| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

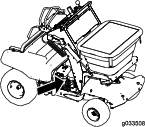

This stand-on spreader sprayer is intended to be used by trained operators in residential and commercial applications. The machine is primarily designed for chemical distribution used for turf care or snow/ice removal at residential grounds, parks, sports fields, and on commercial grounds.

Read the information in the manual carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

You may contact Toro directly at www.Exmark.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

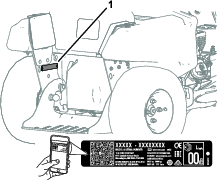

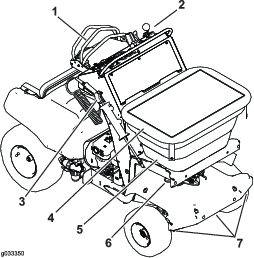

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 illustrates the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

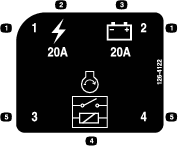

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

Improper use or maintenance by the operator or owner can result in injury. To reduce the potential for injury, comply with these safety instructions, and pay attention to the safety-alert symbol, which means Caution, Warning, or Danger—personal safety instruction. Failure to comply with the instructions may result in personal injury or death.

This machine was manufactured according to the appropriate regulatory standards in effect at the time of manufacture. Modifying this machine in any way may cause it to be out of compliance with those standards and with the instructions in this Operator’s Manual. Modifications to this machine should only be made by either the manufacturer or an authorized Toro distributor.

This product is capable of amputating hands and feet. Follow all safety instructions to avoid serious injury or death.

The owner/user can prevent and is responsible for accidents or injuries occurring to people, or damage to property.

The addition of attachments made by other manufacturers that do not meet American National Standards Institute certification will cause noncompliance of this machine.

Safe Operating Practices

The following instructions are from ANSI standard B71.4-2012.

Training

-

Read the Operator's Manual and other training material. If the operator(s) or mechanic(s) cannot read or understand the information it is the owner's responsibility to explain this material to them.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

All operators and mechanics should be trained. The owner is responsible for training the users.

-

Never let children or untrained people operate or service the equipment. Local regulations may restrict the age of the operator.

-

The owner/user can prevent and is responsible for accidents or injuries occurring to people or damage to property.

Preparation

-

Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Only use accessories and attachments approved by the manufacturer.

-

Wear appropriate clothing including substantial slip-resistant footwear, eye protection, and hearing protection. Tie long hair back and do not wear loose clothing or loose jewelry.

-

Inspect the area where the equipment is to be used and remove all objects such as rocks, toys, and wire which can interfere with the operation of the machine.

-

Check that operator's presence controls, safety switches, and shields are attached and functioning properly. Do not operate unless they are functioning properly.

Operation

-

Do not operate the machine when there is the risk of lightning.

-

Never run an engine in an enclosed area.

-

Only operate in good light, keeping away from holes and hidden hazards.

-

Be sure all drives are in neutral and parking brake is engaged before starting the engine. Only start the engine from the operator's position.

-

Be sure of your traction while using this machine, especially when backing up. Never operate on wet grass. Reduced traction could cause slipping.

-

Slow down and use extra care on hillsides. Be sure to travel side to side on hillsides. Turf conditions can affect the stability of the machine. Use caution while operating near drop-offs.

-

Slow down and use caution when making turns and when changing directions on slopes.

-

Do not change the engine governor setting or overspeed the engine.

-

Stop on level ground, engage the parking brake (if provided), and shut off the engine before leaving the operator's position for any reason.

-

Look behind and down before backing up to be sure of a clear path.

-

Never carry passengers on the machine.

-

Keep pets and bystanders away.

-

Slow down and use caution when making turns and crossing roads and sidewalks.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Use you full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Use care when loading or unloading the machine into or from a trailer or truck.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

-

Do not operate the machine without guards, shields, and safety devices in place and working.

-

Do not operate the machine when children and/or others are around.

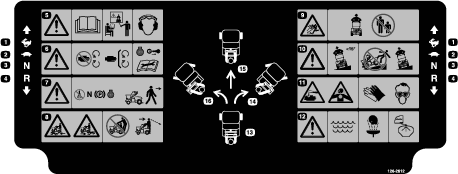

Chemical Safety

Warning

Chemical substances used in the spreader-sprayer system may be hazardous and toxic to you, bystanders, animals, plants, soils or other property.

