| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

Read this manual carefully to learn how to operate and maintain your product properly. The information in this manual can help you and others avoid injury and product damage. Although Toro designs and produces safe products, you are responsible for operating the product properly and safely. You may contact Toro directly at www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

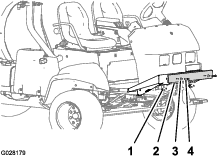

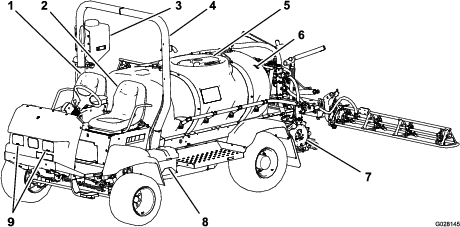

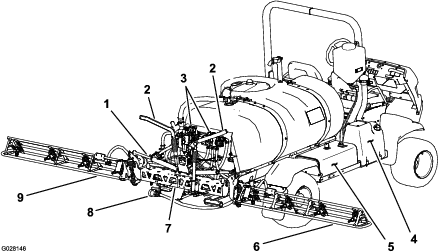

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 illustrates the location of the model and serial numbers on the product.

This manual identifies potential hazards and has safety messages identified by the safety alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

The Multi-Pro® turf sprayer is a dedicated turf spray application vehicle and is intended to be used by professional, hired operators in commercial applications. It is primarily designed for spraying on well-maintained lawns in parks, golf courses, sports fields, and on commercial grounds.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

Warning

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Important: This engine is not equipped with a spark arrester muffler. It is a violation of California Public Resource Code Section 4442 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land. Other states or federal areas may have similar laws.

The enclosed Engine Owner's Manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Safety

Improper use or maintenance by the operator or owner can result in injury. To reduce the potential for injury, comply with these safety instructions and always pay attention to the safety alert symbol, which means Caution, Warning, or Danger—“personal safety instruction.” Failure to comply with the instruction may result in personal injury or death.

The machine meets the requirements of SAE J2258.

Safe Operating Practices

Important: Important: The machine is designed primarily as an off-road vehicle and is not intended for extensive use on public roads. When using the machine on public roads, follow all traffic regulations and use any additional accessories that may be required by law, such as lights, turn signals, slow moving vehicle (SMV) sign, and others as required.

The Multi-Pro 5800 Turf Sprayer was designed and tested to offer safe service when operated and maintained properly. Although hazard control and accident prevention partially are dependent upon the design and configuration of the machine, these factors are also dependent upon the awareness, concern, and proper training of the personnel involved in the operation, maintenance and storage of the machine. Improper use or maintenance of the machine can result in injury or death.

Not all of the attachments that adapt to the Multi-Pro 5800 Turf Sprayer are covered in this manual. See the specific Operator’s Manual provided with each attachment for additional safety instructions. Read these manuals.

To reduce the potential for injury or death, comply with the following safety instructions:

Supervisor's Responsibilities

-

Make sure that operators are thoroughly trained and familiar with the Operator's Manual, engine owner’s manual, and all labels on the sprayer.

-

Establish your own special procedures and work rules for unusual operating conditions (e.g. slopes too steep for sprayer operation).

Training

-

Read the Operator's Manual and other training material before operating the machine.

Note: If the operator(s) or mechanic(s) cannot read the manual language, it is the owner's responsibility to explain this material to them.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

All operators and mechanics should be trained. The owner is responsible for training the users.

-

Never untrained people operate or service the equipment.

Note: Local regulations may restrict the age of the operator.

-

The owner/user can prevent and is responsible for accidents or injuries occurring to himself or herself, other people, or damage to property.

Before Operating

-

Operate the machine only after reading and understanding the contents of this manual.

-

Never allow children to operate the sprayer.

-

Never allow other adults to operate the sprayer without first reading and understanding the Operator's Manual. Only trained and authorized persons should operate this sprayer. Make sure that all operators are physically and mentally capable of operating the sprayer.

-

This sprayer is designed to carry only you, the operator and one passenger in the seat provided by the manufacturer. Never carry any additional passengers on the sprayer.

-

Never operate the sprayer when under the influence of drugs or alcohol. Even prescription drugs and cold medicines can cause drowsiness.

-

Do not drive the sprayer when you are tired. Be sure to take occasional breaks. It is very important that you stay alert at all times.

-

Become familiar with the controls and know how to stop the engine quickly.

-

Keep all shields, safety devices, and decals in place. If a shield, safety device, or decal is malfunctioning, illegible, or damaged, repair or replace it before operating the machine.

-

Wear appropriate clothing; including safety glasses, long pants, safety shoes, rubber boots, gloves, and hearing protection. Do not wear loose fitting clothing or jewelry which could get caught in moving parts and cause personal injury. Always wear substantial shoes.

Caution

This machine produces sound levels in excess of 85 dBA at the operator’s ear and can cause hearing loss through extended periods of exposure.

Wear hearing protection when operating this machine.

-

Avoid driving when it is dark, especially in unfamiliar areas. If you must drive when it is dark, be sure to drive cautiously, use the headlights, and even consider adding additional lights.

-

Be extremely careful when operating around people. Always be aware of where bystanders might be located and keep them away from the work area.

-

Before operating the sprayer, always check the designated areas of the sprayer that are stated in the Pre-Starting Checks in the Operation section. If the machine does not function correctly or is damaged in any way, do not use the sprayer. Make sure that the problem is corrected before the sprayer or attachment is operated.

-

Make sure the operator and passenger area is clean and free from chemical residue and debris buildup.

-

Ensure that all fluid line connectors are tight and all hoses are in good condition before applying pressure to the system.

Note: Do not use the sprayer if it is leaking or damaged.

-

Since fuel is highly flammable, handle it carefully.

-

Use an approved fuel container.

-

Do not remove the cap from the fuel tank when the engine is hot or running. Allow the engine to cool before fueling the machine.

-

Do not smoke while handling fuel.

-

Fill the fuel tank of the machine outdoors.

-

Fill the fuel tank of the machine to about 25 mm (1 inch) below the top of the tank (the bottom of the filler neck). Do not overfill the fuel tank.

-

Wipe up any spilled fuel.

-

Chemical Safety

Warning

Chemical substances used in the spreader-sprayer system may be hazardous and toxic to you, bystanders, animals, plants, soils or other property.

-

Carefully read and follow the chemical warning labels and Material Safety Data Sheets (MSDS) for all chemicals used and protect yourself according to the chemical manufacturer's recommendations. Ensure that as little skin as possible is exposed while using chemicals. Use appropriate Personal Protective Equipment (PPE) to guard against personal contact with chemicals, such as:

-

safety glasses, goggles, and/or face shield

-

respirator or filter mask

-

chemical resistant gloves

-

rubber boots or other substantial footwear

-

hearing protection

-

clean change of clothes, soap, and disposable towels, to be kept on-hand, in the event of a chemical spill.

-

-

Keep in mind that there may be more than one chemical used, and information on each chemical should be assessed.

-

Refuse to operate or work on the sprayer if this information is not available!

-

Before working on a sprayer system, make sure that the system has been triple rinsed and neutralized according to the recommendations of the chemical manufacturer(s) and all of the valves have been cycled 3 times.

-

Verify there is an adequate supply of clean water and soap nearby, and immediately wash off any chemicals that contact you.

-

Obtain proper training before using or handling chemicals.

-

Use the correct chemical for the job.

-

Follow the chemical manufacturer's instructions for the safe application of the chemical. Do not exceed recommended system application pressure.

-

Do not fill, calibrate, or clean the unit when people, especially children, or pets are in the area.

-

Handle chemicals in a well ventilated area.

-

Have clean water available especially when filling the spray tank.

-

Do not eat, drink, or smoke while working with chemicals.

-

Do not clean spray nozzles by blowing through them or placing in mouth.

-

Always wash your hands and other exposed areas as soon as possible after you finish working with chemicals.

-

Keep chemicals in their original packages and stored in a safe location.

-

Properly dispose of unused chemicals and chemical containers as instructed by the chemical manufacturer and your local codes.

-

Chemicals and fumes are dangerous; never enter the tank or place your head over or in the opening of a tank.

-

Follow all local, state, federal regulations for spreading or spraying chemicals.

While Operating

Warning

Engine exhaust contains carbon monoxide, which is an odorless, deadly poison that can kill you.

Do not run engine indoors or in an enclosed area.

-

The operator (and passenger) should remain seated whenever the sprayer is in motion. The operator should keep both hands on the steering wheel whenever possible. Keep your arms and legs within the sprayer body at all times.

-

Failure to operate the sprayer safely may result in an accident, tip over of the sprayer, and serious injury or death. Drive carefully. To prevent tipping or loss of control:

-

Use extreme caution, reduce speed, and maintain a safe distance around sand traps, ditches, creeks, ramps, unfamiliar areas, or any areas that have abrupt changes in ground conditions or elevation.

-

Watch for holes or other hidden hazards.

-

Use extra caution when operating the sprayer on wet surfaces, in adverse weather conditions, at higher speeds, or with a full load. Stopping time and distance will increase with a full load.

-

Avoid sudden stops and starts. Do not go from reverse to forward or forward to reverse without first coming to a complete stop.

