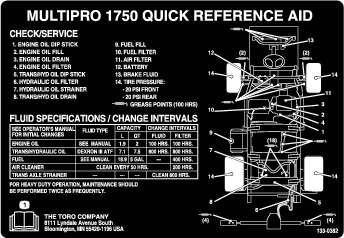

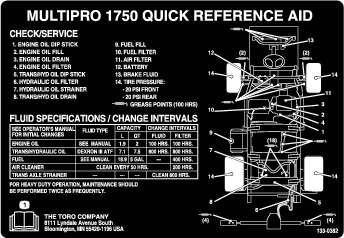

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

Introduction

Read this manual carefully to learn how to operate and maintain your product properly. The information in this manual can help you and others avoid injury and product damage. Although Toro designs and produces safe products, you are responsible for operating the product properly and safely.

You may contact Toro directly at www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

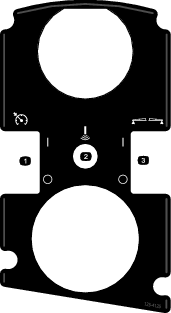

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 illustrates the location of the model and serial numbers on the product.

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

The Multi Pro turf sprayer is a dedicated turf spray application vehicle and is intended to be used by professional, hired operators in commercial applications. It is primarily designed for spraying on well-maintained lawns in parks, golf courses, sports fields, and on commercial grounds.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

This spark ignition system complies with Canadian ICES-002

The enclosed Engine Owner's Manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Safety

Improper use or maintenance by the operator or owner can result in injury. To reduce the potential for injury, comply with these safety instructions and always pay attention to the safety-alert symbol, which means Caution, Warning, or Danger. Failure to comply with the instruction may result in personal injury or death.

The machine was evaluated to the requirements of SAE J2258.

General Safety

This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury.

Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

-

Read and understand the contents of this Operator’s Manual before starting the engine.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and working on the machine.

-

Keep clear of any discharge opening. Keep bystanders and pets a safe distance away from the machine.

-

Keep children out of the operating area. Never allow children to operate the machine.

-

Stop the machine and shut off the engine before servicing, fueling, or unclogging the machine.

Improperly using or maintaining this machine can result in injury. To reduce the potential for injury, comply with these safety instructions and always pay attention to the safety-alert symbol, which means Caution, Warning, or Danger—personal safety instruction. Failure to comply with these instructions may result in personal injury or death.

You can find additional safety information where needed throughout this Operator’s Manual.

Safe Operating Practices

Important: The machine is designed primarily as an off-road vehicle and is not intended for extensive use on public roads. When using the machine on public roads, follow all traffic regulations and use any additional accessories that may be required by law, such as lights, turn signals, slow-moving-vehicle (SMV) sign, and others as required.

The Multi Pro 1750 Turf Sprayer was designed and tested to offer safe service when operated and maintained properly. Although hazard control and accident prevention partially are dependent upon the design and configuration of the machine, these factors are also dependent upon the awareness, concern, and proper training of the personnel involved in the operation, maintenance and storage of the machine. Improper use or maintenance of the machine can result in injury or death.

Not all of the attachments that adapt to the Multi Pro 1750 Turf Sprayer are covered in this manual. See the specific operator’s manual provided with each attachment for additional safety instructions. Read these manuals.

To reduce the potential for injury or death, comply with the following safety instructions:

Supervisor's Responsibilities

-

Make sure that operators are thoroughly trained and familiar with the Operator's Manual, engine manual, and all labels on the machine.

-

Establish your own special procedures and work rules for unusual operating conditions (e.g., slopes too steep for sprayer operation).

Before Operating

-

Operate the machine only after reading and understanding the contents of this manual.

-

Never allow children to operate the machine.

-

This machine is designed to carry the operator. Never carry any passengers on the machine.

-

Never operate the sprayer when ill, tired, or under the influence of drugs or alcohol.

-

Become familiar with the controls and know how to shut off the engine quickly.

-

Keep all shields, safety devices, and decals in place. If a shield, safety device, or decal is malfunctioning, illegible, or damaged, repair or replace it before operating the machine.

-

Wear appropriate clothing; including safety glasses, long pants, substantial slip-resistant footwear, gloves, and hearing protection. Do not wear jewelry or loose clothing. Tie back long hair.

Caution

This machine produces sound levels in excess of 85 dBA at the operator’s ear and can cause hearing loss through extended periods of exposure.

Wear hearing protection when operating this machine.

-

Operate only in daylight or good artificial light.

-

Never spray with bystanders present.

-

Never spray while people, especially children or pets are nearby.

-

Before operating the machine, always check the designated areas of the sprayer that are stated in the Pre-Starting Checks in the Operation section. If the machine does not function correctly or is damaged in any way, do not use the sprayer. Make sure that the problem is corrected before the sprayer or attachment is operated.

-

Make sure that the operator’s area is clean and free from chemical residue and debris buildup.

-

Ensure that all fluid line connectors are tight and all hoses are in good condition before applying pressure to the system.

Chemical Safety

Warning

-

Chemical substances used in the sprayer system may be hazardous and toxic to you, bystanders, animals, plants, soils or other property.

-

Carefully read and follow the chemical warning labels and material safety data sheets (MSDS) for all chemicals used and protect yourself according to the chemical manufacturer's recommendations. Ensure that as little skin as possible is exposed while using chemicals. Use appropriate personal protective equipment (PPE) to guard against personal contact with chemicals, such as:

-

safety glasses, goggles, and/or face shield

-

respirator or filter mask

-

chemical resistant gloves

-

rubber boots or other substantial footwear

-

hearing protection

-

clean change of clothes, soap, and disposable towels, to be kept on hand, in the event of a chemical spill.

-

Important: Keep in mind that there may be more than 1 chemical used, and information on each chemical should be assessed.Refuse to operate or work on the sprayer if this information is not available.Before working on a sprayer system, make sure that the system has been triple rinsed and neutralized according to the recommendations of the chemical manufacturer(s) and all of the valves have been cycled 3 times.Verify there is an adequate supply of clean water and soap nearby, and immediately wash off any chemicals that contact you.

-

Obtain proper training before using or handling chemicals.

-

Use the correct chemical for the job.

-

Follow the chemical manufacturer's instructions for the safe application of the chemical. Do not exceed recommended system application pressure.

-

Do not fill, calibrate, or clean the unit when people, especially children, or pets are in the area.

-

Handle chemicals in a well ventilated area.

-

Have clean water available especially when filling the spray tank.

-

Do not eat, drink, or smoke while working with chemicals.

-

Do not clean spray nozzles by blowing through them or placing in your mouth.

-

Always wash your hands and other exposed areas as soon as possible after you finish working with chemicals.

-

Keep chemicals in their original packages and stored in a safe location.

-

Properly dispose of unused chemicals and chemical containers as instructed by the chemical manufacturer and your local codes.

-

Chemicals and fumes are dangerous; never enter the tank or place your head over or in the opening of a tank.

-

Follow all local, state, and federal regulations for spreading or spraying chemicals.

While Operating

Warning

Engine exhaust contains carbon monoxide, which is an odorless, deadly poison that can kill you.

Do not run engine indoors or in an enclosed area.

-

Remain seated whenever the sprayer is in motion. Keep both hands on the steering wheel whenever possible. Keep your arms and legs within the operator’s compartment at all times.

-

Failure to operate the machine safely may result in an accident, tip over of the sprayer, and serious injury or death. Drive carefully. To prevent tipping or loss of control:

-

Use extreme caution, reduce speed, and maintain a safe distance around sand traps, ditches, creeks, ramps, unfamiliar areas, or any areas that have abrupt changes in ground conditions or elevation.

-

Watch for holes or other hidden hazards.

-

Use extra caution when operating the machine on wet surfaces, in adverse weather conditions, at higher speeds, or with a full load. Stopping time and distance increases with a full load.

-

Avoid sudden stops and starts. Do not go from reverse to forward or forward to reverse without first coming to a complete stop.

-

Slow down before turning. Do not attempt sharp turns or abrupt maneuvers or other unsafe driving actions that may cause a loss of sprayer control.

-

Before backing up, look to the rear and ensure that no one is behind you. Back up slowly.

-

Watch out for traffic when you are near or crossing roads. Always yield the right of way to pedestrians and other vehicles. This sprayer is not designed for use on streets or highways. Always signal your turns or stop early enough so that other people know what you plan to do. Obey all traffic rules and regulations.

-

The electrical and exhaust systems of the sprayer can produce sparks capable of igniting explosive materials. Never operate the sprayer in or near an area where there is dust or fumes in the air which are explosive.

-

If you are ever unsure about safe operation, stop work and ask your supervisor.

-

-

Do not touch the engine or muffler while the engine is running or soon after it has shut off. These areas may be hot enough to cause burns.

-

If the machine ever vibrates abnormally, stop immediately, wait for all motion to stop, and inspect the sprayer for damage. Repair all damage before resuming operation.

-

Before getting off the seat:

-

Stop the machine.

-

Place the range selector in the NEUTRAL position and set the parking brake.

-

Turn the ignition key to the OFF position.

-

Remove the ignition key.

Important: Do not park the machine on an incline.

-

-

Lightning can cause severe injury or death. If lightning is seen or thunder is heard in the area, do not operate the machine; seek shelter.