-

Carefully read and follow the warning labels and Material Safety Data Sheets (MSDS) for all chemicals used and protect yourself according to the chemical manufacturer's recommendations. Ensure that as little skin as possible is exposed while using chemicals. Use appropriate personal protective equipment (PPE) to guard against personal contact with chemicals, such as:

-

eye protection and/or face shield

-

respirator or filter mask

-

chemical resistant gloves

-

rubber boots or other substantial footwear

-

hearing protection

-

clean change of clothes, soap, and disposable towels, to be kept on-hand, in the event of a chemical spill.

-

-

Keep in mind that there may be more than one chemical used, and information on each chemical should be assessed.

-

Refuse to operate or work on the spreader-sprayer if this information is not available!

-

Before working on a spreader-sprayer system, ensure that the system has been triple rinsed and neutralized according to the recommendations of the chemical manufacturer(s) and all of the valves have been cycled 3 times.

-

Verify there is an adequate supply of clean water and soap nearby, and immediately wash off any chemicals that contact you.

-

Obtain proper training before using or handling chemicals.

-

Use the correct chemical for the job.

-

Follow the manufacturer's instructions for the safe application of the chemical. Do not exceed recommended application pressure.

-

Do not fill, calibrate, or clean the unit when people, especially children, or pets are in the area.

-

Handle chemicals in a well ventilated area.

-

Have clean water available especially when filling the spray tank.

-

Do not eat, drink, or smoke while working with chemicals.

-

Do not clean spray nozzles by blowing through them or placing in mouth.

-

Always wash your hands and other exposed areas as soon as possible after you finish the working with chemicals.

-

Keep chemicals in their original packages and stored in a safe location.

-

Properly dispose of unused chemicals and chemical containers as instructed by the chemical manufacturer and your local codes.

-

Chemicals and fumes are dangerous; never enter the tank, hopper, or place your head over or in the opening for a tank or hopper.

-

Follow all local, state, federal regulations for spreading or spraying chemicals.

Safe Handling of Fuel

-

To avoid personal injury or property damage, use extreme care in handling gasoline. Fuel is extremely flammable and the vapors are explosive.

-

Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

-

Use only an approved fuel container.

-

Do not remove the fuel cap or add fuel with the engine running.

-

Allow the engine to cool before fueling.

-

Do not fuel the machine indoors.

-

Do not store the machine or the fuel container where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

-

Do not fill the containers inside a vehicle, on a truck, or on a trailer bed with a plastic liner. Always place the containers on the ground, away from your vehicle before filling.

-

Remove the machine from the truck or the trailer and fuel it on the ground. If this is not possible, then add the fuel with such equipment as a portable container rather than from a fuel-dispenser nozzle.

-

Keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete. Do not use a nozzle-lock open device.

-

If fuel is spilled on your clothing, change your clothing immediately.

-

Do not overfill the fuel tank. Replace the fuel cap and tighten it securely.

Maintenance and Storage

-

Disengage drives, set the parking brake, shut off the engine, remove the key and disconnect the spark-plug wire. Wait for all movement to stop before adjusting, cleaning or repairing the machine.

-

Clean grass and debris from the drives, the mufflers, and the engine to help prevent fires. Clean up oil, fuel, or hydraulic fluid spills.

-

Let the engine cool before storing.

-

Shut off the fuel while storing or transporting the machine. Do not store fuel near flames.

-

Park the machine on level ground and set the parking brake. Never allow untrained personnel to service the machine.

-

Use jack stands to support components when required.

-

Carefully release pressure from components with stored energy.

-

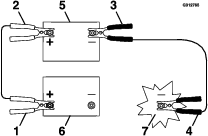

Disconnect the battery or the spark-plug wire before making any repairs. Disconnect the negative terminal first and the positive terminal last. Connect the positive terminal first and negative terminal last.

-

Keep hands and feet away from moving parts. If possible, do not make adjustments with the engine running.

-

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

Hauling

-

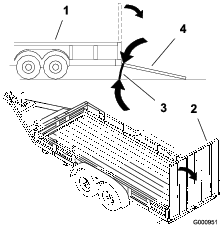

Use care when loading or unloading the machine into a trailer or truck.

-

Use full-width ramps for loading the machine into a trailer or truck.

-

Tie the machine down securely using straps, chains, cable, or ropes. Both front and rear straps should be directed down and outward from the machine.

