| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This machine is intended to be used by residential homeowners. It is designed primarily for removing snow from paved surfaces, such as driveways and sidewalks, and other surfaces for traffic on residential or commercial properties. It is not designed for removing materials other than snow, nor is it designed for clearing gravel surfaces.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

You may contact Toro directly at www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

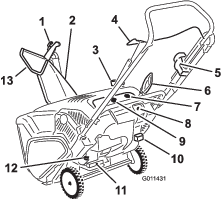

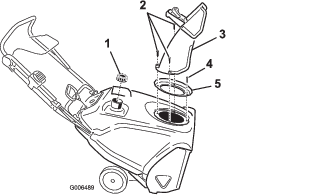

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Important: If you are using this machine above 1500 m (5,000 ft) for a continuous period, ensure that the High Altitude Kit has been installed so that the engine meets CARB/EPA emission regulations. The High Altitude Kit increases engine performance while preventing spark-plug fouling, hard starting, and increased emissions. Once you have installed the kit, attach the high-altitude label next to the serial decal on the machine. Contact any Authorized Toro Service Dealer to obtain the proper High Altitude Kit and high-altitude label for your machine. To locate a dealer convenient to you, access our website at www.Toro.com or contact our Toro Customer Care Department at the number(s) listed in your Emission Control Warranty Statement. Remove the kit from the engine and restore the engine to its original factory configuration when running the engine under 1500 m (5,000 ft). Do not operate an engine that has been converted for high-altitude use at lower altitudes; otherwise, you could overheat and damage the engine.If you are unsure whether or not your machine has been converted for high-altitude use, look for the following label (Figure 3).

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

This snowthrower is capable of injuring hands and feet and of throwing objects. Failure to observe the following safety instructions could result in serious injury.

This machine complies with ANSI/OPEI B71.3 specifications.

General Safety

-

Read and understand the contents of this Operator’s Manual before you start the engine. Ensure that everyone using this product knows how to use it, knows how to shut off the engine quickly, and understands the warnings.

-

Shut off the engine whenever you leave the operating position for any reason.

-

Do not put your hands or feet near moving parts on the machine.

-

Do not operate the machine without all guards and other safety protective devices in place and working.

-

Keep clear of any discharge opening. Keep bystanders, especially small children, out of the operating area.

-

Never allow children to operate the machine.

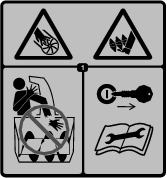

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

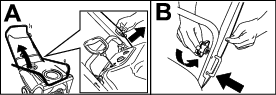

Setup

Unfolding the Handle

Installing the Discharge Chute

Filling the Engine with Oil

Adjusting the Control Cable

Refer to Adjusting the Control Cable.

Product Overview

| Model | Weight | Length | Width | Height |

| 38744 | 40.4 kg | 122 cm | 54 cm | 107 cm |

| (89 lb) | (48 inches) | (21 inches) | (42 inches) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Before Operation

Before Operation Safety

General Safety

-

For electric-start models only: Use extension cords and receptacles as specified in the manual. Inspect the electrical cord before plugging it into a power source. If the cord is damaged, replace it. Unplug the power cord whenever you are not starting the machine.

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair, secure loose clothing, and do not wear loose jewelry.

-

Thoroughly inspect the area where you will use the machine, and remove all doormats, sleds, boards, wires, and other foreign objects.

-

If a shield, safety device, or decal is damaged, illegible, or missing, repair or replace it before beginning operation. Also, tighten any loose fasteners.

-

Two-stage models only: Adjust the collector housing height to clear a gravel or crushed-rock surface.

Fuel Safety

Fuel is extremely flammable and explosive. A fire or explosion from fuel can burn you and others.

-

To prevent a static charge from igniting the fuel, place the container and/or machine on the ground before filling, not in a vehicle or on an object.

-

Fill the fuel tank outdoors when the engine is cold. Replace the fuel cap securely and wipe up spills.

-

Do not handle fuel when smoking or around an open flame or sparks.

-

Store fuel in an approved fuel container, out of the reach of children.

-

When fuel is in the tank, tip the machine only as directed in the instructions.

-

If you spill fuel on your clothing, change your clothing immediately.

Filling the Fuel Tank

-

For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method).