-

Slow down before turning. Do not attempt sharp turns or abrupt maneuvers or other unsafe driving actions that may cause a loss of sprayer control.

-

Before backing up, look to the rear and ensure that no one is behind you. Back up slowly.

-

Watch out for traffic when you are near or crossing roads. Always yield the right of way to pedestrians and other vehicles. This sprayer is not designed for use on streets or highways. Always signal your turns or stop early enough so that other people know what you plan to do. Obey all traffic rules and regulations.

-

The electrical and exhaust systems of the sprayer can produce sparks capable of igniting explosive materials. Never operate the sprayer in or near an area where there is dust or fumes in the air which are explosive.

-

If you are ever unsure about safe operation, stop work and ask your supervisor.

-

-

Do not touch the engine or muffler while the engine is running or soon after it has stopped. These areas may be hot enough to cause burns.

-

If the machine ever vibrates abnormally, stop immediately, wait for all motion to stop, and inspect the sprayer for damage. Repair all damage before resuming operation.

-

Before getting off of the seat:

-

Stop the movement of the machine.

-

Remove your foot from the traction pedal and set the parking brake.

-

Turn the key for the starter switch to the Off position.

-

Remove the key from the starter switch.

Important: Do not park the machine on an incline.

-

-

Lightning can cause severe injury or death. If lightning is seen or thunder is heard in the area, do not operate the machine; seek shelter.

Braking

-

Slow down before you approach an obstacle. This gives you extra time to stop or turn away. Hitting an obstacle can damage the sprayer and its contents. More important, it can injure you.

-

Gross Vehicle Weight (GVW) has a major impact on your ability to stop and/or turn. Heavy loads and attachments make a sprayer harder to stop or turn. The heavier the load, the longer it takes to stop.

-

Turf and pavement are much more slippery when they are wet. It can take 2 to 4 times as long to stop on wet surfaces as on dry surfaces. If you drive through standing water deep enough to get the brakes wet, they will not work well until they are dry. After driving through water, you should test the brakes to make sure they work properly. If they do not, drive slowly while putting light pressure on the brake pedal. This will dry the brakes out.

ROPS Safety

Note: For each machine covered in this Operator’s Manual, a cab installed by Toro is a ROPS.

-

Do not remove the ROPS from the machine.

-

Fasten the seat belt and ensure that you can release it quickly in an emergency. Always wear your seat belt when the roll bar is up or on a machine with a cab installed by Toro.

-

Check carefully for overhead obstructions and do not contact them.

-

Keep the ROPS in safe operating condition by thoroughly inspecting it periodically for damage and keeping all the mounting fasteners tight.

-

Replace any damaged ROPS component. Do not repair or alter it.

Operating on Hills and Rough Terrain

Operating the sprayer on a hill may cause tipping or rolling of the sprayer, or the engine may stall and you could lose headway on the hill. This could result in personal injury.

-

Do not accelerate quickly or slam on the brakes when backing down a hill, especially with a load.

-

Never drive across a steep hill; always drive straight up or down or go around the hill.

-

If the engine stalls or you begin to lose headway while climbing a hill, gradually apply the brakes and slowly back straight down the hill.

-

Turning while traveling up or down hills can be dangerous. If you have to turn while on a hill, do it slowly and cautiously. Never make sharp or fast turns.

-

Heavy loads affect stability. Reduce the weight of the load and your speed when operating on hills.

-

Avoid stopping on hills, especially with a load. Stopping while going down a hill will take longer than stopping on level ground. If the sprayer must be stopped, avoid sudden speed changes, which may initiate tipping or rolling of the sprayer. Do not slam on the brakes when rolling backward, as this may cause the sprayer to overturn.

-

Reduce speed and load when operating on rough terrain, uneven ground, and near curbs, holes, and other sudden changes in terrain. Loads may shift, causing the sprayer to become unstable.

Warning

Sudden changes in terrain may cause abrupt steering wheel movement, possibly resulting in hand and arm injuries.

-

Reduce your speed when operating on rough terrain and near curbs.

-

Grip the steering wheel loosely around the perimeter. Keep your hands clear of the steering wheel spokes.

Loading

The weight of the cargo can change the sprayer center of gravity and sprayer handling. To avoid loss of control and personal injury, follow these guidelines:

-

Reduce the weight of the load when operating on hills and rough terrain to avoid tipping or overturning of the sprayer.

-

Liquid loads can shift. This shifting happens most often while turning, going up or down hills, suddenly changing speeds, or while driving over rough surfaces. Shifting loads can cause the sprayer to tip over.

-

When operating with a heavy load, reduce your speed and allow for sufficient braking distance. Do not suddenly apply the brakes. Use extra caution on slopes.

-

Be aware that heavy loads increase your stopping distance and reduce your ability to turn quickly without tipping over.

Maintenance

-

Only permit qualified and authorized personnel to maintain, repair, adjust, or inspect the sprayer.

-

Before performing any maintenance, ensure that the system has been thoroughly rinsed and cleaned.

-

Before servicing or making adjustments to the machine, stop the engine, set the parking brake, and remove the key from the starter switch to prevent someone from accidentally starting the engine.

-

To make sure that the entire machine is in good condition, keep all nuts, bolts, and screws properly tightened.

-

To reduce the potential for fire, keep the engine area free of excessive grease, grass, leaves, and accumulation of dirt.

-

Never use an open flame to check the level or leakage of fuel or battery electrolyte.

-

If the engine must be running to perform a maintenance adjustment, keep your hands, feet, clothing, and any parts of your body away from the engine and any moving parts. Keep everyone away.

-

Do not use open pans of fuel or flammable cleaning fluids when cleaning parts.

-

Do not adjust the traction control speed. To ensure safety and accuracy, have an Authorized Toro Distributor check the ground speed.

-

Keep your body and hands away from pin hole leaks or nozzles that eject high pressure fluid. Use cardboard or paper to find leaks. Fluid escaping under pressure can penetrate skin and cause injury requiring surgery within a few hours by a qualified surgeon or gangrene may result.

-

If major repairs are ever needed or assistance is required, contact an Authorized Toro Distributor.

-

To be sure of optimum performance and safety, always purchase genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous. Altering this sprayer in any manner that may affect sprayer operation, performance, durability, or its use, may result in injury or death. Such use could void the product warranty.

Sound Power

This unit has a guaranteed sound power level of 101 dBA, which includes an Uncertainty Value (K) of 1 dBA.

Sound power level was determined according to the procedures outlined in ISO 11094.

Sound Pressure

This unit has a sound pressure level at the operator’s ear of 90 dBA, which includes an Uncertainty Value (K) of 1 dBA.

Sound pressure level was determined according to the procedures outlined in EN ISO 11201.

Hand-Arm Vibration

Measured vibration level for right hand = 0.8 m/s2

Measured vibration level for left hand = 0.8 m/s2

Uncertainty Value (K) = 0.4 m/s2

Measured values were determined according to the procedures outlined in EN 1032.

Whole Body Vibration

Measured vibration level = 0.28 m/s2

Uncertainty Value (K) = 0.14 m/s2

Measured values were determined according to the procedures outlined in EN 1032.

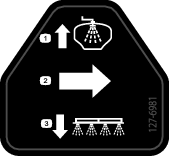

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. |

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Note: If you have questions or need additional information regarding the spray control system, refer to the Operator’s Manual supplied with the system.

Important: This sprayer is sold without nozzles and a application-rate controller. Either a Manual Spray Operation Kit or ProControl™ XPKit is necessary for the proper function of the machine.To use the sprayer, you must obtain and install nozzles. Contact your Authorized Toro Distributor for information on the available boom kit and accessories. After you install your nozzles and before using the sprayer for the first time (if you do not use Pro Control™XP Spray System), adjust the boom bypass valves so that the pressure and application rate remains the same for all booms when you turn one or more booms off. Refer to Calibrating the Boom Bypass Valves section in the Operation section.

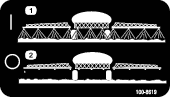

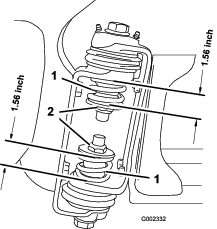

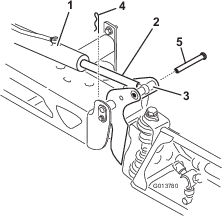

Checking the Boom Hinge Springs

Important: Operating the spray system with the boom hinge springs under the incorrect compression could damage the boom assembly. Measure the springs and use the jam nut to compress the springs to 3.96 cm (1.56 inches), if necessary.

The sprayer is shipped with the boom extensions swung forward to facilitate packaging of the machine. The springs are not fully tightened at the time of manufacture to allow the booms to be in this position for transit. Before operating the machine, adjust the springs to the correct compression.

-

If necessary, remove the packing components that secure the right and left extension booms during shipping.

-

Support the booms while they are extended to the spray position.

-

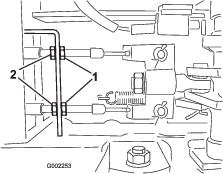

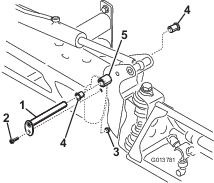

At the boom hinge, measure the compression of the upper and lower springs while the booms are in their extended position (Figure 3).