Toro Spreader Sprayer Safety

The following list contains safety information specific to Toro products and other safety information you must know.

General Operation

-

Check carefully for overhead clearances (i.e. branches, doorways, electrical wires, etc.) before operating under any objects, and do not contact them.

-

Use caution when you are riding on the platform and driving the machine over curbs, rocks, roots, or other obstructions.

-

Do not jerk the controls; use a steady motion.

-

Do not carry passengers.

-

Do not carry equipment on the machine.

Sprayer and Spreader Operation

Warning

The spray wand traps liquids under high pressure, even when engine is off. High-pressure spray could cause serious injury or death.

-

Keep clear of nozzle and do not direct spray or stream at people, pets, or non-work area property.

-

Do not direct spray on or near electrical-power components or source.

-

Do not attach hoses or other components to the end of the spray-wand nozzle.

-

Do not attempt to disconnect the spray wand from the unit while the system is pressurized.

-

Do not use spray wand if trigger lock is damaged or missing.

-

Do not keep spray wand in locked-open position when job is complete.

-

Do not touch the impeller for the spreader while the impeller is rotating.

-

Stop spreading/spraying when making tight turns to minimize an uneven distribution pattern, application rate, and chemical drift.

-

Chemicals may drift and cause injury to people and animals; it may also damage plants, soil, or other property.

-

Liquid loads and granular materials can shift. This shifting happens most often while turning, going up or down hills, suddenly changing speeds, or while driving over rough surfaces. Shifting loads can cause the unit to tip over.

-

Safely relieve pressure from spray wand every time engine is shut off.

-

When draining or relieving system, do not let anyone stand in front of nozzles and do not drain on a person’s feet.

-

Do not repair spray wand, hoses, seals, nozzle, or other wand components; replace them.

Slope Operation

Use extreme caution when spreading or spraying chemicals and/or turning on slopes as loss of traction and/or tip-over could occur. The operator is responsible for safe operation on slopes.

-

Remove or mark obstacles such as rocks, tree limbs, etc., from the area on which you are spreading or spraying chemicals.

-

Watch for holes, ruts or bumps.

Note: Tall grass can hide obstacles.

-

Use caution near drop-offs, ditches, or embankments.

Note: The machine could suddenly turn over if a wheel goes over the edge of a cliff or ditch, or if an edge caves in.

-

Be aware that operating on wet grass, across steep slopes or downhill may cause the machine to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering.

-

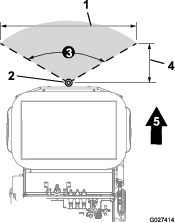

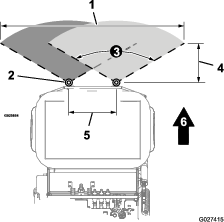

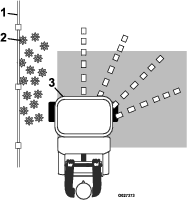

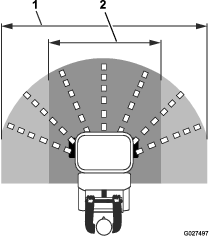

Do not spread or spray chemicals on slopes greater than 15 degrees; refer to Figure 3 to determine the approximate slope angle of the work area.

-

Avoid sudden starts and stops when spreading or spraying chemicals uphill because the machine may tip backward.

Note: The machine is more stable driving uphill.

-

Keep all movement on slopes slow and gradual.

-

Do not make sudden changes in speed or direction.

-

Follow the manufacturer’s recommendations for wheel weights or counter weights to improve stability.

-

Use extra care with attachments.

Note: Use of attachments can change the stability of the machine.

Service

-

To ensure safe, optimal performance of the machine, use only genuine Toro replacement parts. Replacement parts made by other manufacturers could be dangerous, and such use could void the product warranty.

-

Never remove or tamper with safety devices. Check their proper operation regularly. Never do anything to interfere with the intended function of a safety device or to reduce the protection provided by a safety device.

-

Check brake operation frequently. Adjust and service as required.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Setup

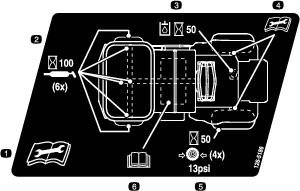

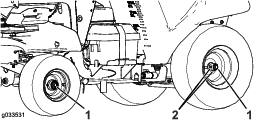

Checking the Tire Pressure

Front and Rear Tire Pressure: 83 to 97 kPa (12 to 14 psi)

-

Check the air-pressure in the front and rear tires.