Braking

-

Slow down before you approach an obstacle. This gives you extra time to stop or turn away. Hitting an obstacle can damage the machine and its contents. More important, it can injure you.

-

Gross Vehicle Weight (GVW) has a major impact on your ability to stop and/or turn. Heavy loads and attachments make a machine harder to stop or turn. The heavier the load, the longer it takes to stop.

-

Turf and pavement are much more slippery when they are wet. It can take 2 to 4 times as long to stop on wet surfaces as on dry surfaces. If you drive through standing water deep enough to get the brakes wet, they will not work well until they are dry. After driving through water, you should test the brakes to make sure that they work properly. If they do not, drive slowly while putting light pressure on the brake pedal. This will dry the brakes out.

ROPS Safety

Note: For each machine covered in this Operator’s Manual, a cab installed by Toro is a ROPS.

-

Do not remove the ROPS from the machine.

-

Fasten the seat belt and ensure that you can release it quickly in an emergency. Always wear your seat belt when the roll bar is up or on a machine with a cab installed by Toro.

-

Check carefully for overhead obstructions and do not contact them.

-

Keep the ROPS in safe operating condition by thoroughly inspecting it periodically for damage and keeping all the mounting fasteners tight.

-

Replace any damaged ROPS component. Do not repair or alter it.

Operating on Hills and Rough Terrain

Operating the sprayer on a hill may cause tipping or rolling of the machine, or the engine may stall and you could lose headway on the hill. This could result in personal injury.

-

Do not accelerate quickly or suddenly apply the brakes when backing down a hill, especially with a load.

-

Never drive across a steep hill; always drive straight up or down or go around the hill.

-

If the engine stalls or you begin to lose headway while climbing a hill, gradually apply the brakes and slowly back straight down the hill.

-

Turning while traveling up or down hills can be dangerous. If you have to turn while on a hill, do it slowly and cautiously. Never make sharp or fast turns.

-

Heavy loads affect stability. Reduce the weight of the load and your speed when operating on hills.

-

Avoid stopping on hills, especially with a load. Stopping while going down a hill will take longer than stopping on level ground. If you must stop the machine, avoid sudden speed changes, which may initiate tipping or rolling of the machine. Do not suddenly apply the brakes when rolling backward, as this may cause the machine to overturn.

-

Use the seat belt when operating the machine and be certain that it can be released quickly in the event of an emergency.

-

Do not remove or alter the rollover protection system (ROPS).

-

Always keep the transmission in gear when you drive the machine down a slope.

-

Reduce speed and load when operating on rough terrain, uneven ground, and near curbs, holes, and other sudden changes in terrain. Loads may shift, causing the machine to become unstable.

Warning

Sudden changes in terrain may cause abrupt steering wheel movement, possibly resulting in hand and arm injuries.

Grip the steering wheel loosely around the perimeter. Keep your hands clear of the steering wheel spokes

Loading

The weight of the cargo can change the center of gravity of the machine and the handling of it. To avoid loss of control and personal injury, follow these guidelines:

-

Liquid loads can shift. This shifting happens most often while turning, going up or down hills, suddenly changing speeds, or while driving over rough surfaces. Shifting loads can cause the machine to tip over.

-

When operating with a heavy load, reduce your speed and allow for sufficient braking distance. Do not suddenly apply the brakes. Use extra caution on slopes.

-

Be aware that heavy loads increase your stopping distance and reduce your ability to turn quickly without tipping over.

Maintenance

-

Only permit qualified and authorized personnel to maintain, repair, adjust, or inspect the machine.

-

Before servicing or making adjustments to the machine, park the machine on a level surface, engage the parking brake, shut off the engine, and remove the key to prevent someone from accidentally starting the engine.

-

To make sure that the entire machine is in good condition, keep all nuts, bolts, and screws properly tightened.

-

To reduce the potential for fire, keep the engine area free of excessive grease, grass, leaves, and accumulation of dirt.

-

Never use an open flame to check the level or leakage of fuel or battery electrolyte.

-

If you must run the engine to perform a maintenance adjustment, keep your hands, feet, clothing, and any parts of your body away from the engine and any moving parts. Keep everyone away.

-

Do not use open pans of fuel or flammable cleaning fluids when cleaning parts.

-

Do not adjust the traction control speed. To ensure safety and accuracy, have an Authorized Toro Distributor check the ground speed.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure fluid. Use cardboard or paper to find leaks. Fluid escaping under pressure can penetrate skin and cause injury requiring surgery within a few hours by a qualified surgeon; otherwise, gangrene may result.

-

If major repairs are ever needed or assistance is required, contact an Authorized Toro Distributor.

-

To be sure of optimum performance and safety, always purchase genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous. Altering this machine in any manner that may affect sprayer operation, performance, durability, or its use, may result in injury or death. Such use could void the product warranty.

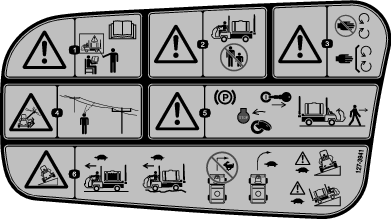

Safety and Instructional Decals

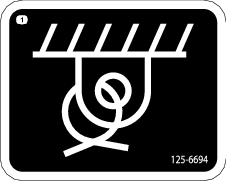

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

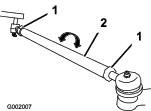

Installing the Anti-Siphon Fill Receptacle

Parts needed for this procedure:

| 90° fitting | 1 |

| Quick coupler | 1 |

| Hose adapter | 1 |

| Fill-receptacle bracket | 1 |

| Flange-head bolt (5/16 x 3/4 inch) | 1 |

| Anti-siphon hose | 1 |

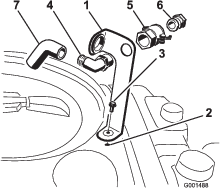

-

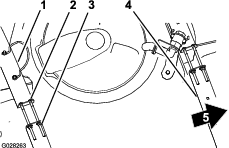

Place the fill-receptacle bracket over the threaded hole in the tank and secure it with a flange-head bolt (5/16 x 3/4 inch) as shown in Figure 3.

-

Place the threaded end of the 90° elbow fitting through the bracket and thread the quick coupler onto it, securing it to the bracket (Figure 3).

Note: Install the fitting with the open end pointing toward the large opening in the bracket and toward the tank opening so that the water arcs into the tank when you fill it.

-

Install the hose adapter into the quick coupler (Figure 3).

-

Lock the adapter into place by swinging the levers toward the adapter and then secure them with the hairpin cotters (Figure 3).

-

Install the anti-siphon hose through the large opening on the bracket and onto the barbed end of the 90° elbow fitting (Figure 3).

Important: Do not lengthen the hose to allow contact with the tank fluids.

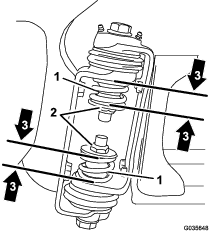

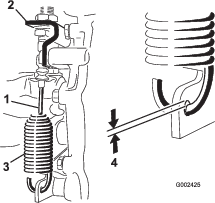

Checking the Section-Hinge Springs

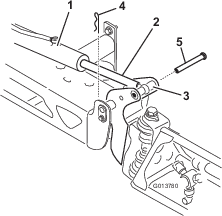

Important: Operating the spray system with the section-hinge springs under the incorrect compression could damage the boom assembly. Measure the springs and use the jam nut to compress the springs to 3.96 cm (1.56 inches) if necessary.

The sprayer is shipped with the section extensions swung forward to facilitate shipping the machine. The springs are not fully tightened at the time of manufacture to allow the sections to be in this position for transit. Before operating the machine, the springs must be adjusted to the correct compression.

-

If necessary, remove the packing components that secure the right and left extension sections during shipping.

-

Support the sections while they are extended to the spray position.

-

At the section hinge, measure the compression of the upper and lower springs while the sections are in their extended position (Figure 4).

-

All springs must be compressed until they measure 3.96 cm (1.56 inches).

-

Use the jam nut to compress any spring that measure greater than 3.96 cm (1.56 inches).

-

-

Repeat the procedure for each spring on both section hinges.

-

Move the sections into the transport ‘X’ position. See Using the Boom-Transport Cradle for more information.

Learning More about Your Product

Parts needed for this procedure:

| Ignition key | 1 |

| Operator's Manual | 1 |

| Engine operator's manual | 1 |

| Parts Catalog | 1 |

| Operator training material | 1 |

| Registration card | 1 |

| Pre-delivery Inspection Sheet | 1 |

-

Read the manuals.

-

View the operator training material.

-

Complete the registration card and return it to Toro.

-

Store the documentation in a safe place.

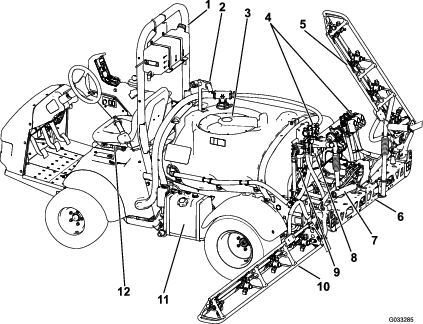

Product Overview

Accelerator Pedal

The accelerator pedal (Figure 8) gives you the ability to vary the ground speed of the sprayer. Pressing the pedal increases ground speed. Releasing the pedal slows the sprayer and reduces the engine speed to idle.