-

Oxygenated fuel with up to 10% ethanol or 15% MTBE by volume is acceptable.

-

Do not use ethanol blends of gasoline (such as E15 or E85) with more than 10% ethanol by volume. Performance problems and/or engine damage may result which may not be covered under warranty.

-

Do not use gasoline containing methanol.

-

Do not store fuel either in the fuel tank or fuel containers over the winter unless you use a fuel stabilizer.

-

Do not add oil to gasoline.

Do not fill above the bottom of the fuel tank neck (Figure 8).

Important: For best results, purchase only the quantity of fuel that you expect to use in 30 days. Otherwise, you may use fuel stabilizer/conditioner in the machine at all times to keep the fuel fresh longer when used as directed by the fuel-stabilizer manufacturer.

Checking the Engine-Oil Level

During Operation

During Operation Safety

General Safety

-

Shut off the engine before unclogging the machine and always use a stick or the snow-cleanout tool (if provided).

-

Stay behind the handles and away from the discharge opening while operating the machine. Keep your face, hands, feet, and any other part of your body or clothing away from moving or rotating parts.

-

Never direct the discharge toward people or areas where property damage can occur.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Exercise caution to avoid slipping or falling, especially when operating the machine in reverse.

-

Always be sure of your footing, and keep a firm hold on the handles. Walk; never run.

-

Exercise extreme caution when operating the machine on a slope.

-

Do not operate the machine without good visibility or light.

-

Look behind and use care when backing up the machine.

-

When not actively clearing snow, disengage power to the auger.

-

Exercise extreme caution when operating the machine on or crossing gravel drives (2-stage models only), walks, or roads. Stay alert for hidden hazards or traffic.

-

Never attempt to make any adjustments while the engine is running, except as directed in the instructions.

-

After striking a foreign object, shut off the engine, remove the ignition key (electric-start models only), inspect the machine for damage. Repair any damage before starting the machine.

-

If the machine starts to vibrate abnormally, shut off the engine and check immediately for the cause.

-

Do not run the engine indoors; exhaust fumes are dangerous.

-

Do not overload the machine capacity by attempting to clear snow at too fast a rate.

-

Disengage all clutches and shift into neutral before starting the engine.

-

Shut off the engine whenever you leave the operating position, before clearing or unclogging the collector, impeller, or discharge chute, and when making any repairs, adjustments, or inspections.

-

Never operate the machine at high transport speeds on slippery surfaces.

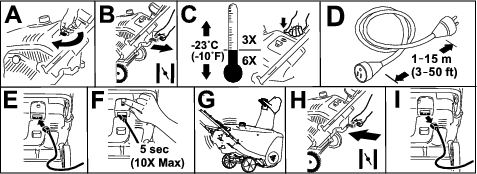

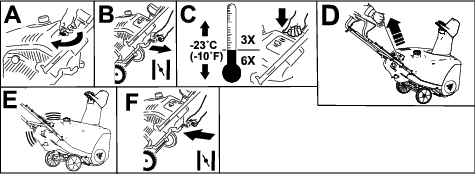

Starting the Engine

Using Electric Start

Note: Remove your glove when you push in the primer so that air cannot escape from the primer hole.

Important: Do not use the primer or the choke if the engine has been running and is hot. Excessive priming may flood the engine and prevent it from starting.

To use the electric starter (electric-start models only), connect a power cord to the electric-start plug-in first and then to a ground fault circuit interrupter (GFCI) power outlet. Use only a UL-listed, 16-gauge power cord recommended for outdoor use that is not longer than 15 m (50 ft).

Warning

The electrical cord can become damaged, causing a shock or fire.

Thoroughly inspect the electrical cord before plugging it into a power source. If the cord is damaged, do not use it. Replace or repair the damaged cord immediately. Contact an Authorized Service Dealer for assistance.

Important: Run the electric starter no more than 10 times at intervals of 5 seconds on, then 5 seconds off. Running the electric starter extensively can overheat and damage it. If the engine does not start after this series of attempts, wait at least 40 minutes to allow the starter to cool before attempting to start it again. If the engine does not start after the second series of attempts, take the machine to an Authorized Service Dealer for service.

If the recoil starter does not operate properly, it may be frozen. Thaw out the starter before attempting to start the machine.