-

Compress all springs until they measure 3.96 cm (1.56 inches).

-

Use the jam nut to compress any spring that measure greater than 3.96 cm (1.56 inches).

-

-

Repeat the procedure for each spring on both boom hinges.

-

Move the booms into the transport “X” position; refer to Operating the Booms.

Product Overview

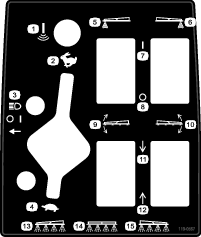

Vehicle Controls

Traction Pedal

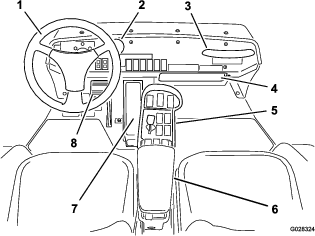

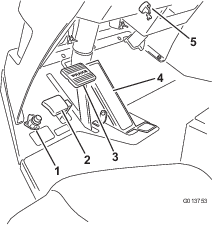

The traction pedal (Figure 8) controls the movement of the machine, both forward and reverse. Using the heel and toe of the right foot, press the top of the pedal to move forward or the bottom of the pedal to move in reverse. Release the pedal to slow and stop.

Important: Ensure that you allow the sprayer to come to a stop before switching between the Forward and the Reverse positions.

Note: The farther you press the pedal in either direction, the faster the sprayer will travel. To obtain maximum forward speed, set the throttle lever to the Fast position and press the traction pedal all the way forward.

Note: To get maximum power under heavy load or when ascending a hill, have the throttle in the Fast position while pressing traction pedal slightly to keep the engine speed high. When the engine speed begins to decrease, release the traction pedal slightly to allow the engine speed to increase.

Brake Pedal

Use the brake pedal to stop or slow the sprayer (Figure 8).

Caution

If you operate the sprayer with poorly adjusted or worn brakes, you could lose control of the sprayer, resulting in serious injury or death to you or bystanders.

Always check the brakes before operating the sprayer and keep them properly adjusted and repaired.

Parking Brake

The parking brake is a pedal to the left of the brake (Figure 8). Engage the parking brake whenever you plan on leaving the seat to prevent the sprayer from accidently moving. To engage the parking brake, press the brake pedal and, while holding the brake, press the parking brake pedal. To disengage, press and release the brake pedal. If the sprayer is parked on a steep grade, apply the parking brake and place blocks on the downhill side of the wheels.

Starter Switch

The starter switch (Figure 8), used to start and stop the engine, has 3 positions: Off, On/Preheat and Start.

Ground-Speed Lock Switch

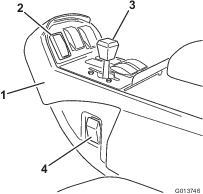

The ground speed lock switch locks the position of the traction pedal at the time the switch is set (Figure 9). This ensures the sprayer travels at a constant speed while driving the machine on level ground.

Throttle Lever

The throttle lever, located on the control panel between the seats (Figure 9), controls the speed of the engine. Push the lever forward to increase the engine speed and pull it rearward to decrease the engine speed.

Headlight Switch

Toggle the switch to operate the headlights (Figure 9). Push it forward to turn the lights on and rearward to turn them off.

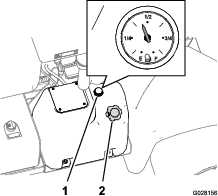

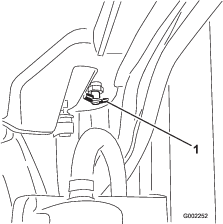

Fuel Gauge

The fuel gauge is located on top of the fuel tank (Figure 10), on the left side of the machine and shows the amount of fuel in the tank.

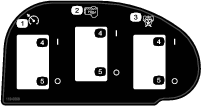

Hour Meter

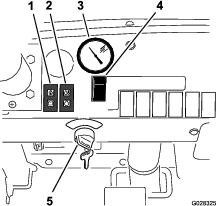

The hour meter (Figure 11) indicates the total number of hours the engine has run. The hour meter starts to function whenever the key is turned to the Run position.

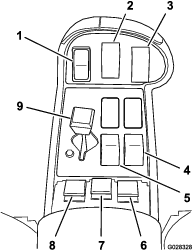

Sprayer Controls

Application Rate Switch

The application rate switch is located on the dash to the right of the steering wheel (Figure 14). Press and hold the switch forward to increase the spray system pressure, or press and hold it rearward to decrease pressure.

Pressure Gauge

The pressure gauge (Figure 12) is located on the dash. This gauge shows the pressure of the fluid in the system in psi and kPa.

Master Boom Switch

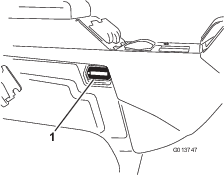

The master boom switch is located on the floor board of the machine cab and to the left of the operator. It allows you to start or stop the spray operation. Press the switch with your foot to enable or disable the spray system (Figure 13).

Section Switches

The section switches are located on the control panel to the right of the seat (Figure 14). Toggle each switch forward to turn the corresponding boom section on and rearward to turn each off. When the switch is in the On position, a light will illuminate on the switch. These switches will only affect the spray system when the master boom switch is in the On position.

Pump Switch

The pump switch is located on the control panel to the right of the seat (Figure 14). Toggle this switch forward to run the pump or rearward to stop the pump. When the switch is turned on, a light on the switch illuminates.

Important: Only engage the pump switch when the engine is at low idle to avoid damaging the pump drive.

Boom Lift

The boom lift switches are located on the control panel to the right of the seat and used to raise the left and right booms respectively (Figure 14).

Agitation Switch

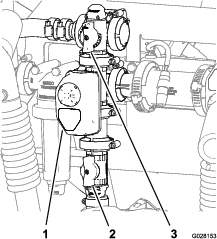

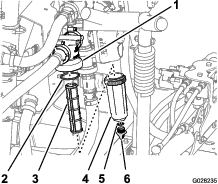

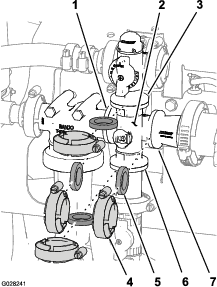

The agitation switch is located on the control panel to the right of the seat (Figure 14). Toggle this switch forward to turn on the agitation in the tank or rearward to stop the agitation. When the switch is turned on, a light on the switch illuminates. To operate the agitation function, you must run the sprayer system pump and you must run the engine above an idle. The agitation valve is located behind the tank (Figure 15)

Agitation Bypass Valve

The agitation bypass valve redirects the flow of fluid to the sprayer system pump when you turn off the agitation function (Figure 15). The agitation bypass valve is located at the above of the agitation valve. You can adjust the bypass valve to ensure that pressure remains constant during agitation; refer to Calibrating the Agitation Bypass Valve.

Agitation Throttle Valve

The agitation throttle valve is a manually operated ball valve that controls flow to the agitation nozzles in the main tank (Figure 15). Using this valve allows the user to control the sprayer system pressure at the agitation nozzles of the main tank when larger application rates are required.

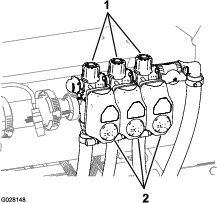

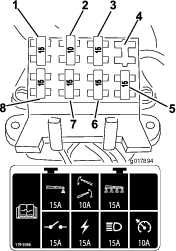

Section Valves

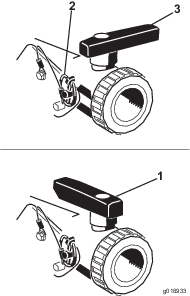

The section valves control flow to the 3 boom sections (Figure 16). If you ever need to manually turn off a section, rotate the knob on the valve clockwise to turn the valve off or counterclockwise to turn it on.

Note: Turning the section valve manually can interfere with the function of the fuses. The fuses should be checked after manually rotating the valve.

Pro Foam Marker Switch Locations (Optional)

If you install the Pro Foam Marker kit, you will add switches to the control panel for controlling their operation. The sprayer comes with plastic plugs in these locations.

Ultra Sonic Boom (Optional)

If you install the Ultra Sonic Boom, you will add a switch to the dash for controlling its operation. The sprayer comes with a plastic plug in this location.

Anti-siphon Fill Receptacle

To the front of the tank cover is a hose receptacle with a threaded fitting, a 90-degree barbed fitting, and a short hose which you can direct toward the tank opening. This receptacle allows you to connect a water hose to it and fill the tank with water without contaminating the hose with the chemicals in the tank.

Important: Do not lengthen the hose to allow contact with the tank fluids. The distance from the end of the hose to the uppermost water level should be within local regulatory limits.

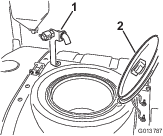

Tank Cover

The tank cover is located in the center of the top of the tank. To open it, turn off the engine, then turn the front half of the cover to the left and swing it open. You can remove the strainer inside for cleaning. To seal the tank, close the cover and rotate the front half toward the right.