Clutch Pedal

Fully press the clutch pedal (Figure 8) to disengage the clutch when starting the engine or shifting transmission gears. Release the pedal smoothly when the transmission is in gear to prevent unnecessary wear on the transmission and other related parts.

Important: Do not ride the clutch pedal during operation. The clutch pedal must be fully out or the clutch will slip, causing heat and wear. Never hold the vehicle stopped on a hill using the clutch pedal. Damage to the clutch may occur.

Brake Pedal

Use the brake pedal to stop or slow the sprayer (Figure 8).

Caution

Brakes can become worn or can be adjusted incorrectly resulting in personal injury.

If brake pedal travels to within 2.5 cm (1 inch) of the sprayer floor board, adjust or repair the brakes.

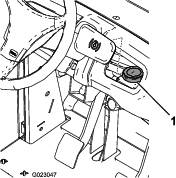

Parking Brake

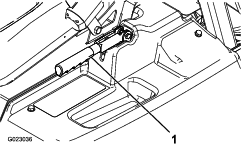

The parking brake is a large lever to the left of the seat (Figure 9). Engage the parking brake whenever you plan on leaving the seat to prevent accidental movement of the sprayer. To engage the parking brake, pull up and back on the lever. To disengage, push it forward and down. If the sprayer is parked on a steep grade, apply the parking brake and place blocks at the downhill side of the wheels.

Hill Assist

Hill assist prevents the sprayer from rolling or jerking by temporarily holding the sprayer on hilly terrain when you move your foot from the brake pedal to the accelerator pedal. To engage hill assist, engage the clutch and push down on the brake pedal firmly. When hill assist is engaged, the hill assist icon appears on the InfoCenter; refer to the Multi Pro 1750 Turf Sprayer Software Guide. Hill assist holds the machine for 2 seconds after releasing the brake pedal.

Note: The hill assist only temporarily holds the machine, you cannot use it in place of the parking brake.

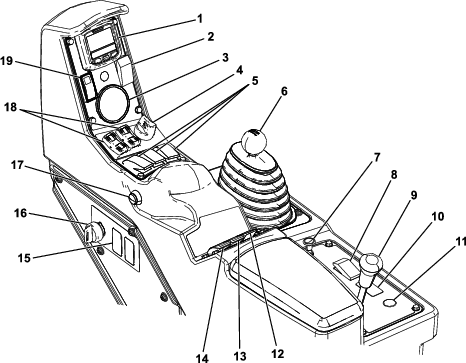

Differential Lock

The differential lock allows you to lock the rear axle for increased traction. You may engage the differential lock (Figure 7) while the sprayer is in motion. Move the lever forward and to the right to engage the lock.

Note: You may need to drive the machine forward while turning slightly to engage or disengage the differential lock.

Caution

Turning with the differential lock on can result in loss of machine control.

Do not operate with differential lock on when making sharp turns or at high speeds; refer to Adjusting the Differential-Lock Cable.

Choke Control

The choke control is a small knob behind the range selector (Figure 7). To start a cold engine, pull the choke control up. After the engine starts, regulate the choke to keep the engine running smoothly. As soon as possible, push the control down to the OFF position. A warm engine requires little or no choking.

Range Selector

The range selector (Figure 7) has 5 positions: 3 forward speeds, NEUTRAL, and REVERSE. The engine starts only when the range selector is in the NEUTRAL position.

Ignition Switch

The ignition switch (Figure 7), has 3 positions: STOP, RUN, and START. Rotate the key clockwise to the START position to start the engine and release it to the RUN position when started. Rotate the key to the STOP position to shut off the engine.

Headlight Switch

Toggle the switch to operate the headlights (Figure 7). Push it forward to turn the lights on and rearward to turn them off.

Throttle/Speed-Lock Switch

When the range selector is in the NEUTRAL position, you can use the accelerator pedal to speed up the engine, then push the switch below the InfoCenter forward to set the engine at that speed. This is necessary to run the chemical agitation while stationary or operating attachments such as the hand sprayer (Figure 7).

Important: The range selector must be in the NEUTRAL position and the parking brake must be set for the switch to work.

Fuel Gauge

The fuel gauge is located on top of the fuel tank, on the left side of the machine, and shows the amount of fuel in the tank.

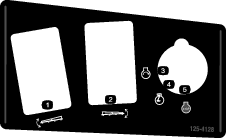

Master Section Switch

The master section switch (Figure 7) is located on the side of the console and to the right of the operator. It allows you to start or stop the spray operation. Press the switch to enable or disable the spray system.

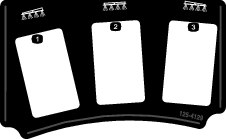

Left, Center, and Right Section Switches

The left, center, and right section switches are located on the control panel (Figure 7). Toggle each switch forward to turn the corresponding section on and rearward to turn them off. When the switch is turned on, a light on the switch illuminates. These switches affect the spray system only when the master section switch is on.

Pump Switch

The pump switch is located on the control panel to the right of the seat (Figure 7). Toggle this switch forward to run the pump or rearward to stop the pump.

Important: The pump switch will only engage when the engine is at low idle to avoid damaging the pump drive.

Application-Rate Switch

The application-rate switch is located on the control panel to the right of the seat (Figure 7). Press and hold the switch forward to increase the spray system pressure, or press and hold it rearward to decrease the pressure.

Supervisor (Rate-Lockout) Switch

The supervisor switch is located on the control panel to the right of the seat (Figure 7). Turn the key counterclockwise to the LOCK position to disable the application-rate switch, thereby keeping anyone from accidentally changing the application rate. Turn the key clockwise to the UNLOCKED position to enable the application-rate switch.

Boom-Section Lift Switches

The boom-section lift switches are located on the control panel and are used to raise the outer boom sections.

Hour Meter

The hour meter indicates the total number of hours the engine has run. This number is displayed on the first screen of the InfoCenter. The hour meter starts to function whenever the key is turned to the RUN position.

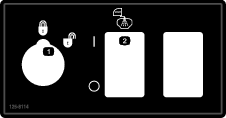

Foam-Marker Switch Locations (Optional)

If you install the Foam Marker kit, you will add switches to the control panel for controlling their operation. The sprayer comes with plastic plugs in these locations.

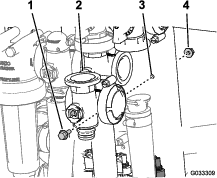

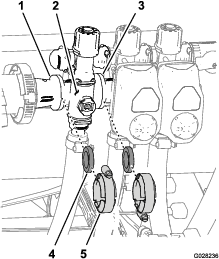

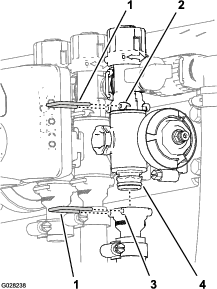

Regulating (Rate-Control) Valve

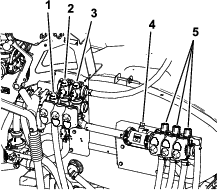

This valve, located behind the tank (Figure 10), controls the amount of fluid routed to the sections or the rate return to the tank.

Master-Section Valve

The master-section valve (Figure 10) controls the flow to the flow meter and section valves.

Flow meter

The flow meter measures the flow rate of the fluid for use by the InfoCenter system (Figure 10).

Section Bypass Valves

These valves turn the right, center, and left sections on or off (Figure 10).

Section-Bypass Shutoff Valve

The section bypass shutoff valve redirects the fluid flow for a section to the tank when you turn off the section. You can adjust the section bypass to ensure that the section pressure remains constant no matter how many sections are on. Refer to Adjusting the Master-Section-Bypass Valve.

Agitation Valve

This valve is located on the rear of the tank (Figure 10). When agitation is on, the flow is directed through the agitation nozzles in the tank. When agitation is off, the flow is directed through the pump suction.

Pressure Gauge

The pressure gauge is located on the control panel (Figure 7). This gauge shows the pressure of the fluid in the system in psi and kPa.

InfoCenter LCD Display

The InfoCenter LCD display shows information about your machine and battery pack, such as the current battery charge, the speed, diagnostics information, and more (Figure 7).

For more information, refer to the Multi Pro 1750 Software Guide.

Agitation-Throttle Valve

The agitation-throttle valve is used to reduce the flow available for the agitation circuit. It provides additional flow for the sections.

Note: Specifications and design are subject to change without notice.

| Weight with standard spray system, empty, without operator | 953 kg (2,100 lb) |

| Weight with standard spray system, full, without operator | 1678 kg (3,700 lb) |

| Maximum gross vehicle weight (GVW) (on level ground) | 1814 kg (4,000 lb) |

| Overall length with standard spray system | 343 cm (135 inches) |

| Overall height with standard spray system | 191 cm (75 inches) |

| Overall height with standard spray system to the top of the sections stored in the X position | 246 cm (97 inches) |

| Overall width with standard spray system sections stored in the ‘X’ position | 178 cm (70 inches) |

| Ground clearance | 14 cm (5.5 inches) |

| Wheel base | 155 cm (61 inches) |

| Tank capacity (includes the CE 5% overflow) | 662 L (175 US gallons) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or Distributor.