Caution

If you leave the machine plugged into a power source, someone can inadvertently start the machine and injure people or damage property (electric-start models only).

Unplug the power cord whenever you are not starting the machine.

Using Recoil Start

Note: Remove your glove when you push in the primer so that air cannot escape from the primer hole.

Important: Do not use the primer or the choke if the engine has been running and is hot. Excessive priming may flood the engine and prevent it from starting.

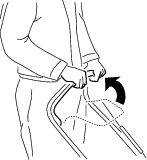

Engaging the Rotor Blades

To engage the rotor blades, hold the control bar against the handle (Figure 12).

Disengaging the Rotor Blades

To disengage the rotor blades, release the control bar (Figure 13).

Shutting Off the Engine

To shut off the engine, turn the ignition key counterclockwise to the OFF position (Figure 14).

Adjusting the Discharge Chute and Chute Deflector

To adjust the discharge chute, press the trigger of the Quick Shoot™ control on the right side of the handle and move it up or down along the handle. Moving the control down the handle rotates the discharge chute to the left; moving the control up the handle rotates the discharge chute to the right (Figure 15).

To raise or lower the angle of the chute deflector, press the trigger on the chute deflector and move the chute deflector up or down (Figure 16).

Clearing a Clogged Discharge Chute

To clear the chute:

-

Shut the engine off!

-

Wait 10 seconds to ensure that the rotor blades have stopped rotating.

-

Always use a clean-out tool; never use your hands.

Operating Tips

Warning

The rotor blades can throw stones, toys, and other foreign objects and cause serious personal injury to you or bystanders.

-

Keep the area to be cleared free of all objects that the rotor blades could pick up and throw.

-

Keep all children and pets away from the area of operation.

-

Remove the snow as soon as possible after it falls.

-

Overlap each swath to ensure complete snow removal.

-

Discharge the snow downwind whenever possible.

-

If the machine does not propel itself forward on slippery surfaces or in heavy snow, push forward on the handle, but allow the machine to work at its own pace.

-

The machine may leave rubber marks on new brushed or light-colored concrete. Test on an inconspicuous location before use. These marks are not permanent.

After Operation

After Operation Safety

General Safety

-

Never store the machine with fuel in the fuel tank inside a building where ignition sources are present, such as hot water heaters, space heaters, or clothes dryers. Allow the engine to cool before storing the machine in any enclosure.

-

When storing the machine for more than 30 days, refer to Before storage for important information.

-

Run the machine a few minutes after throwing snow to prevent freeze-up of the collector and impeller.

Preventing Freeze-up after Use

-

Let the engine run for a few minutes to prevent moving parts from freezing. Shut off the engine, wait for all moving parts to stop, and remove ice and snow from the machine.

-

Clean off any snow and ice from the base of the chute.

-

Rotate the discharge chute left and right to free it from any ice buildup.

-

With the ignition key in the OFF position, pull the recoil-start handle several times or connect the electrical cord to a power source and the machine and push the electric-start button once to prevent the recoil starter and/or the electric starter from freezing up (electric-start models only).

-

In snowy and cold conditions, some controls and moving parts may freeze. Do not use excessive force when trying to operate frozen controls. If you have difficulty operating any control or part, start the engine and let it run for a few minutes.

Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first hour |

|

| After the first 2 hours |

|

| Before each use or daily |

|

| Yearly |

|

| Yearly or before storage |

|

Maintenance Safety

Read the following safety precautions before performing any maintenance on the machine:

-

Before servicing, adjusting, or cleaning the machine, shut off the engine and remove the key. If major repairs are ever needed, contact an Authorized Service Dealer.

-

Always wear eye protection while performing an adjustment or repair to protect your eyes from foreign objects that the machine may throw.

-

Check all fasteners at frequent intervals for proper tightness to ensure that the machine is in safe working condition.

-

Do not change the governor settings on the engine.

Purchase only genuine Toro replacement parts and accessories.