-

If the air-pressure in the tires need adjustment, inflate the tires to 83 to 97 kPa (12 to 14 psi).

Checking the Engine-Oil Level

The engine is shipped with oil; check the engine-oil level and, if necessary, add to the appropriate level. Refer to Checking the Engine-Oil Level for instructions and the oil specification.

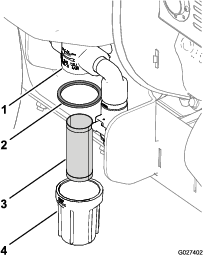

Checking the Transaxle-Fluid Level

Transaxle Oil Type: Toro® HYPR-OIL™ 500 hydraulic fluid or Mobil® 1 15W-50

The Transaxle is shipped with fluid; check transaxle-fluid level in the expansion tank, and if necessary, add to the appropriate level; refer to Servicing the Transaxle

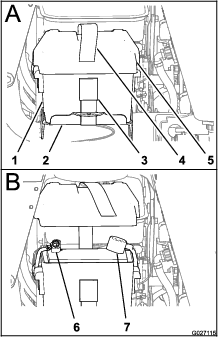

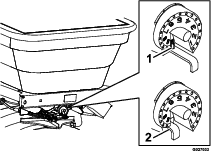

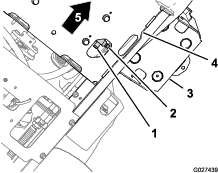

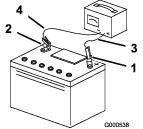

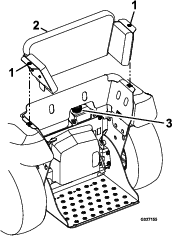

Connecting the Battery

-

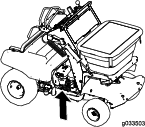

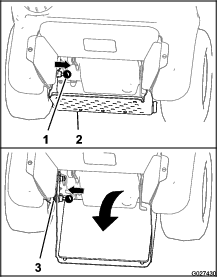

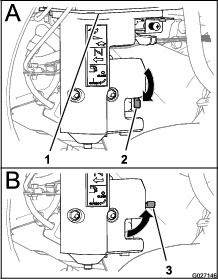

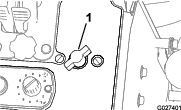

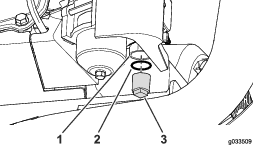

Remove the battery cover from the battery box (Figure 3).

-

Install the negative battery cable to the negative (–) battery terminal with a flanged bolt and flanged nut (Figure 3).

-

Install the positive battery cable to the positive (+) battery terminal with a flanged bolt and flanged nut (Figure 3).

-

Install the cover on the battery box and secure the cover and box to the battery tray with the battery strap (Figure 3).

Product Overview

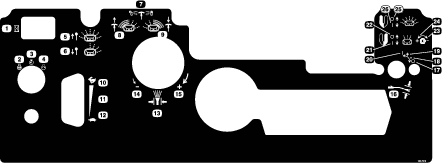

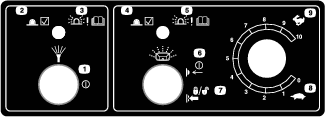

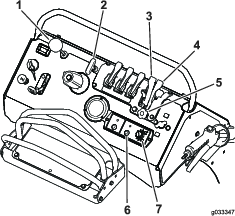

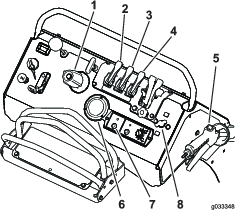

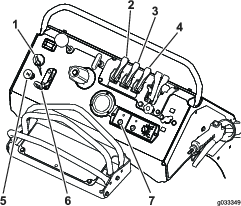

Machine Controls

Steering Control

The steering control is located behind the control console (see Figure 6).

-

Move the steering control to the right or left to steer the machine to the right or left respectively.

-

Moving the steering control to the center allows the machine to steer straight.

Motion-Control Lever

The motion-control lever, located in the center of the steering control, controls the forward and reverse motion of the machine (see Figure 6).