To best protect your investment and maintain optimal performance of your Toro equipment, count on Toro genuine parts. When it comes to reliability, Toro delivers replacement parts designed to the exact engineering specification of our equipment. For peace of mind, insist on Toro genuine parts.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Safety First

Please carefully read all of the safety instructions and decals in the safety section. Knowing this information could help you or bystanders avoid injury.

Preparing to Drive the Machine

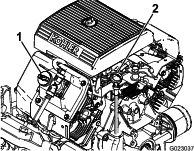

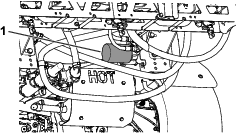

Checking the Engine Oil

The engine is shipped with oil in the crankcase; however, the level of oil must be checked before you first start the engine and after you have run it.

-

Position the machine on a level surface.

-

Remove the dipstick and wipe it with a clean rag (Figure 11).

-

Insert the dipstick into the tube and make sure that it is seated fully. Remove the dipstick and check the oil level.

-

If the oil level is low, remove the filler cap from the valve cover (Figure 11) and pour oil into the opening until the oil level is up to the FULL mark on the dipstick; refer toServicing the Engine Oil for the proper oil type and viscosity.

Note: Add the oil slowly and check the level often during this process. Do not overfill.

-

Install the dipstick firmly in place.

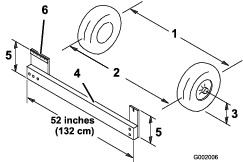

Checking the Tire Pressure

Check the tire pressure every 8 hours or daily to ensure proper levels. Fill the tires to 138 kPa (20 psi). Also, check the tires for wear or damage.

Adding Fuel

Danger

In certain conditions, fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

-

Fill the fuel tank outdoors, in an open area, when the engine is cold. Wipe up any fuel that spills.

-

Never fill the fuel tank inside an enclosed trailer.

-

Do not fill the fuel tank completely full. Add fuel to the fuel tank until the level is 6 to 13 mm (1/4 to 1/2 inch) below the bottom of the filler neck. This empty space in the tank allows fuel to expand.

-

Never smoke when handling fuel, and stay away from an open flame or where sparks may ignite fuel fumes.

-

Store fuel in an approved container and keep it out of the reach of children. Never buy more than a 30-day supply of fuel.

-

Do not operate the machine without the entire exhaust system in place and in proper working condition.

Danger

In certain conditions during fueling, static electricity can be released causing a spark which can ignite the fuel vapors. A fire or explosion from fuel can burn you and others and can damage property.

-

Always place fuel containers on the ground away from your vehicle before filling.

-

Do not fill fuel containers inside a vehicle or on a truck or trailer bed because interior carpets or plastic truck bed liners may insulate the container and slow the loss of any static charge.

-

When practical, remove fuel-powered equipment from the truck or trailer and refuel the equipment with its wheels on the ground.

-

If this is not possible, then refuel such equipment on a truck or trailer from a portable container rather than from a fuel-dispenser nozzle.

-

If you must use a fuel-dispenser nozzle, keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

-

For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method).

-

ETHANOL: Gasoline with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. Ethanol and MTBE are not the same. Gasoline with 15% ethanol (E15) by volume is not approved for use. Never use gasoline that contains more than 10% ethanol by volume, such as E15 (contains 15% ethanol), E20 (contains 20% ethanol), or E85 (contains up to 85% ethanol). Using unapproved gasoline may cause performance problems and/or engine damage which may not be covered under warranty.

-

Do not use gasoline containing methanol.

-

Do not store fuel either in the fuel tank or fuel containers over the winter unless you use a fuel stabilizer.

-

Do not add oil to gasoline.

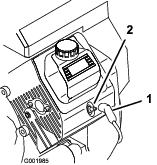

Filling the Fuel Tank

The fuel tank capacity is approximately 19 L (5 US gallons).

Note: The fuel-tank cap contains a gauge which shows the fuel level; check it frequently.

-

Park the machine on a a level surface, engage the parking brake, shut off the engine, and remove the key.

-

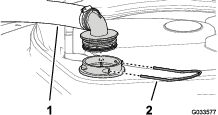

Clean the area around the fuel-tank cap (Figure 12).

-

Remove the fuel-tank cap.

-

Fill the tank to about 2.5 cm (1 inch) below the top of the tank (bottom of the filler neck).

Note: This air space in the tank allows fuel to expand. Do not overfill the tank.

-

Install the fuel-tank cap to the tank securely.

-

Wipe up any fuel that may have spilled.

Performing the Pre-Starting Checks

Check the following items each time you begin using the sprayer for the day:

-

Check the tire pressure.

Note: These tires are different than car tires; they require less pressure to minimize turf compaction and damage.

-

Check all fluid levels and add the appropriate amount of specified fluids, if any are found to be low.

-

Check the brake pedal operation.

-

Check to see that the lights are working.

-

Turn the steering wheel to the left and right to check steering response.

-

Check for oil leaks, loose parts, and any other noticeable malfunctions. Make sure that the engine is off and all moving parts have stopped before checking for oil leaks, loose parts, and other malfunctions.

If any of the above items are not correct, notify your mechanic or check with your supervisor before taking the sprayer out for the day. Your supervisor may want you to check other items on a daily basis, so ask what your responsibilities are.

Operating the Machine

Starting the Engine

-

Sit in the operator's seat, insert the key into the ignition switch, and rotate the key clockwise to the RUN position.

-

Press the clutch and move the range selector to the NEUTRAL position.

-

Ensure that the pump switch is in the OFF position.

-

If the engine is cold, pull the choke knob up.

Important: Do not use the choke if the engine is warm.

-

Turn the key to the START position until the engine starts.

Important: Do not hold the key in the START position for more than 10 seconds. If the engine has not started after 10 seconds, wait 1 minute before trying again. Do not attempt to push or tow the sprayer to start the engine.

-

Once the engine starts, push the choke knob down slowly.

Driving the Machine

-

Release the parking brake.

-

Fully press the clutch pedal.

-

Move the gear shift lever to first gear.

-

Release the clutch pedal smoothly while pressing the accelerator pedal.

-

When the vehicle gains enough speed, remove your foot from the accelerator pedal, fully press the clutch pedal, move the gear shift lever to the next gear and release the clutch pedal while pressing the accelerator pedal. Repeat the procedure until the desired speed is attained.

Important: Always stop the vehicle before shifting from a forward gear to reverse or from reverse to a forward gear.

Note: Avoid long periods of engine idling.

Use the chart below to determine the ground speed of an empty vehicle at 3,400 rpm.

Gear Ratio Speed (km/h) Speed (mph) 1 66.4:1 5.6 3.5 2 38.1:1 9.8 6.1 3 19.6:1 19.2 11.9 R 80.7:1 4.7 2.9 Note: Leaving the ignition switch in the ON position for long periods of time without running the engine will discharge the battery.

Important: Do not attempt to push or tow the vehicle to get it started. Damage to the drive train could result.

Setting the Throttle Lock

Note: You must have the parking brake and spray pump on and the range selector in the NEUTRAL position to set the throttle lock.

-

Press down on the accelerator pedal to obtain the desired engine rpm.

-

Toggle the throttle lock switch on the control panel to the ON position.

-

To release the throttle lock, toggle the switch to the OFF position, or press the brake or clutch pedal.

Setting the Speed Lock

Note: Before setting the speed lock, you must sit in the operator’s seat with the parking brake off, the pump on, and the range selector in gear.

-

Press down on the accelerator pedal to obtain the desired engine speed.

-

Toggle the speed lock switch on the control panel to the ON position.

-

To release the speed lock, toggle the switch to the OFF position, or press the brake or clutch pedal.

Shutting Off the Engine

-

Press the clutch and apply the brake to stop the sprayer.

-

Pull the parking-brake lever up and back to set it.

-

Move the range selector out of gear into the NEUTRAL position.

-

Turn the ignition key to the STOP position.

-

Remove the key from the switch to prevent accidental starting.

Breaking in a New Sprayer

-

Check the engine-oil and fluid levels regularly and be alert for indications of overheating in any component of the sprayer.

-

After starting a cold engine, let it warm up for about 15 seconds before accelerating.

-

To optimize the brake system, burnish (break in) the brakes as follows:

-

Load 454 L (120 US gallons) of water into the tank.

-

Move the machine to an open-level area.

-

Drive the machine at full speed.

-

Apply the brakes rapidly.

Note: Stop the machine in a straight line without locking up the tires.

-

Wait 1 minute to allow the brakes to cool.

-

Repeat steps 3 through 5 an additional 9 times.

-

-

Avoid racing the engine.

-

Vary the sprayer speed during operation. Avoid fast starts and quick stops.

-

Refer to for any special, low-hour checks.

Preparing to Use the Sprayer

Cleaning the Suction Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

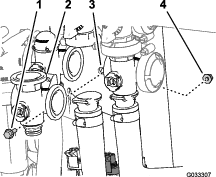

-

Park the machine on a level surface, engage the parking brake, shut off the pump, shut off the engine, and remove the key.

-

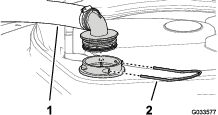

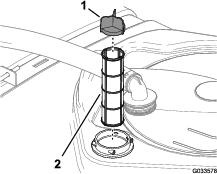

At the top of the sprayer tank, remove the retainer that secures the hose fitting attached to the large hose from the filter housing (Figure 13).