Adjusting the Control Cable

Checking the Control Cable

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first hour |

|

| Yearly |

|

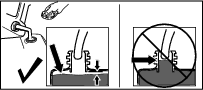

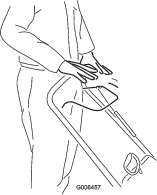

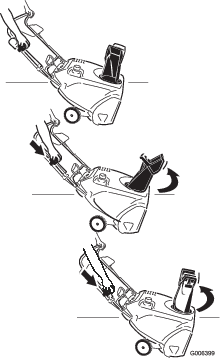

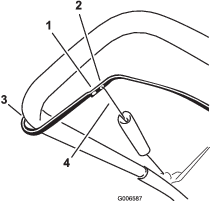

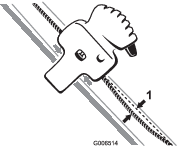

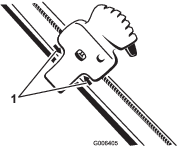

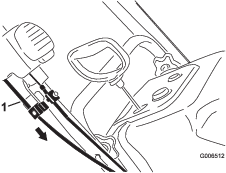

Move the control bar back toward the handle to remove the slack in the control cable (Figure 17).

Note: Ensure that a 2 to 3 mm (1/16 to 1/8 inch) gap exists between the control bar and the handle (Figure 17).

Important: The control cable must contain some slack when you disengage the control bar for the rotor blades to stop properly.

Adjusting the Control Cable

-

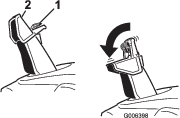

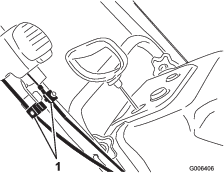

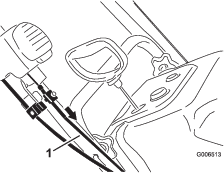

Slide up the spring cover and unhook the spring from the adjuster link (Figure 18).

Note: You can pull up the adjuster link and cable to make unhooking the spring easier.

-

Move the Z-fitting to a higher or lower hole on the adjuster link as needed to obtain the 2 to 3 mm (1/16 to 1/8 inch) gap between the control bar and the handle (Figure 17).

Note: Moving the Z-fitting higher decreases the gap between the control bar and the handle; moving it lower increases the gap.

-

Hook the spring to the adjuster link and slide the spring cover over the adjuster link.

-

Check the adjustment; refer to Adjusting the Control Cable.

Note: After extended use, the drive belt may wear and lose its proper belt tension. If the drive belt slips (continuously squeals) under a heavy load, disconnect the spring from the adjustor link and move the upper end of the spring to the hole that is further from the pivot point in the control bar (Figure 19). Then connect the spring to the adjustor link and adjust the control cable.

Note: The belt may slip (squeal) in wet conditions; to dry out the drive system, start the rotor and run it without a load for 30 seconds.

Inspecting the Rotor Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

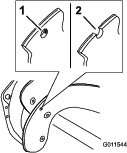

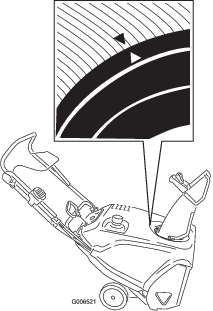

Before each session, inspect the rotor blades for wear. When a rotor-blade edge has worn down to the wear-indicator hole, have an Authorized Service Dealer replace the rotor blades and the scraper (Figure 20).

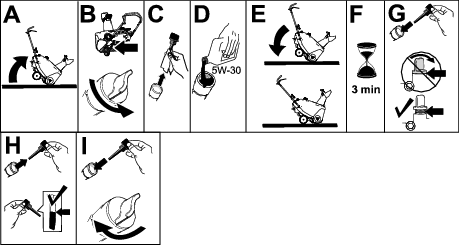

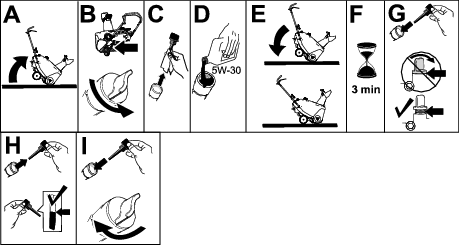

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

If possible, run the engine for a few minutes before changing the oil to warm it. Warm oil flows better and carries more contaminants.

| Engine oil capacity | 0.60 L (20 fl oz) |

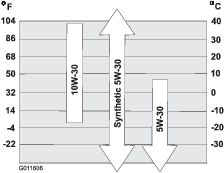

| Oil viscosity | Refer to Figure 23. |

| API service classification | SJ or higher |

-

Siphon the fuel from the fuel tank into an approved fuel container, or run the engine until it shuts off.