-

Move the motion-control lever forward or backward to drive the machine respectively.

Note: The machine speed is proportional to the amount that you move the motion-control lever.

-

When you move the motion-control lever to the center position, the machine should stop.

Note: When you release the motion-control lever, it should return to the NEUTRAL position.

Important: If the motion-control lever does not return to the NEUTRAL position when you release it, contact an Authorized Service Dealer.

Throttle Control

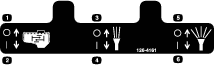

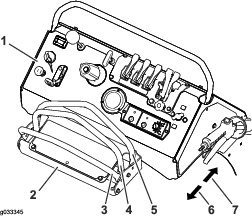

The throttle control (the red lever) is located at the left side of the control console (Figure 7).

Choke Control

The choke control is located at the left side of the control console, and is used to aid in starting a cold engine (Figure 7).

Note: Do not start or run a warm engine with the choke in the ON position.

-

Pull up on the choke control to set the choke to the ON position.

-

Push down on the choke control to set the choke to the OFF position.

Ignition Switch

The ignition switch is located at the left side of the control console (Figure 7).

Use the ignition switch to start and shut off the engine. The ignition switch has three positions, OFF, ON and START.

Note: You must have the parking brake set in order to start the engine.

Hour Meter

The hour meter is located above the ignition switch at the left side of the control console (Figure 7).

The hour meter records the number of hours that the machine has operated.

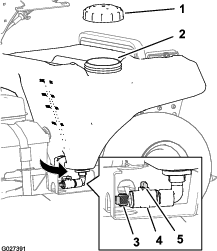

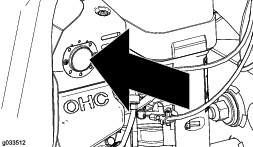

Fuel-Shut-Off Valve

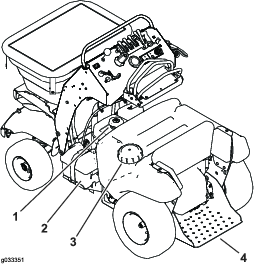

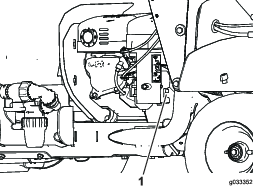

The fuel-shut-off valve is located at the front, right side of the engine below the fuel tank (Figure 8).

Note: Close the fuel-shut-off valve when the machine is not used for a few days, during transport to and from the job site, or when the machine is parked inside a building.

Parking-Brake Lever

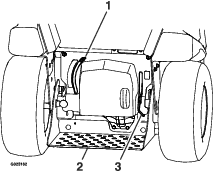

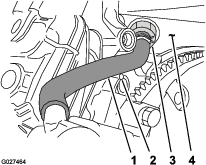

The parking-brake lever is located above the platform on the right side (Figure 9).

-

To set the parking brake, push the parking-brake lever down.

Note: The brake lever engages a parking brake in the transaxle.

-

To release the parking brake, pull the lever up.

Note: When parking on a steep slope, chock or block the wheels in addition to setting the parking brake. When transporting the machine, set the parking brake and bind the machine to the transport vehicle.

Drive-Wheel-Release Lever

The drive-wheel-release lever is located above the platform on the left side (Figure 9).

Use the drive-wheel-release lever to disengage the hydrostatic-drive system to move the machine by hand.

-

To push or pull the machine, move the drive-wheel-release lever up.

-

To operate the machine, move the drive-wheel-release lever down.

Spreader Controls

Deflector Gate Control

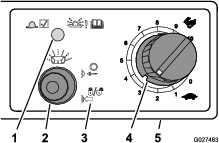

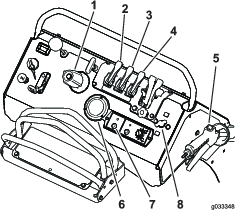

The deflector-gate control is located to the right of the hour meter on the control console (Figure 10).

Use the deflector-gate control to temporarily stop the discharge of granular materials from the left side of the spreader. Close the deflector gate with the control when it is not desirable to broadcast granular materials onto sidewalks, parking lots, or patios.

-

Push the knob for the deflector-gate control down to close the gate and temporarily deflect the granular materials.

-

Pull the knob up to open the deflector gate for full granular broadcasting.

Spreader-Pattern Control

The spreader-pattern control is located to the right of the deflector-gate control at the control console (Figure 10).