-

Remove the hose and hose fitting from the filter housing (Figure 13).

-

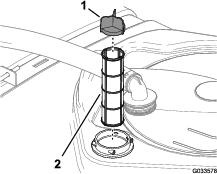

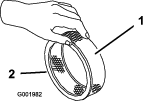

Pull the suction strainer out of the filter housing in the tank (Figure 14).

-

Clean the suction filter with clean water.

Important: Replace the filter if it is damaged or cannot be cleaned.

-

Insert the suction filter into the filter housing until the filter is fully seated.

-

Align the hose and hose fitting to the filter housing at the top of the tank, and secure fitting and housing with the retainer that you removed in step 2.

Cleaning the Pressure Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

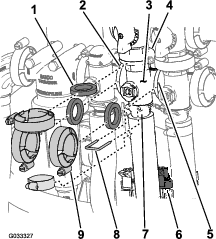

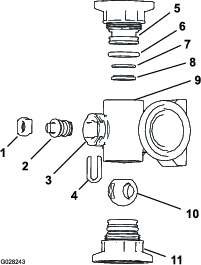

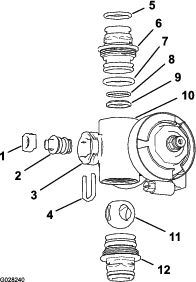

-

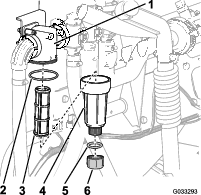

Park the machine on a level surface, engage the parking brake, shut off the sprayer pump, shut off the engine, and remove the key.

-

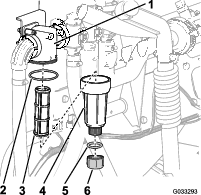

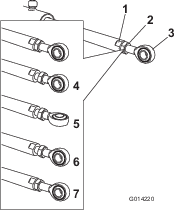

Align a drain pan under the pressure filter (Figure 15).

-

Rotate the drain cap counterclockwise and remove it from the bowl of the pressure filter (Figure 15).

Note: Allow the bowl to drain completely.

-

Rotate the bowl counterclockwise and remove the filter head (Figure 15).

-

Remove the pressure filter element (Figure 15).

-

Clean the pressure filter element with clean water.

Important: Replace the filter if it is damaged or cannot be cleaned.

-

Check the gasket for the drain plug (located inside the bowl) and the gasket for bowl (located inside the filter head) for damage and wear (Figure 15).

Important: Replace any damaged or worn gaskets for the plug, bowl, or both.

-

Install the pressure filter element into the filter head (Figure 15).

Note: Ensure that the filter element is firmly seated into the filter head.

-

Install the bowl onto the filter head, and tighten by hand (Figure 15).

-

Assemble the drain cap onto the fitting at the bottom of the bowl, and tighten the cap by hand (Figure 15).

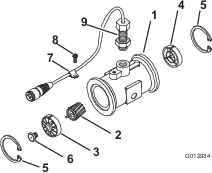

Cleaning the Nozzle Filter

-

Park the machine on a level surface, engage the parking brake, shut off the sprayer pump, shut off the engine, and remove the key.

-

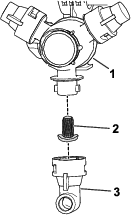

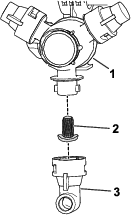

Remove the nozzle from the spray turret (Figure 16).

-

Remove the nozzle filter (Figure 16).

-

Clean the nozzle filter with clean water.

Important: Replace the filter if it is damaged or cannot be cleaned.

-

Install the nozzle filter (Figure 16).

Note: Ensure that the filter is fully seated.

-

Install the nozzle onto the spray turret (Figure 16).

Inspecting the Tank Straps

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Important: Overtightening the tank strap fasteners can result in deforming and damaging the tank and straps.

-

Fill the main tank with water.

-

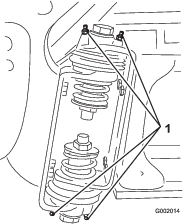

Check to see if there is any movement between the tank straps and the tank (Figure 17).

-

If the tank straps fit loose to the tank, tighten the flanged locknuts and bolts at the top of straps until the straps are flush with the surface of the tank (Figure 17).

Note: Do not overtighten the tank strap hardware.

Operating the Sprayer

To operate the Multi Pro Sprayer, first fill the spray tank, then apply the solution to the work area, and finally clean the tank. Complete all 3 of these steps in sequence to avoid damaging the sprayer. For example, do not mix and add chemicals in the spray tank at night and then spray in the morning. This would lead to separation of the chemicals and to possible damage to the sprayer components.

Caution

Chemicals are hazardous and can cause personal injury.

-

Read the directions on the chemical labels before handling the chemicals, and follow all manufacturer recommendations and precautions.

-

Keep chemicals away from your skin. Should contact occur, wash the affected area thoroughly with soap and clean water.

-

Wear goggles and any other protective equipment recommended by the chemical manufacturer.

The Multi Pro Sprayer has been specifically designed to have high durability in order to give it the long sprayer life you need. Different materials have been chosen for specific reasons at different locations on your sprayer to meet this goal. Unfortunately, there is no single material which is perfect for all foreseeable applications.

Some chemicals are more aggressive than others, and each chemical interacts differently with various materials. Some consistencies (e.g., wettable powders, charcoal) are more abrasive and lead to higher-than-normal wear rates. If a chemical is available in a formulation that would provide increased life to the sprayer, use this alternative formulation.

As always, remember to clean your sprayer thoroughly after all applications. This will do the most to ensure that your sprayer has a long and trouble-free life.

Using the Differential Lock

The differential lock increases the sprayer’s traction by locking the rear wheels so that 1 wheel will not spin out. This can help when you have heavy loads to haul on wet turf or slippery areas, going up hills, and on sandy surfaces. It is important to remember, however, that this extra traction is intended for temporary or limited use. Its use does not replace the safe operation, already discussed concerning steep hills and heavy loads.

The differential lock causes the rear wheels to turn at the same speed. When using differential lock your ability to make sharp turns is somewhat restricted and the tires may scuff the turf. Use the differential lock only when needed, at slower speeds and only in first or second gear.

Warning

Tipping or rolling the sprayer on a hill will cause serious injury.

-

The extra traction available with the differential lock can be enough to get you into dangerous situations such as climbing slopes that are too steep to turn around. Be extra careful when operating with the differential lock on, especially on steeper slopes.

-

If the differential lock is on when making a sharp turn at a higher speed and the inside rear wheel lifts off the ground, there may be a loss of control which could cause the sprayer to skid. Use the differential lock only at slower speeds.

Filling the Fresh-Water Tank

Always fill the fresh-water tank with clean water before handling or mixing any chemicals.

The fresh-water tank is located on the left side of the ROPS bar. It supplies a source of fresh water for you to wash chemicals off your skin, eyes, or other surfaces in the case of accidental exposure.

To open the fresh-water tank spigot, turn the lever on the spigot.

Filling the Spray Tank

Install the Chemical Pre-Mix Kit for optimal mixing and exterior tank cleanliness.

Important: Ensure that the chemicals you will be using are compatible for use with VitonTM (see the manufacturer's label; it should indicate if it is not compatible). Using a chemical that is not compatible with VitonTM will degrade the O-rings in the sprayer, causing leaks.

Important: Verify that the proper application rate has been set prior to filling the tank with chemicals.

-

Stop the sprayer on a level surface, move the range selector to the NEUTRAL position, shut off the engine, and set the parking brake.

-

Ensure that the tank drain valve is closed.

-

Determine the amount of water needed to mix the amount of chemical you need as prescribed by the chemical manufacturer.

-

Open the tank cover on the spray tank.

Note: The tank cover is located in the center of the top of the tank. To open it, turn the front half of the cover counterclockwise and swing it open. You can remove the strainer inside for cleaning. To seal the tank, close the cover and rotate the front half clockwise.

-

Add 3/4 of the required water to the spray tank using the anti-siphon fill receptacle.

Important: Always use fresh clean water in the spray tank. Do not pour concentrate into an empty tank.

-

Start the engine and set the pump switch to the ON position.

-

Press the accelerator pedal to the floor and set the throttle lock to the ON position.

-

Set the master section switch to the OFF position.

-

Turn the agitation valve to the ON position.

-

Add the proper amount of chemical concentrate to the tank as directed by the chemical manufacturer.

Important: If you are using a wettable powder without full agitation, mix the powder with a small amount of water to form a slurry before adding it to the tank.

-

Add the remaining water to the tank.

Operating the Sections

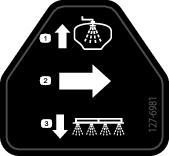

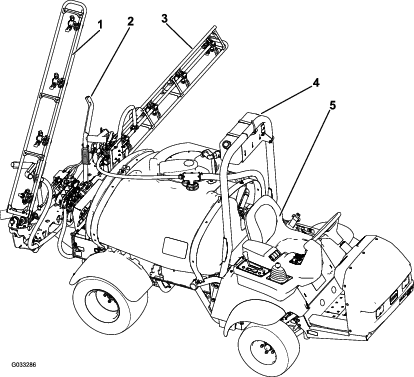

The boom-section lift switches on the sprayer control panel allows you to move the sections between the TRANSPORT position and the SPRAY position without leaving the operator's seat. It is recommended to change section positions while the machine is not moving.