Note: Specifications and design are subject to change without notice.

| Base weight | 1307 kg (2,882 lb) |

| Weight with standard spray system, empty, without operator | 1307 kg (2,882 lb) |

| Weight with standard spray system, full, without operator | 2,499 kg (5,510 lb) |

| Maximum gross vehicle weight (GVW) (on level ground) | 3,023 kg (6,665 lb) |

| Tank capacity | 1135.6 L (300 US gallons) |

| Overall width with standard spray system booms stored in the X position | 189 cm (74-3/4 inches) |

| Overall length with standard spray system | 391 cm (154 inches) |

| Overall length with standard spray system to the top of the booms stored in the X position | 442 cm (174 inches) |

| Overall height with standard spray system | 146 cm (57.5 inches) |

| Overall height with standard spray system to the top of the booms stored in the X position | 231 cm (91 inches) |

| Ground clearance | 18.4 cm (7.25 inches) |

| Wheel base | 198 cm (78 inches) |

Optional Equipment

The Toro Company has optional equipment and accessories that you can purchase separately and install on your sprayer. Contact your Authorized Service Dealer for a complete list of optional equipment that is currently available for your sprayer.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Think Safety First

Please carefully read all of the safety instructions and decals in the safety section. Knowing this information could help you or bystanders avoid injury.

Performing Pre-Starting Checks

Check the following items each time you begin using the sprayer for the day:

-

Check the tire pressure.

Note: These tires are different than car tires; they require less pressure to minimize turf compaction and damage.

-

Check all fluid levels and add the appropriate amount of specified fluids, if any are found to be low.

-

Check the brake pedal operation.

-

Check to see that the lights are working.

-

With the engine off, check for oil leaks, loose parts, and any other noticeable malfunctions.

If any of the above items are not correct, notify your mechanic or check with your supervisor before taking the sprayer out for the day. Your supervisor may want you to check other items on a daily basis, so ask what your responsibilities are.

Preparing to Drive the Machine

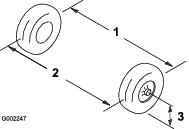

Checking the Tire Air Pressure

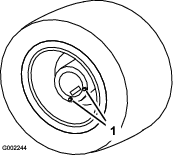

Check the tire air pressure to ensure proper levels. Fill the tires to 124 kPa (18 psi).

Note: Also, check the tires for wear or damage.

Checking the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Engine oil specification:

-

Oil type—API service CH-4, CI-4 or higher.

-

Preferred oil viscosity—SAE 15W40 (above 0 degrees F)

-

Alternate oil viscosity—SAE 10W30 or 5W30 (all temperatures)

Toro Premium Engine Oil is available from your distributor in either 15W40 or 10W30 viscosity. Refer to the Parts Catalog for part numbers.

Note: The best time to check the engine oil is when the engine is cool, before it has been started for the day. If it has already been run, allow the oil to drain back down to the sump for at least 10 minutes before checking.

The engine is shipped with oil in the crankcase; however, the level of oil must be checked before you first start the engine and after you have run it.

-

Position the machine on a level surface.

-

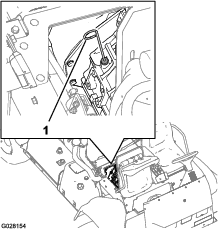

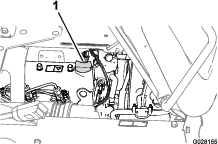

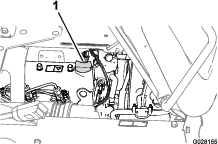

Remove the dipstick, located under the passenger seat, and wipe it with a clean rag (Figure 18).

Note: Insert the dipstick into the tube and make sure it is seated fully. Remove the dipstick and check the oil level.

-

If the oil level is low, remove the filler cap from the valve cover (Figure 19) and pour oil into the filler neck until the oil level is up to the Full mark on the dipstick.

Note: Add the oil slowly and check the level often during this process. Do not overfill.

-

Install the filler cap.

-

Install the dipstick firmly in place.

Checking the Coolant Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Coolant type: a solution of 50% water and 50% permanent ethylene glycol antifreeze

Caution

If the engine has been running, the coolant may be hot and pressurized. If you open the radiator cap when the coolant is hot, it could spray out and severely burn you or bystanders.

Allow the engine to cool for at least 15 minutes before opening the radiator cap.

-

Position the sprayer on a level surface.

-

Set the parking brake, stop the pump, stop the engine, and remove the key from the starter switch.

-

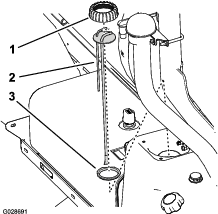

Carefully remove the radiator cap and the expansion tank cap (Figure 20).

-

Check the coolant level in the radiator and in the expansion tank.

Note: The radiator should be filled to the top of the filler neck and the expansion tank filled to the Full mark on the tank (Figure 20).

-

If coolant level is low, remove the expansion tank cap and the radiator cap, and fill expansion tank to the Full mark and the radiator to the top of the filler neck (Figure 20).

Important: Do not overfill the expansion tank.

Important: Do not use water only or an alcohol/methanol-based coolant.

-

Install the radiator cap and the expansion tank cap (Figure 20).

Checking the Hydraulic Fluid

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Hydraulic fluid specifications:

Toro Premium All Season Hydraulic Fluid

Note: (Available in 5-gallon pails or 55-gallon drums. See parts catalog or Toro distributor for part numbers.)

Alternate hydraulic fluids: If the Toro fluid is not available, other fluids may be used provided they meet all the following material properties and industry specifications. We do not recommend the use of synthetic fluid. Consult with your lubricant distributor to identify a satisfactory product.

Note: Toro will not assume responsibility for damage caused by improper substitutions, so use only products from reputable manufacturers who will stand behind their recommendation.

| High Viscosity Index/Low Pour Point Anti-wear Hydraulic Fluid, ISO VG 46 | |||

| Material Properties: | |||

| Viscosity, ASTM D445 | cSt @ 40°C 44 to 48cSt @ 100°C 7.9 to 8.5 | ||

| Viscosity Index ASTM D2270 | 140 to 160 | ||

| Pour Point, ASTM D97 | -34°F to -49°F | ||

| Industry Specifications: | |||

| Vickers I-286-S (Quality Level), Vickers M-2950-S (Quality Level), Denison HF-0 | |||

Important: The ISO VG 46 Multigrade fluid has been found to offer optimal performance in a wide range of temperature conditions. For operation in consistently high ambient temperatures, 18° C (65° F) to 49° C (120° F), ISO VG 68 hydraulic fluid may offer improved performance.

Premium Biodegradable Hydraulic Fluid-Mobil EAL EnviroSyn 46H

Important: Mobil EAL EnviroSyn 46H is the only synthetic biodegradable fluid approved by Toro. This fluid is compatible with the elastomers used in Toro hydraulic systems and is suitable for a wide-range of temperature conditions. This fluid is compatible with conventional mineral oils, but for maximum biodegradability and performance the hydraulic system should be thoroughly flushed of conventional fluid. The oil is available in 5-gallon (19 L) containers or 55-gallon drums from your Mobil Distributor.

-

Position the sprayer on a level surface, set the parking brake, stop the sprayer pump, stop the engine, and remove the key from the starter switch.

-

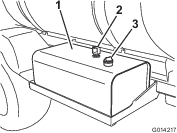

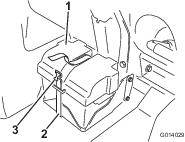

Clean the area around the hydraulic-oil-tank dipstick cap and remove it (Figure 21).

Important: Be very careful not to get dirt or other contaminants into the opening when checking the oil.

-

Wipe the dipstick clean with a cloth and replace it completely in the tank.

-

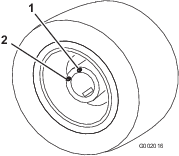

Remove the dipstick from the filler neck and check the fluid level. The fluid level should be within the safe operating range on the dipstick (Figure 22).

-

If the oil is low, fill the tank with the specified hydraulic fluid or equivalent to raise the level to the upper mark.

-

Install the dipstick cap into the tank and secure.

Checking the Brakes

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Before starting the sprayer, lightly press the brake pedal. If the pedal travels more than 2.5 cm (1 inch) before you feel resistance, adjust the brakes; refer to Adjusting the Brakes.

Warning

If you operate the sprayer with poorly adjusted or worn brakes, you could lose control of the sprayer, resulting in serious injury or death to you or bystanders.

Always check the brakes before operating the sprayer and keep them properly adjusted and repaired.

Adding Fuel

Danger

In certain conditions, fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

-

Fill the fuel tank outdoors, in an open area, when the engine is cold. Wipe up any fuel that spills.

-

Do not fill the fuel tank completely full. Add fuel to the fuel tank until the level is 25 mm (1 inch) below the bottom of the filler neck. This empty space in the tank allows fuel to expand.

-

Never smoke when handling fuel, and stay away from an open flame or where fuel fumes may be ignited by a spark.

-

Store fuel in an approved container and keep it out of the reach of children. Never buy more than a 30-day supply of fuel.

Danger

In certain conditions during fueling, static electricity can be released causing a spark which can ignite the fuel vapors. A fire or explosion from fuel can burn you and others and can damage property.

-

Always place fuel containers on the ground away from your vehicle before filling.