Use the spreader-pattern control to broadcast a heavier pattern of granular material to the left or right side of the machine.

-

To broadcast a heavier pattern to the left, unlock the spreader-pattern control, pull the control up slightly, and lock the control.

-

To broadcast a heavier pattern to the right, unlock the spreader-pattern control, push the control down slightly, and lock the control.

Wide-distribution Impeller-Gate Lever

The wide-distribution impeller-gate lever is the 4th lever located at the top center of the control console (Figure 10).

-

To broadcast a wide pattern of granular material, pull the wide-distribution impeller-gate lever rearward fully to the full open position.

-

To close the impeller gate, push the wide-distribution impeller-gate lever forward full closed position.

Narrow-distribution Impeller-Gate Lever

The narrow-distribution impeller-gate lever is the 5th lever located at the top center of the control console (Figure 10).

-

To broadcast a narrow pattern of granular material, pull the narrow-distribution impeller-gate lever rearward fully to the limited OPEN position.

-

To close the impeller gate, push the wide-distribution impeller-gate lever forward fully.

Note: Only the wide-distribution impeller-gate lever will close the impeller gate. Pushing the wide-distribution impeller-gate lever forward will also reset the narrow-distribution impeller-gate lever to the forward position.

Narrow-Spreader Distribution Flow-Rate Knob

The narrow-spreader distribution flow-rate knob is located below the wide- and narrow-impeller-gate levers (Figure 10).

Use the narrow-spreader distribution-flow-rate knob to control the discharge rate of granular material from the hopper onto the impeller when the narrow-distribution impeller-gate lever is in the OPEN position (limited).

-

Rotate the narrow-spreader distribution-flow-rate knob clockwise to decrease the discharge rate of granular material from the hopper.

-

Rotate the distribution flow-rate-knob counterclockwise to increase the discharge rate of granular material from the hopper.

Impeller On/Off Switch

The impeller On/Off switch is located below the impeller-distribution flow-rate knob at the bottom of the control console (Figure 10).

Use the impeller On/Off switch to run the electric motor that drives the impeller.

-

Press the impeller On/Off switch up to run the impeller.

-

Press the impeller On/Off switch down to stop the impeller.

Impeller-speed Control

The impeller-speed control is located to the right of the impeller On/Off switch at the bottom of the control console (Figure 10).

Use the impeller-speed control to adjust the rotational speed of the impeller.

-

Rotate the impeller-speed control counterclockwise to decrease the rotational speed of the impeller.

-

Rotate the impeller-speed control clockwise to increase the impeller speed.

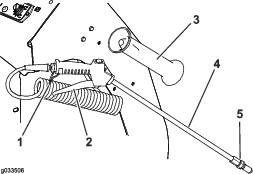

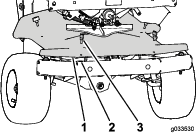

Drop-rate Cam and Linkage

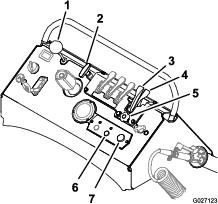

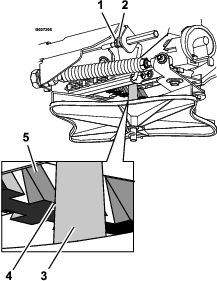

The drop-rate cam and linkage is located at the front of the machine and below the hopper on the spreader (Figure 11).

Use the drop-rate cam to set the maximum amount of material to be dispensed through the impeller gate and onto the impeller.

The slot in the cam, after setting 9 on the cam, allows the impeller gate to be opened to the maximum position. This setting can be used for dry sand, ice melt, or other materials that are difficult to spread.

Note: Use cam setting 9 may when you are cleaning out the hopper.

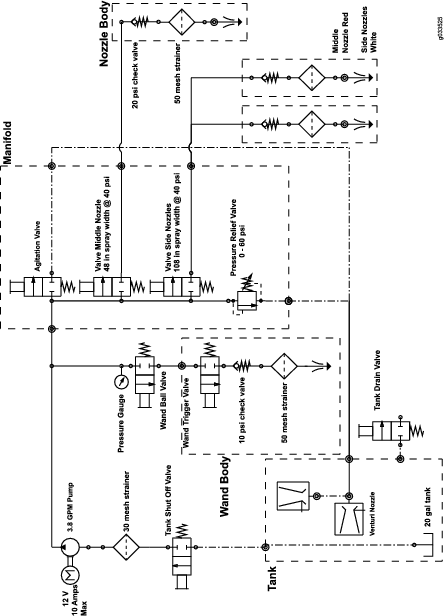

Sprayer Controls

Sprayer Pressure Control

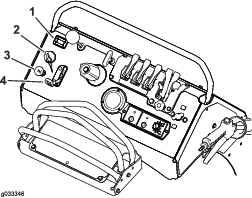

The sprayer-pressure control is located on the control console (Figure 12).