Changing the Section Position

-

Stop the sprayer on level ground.

-

Use the boom-section lift switches to lower the sections.

Note: Wait until the sections reach the full, extended SPRAY position.

-

When the sections need to be retracted, stop the sprayer on level ground.

-

Use the boom-section lift switches to raise the sections until they have moved completely into boom-transport cradle forming the ‘X’ transport position and the section cylinders are fully retracted.

Important: To prevent damage to the section actuator cylinder, make sure that the actuators are fully retracted before transport.

Using the Boom-Transport Cradle

The sprayer is equipped with a boom-transport cradle that has a unique safety feature. In the event of accidental section contact with a low overhead object while in the TRANSPORT position, you can push the section(s) out of the transport cradles. If this occurs, the sections will come to rest in a near horizontal position to the rear of the vehicle. While the sections will not be damaged due to this movement, they should be immediately put back into the transport cradle.

Important: You can damage the sections if you transport them in any position other than the ‘X’ transport position using the boom-transport cradle.

To put the sections back into the transport cradle, lower the sections(s) to the SPRAY position, and then raise the section(s) back into the TRANSPORT position. Make sure that the section cylinders are fully retracted to prevent actuator rod damage.

Spraying

Important: To ensure that your solution remains well mixed, use the agitation feature whenever you have a solution in the tank. For agitation to work, you must have the pump on and the engine running above an idle. If you stop the vehicle and need agitation, set the parking brake, turn the pump on, press the accelerator pedal to floor, and switch the throttle lock to the ON position.

Note: This procedure assumes that the pump is on from the Operating the Sprayer procedure.

-

Lower the sections into position.

-

With the master-section switch in the OFF position, set the 3 section switches to the ON position.

-

Drive to the location where you will be spraying.

-

Set the master-section switch to the ON position to begin spraying.

Note: The InfoCenter shows the sections with the spray on.

Note: When the tank is nearly empty, the agitation may cause foaming in the tank. To prevent this, turn the agitation valve off. Alternatively, you can use an anti-foaming agent in the tank.

-

Use the rate switch to adjust and set a target.

-

When finished spraying, set the master-section switch to the OFF position to turn off all sections, then set the pump switch to the OFF position.

Spraying Tips

-

Do not overlap areas that you have previously sprayed.

-

Watch for plugged nozzles. Replace all worn or damaged nozzles.

-

Use the master-section switch to stop the spray flow before stopping the sprayer. Once stopped, place the range selector in the NEUTRAL position and use the neutral engine speed lock to hold the engine speed up to keep the agitation running.

-

You will obtain better results if the sprayer is moving when you turn the sections on.

-

Watch for changes in the application rate that may indicate that your speed has changed beyond the range of the nozzles or there is a problem with the spray system.

Calibrating the Sprayer Flow

Before using the sprayer for the first time, if you change the nozzles, or as needed, calibrate the sprayer flow.

Operator supplied equipment: Stop watch capable of measuring ± 1/10 second and a container graduated in 50 ml (1 fl oz) increments.

Preparing to Calibrate the Sprayer Flow

-

Fill the spray tank with clean water.

Note: Ensure that there is enough water in the tank to complete the calibration.

-

Set the parking brake and turn the engine on.

-

Set the pump switch to the ON position, and turn on the agitation.

-

Press down on the accelerator pedal until you reach the maximum engine speed, and toggle the throttle lock switch to the ON position.

Performing a Catch Test

-

Set all 3 section switches and the master-section switch to the ON position.

-

Turn the supervisor (rate-lockout) switch to the UNLOCK position.

-

Prepare to perform a catch test using the graduated container.

-

Start at 2.75 bar (40 psi) and use the application-rate switch to adjust the spray pressure so a catch test yields the amounts listed in the table below.

Note: Repeat the test 3 times and use the average.

Nozzle Color Milliliters collected in 15 seconds Ounces collected in 15 seconds Yellow 189 6.4 Red 378 12.8 Brown 473 16.0 Gray 567 19.2 White 757 25.6 Blue 946 32.0 Green 1,419 48.0 -

Once the catch test has yielded the amounts listed in the table above, set the supervisor rate lock out switch to the LOCK position.

-

Turn off the master-section switch.

Performing the Sprayer Flow Calibration

-

On the InfoCenter, navigate to the Calibration menu and select FLOW CAL as follows:

Note: Selecting the Home Screen icon at any time cancels calibrations.

-

Press the center selection button on the InfoCenter twice to access the menus.

-

Enter the calibration menu by pressing the right selection button on the InfoCenter.

-

Select FLOW CAL by highlighting FLOW CAL and press the right selection button on the InfoCenter.

-

In the next screen, enter the known quantity of water that will be sprayed out of the sections for the calibration procedure; refer to the chart below.

-

Press the right selection button on the InfoCenter.

-

-

Using the plus (+) and minus (-) symbols, enter the flow volume according to the table that follows:

Nozzle Color Liters US Gallons Yellow 42 11 Red 83 22 Brown 106 28 Gray 125 33 White 167 44 Blue 208 55 Green 314 83 -

Turn on the master-section switch for 5 minutes.

Note: As the machine sprays, the InfoCenter displays the quantity of fluid that it is counting.

-

After the 5 minute duration of spraying click the check mark by pressing the center button on the InfoCenter.

Note: It is acceptable if the gallons displayed during the calibration process do not match the known quantity of water entered into the InfoCenter.

-

After 5 minutes, turn off the master-section switch and select the check mark on the InfoCenter.

Note: Calibration is now complete.

Calibrating the Sprayer Speed

Before using the sprayer for the first time, if you change the nozzles, or as needed, calibrate the sprayer speed.

-

Fill the tank with fresh water.

-

On an open, flat area, mark off a distance between 45 to 152 m (150 to 500 ft).

Note: Toro recommends marking off 152 m (500 ft) for more accurate results.

-

Start the engine and drive to the start of the marked-off distance.

Note: Align the center of the front tires with the starting line for the most accurate measurement.

-

On the InfoCenter, navigate to the Calibration menu and select SPEED CAL.

Note: Selecting the Home Screen icon at any time cancels calibrations.

-

Select the Next arrow (→) on the InfoCenter.

-

Using the plus (+) and minus (-) symbols, enter the marked-off distance into the InfoCenter.

-

Shift the machine into first gear and drive the marked distance in a straight line at full throttle.

-

Stop the machine at the marked-off distance and select the check mark on the InfoCenter.

Note: Slow down and roll to a stop to align the center of the front tires with the finish line, for the most accurate measurement.

Note: Calibration is now complete.

Calibrating the Section-Bypass Valves

Before using the sprayer for the first time, if you change the nozzles, or as needed, calibrate the sprayer section bypass

Important: Select an open flat area to perform this procedure.

Preparing to Calibrate the Section-Bypass Valves

-

Fill the spray tank halfway with clean water.

-

Lower the sprayer sections.

-

Move the range selector to the NEUTRAL position and set the parking brake.

-

Set the 3 section switches to the ON position, but leave the master-section switch off.

-

Set the pump switch to the ON position, and turn on the agitation.

-

Press down on the accelerator pedal until you reach the maximum engine speed, and toggle the throttle lock switch to the ON position.

-

On the InfoCenter, navigate to the Calibration menu and select TEST SPEED.

Note: Selecting the Home Screen icon at any time cancels the calibration.

-

Using the plus (+) and minus (-) symbols, enter a test speed of 5.6 km/h (3.5 mph), then select the Home icon.

-

Turn the supervisor (rate-lockout) switch to the UNLOCK position, and turn the master-section switch to the ON position.

Adjusting the Bypass Valves

-

Using the application-rate switch, adjust the application rate according to the table below.

Nozzle Color SI (Metric) English Turf Yellow 159 l/ha 17 gpa 0.39 gpk Red 319 l/ha 34 gpa 0.78 gpk Brown 394 l/ha 42 gpa 0.96 gpk Gray 478 l/ha 51 gpa 1.17 gpk White 637 l/ha 68 gpa 1.56 gpk Blue 796 l/ha 85 gpa 1.95 gpk Green 1,190 l/ha 127 gpa 2.91 gpk -

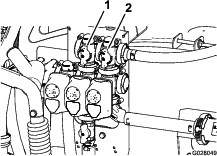

Turn off the left section and adjust the section-bypass knob (Figure 18) until the pressure reading is at the previously adjusted level (typically 2.75 bar or 40 psi).

Note: The numbered indicators on the bypass knob and needle are for reference only.

-

Turn on the left section and turn off the right section.

-

Adjust the right section-bypass knob (Figure 18) until the pressure reading is at the previously adjusted level (typically 2.75 bar or 40 psi).

-

Turn on the right section and turn off the center section.

-

Adjust the center section-bypass knob (Figure 18) until the pressure reading is at the previously adjusted level (typically 2.75 bar or 40 psi).

-

Turn each section off.

-

Turn the pump off.

Note: Calibration is now complete.