-

Do not fill fuel containers inside a vehicle or on a truck or trailer bed because interior carpets or plastic truck bed liners may insulate the container and slow the loss of any static charge.

-

When practical, remove gas-powered equipment from the truck or trailer and refuel the equipment with its wheels on the ground.

-

If this is not possible, then refuel such equipment on a truck or trailer from a portable container, rather than from a fuel dispenser nozzle.

-

If a fuel dispenser nozzle must be used, keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

Important: Your engine runs on No. 2-D or 1-D automotive-type diesel fuel with a minimum cetane rating of 40.

Note: Your engine may require a higher cetane-rated fuel if you operate the machine at high altitudes or in low atmospheric temperatures.

Using Biodiesel Fuel

This machine can also use a biodiesel blended fuel of up to B20 (20% biodiesel, 80% petrodiesel). The petrodiesel portion should be low or ultra low sulfur. Observe the following precautions:

-

The biodiesel portion of the fuel must meet specification ASTM D6751 or EN14214.

-

The blended fuel composition should meet ASTM D975 or EN590.

-

Painted surfaces may be damaged by biodiesel blends.

-

Use B5 (biodiesel content of 5%) or lesser blends in cold weather.

-

Monitor seals, hoses, gaskets in contact with fuel as they may be degraded over time.

-

Fuel filter plugging may be expected for a time after converting to biodiesel blends.

-

Contact your distributor if you wish for more information on biodiesel.

Filling the Fuel Tank

Fuel tank capacity: approximately 45 L (12 US gallons).

Note: The fuel tank features a fuel gauge which shows the level of fuel in the tank—check the fuel gauge frequently.

-

Position the sprayer on a level surface.

-

Set the parking brake, stop the pump, stop the engine, remove the key, and allow the engine to cool.

-

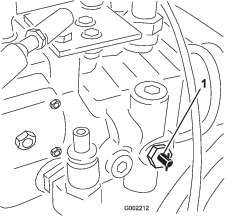

Clean the area around the fuel-tank cap (Figure 23).

-

Remove the fuel-tank cap.

-

Fill the tank to about 2.5 cm (1 inch) below the top of the tank, (bottom of the filler neck).

Note: This space in the tank allows fuel to expand. Do not overfill.

-

Install the fuel tank cap securely.

-

Wipe up any fuel that may have spilled.

Preparing to Use the Sprayer

Cleaning the Suction Strainer

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Position the sprayer on a level surface, set the parking brake, stop the pump, stop the engine, and remove the key from the starter switch.

-

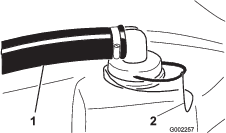

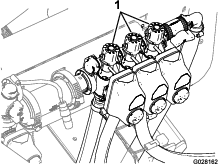

At the top of the sprayer tank, remove the retainer that secures the hose fitting to attached to the large hose and the strainer housing (Figure 24).

-

Remove the hose and hose fitting from the strainer housing (Figure 24).

-

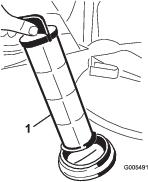

Pull the suction strainer out of the strainer housing in the tank (Figure 25).

-

Clean the suction strainer with clean water.

-

Insert the suction strainer into the strainer housing until the strainer is fully seated.

-

Align the hose and hose fitting to the strainer housing at the top of the tank to the and secure fitting and housing with the retainer that you removed in step 2.

Inspecting the Tank Straps

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Important: Over tightening the tank strap fasteners can result in deforming and damaging the tank and straps.

-

Fill the main tank with water.

-

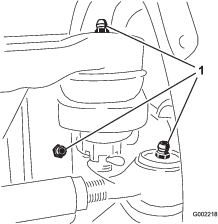

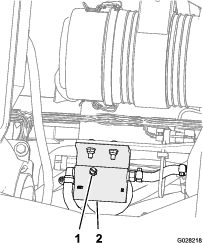

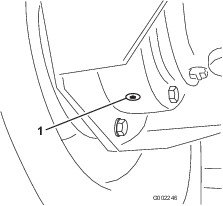

Check to see if there is any movement between the tank straps and the tank (Figure 26).

-

If the tank straps fit loose to the tank, tighten the flanged locknuts and bolts at the top of straps until the straps are flush with the surface of the tank (Figure 26).

Note: Do not over tighten the tank strap hardware.

Operating the Machine

Starting the Engine

-

Sit on the operator’s seat and keep your foot off the traction pedal.

-

Ensure that the parking brake is engaged, the traction pedal is in the Neutral position, the throttle is in the Slow position.

-

Turn the switch to the On/Preheat position.

Note: An automatic timer will control the preheat for approximately 6 seconds.

-

After preheating, turn the key to the Start position.

-

Crank the engine for no longer than 15 seconds.

-

Release the key when the engine starts.

-

If the engine requires additional preheating, turn the key to the Off position, then to the On/Preheat position.

Note: Repeat steps through as required.

-

Run the engine at idle speed or partial throttle until the engine warms up.

Driving the Machine

-

Press the traction pedal forward to drive the machine forward or press the pedal rearward to drive the machine in reverse.

Important: Ensure that you allow the sprayer to come to a stop before switching between the Forward and Reverse positions.

-

To slowly stop the machine, release the traction pedal.

Note: The traction pedal will return to the Neutral position.

-

To stop quickly, press the brake pedal.

Note: The stopping distance of you machine may vary depending on the sprayer-tank load and ground speed of the machine.

Setting the Ground Speed Lock Switch

Caution

If you press the ground speed lock switch and do not have your foot on the traction pedal, the traction unit may suddenly stop and cause you to lose control, possibly injuring you or bystanders.

Ensure that you have your foot on the traction pedal when you disengage the ground speed lock switch.

-

Drive forward and attain the desired ground speed; refer to Driving the Machine.

-

Press the top of the ground speed lock switch.

Note: The light on the switch illuminates.

-

Take your foot off the traction pedal.

Note: The sprayer will maintain the speed you set.

-

To release the ground speed lock switch, either place your foot on the traction pedal and press the bottom of the switch or remove your foot from the traction pedal and press the brake pedal.

Note: The light on the switch turns off and the traction control returns to the traction pedal.

Stopping the Engine

-

Move all the controls to the Neutral position.

-

Press the brake to stop the sprayer.

-

Set the parking brake.

-

Shift the throttle lever to the Idle position.

-

Turn the starter key to the Off position.

-

Remove the key from the switch to prevent someone from accidentally starting the engine.

Breaking in a New Sprayer

To provide proper performance and long sprayer life, follow these guidelines for the first 100 operating hours:

-

Check the fluid and engine oil levels regularly and be alert for indications of overheating in any component of the sprayer.

-

After filling the tank, check the tank straps for any play. Tighten as necessary.

-

After starting a cold engine, let it warm up for about 15 seconds before accelerating.

-

Avoid hard braking situations for the first several hours of new sprayer break-in operation. New brake linings may not be at optimum performance until several hours of use has caused the brakes to become burnished (broken-in).

-

Avoid racing the engine.

-

Refer to the Maintenance section for any special low hour checks.

Operating the Sprayer

To operate the Multi-Pro Sprayer first fill the spray tank, then apply the solution to the work area, and finally clean the tank. It is important that you complete all three of these steps in succession to avoid damaging the sprayer. For example, do not mix and add chemicals in the spray tank at night and then spray in the morning. This would lead to separation of the chemicals and possible damage to the sprayer components.

Caution

Chemicals are hazardous and can cause personal injury.

-

Read the directions on the chemical labels before handling the chemicals and follow all manufacturer recommendations and precautions.

-

Keep chemicals away from your skin. Should contact occur, wash the affected area thoroughly with soap and clean water.

-

Wear goggles and any other protective equipment recommended by the chemical manufacturer.

The Multi-Pro Sprayer has been specifically designed to have high durability in order to give it the long sprayer life you need. Different materials have been chosen for specific reasons at different locations on your sprayer to meet this goal. Unfortunately there is no single material which is perfect for all foreseeable applications.

Some chemicals are more aggressive than others and each chemical interacts differently with various materials. Some consistencies (e.g. wettable powders, charcoal) are more abrasive and lead to higher wear rates. If a chemical is available in a formulation that would provide increased life to the sprayer, use this alternative formulation.

As always, remember to clean your sprayer thoroughly after all applications. This will do the most to ensure your sprayer has a long and trouble free life.

Note: If you have questions or need additional information regarding the spray control system, refer to the Operators Manual supplied with the system.

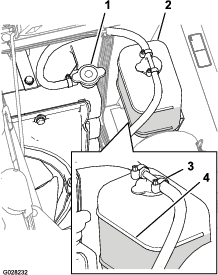

Filling the Fresh Water Tank

Always fill the fresh water tank with clean water before handling or mixing any chemicals.

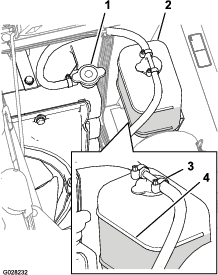

The fresh water tank is located on the ROPS, behind the passenger seat (Figure 27). It supplies a source of fresh water for you to wash chemicals off of your skin, eyes, or other surfaces in the case of accidental exposure.