-

Rotate the sprayer-pressure control clockwise to increase the pressure to the sprayer nozzles

-

Rotate the pressure-control counterclockwise to the decrease nozzle pressure.

Tank Agitation Lever

The tank-agitation lever is located on the control console (Figure 12).

Setting the tank-agitation lever to the ON position allows the sprayer pump to circulate the content in the spray tank in order to keep the chemical solution mixed.

-

Pull the tank-agitation lever rearward to circulate the content in the spray tank.

-

Push the lever forward to stop circulating the content in the spray tank.

Note: Agitation is not meant to be used while spraying. Shut off the tank agitation to ensure proper spray distribution.

Note: Run the engine speed above idle and run the sprayer pump for the tank agitation to work effectively.

Narrow-Spray Pattern Lever

The narrow-spray pattern lever is located on the control console (Figure 12).

-

Pull the narrow-spray pattern lever toward you to turn on the sprayer in a narrow-spray pattern (the center nozzle only).

-

Push the narrow-spray pattern lever away from you to turn off the sprayer.

Wide-Spray Pattern Lever

The wide-spray pattern lever is located on the control console (Figure 12).

-

Pull the wide-spray pattern lever toward you to turn ON the sprayer in a wide-spray pattern (the right and left nozzles).

-

Push the wide-spray pattern lever away from you to turn OFF the sprayer.

Sprayer-Pressure Gauge

The sprayer-pressure gauge is located on the control console (Figure 12).

Use the pressure gauge to see the fluid pressure in the sprayer system.

Sprayer-Pump Switch

The sprayer-pump switch is located on the control console (Figure 12).

Use the sprayer-pump switch to start and stop the pump when spraying or circulating the fluid in the sprayer tank.

-

Push down on the top of the sprayer-pump switch to start the pump.

-

Push down on the bottom of the switch to stop the pump.

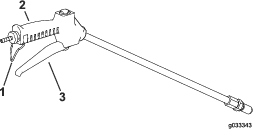

Spray-Wand Trigger and Trigger Lock

The spray-wand trigger and trigger lock are located on the bottom of the spray-wand handle (Figure 12 and Figure 13).

-

To use the spray wand, hold the handle of the wand squeeze the trigger.

-

To lock the trigger to the ON position, fully squeeze the trigger against the handle and then latch the trigger lock over the trigger; to unlock the trigger, unlatch the trigger lock from the trigger.

-

Release the trigger to stop the spray.

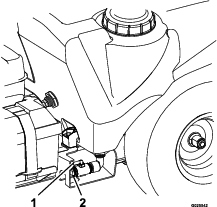

Tank Drain Valve

The tank drain valve is located at the left side and under the sprayer tank (Figure 15).

Use the tank drain valve to empty the sprayer tank of liquid chemicals.

-

Rotate the handle of the tank drain valve 90° clockwise (lever in-line with valve) to open the valve.

-

Rotate the handle 90° counterclockwise to close the valve.

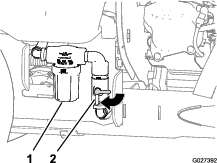

Sprayer-Pump-Supply Valve

The sprayer-pump-supply valve is located at the right side of the machine and under the sprayer tank (Figure 15).

Use the sprayer-pump-supply valve to shut off the flow of liquid chemicals to the pump.

-

Rotate the handle of the tank drain valve 90° clockwise (lever in-line with valve) to open the valve.

