Maintenance

Changing the Gearbox Lubricant

| Service Interval |

| After the first 100 hours |

| Every 500 hours / Yearly (Whichever comes first) |

-

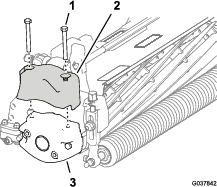

Clean the external surfaces of the groomer housing.

Important: Ensure that there is no dirt or clippings on the outside of the groomer housing; if debris gets inside of the groomer it can damage the gearbox.

-

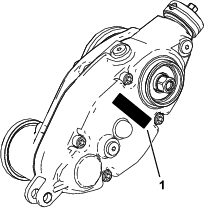

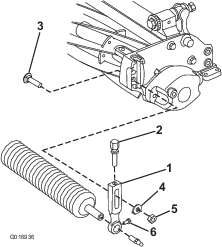

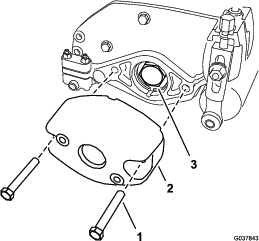

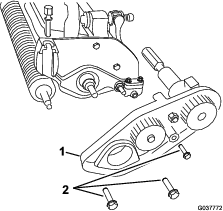

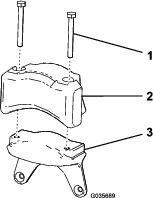

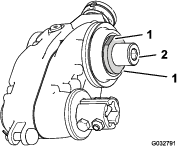

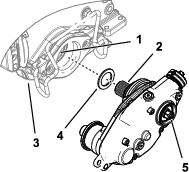

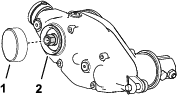

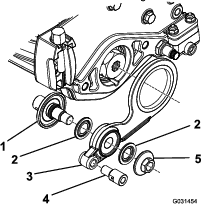

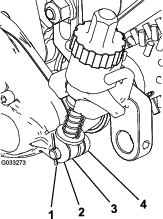

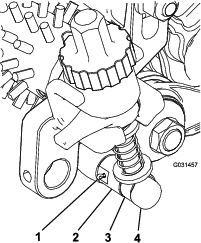

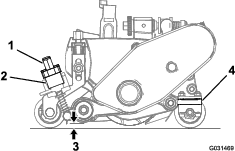

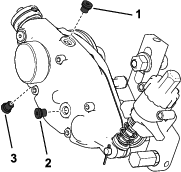

Remove the drain plug on the bottom of the housing (Figure 29).

-

Remove the fill plug on the side of the housing and loosen the air vent plug on the top so air can pass through (Figure 29).

-

Align a suitable container beneath the oil drain port to catch drained oil.

-

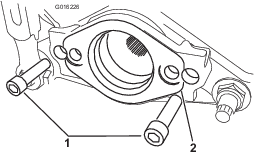

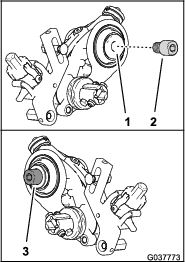

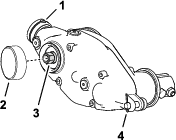

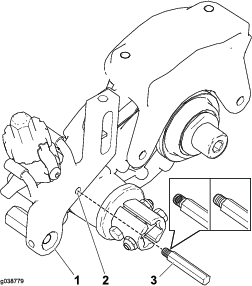

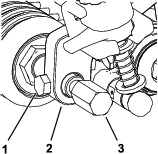

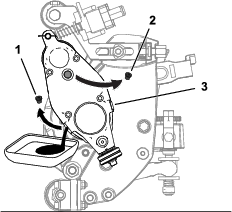

Tip the cutting unit vertically until the drain port is at the bottom to ensure complete drainage (Figure 27).

-

Rock the cutting unit back and forth to ensure complete drainage. When the oil is completely drained, place the cutting unit on a level surface.

-

Install the drain plug.

-

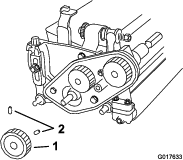

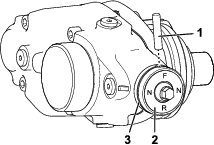

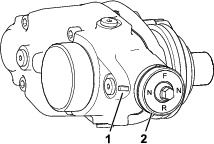

Use a syringe (Part No. 137-0872) to fill the drive box with 50 cc of 80-90W oil.

-

Install the fill plug and tighten the air-vent plug.

-

Torque all plugs to 3.62 to 4.75 N∙m (32 to 42 in-lb).

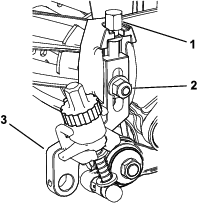

Cleaning the Grooming Reel

Clean off the grooming reel after using it by spraying it with water. Do not direct the water stream directly at the groomer bearing seals. Do not permit the grooming reel to stand in water so that the components rust.

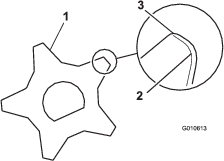

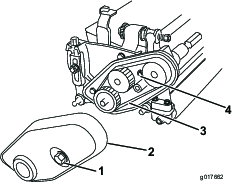

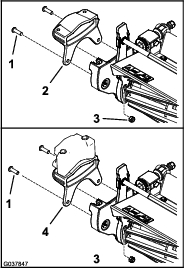

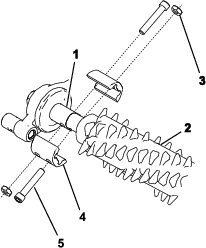

Inspecting the Blades

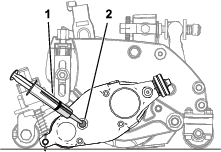

Inspect the grooming-reel blades frequently for damage and wear. Straighten bent blades with a pliers. Replace worn blades, and torque the locknuts to 42 to 49 N∙m (31 to 36 ft-lb). When inspecting the blades, check to see that nuts on the right and left blade-shaft ends are tight.

Note: If you are using spring steel blades, when 1 side of the blades become worn, remove the grooming reel, rotate it 180 degrees, and install it so that the unworn side is facing the direction of rotation.

Note: Because the groomer may introduce more debris (i.e., dirt and sand) into the cutting unit than what the reel would normally be exposed to, check the bedknife and main reel for wear more frequently. This is especially important in sandy soil and/or when the groomer is set for penetration.