To fill the tank, unscrew the cap on the top of the tank and fill the tank with fresh water. Replace the cap.

To open the fresh water tank spigot, turn the lever on the spigot.

Filling the Spray Tank

Important: Ensure that the chemicals you will be using are compatible for use with Viton (see the manufacturer's label; it should indicate if it is not compatible). Using a chemical that is not compatible with Viton will degrade the O-rings in the sprayer, causing leaks.

Important: The tank markings are for reference only and cannot be considered accurate for calibration.

Important: After filling the tank for the first time, check the tank straps for any play. Tighten as necessary.

-

Stop the sprayer on a level surface, stop the engine, and set the parking brake.

-

Determine the amount of water needed to mix the amount of chemical you need as prescribed by the chemical manufacturer.

-

Open the tank cover on the spray tank.

The tank cover is located in the center of the top of the tank. To open it, turn the front half of the cover counterclockwise and swing it open. You can remove the strainer inside for cleaning. To seal the tank, close the cover and rotate the front half clockwise.

-

Add 3/4 of the required water to the spray tank using the anti-siphon fill receptacle.

Important: Always use fresh clean water in the spray tank. Do not pour concentrate into an empty tank.

-

Start the engine, set the pump switch to the On position, and move the throttle lever to a higher idle.

-

Set the agitation switch to the On position.

Important: Prior to introducing wettable powders into any Toro Spray System mix the powders in a suitable container with sufficient fresh water to create a free flowing slurry. Failure to do so may result in chemical deposits on the bottom of the tank, degraded agitation, clogging of filters and improper agitation rates.Toro recommends using the approved Eductor Kit for this machine. Contact your Authorized Toro Dealer for more information.

-

Add the proper amount of chemical concentrate to the tank, as directed by the chemical manufacturer.

-

Add the remaining water to the tank.

Operating the Booms

The boom lift switches on the sprayer control panel allows you to move the booms between transport position and spray position without leaving the Operator's seat. It is recommended to change boom positions while the machine is stationary.

To change the boom position:

-

Stop the sprayer on level ground.

-

Use the boom lift switches to lower booms. Wait until the booms reach the full, extended spray position.

-

When the booms need to be retracted, stop the sprayer on level ground.

-

Use the boom lift switches to raise the booms. Raise the booms until they have moved completely into boom transport cradle forming the “X” transport position and the boom cylinders are fully retracted.

Important: To prevent damage to the boom actuator cylinder, make sure the actuators are fully retracted before transport.

Important: Release the actuator switch once the booms have reached the desired position. Running the actuators against the stops may cause damage to the cylinders and or other hydraulic components.

Operating the Boom Transport Cradle

The sprayer is equipped with a boom transport cradle that has a unique safety feature. In the event of accidental boom contact with a low overhead object while in the transport position, the boom(s) can be pushed out of the transport cradles. If this occurs, the booms will come to rest in a near horizontal position to the rear of the vehicle. While the booms will not be damaged due to this movement, they should be immediately put back into the transport cradle.

Important: The booms can be damaged by transporting them in any position other than the “X” transport position using the boom transport cradle.

To put the booms back into the transport cradle, lower the boom(s) to the spray position, and then raise the boom(s) back into the transport position. Make sure the boom cylinders are fully retracted to prevent actuator rod damage during storage.

Spraying

Important: In order to ensure that your solution remains well mixed, use the agitation feature whenever you have solution in the tank. For agitation to work, the pump must be on and the engine must be running above an idle.

Note: This procedure assumes that the pump is on; refer to Filling the Spray Tank.

-

Set the master boom switch to the Off position.

-

Adjust the throttle to the desired position to spray at.

-

Drive to the location where you will be spraying.

-

Lower the booms into position.

-

Set the individual section switches, as needed, to the On positions.

-

Use the application rate switch to achieve the desired pressure as indicated in the nozzle selection guide provided with the sprayer.

-

Drive at the desired speed and then set the master boom switch to the On position to begin spraying.

Note: When the tank is nearly empty, the agitation may cause foaming in the tank. In this case, turn the agitation switch off. Alternatively, you can use an anti-foaming agent in the tank.

-

When finished spraying, set the master boom switch to the Off position to turn off all booms, then set the pump switch to the Off position.

Note: Return the booms to the transport position and drive the sprayer to the cleaning area.

Important: Always raise the booms until they have moved completely into boom transport cradle forming the “X” transport position and the boom cylinders are fully retracted whenever you move the sprayer from one spraying area to another or move to a storage or cleaning area.

Turf Care Precautions while Operating in Stationary Modes

Important: Under some conditions, heat from the engine, radiator, and muffler can potentially damage grass when operating the sprayer in a stationary mode. Stationary modes include tank agitation, hand spraying with a spray gun, or using a walking boom.

Use the following precautions:

-

Avoid stationary spraying when conditions are very hot and/or dry, as turf can be more stressed during these periods.

-

Avoid parking on the turf while stationary spraying. Park on a cart path whenever possible.

-

Minimize the amount of time the machine is left running over any particular area of turf. Both time and temperature affect how much the grass may be damaged.

-

Set the engine speed as low as possible to achieve the desired pressure and flow. This will minimize the heat generated and the air velocity from the cooling fan.

-

Allow heat to escape upward from the engine compartment by raising the seat assemblies during stationary operation rather than being forced out under the vehicle.

Spraying Tips

-

Do not overlap areas that you have previously sprayed.

-

Watch for plugged nozzles. Replace all worn or damaged nozzles.

-

Use the master boom switch to stop the spray flow before stopping the sprayer. Once stopped, use the neutral engine speed control to hold the engine speed up to keep the agitation running.

-

You will obtain better results if the sprayer is moving when you turn the booms on.

Unclogging a Nozzle

If a nozzle becomes clogged while you are spraying, you can clean it using a hand spray bottle of water or a toothbrush.

-

Stop the sprayer on a level surface, stop the engine, and set the parking brake.

-

Set the master boom switch to the Off position and then set the pump switch to the Off position.

-

Remove the clogged nozzle and clean it using a spray bottle of water or a toothbrush.

Selecting a Nozzle

Note: Refer to the nozzle selection guide that is available through your Authorized Toro Dealer.

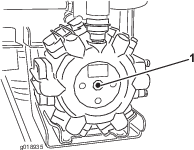

The turret bodies can accept up to 3 different nozzles. To select the desired nozzle:

-

Stop the sprayer on a level surface, stop the engine, and set the parking brake.

-

Set the master boom switch to the Off position and set the pump switch to the Off position.

-

Rotate the turret of the nozzles in either direction to the correct nozzle.

Cleaning the Sprayer

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

Important: You must always empty and clean the sprayer immediately after each use. Failure to do so may cause the chemicals to dry or thicken in the lines, clogging the pump and other components.

Toro recommends using the approved rinse kit for this machine. Contact your Authorized Toro Dealer for more information.

Clean the spray system after each spraying session. To properly clean the spray system:

-

Use three separate rinses.

-

Use the cleaners and neutralizers as recommended by the chemical manufacturers.

-

Use pure clean water (no cleaners or neutralizers) for the last rinse.

-

Stop the sprayer, set the parking brake, and turn off the engine.

-

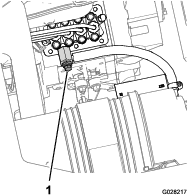

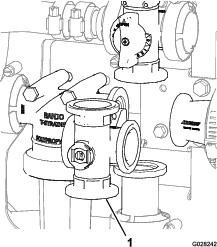

Locate the tank drain valve on the rear of the machine (Figure 28).

Note: The valve is to the rear of pump, attached to the support bracket.

Open the valve to drain any unused material from the tank and dispose of it according to local codes and the material manufacturer's instructions (Figure 29). After draining, remove the lynch pin on the bracket securing the drain valve to the machine and let the valve rest on the ground . This allows any residual material in the line to drain.

-

When the tank has drained completely, install the valve to frame with the lynch pin removed previously and close the drain valve (Figure 29).

-

Fill the tank with at least 190 L (50 US gallons) of clean fresh water and close the cover.

Note: You can use a cleaning/neutralizing agent in the water as needed. On the final rinse, use only clean, clear water.

-

Lower the booms into the spray position.

-

Start the engine and move the throttle lever to a higher idle.

-

Ensure that the agitation switch is in the On position.

-

Set the pump switch to the On position and use the application rate switch to increase the pressure to a high setting.

-

Set the master boom switch and boom control switches to the On positions to begin spraying.

-

Allow all of the water in the tank to spray out though the nozzles.

-

Check the nozzles to ensure that they are all spraying correctly.

-

Set the master boom switch to the Off position, set the pump switch to the Off position, and stop the engine.

-

Repeat steps 4 through 12 at least 2 more times to ensure that the spray system is fully cleaned.

Important: You must always complete this procedure at least 3 times to ensure that the spray system is fully clean, preventing damage to the system.

-

Clean the strainer; refer to Cleaning the Suction Strainer.

Important: If you used wettable powder chemicals, clean the strainer after each tank.

-

Using a garden hose, rinse off the outside of the sprayer with clean water.

-

Remove the nozzles and clean them by hand. Replace damaged or worn nozzles.