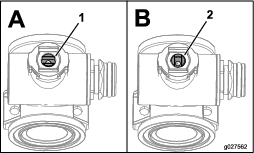

Agitation-Bypass Valve Knob Position

-

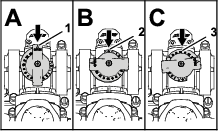

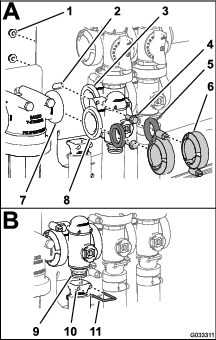

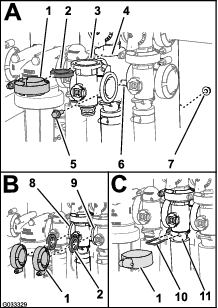

The agitation-bypass valve is in the full open position as shown in Figure 19A.

-

The agitation-bypass valve is in the closed (0) position as shown in Figure 19B.

-

The agitation-bypass valve is in an intermediate (adjusted relative to the pressure gauge for the sprayer system) position as shown in Figure 19C.

Calibrating the Agitation-Bypass Valve

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

Select an open flat area to perform this procedure.

-

Fill the spray tank with clean water.

-

Verify the agitation-control valve is open. If it has been adjusted, open it completely at this time.

-

Set the parking brake and start the engine.

-

Set the range selector to NEUTRAL.

-

Set the pump switch to the ON position.

-

Press the accelerator pedal to achieve maximum engine speed and set the throttle lock.

-

Set the 3 section valves to the OFF position.

-

Set the master-section switch to the ON position.

-

Set the system pressure to MAXIMUM.

-

Press the agitation switch to the OFF position and read the pressure gauge.

-

If the reading remains at 6.9 bar (100 psi) the agitation-bypass valve is properly calibrated.

-

If the pressure gauge reads differently, continue to the next step.

-

-

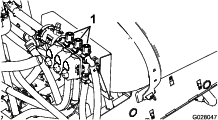

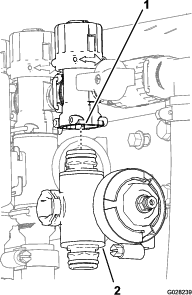

Adjust the agitation-bypass valve (Figure 20) on the backside of the agitation valve until the pressure reading on the gauge is 6.9 bar (100 psi).

-

Press the pump switch to the OFF position, shift the throttle lever to the IDLE position, and turn the ignition switch to the OFF position.

Adjusting the Master-Section-Bypass Valve

Note: Adjusting the master-section-bypass valve reduces or increases the amount of flow sent to the agitation nozzles in the tank when the master-section switch is set to the OFF position.

-

Fill the sprayer tank 1/2 full with clean water.

-

Move the machine to an open level surface.

-

Set the parking brake.

-

Set the range selector to the NEUTRAL position.

-

Set the pump switch to the ON position.

-

Set the agitation switch to the ON position.

-

Set the master-section switch to the OFF position.

-

Increase the engine speed to full throttle and set the throttle lock to the ON position.

-

Adjust the master-section-bypass handle to control the amount of agitation occurring in the tank (Figure 20).

-

Reduce the throttle speed to idle.

-

Set the agitation switch and pump switch to the OFF position.

-

Shut off the machine.

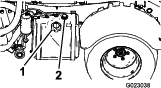

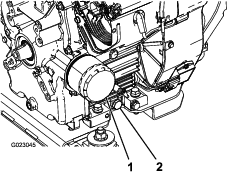

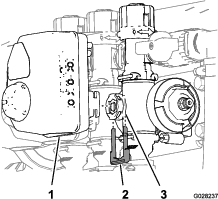

Locating the Spray Pump

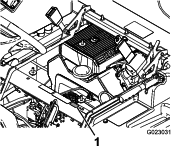

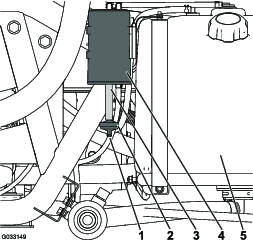

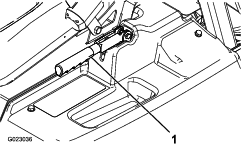

The spray pump is located under the seat (Figure 21).

Hauling the Machine

-

Use full-width ramps for loading the machine onto a trailer or truck.

-

Tie the machine down securely.

Transporting the Sprayer

Towing the Sprayer

In case of an emergency, you can tow the sprayer for a short distance. However, do not use this as a standard procedure.

Warning

Towing at excessive speeds could cause a loss of steering control, resulting in personal injury.

Never tow the sprayer faster than 8 km/h (5 mph).

Towing the sprayer is a 2–person job. If you must move the machine a considerable distance, transport it on a truck or trailer; refer to Transporting the Sprayer.

-

Attach a tow line to the frame.

-

Put the range selector in the NEUTRAL position and release the parking brake.

-

Tow the sprayer at less than 8 km/h (5 mph).

Spray Filter Recommendations

Selecting a Suction Filter

Standard Equipment: 50 mesh suction filter (blue)

Use the suction filter table to identify the screen mesh for the spray nozzles you are using based on chemicals products or solutions with a viscosity equivalent to water.

| Spray Nozzle Color Code (flow rate) | Screen Mesh Size* | Filter Color Code |

|---|---|---|

| Yellow (0.2 gpm) | 50 | Blue |

| Red (0.4 gpm) | 50 | Blue |

| Brown (0.5 gpm) | 50 (or 30) | Blue (or green) |

| Gray (0.6 gpm) | 30 | Green |

| White (0.8 gpm) | 30 | Green |

| Blue (1.0 gpm) | 30 | Green |

| Green (1.5 gpm) | 30 | Green |

| *The mesh size of the suction filters in this table are based on spray chemicals or solutions with the viscosity equivalent to water. | ||

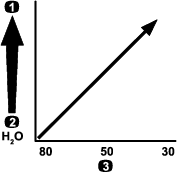

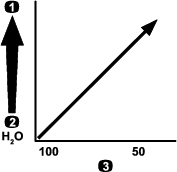

Important: When you spray with higher viscosity (thicker) chemical products or solutions with wettable powders, you may need to use an coarser screen mesh for the optional suction filter; refer to Figure 23.

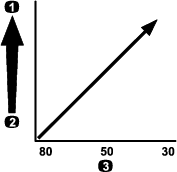

When you spray at a higher application rate, consider using an courser optional suction-filter mesh; refer to Figure 24.

Selecting a Pressure Filter

Available screen sizes include:

Standard Equipment: 50 mesh suction filter (blue)

Use the pressure filter table to identify the screen mesh for the spray nozzles you are using based on chemicals products or solutions with a viscosity equivalent to water.

| Spray Nozzle Color Code (flow rate) | Screen Mesh Size* | Filter Color Code |

|---|---|---|

| As required for low viscosity chemicals or solutions or low application rates | 100 | Green |

| Yellow (0.2 gpm) | 80 | Yellow |

| Red (0.4 gpm) | 50 | Blue |

| Brown (0.5 gpm) | 50 | Blue |

| Gray (0.6 gpm) | 50 | Blue |

| White (0.8 gpm) | 50 | Blue |

| Blue (1.0 gpm) | 50 | Blue |

| Green (1.5 gpm) | 50 | Blue |

| As required for high viscosity chemicals or solutions or high application rates | 30 | Red |

| As required for high viscosity chemicals or solutions or high application rates | 16 | Brown |

| *The mesh size of the pressure filters in this table are based on spray chemicals or solutions with the viscosity equivalent to water. | ||

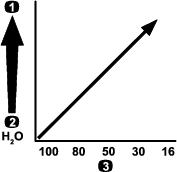

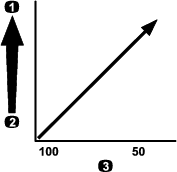

Important: When you spray with higher viscosity (thicker) chemical products or solutions with wettable powders, you may need to use a coarser screen mesh for the optional pressure-filter; refer to Figure 25.

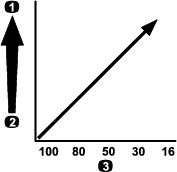

When you spray at a higher application rate, consider using an courser optional pressure-filter mesh; refer to Figure 26.

Selecting a Nozzle-Tip Filter (Optional)

Note: The use the optional nozzle-tip filter to protect the spray-nozzle tip and increase its service life.

Use the nozzle-tip filter table to identify the screen mesh for the spray nozzles you are using based on chemicals products or solutions with a viscosity equivalent to water.

| Spray Nozzle Color Code (flow rate) | Filter Mesh Size* | Filter Color Code |

|---|---|---|

| Yellow (0.2 gpm) | 100 | Green |

| Red (0.4 gpm) | 50 | Blue |

| Brown (0.5 gpm) | 50 | Blue |

| Gray (0.6 gpm) | 50 | Blue |

| White (0.8 gpm) | 50 | Blue |

| Blue (1.0 gpm) | 50 | Blue |

| Green (1.5 gpm) | 50 | Blue |

| *The mesh size of the nozzle filters in this table are based on spray chemicals or solutions with the viscosity equivalent to water. | ||

Important: When you spray with higher viscosity (thicker) chemical products or solutions with wettable powders, you may need to use a coarser screen mesh for the optional tip-filter; refer to Figure 27.

When you spray at a higher application rate, consider using an courser tip-filter mesh; refer to Figure 28.