-

Move the machine to a level surface.

-

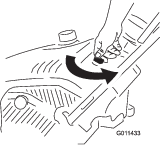

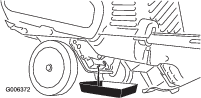

Place an oil-drain pan under the oil-drain plug, remove the plug, and tip the machine backward and drain the used oil in the pan (Figure 21).

-

After draining the used oil, return the machine to the operating position.

-

Install the oil-drain plug and tighten it securely.

-

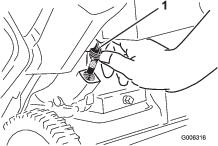

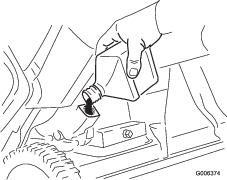

Clean around the oil-fill cap (Figure 22).

-

Unscrew the oil-fill cap and remove it (Figure 22).

-

With the machine in the operating position, carefully pour oil into the oil-fill hole to the point of overflow (Figure 24).

Note: You may tip the machine forward (handle up) to make adding oil easier. Remember to return the machine to the operating position before checking the oil level.

Important: Do not tip the machine all the way forward onto its nose, or fuel may leak out of the machine.

Use Figure 23 below to select the best oil viscosity for the outdoor temperature range expected.

-

Wait 3 minutes for the oil to settle and add enough oil to bring it to the point of overflow.

-

Screw the oil-fill cap into the oil-fill hole, and tighten it securely by hand.

-

Wipe up any spilled oil.

-

Dispose of the used oil properly at a local recycling center.

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

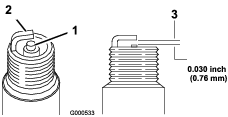

Use a NGK BPR6ES or Champion RN9YC spark plug or equivalent.

-

Shut off the engine and wait for all moving parts to stop.

-

Rotate the discharge chute so that it faces forward.

-

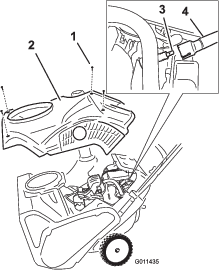

Remove the discharge chute, the discharge-chute handle, and the chute seal by removing the 3 large screws and 1 small screw (Figure 25).

-

Remove the 4 screws that secure the shroud (Figure 26).

-

Remove the fuel-tank cap.

-

Remove the shroud (Figure 26).

-

Install the fuel-tank cap.

-

Disconnect the wire from the spark plug.

-

Clean around the spark plug.

-

Remove the spark plug from the cylinder head.

Important: Replace a cracked, fouled, or dirty spark plug. Do not clean the electrodes because grit entering the cylinder can damage the engine.

-

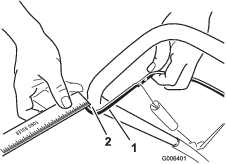

Set the gap on the plug to 0.76 mm (0.030 inch) as shown in Figure 27.

-

Install the spark plug and torque it to 27 to 30 N∙m (20 to 22 ft-lb).

-

Connect the wire to the spark plug.

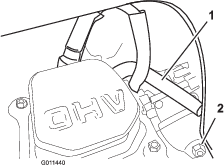

Note: Ensure that the breather tube is routed above the spark-plug wire as shown in Figure 28.

-

Remove the fuel-tank cap.

-

Install the shroud with the screws that you removed in step 4.

Note: Ensure that the upper and lower shrouds fit together in the side grooves.

-

Install the fuel-tank cap.

-

Install the chute seal, discharge chute, and discharge-chute handle onto the machine using the hardware that you removed in step 3.

Note: The small screw goes through the small hole in the chute seal at the front of the discharge-chute opening.

Replacing the Drive Belt

If the drive belt becomes worn, oil-soaked, excessively cracked, frayed, or otherwise damaged, replace the belt.

-

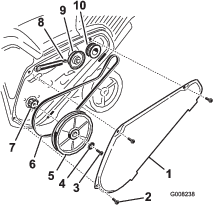

Remove the drive-belt cover by removing the 3 bolts as shown in Figure 29.