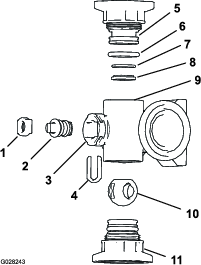

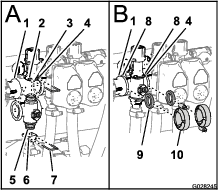

Calibrating the Section Valves

Important: If you have the Pro Control™ Spray System installed, the boom bypass valves must be closed. Use the following adjustment only when you are not using the Pro Control Spray System.

Before using the sprayer for the first time or if the nozzles are changed, adjust the section valves so that the pressure and application rate remains the same for all boom sections when you turn one or more sections off.

Note: The section valves must be calibrated each time the nozzles are changed.

Important: If machine is equipped with a Pro Control™ Spray System, disregard the following steps below this important note for calibrating the section valves and read this notice: When using a Pro Control™ system, the section valves are not used; close the section valves by rotating the red bypass knobs clockwise. The valve is closed once you feel a slight resistance while rotating the knob. Applying excessive torque to the bypass knob could damage the valve. The bypass knob may require 3 to 4 full rotations (360° = 1 rotation) to completely close the valve. The numbers printed on the valve are for reference only; setting the knob to “0” does not guarantee the valve is closed. If you are using the Pro Control™ system, you do not need to adjust the section valves once they are closed. If you use the machine to spray manually (without the Pro Control™ system), refer to the steps for calibrating the boom bypass valves prior to using the machine.

-

Select an open flat area to perform this procedure.

-

Fill the spray tank with clean water.

-

Lower the left and right boom sections.

-

Set the parking brake and start the engine.

-

Set all three section switches and the master boom switch to the On position.

-

Use the application rate switch to adjust the pressure, as read on the pressure gauge, until it is in the correct range for the nozzles that you installed on the boom sections (typically 276 kPa or 40 psi); refer to the nozzle selection guide that is available through your Authorized Toro Dealer.

-

Record the reading on the pressure gauge.

-

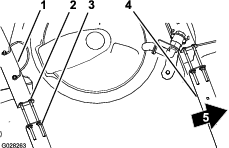

Turn off 1 of the boom section using the appropriate section switch.

-

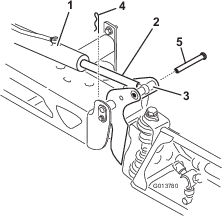

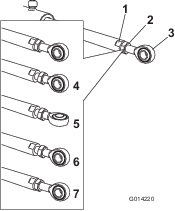

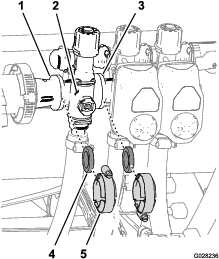

Adjust the section bypass valve (Figure 30) at the top of the section control valve for the boom section you turned off until the pressure reading on the gauge is the same as the pressure reading that you recorded in step 7.

-

Turn the boom on and off to verify the pressure does not change.

-

Repeat steps 9 through 10 for the other boom sections.

-

Drive the sprayer at the desired speed while spraying and turn each boom section off individually.

Note: The pressure on the gauge should not change.

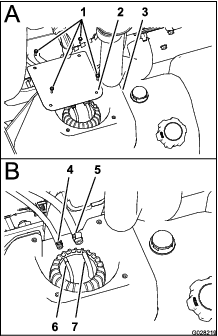

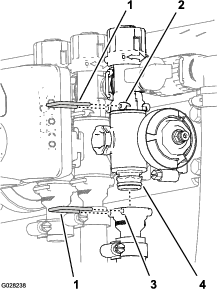

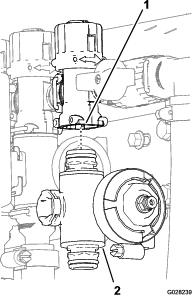

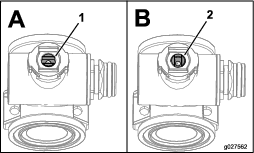

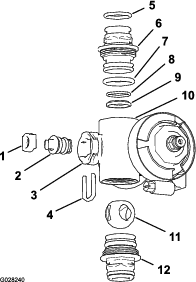

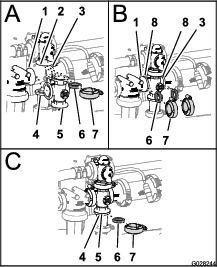

Agitation Bypass Valve Knob Position

-

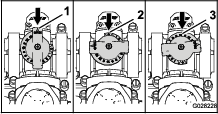

The agitation bypass valve is in the full Open position as shown in A of Figure 31.

-

The agitation bypass valve is in the Close (0) position as shown in B of Figure 31.

-

The agitation bypass valve is in an intermediate (adjusted relative to the pressure gauge for the sprayer system) position as shown in C of Figure 31

Calibrating the Agitation Bypass Valve

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

Important: If you have the Pro Control™ XP Spray System installed turn the power switch to Off now. The following procedure should be performed only when the controller is not powered.

-

Select an open flat area to perform this procedure.

-

Fill the spray tank with clean water.

-

Verify the agitation control valve is open.

Note: If it has been adjusted open it completely at this time.

-

Set the parking brake and start the engine .

-

Move the throttle lever to the Fast position.

-

Set the pump switch and the agitation switch to the On position.

-

Use the application rate switch to adjust the sprayer system pressure on the gauge reads 689 kPa (100 psi).

-

Turn the agitation switch to the Off position and read the pressure gauge.

-

If the pressure gauge indicates 689 kPa (100 psi), the agitation bypass valve is properly calibrated.

-

If the pressure gauge indicates differently, continue to the next step.

-

-

Adjust the agitation bypass valve (Figure 32) on the backside of the agitation valve until the sprayer system pressure indicated on the gauge indicates 689 kPa (100 psi).

-

Turn the pump switch to the Off position. Shift the throttle lever to the Idle position and turn the switch to the Off position.

Pump

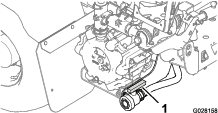

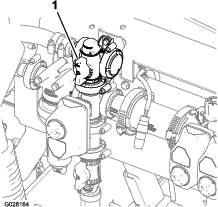

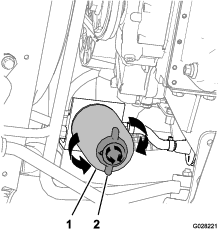

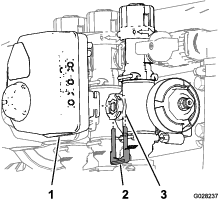

The pump is located near the back of the tank on the left side (Figure 33).

Transporting the Sprayer

Towing the Sprayer

In case of an emergency, the sprayer can be towed for a short distance after you open the tow valve. However, we do not recommend this as a standard procedure.

Warning

Towing at excessive speeds could cause a loss of steering control, resulting in personal injury.

Never tow the sprayer faster than 4.8 kph (3 mph).

Towing the sprayer is a 2-person job. If the machine must be moved a considerable distance, transport it on a truck or trailer; refer to Transporting the Sprayer.

-

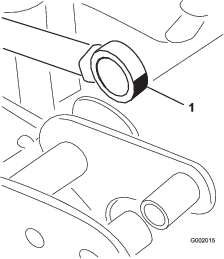

Rotate the tow valve (Figure 36) 90 degrees in either direction to open it.

Important: If you do not open the tow valve before towing the sprayer you will damage the transmission.

-

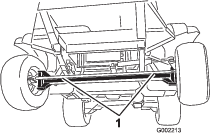

Affix a tow line to the frame. Refer to the front and rear towing points in Figure 37 and Figure 38.

-

Release the parking brake.

-

Tow the sprayer at less than 4.8 kph (3 mph).

-

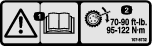

When finished, close the tow valve and torque it to no more than 7 to 11 N-m (5 to 8 ft-lb).

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| After the first 8 hours |

|

| After the first 50 hours |

|

| After the first 200 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 150 hours |

|

| Every 200 hours |

|

| Every 400 hours |

|

| Yearly |

|

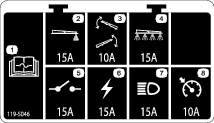

Important: Refer to your engine owner’s manual for additional maintenance procedures.

Note: Looking for an Electrical Schematic or Hydraulic Schematic for your machine? Download a free copy of the schematic by visiting www.Toro.com and searching for your machine from the Manuals link on the home page.

Notation for Areas of Concern

| Inspection performed by: | ||

| Item | Date | Information |

| 1 | ||

| 2 | ||

| 3 | ||

| 4 | ||

| 5 | ||

| 6 | ||

| 7 | ||

| 8 | ||

| 9 | ||

| 10 | ||

Caution

If you leave the key in the starter switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the starter switch before you do any maintenance.

Pre-Maintenance Procedures

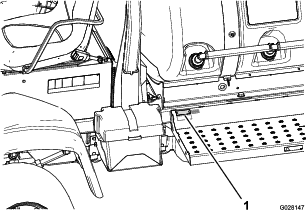

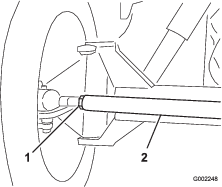

Jacking the Sprayer Up

Whenever the engine is run for routine maintenance and/or engine diagnostics, the rear wheels of the sprayer should be 25 mm (1 inch) off the ground with the rear axle supported on jack stands.

