controlled manner and stop it when it is fully raised.

-

With the cab fully raised, install the safety support bracket as follows:

-

Remove the safety support bracket from the storage pod.

-

Using either of the 2 cross-beam brackets, place the safety support bracket within the cross-beam brackets and insert the appropriate locking lever through both brackets and rotate it downward.

-

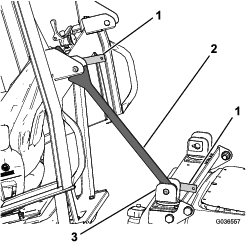

Once the safety support bracket is secured, rotated the cross-beam bracket toward the cab so that it rests against the bracket on the rear of the cab (Figure 22).

-

Insert the remaining locking lever through the top bracket to ensure that the safety support bracket stays in place (Figure 22).

-

Lowering the Cab

-

Remove the safety support bracket as follows:

-

Remove the 2 locking levers securing the safety support bracket to the cross-beam brackets.

-

Remove the safety support bracket from the cross-beam bracket.

-

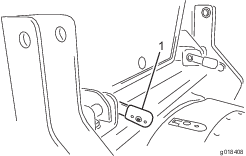

Place the safety support bracket in the storage pod (Figure 21).

-

-

Pull down on 1 of the grab handles to lower the cab so that the brackets on the rear of the cab align between the brackets on the cross beam.

-

With the levers in the vertical position (Figure 20), push them through the sets of brackets.

Note: Move the levers back and forth into the brackets to align the locking pegs in the slots.

-

When the levers are fully inserted, rotate them backward to lock them in position (Figure 23).

-

Install the R-clips.

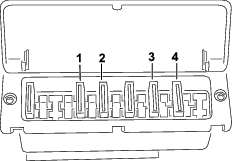

Locating the Fuses

Washing the Machine and Cab

When washing the machine and the cab, do not direct water into the roof area.