Maintenance

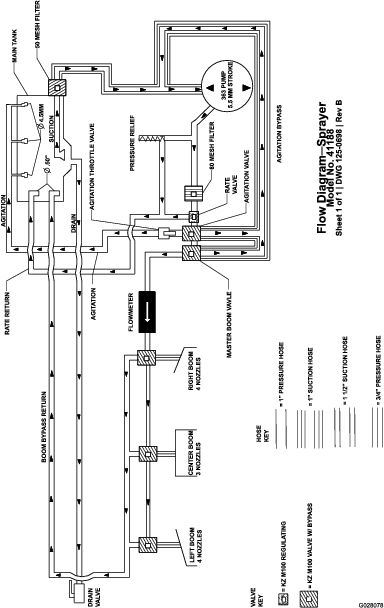

Note: Download a free copy of the schematic by visiting www.Toro.com and searching for your machine from the Manuals link on the home page.For additional information about the sprayer system, refer to the sprayer system schematic in .

Note: Determine the left and right sides of the machine from the normal operating position.

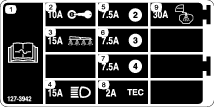

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| After the first 50 hours |

|

| After the first 100 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 400 hours |

|

| Every 800 hours |

|

| Yearly |

|

Refer to your engine owner’s manual for additional maintenance procedures.

Notation for Areas of Concern

| Inspection performed by: | ||

| Item | Date | Information |

| 1 | ||

| 2 | ||

| 3 | ||

| 4 | ||

| 5 | ||

| 6 | ||

| 7 | ||

| 8 | ||

| 9 | ||

| 10 | ||

| 11 | ||

| 12 | ||

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the ignition and disconnect the wire(s) from the spark plug(s) before you perform any maintenance. Set the wire(s) aside so that it does not accidentally contact the spark plug(s).

Pre-Maintenance Procedures

Raising the Sprayer

Whenever the engine is run for routine maintenance and/or engine diagnostics, the rear wheels of the sprayer should be 2.5 cm (1 inch) off the ground with the rear axle supported on jack stands.

Danger

A sprayer on a jack may be unstable and slip off the jack, injuring anyone beneath it.

-

Do not start the engine while the sprayer is on a jack.

-

Always remove the key from the ignition before getting off the sprayer.

-

Block the tires when the sprayer is on a jack.

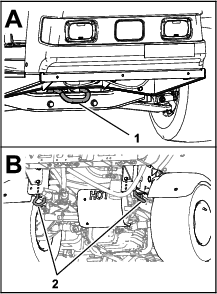

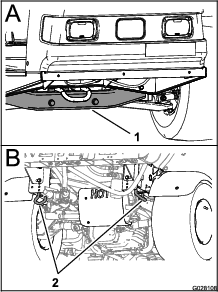

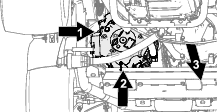

The jacking point at the front of the sprayer is under the front crossbar (Figure 30A). The jacking point at the rear of the sprayer is on the rear frame support, behind the rear tie-down loops (Figure 30B).

Lubrication

Greasing the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Grease Type: No. 2 lithium grease

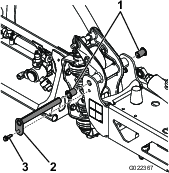

Refer Figure 31 for the grease-point locations.

-

Wipe the grease fitting clean so that you do not force dirt or debris into the bearing or bushing.

-

Pump grease into the bearing or bushing.

-

Wipe off the excess grease.

Greasing the Sprayer Pump

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Grease Type: Mobil XHP 461

-

Raise the sprayer; refer to Raising the Sprayer.

-

Locate the sprayer pump.

Note: The pump is located below the seat; refer to Locating the Spray Pump.

-

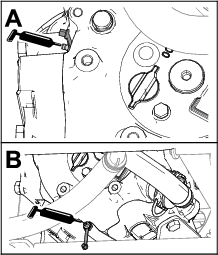

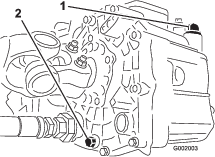

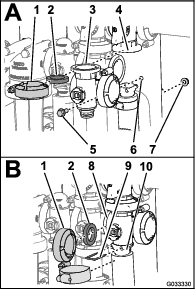

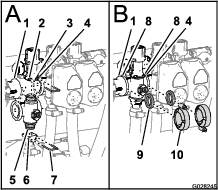

Wipe the 2 remote grease fittings clean (Figure 32A and Figure 32B).

-

Pump grease into each remote grease fitting (Figure 32A and Figure 32B).

-

Wipe off the excess grease.

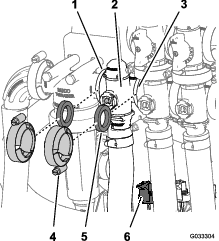

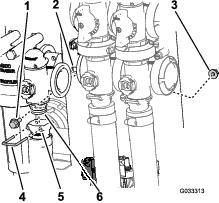

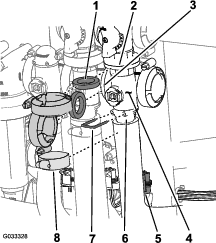

Greasing the Section Hinges

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Important: If the section hinge is washed with water, clear all water and debris from the hinge assembly and apply fresh grease.

Grease Type: No. 2 lithium grease

-

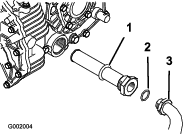

Wipe the grease fittings clean so that foreign matter cannot be forced into the bearing or bushing.

-

Pump grease into the bearing or bushing at each fitting (Figure 33).

-

Wipe off excess grease.

-

Repeat the procedure for each section pivot.

Engine Maintenance

Checking the Air-Intake Screen

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 100 hours |

|

Check and clean as necessary the air-intake screen on the front of the engine before each use or daily.

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

| Every 200 hours |

|

Removing the Foam and Paper Elements

-

Set the parking brake, stop the pump, shut off the engine, and remove the ignition key.

-

Release the latch on the back of the seat and lift the seat forward.

-

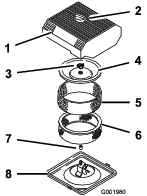

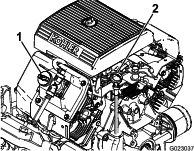

Clean around the air cleaner to prevent dirt from getting into the engine and causing damage (Figure 34).

-

Loosen the knob on the air-cleaner cover and remove the cover (Figure 34).

-

Carefully slide the foam element off the paper element (Figure 34).

-

Unscrew the cover nut and remove the cover and paper element (Figure 34).

Cleaning the Foam Element

-

Wash the foam element in liquid soap and warm water.

-

When the element is clean, rinse it thoroughly.

-

Dry the element by squeezing it in a clean cloth.

-

Put 30 to 59 ml (1 to 2 fl oz) of oil on the element (Figure 35).

Important: Replace the foam element if it is torn or worn.

-

Squeeze the element to distribute the oil.

Checking the Paper Element

Inspect the paper element for tears, an oily film, damage to the rubber seal, excessive dirt, or other damage (Figure 36). If any of these conditions exist, replace the filter.

Important: Do not clean the paper element with pressurized air or liquids, such as a solvent, gasoline, or kerosene.

Important: To prevent engine damage, always operate the engine with the complete foam and paper air-cleaner assembly installed.

Installing the Foam and Paper Elements

-

Carefully slide the foam element onto the paper air-cleaner element (Figure 34).

-

Slide the air-cleaner assembly and cover onto the long rod.

-

Install the cover nut finger-tight against the cover (Figure 34).

Note: Ensure that the rubber seal is flat against the air-cleaner base and cover.

-

Install the air-cleaner cover and knob (Figure 34).

-

Close and latch the seat.

Servicing the Engine Oil

Crankcase Capacity is 2.0 L (2.1 US qt) with the filter.

Use high-quality engine oil that meets the following specifications:

-

API classification Level required: SJ, JK, SL, or higher.

-

Preferred oil: SAE 10W30 (above 0°F)

-

Alternate oil: SAE 5W30 (below 32°F)

Toro Premium Engine Oil is available from your distributor in either 10W30 or 5W30 viscosity. See the Parts Catalog for part numbers.

Checking the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 400 hours |

|

The engine is shipped with oil in the crankcase; however, you must check the level of oil before you first start the engine and after you have run it.

-

Position the machine on a level surface.

-

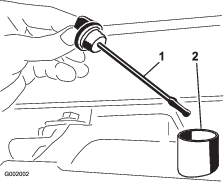

Remove the dipstick and wipe it with a clean rag (Figure 37). Insert the dipstick into the tube and make sure that it is seated fully. Remove the dipstick and check the oil level.

-

If the oil level is low, remove the filler cap from the valve cover (Figure 37) and pour oil into the opening until the oil level is up to the FULL mark on the dipstick. Add the oil slowly and check the level often during this process. Do not overfill.

-

Install the dipstick firmly in place.

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 100 hours |

|

-

Start the engine and let it run for 5 minutes. This warms the oil so it drains better.

-

Position the machine on a level surface, engage the parking brake, shut off the sprayer pump, shut off the engine, and remove the key.

-

Release the latch on the back of the seat and lift the seat forward.

Caution

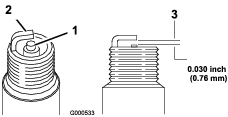

Components under the seat are hot if the sprayer has been running. If you touch hot components, you may be burned.