Danger

A sprayer on a jack may be unstable and slip off of the jack, injuring anyone beneath it.

-

Always remove the key from the starter switch before getting off the sprayer.

-

Block the tires when the sprayer is on a jack.

-

Support the machine with jack stands.

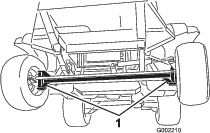

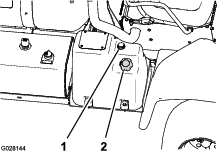

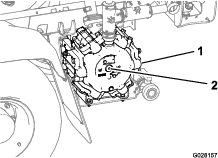

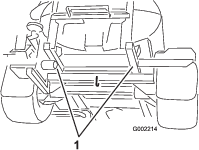

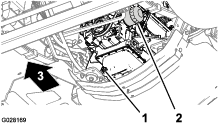

The jacking point at the front of the sprayer is under the front axle, directly under the leaf springs (Figure 39).

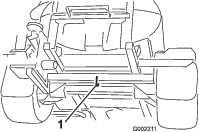

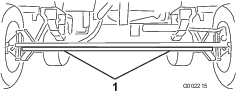

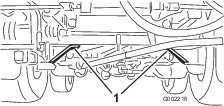

The jacking point at the rear of the sprayer is on the rear side where the boom supports are (Figure 40).

Accessing the Engine

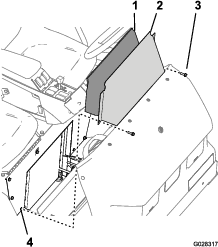

Removing the Forward Heat Shield

-

Start the engine and let it run until warm; this warms the oil so that it drains better.

-

Set the parking brake, stop the pump, stop the engine, and remove the key from the starter switch.

-

Raise the front and back of the machine and support it with jack stands; refer to Jacking the Sprayer Up.

-

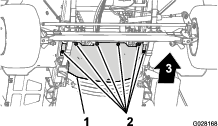

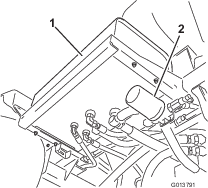

Remove the 6 hex-head bolts and 6 washers that secure the front forward heat shield to the chassis and remove the shield (Figure 41).

Note: Retain the bolts, washers and heat shield for installation in Installing the Engine Heat Shield.

Installing the Engine Heat Shield

-

Align the rear flange of the forward heat shield over the forward flange of the rear heat shield (Figure 42).

-

Align the holes in the forward heat shield with the threaded holes in the chassis (Figure 42).

-

Assemble the forward heat shield to the machine with the 6 hex-head bolts and 6 washers (Figure 42) that you removed in step 4 of Removing the Forward Heat Shield.

-

Torque the bolts to 1129 to 1582 N·cm (100 to 140 in-lb).

-

Lower the machine and remove the jack stands.

Removing the Seat Base Access Panel

Installing the Seat Base Access Panel

-

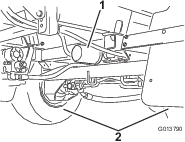

Align the acoustic panel to the opening in the seat base for the seat base access cover (Figure 43).

-

Align the holes in the seat base access cover with the holes in the seat base (Figure 43).

-

Assemble the seat base access cover to the seat base with the 2 flanged-head bolts (Figure 43) that you removed in 1 in Removing the Seat Base Access Panel.

-

Torque the bolts to 1975 to 2542 N-cm (175 to 225 in-lb).

Lubrication

Greasing the Sprayer

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Grease Type: No. 2 general-purpose, lithium-base grease. Toro Premium All Purpose Grease is available from your Toro Distributor.

-

Wipe the grease fitting clean so that foreign matter cannot be forced into the bearing or bushing.

-

Pump grease into the bearing or bushing.

-

Wipe off excess grease.

The grease fittings positions are illustrated in Figure 44 and Figure 45.

Greasing the Boom Hinges

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Important: If the boom hinge is washed with water, all water and debris must be cleared from the hinge assembly and fresh grease must be applied.

Grease Type: No. 2 general-purpose, lithium-base grease.

-

Wipe the grease fittings clean so that foreign matter cannot be forced into the bearing or bushing.

-

Pump grease into the bearing or bushing at each fitting Figure 46.

-

Wipe off excess grease.

-

Repeat the procedure for each boom pivot.

Greasing the Actuator Rod Bearings

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 400 hours |

|

Grease Type: No. 2 general-purpose, lithium-base grease.

-

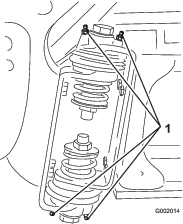

Extend the booms to the spray position.

-

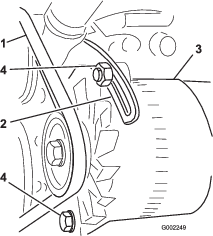

Remove the cotter pin from the pivot pin (Figure 47).

-

Lift up on the boom and remove the pin (Figure 47). Slowly lower the boom to the ground.

-

Inspect the pin for any damage, replace if necessary.

-

Manipulate the actuator rod bearing end and apply grease into the bearing (Figure 48).

Note: Wipe off excess grease.

-

Lift up on the boom to align the pivot with the actuator rod.

-

While holding the boom, insert the pin through both boom pivot and actuator rod (Figure 47).

-

With the pin in place, release the boom and secure the pin with the cotter removed previously.

-

Repeat the procedure for each actuator rod bearing.

Engine Maintenance

Checking the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Set the parking brake, stop the pump, stop the engine, and remove the key from the starter switch.

-

Tilt the passenger seat forward and align the prop rod into the detent in the prop rod guide slot.

-

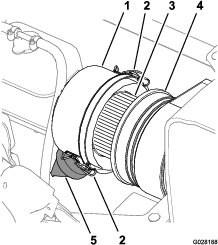

Wipe clean the dust cap and air cleaner body (Figure 49).

-

Check the air cleaner body for damage that could cause an air leak (Figure 49).

Note: Replace the dust cap and air cleaner body if either is damaged.

-

Squeeze the dust valve to clear it of dirt, dust, and debris (Figure 49).

-

Loosen the 2 latches that secure the dust cap to the air cleaner body.

-

Check the air filter element for excessive accumulation of dust, dirt , and debris (Figure 49).

Note: Do not clean the air filter element if it is dirty, replace the air filter element if it is dirty.

-

Install the dust cap onto the air cleaner body and secure the cap with the 2 latches (Figure 49).

Note: Ensure that the dust valve os aligned between 5 to 7 o’clock position when viewed from the end.

-

Lower the passenger seat.

Replacing a the Filter Element

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

-

If you are installing a new filter, inspect the new air filter element for shipping damage, including the sealing end of the filter.

Important: Do not install a damaged filter.

-

Wipe clean the dust cap and air cleaner body (Figure 49).

-

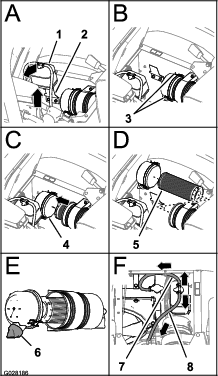

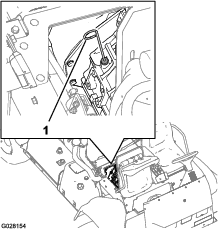

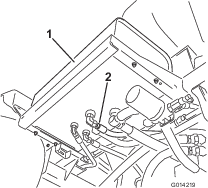

Lift the coolant overflow tank up and off of the tank-support bracket(Figure 50).

-

Loosen the 2 latches that secure the dust cap to the air cleaner body (Figure 50).

-

Gently slide the old filter element out of the air cleaner body to reduce the amount of dust dislodged.

Note: Avoid knocking the filter element against the air cleaner body.

-

Wipe clean the inside of the dust cap, air cleaner body, and dust valve with a damp rag (Figure 49 and Figure 50).

-

Insert the air filter element into the air cleaner body (Figure 50).

Note: Ensure that the filter is seated in the air cleaner body properly by applying pressure to the outer rim of the filter element when you install it. Do not press on the flexible center part of the filter.

-

Install the cover onto air cleaner body and secure the cover with the 2 latches (Figure 50).

Note: Ensure that the dust valve os aligned between 5 to 7 o’clock position when viewed from the end (Figure 50).

-

Align the coolant overflow tank to the tank-support bracket and seat the tank firmly (Figure 50).

Important: Ensure that the pressure relief hose is routed forward and down and tank-vent hose is routed rearward as shown in Figure 50.

-

Lower the passenger seat.

Servicing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 150 hours |

|

| Every 400 hours |

|

Crankcase oil capacity: 4.6 L (4.9 US qt) with the filter.

Engine oil specification:

-

Oil type—API service CH-4, CI-4 or higher.

-

Preferred oil viscosity—SAE 15W40 (above 0 degrees F)

-

Alternate oil viscosity—SAE 10W30 or 5W30 (all temperatures)

Toro Premium Engine Oil is available from your distributor in either 15W40 or 10W30 viscosity. Refer to the Parts Catalog for part numbers.

Changing the Engine Oil Filter

-