-

Unhook the brake spring from the idler arm to release the belt tension (Figure 29).

-

Remove the screw and curved washer that holds the rotor pulley (Figure 29).

-

Remove the rotor pulley and the drive belt (Figure 29).

-

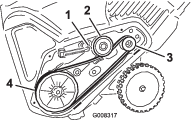

Install the new drive belt, routing it as shown in Figure 30.

Note: Route the new drive belt first around the engine pulley, then the idler pulley, and finally around the loose rotor pulley positioned just above the rotor shaft (Figure 29).

-

Install the rotor pulley onto the rotor shaft (Figure 29).

-

Install the curved washer and the rotor-pulley bolt and tighten them securely (Figure 29).

Note: The concave side of the curved washer goes against the outside of the pulley.

-

Install the brake spring onto the idler arm (Figure 30).

-

Install the drive-belt cover with the bolts that you removed in step 1.

Note: Ensure that the drive belt is properly adjusted and operating; refer to Checking the Control Cable and Adjusting the Control Cable.

Adjusting the Quick Shoot Control

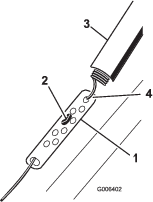

If there is more than 13 mm (1/2 inch) of slack in the Quick Shoot cable (Figure 31) or the discharge chute does not rotate left and right in equal angles, adjust the Quick Shoot control cables.

-

Loosen the 2 Quick Shoot control-cable clamps (Figure 32).

-

Position the Quick Shoot control between the 2 arrows located on the right side of the upper handle (Figure 33).

-

Rotate the discharge chute so that it faces straight ahead and the arrow on the back of the discharge chute aligns with the arrow on the shroud (Figure 34).

-

Hold the discharge chute in the straight-ahead position, pull the lower cable casing downward until you remove the slack in the cable, and tighten the screw on the lower cable clamp securely (Figure 35).

-

Pull the upper cable casing forward until you remove the slack in the cable, and tighten the screw on the upper cable clamp securely (Figure 36).

Note: Do not over-tension the cables. If the cables are over-tensioned, the Quick Shoot will be hard to operate.

Storage

Storing the Machine

Warning

Fuel fumes are highly flammable, explosive, and dangerous if inhaled. If you store the product in an area with an open flame, the fuel fumes may ignite and cause an explosion.

-

Do not store the machine in a house (living area), basement, or any other area where ignition sources may be present, such as hot water and space heaters, clothes dryers, furnaces, and other appliances.

-

Do not tip the machine either forward or backward with fuel in the fuel tank; otherwise, fuel may leak out of the machine.

-

Do not store the machine with its handle tipped down onto the ground; otherwise, oil leaks into the engine cylinder and onto the ground, and the engine does not start or run.

-

On the last refueling of the season, add fuel stabilizer to fresh fuel as directed by the fuel-stabilizer manufacturer.

Important: Do not store fuel longer than that suggested by the fuel-stabilizer manufacturer.

-

Run the engine for 10 minutes to distribute the conditioned fuel through the fuel system.

-

Shut off the engine, allow it to cool, and siphon the fuel tank or run the engine until it shuts off.

-

Start the engine and run it until it shuts off.

-

Choke or prime the engine, start it a third time, and run the engine until it does not start.

-

Drain the fuel in the carburetor through the carburetor-drain bolt into an approved gasoline container.

-

Dispose of unused fuel properly. Recycle it according to local codes, or use it in your automobile.

-

While the engine is still warm, change the engine oil. Refer to Changing the Engine Oil.

-

Remove the spark plug.

-

Squirt 10 ml (2 tsp) of oil into the spark-plug hole.

-

Install the spark plug by hand and then torque it to 27 to 30 N∙m (20 to 22 ft-lb).

-

With the ignition key in the OFF position, pull the recoil-start handle slowly to distribute the oil on the inside of the cylinder.

-

Clean the machine.

-

Touch up chipped surfaces with paint available from an Authorized Service Dealer. Sand affected areas before painting, and use a rust preventative to prevent the metal parts from rusting.

-

Tighten any loose fasteners. Repair or replace any damaged parts.

-

Cover the machine and store it in a clean, dry place out of the reach of children. Allow the engine to cool before storing the machine in any enclosure.