-

Rotate the handle 90° counterclockwise to close the valve.

| Overall width | 90 cm (35.5 inches) | |

| Overall length | 171 cm (67.5 inches) | |

| Overall height | 131 cm (51.5 inches) | |

| Weight | sprayer tank and hopper empty | 227 kg (500 lb) |

| only hopper full | 307 kg (676 lb) | |

| only sprayer tank full | 309 kg (682 lb) | |

| sprayer tank and hopper empty and 1 extra bag of granular material in the tank | 412 kg (909 lb) | |

| Maximum machine weight | loaded machine + operator | ≤ 513 kg (1130 lb) |

| Hopper capacity | 79 kg (175 lb) | |

| Sprayer tank capacity | 76 L (20 US gallon) | |

| Maximum ground speed | forward | 9 kph (5.5 mph) |

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

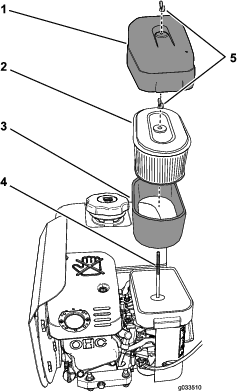

Checking the Engine-Oil Level

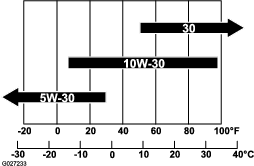

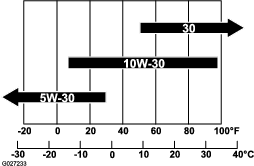

Oil Type: Detergent oil (API service SJ or higher)

Oil viscosity: Refer to the table below.

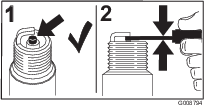

Important: Do not operate the engine with the oil level below the Low (or Add) mark on the dipstick, or over the Full mark.

-

Move the machine to a level surface.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position

-

Allow the engine to cool.

-

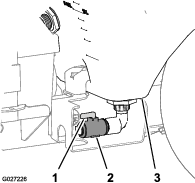

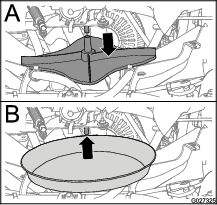

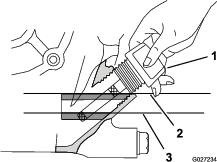

Remove the dipstick from the engine and wipe the dipstick with a clean rag (Figure 17).

-

Insert the dipstick from the engine as shown in Figure 17.

Note: Do not thread the dipstick into the filler neck when checking the engine oil level.

-

Remove the dipstick from the filler neck and look at the oil level in the dipstick (Figure 17).

Note: The engine oil level must cover between the hatch marked areas on the dipstick (Figure 17).

-

If the oil level is low, wipe off the area around the filler neck and add the specified oil until the oil level is between the hatch marked areas on the dipstick.

Important: Do not overfill the engine with oil.

-

Hand tighten the dipstick into the filler neck (Figure 17).

Adding Fuel

Fuel tank capacity: 6.1 L (1.6 US gallons)

-

For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method).

-

ETHANOL: Gasoline with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. Ethanol and MTBE are not the same. Gasoline with 15% ethanol (E15) by volume is not approved for use. Never use gasoline that contains more than 10% ethanol by volume, such as E15 (contains 15% ethanol), E20 (contains 20% ethanol), or E85 (contains up to 85% ethanol). Using unapproved fuel may cause performance problems and/or engine damage which may not be covered under warranty.

-

Do not use gasoline containing methanol.

-

Do not store fuel either in the fuel tank or fuel containers over the winter unless a fuel stabilizer is used.

-

Do not add oil to the fuel.

Danger

In certain conditions, fuel is extremely flammable and highly explosive. A fire or explosion from the fuel can burn you and others and can damage property.

-

Fill the fuel tank outdoors, in an open area, and when the engine is cold. Wipe up any fuel that spills.

-

Do not fill the fuel tank completely full. Add fuel to the tank until the level is 6 to 13 mm (1/4 to 1/2 inch) below the bottom of the filler neck. This empty space in the tank allows the fuel to expand.

-

Never smoke when handling fuel, and stay away from an open flame or where a spark may ignite the fumes.

-

Store the fuel in an approved container and keep it out of the reach of children.

-

Never buy more than a 30-day supply of gasoline.

Danger

In certain conditions during fueling, static electricity can be released causing a spark which can ignite the gasoline vapors. A fire or explosion from the fuel can burn you and others and can damage property.

-

Always place the fuel containers on the ground away from your vehicle before filling.

-

Do not fill the fuel containers inside a vehicle or on a truck or trailer bed because interior carpets or plastic truck bed liners may insulate the container and slow the loss of any static charge.

-

When practical, remove equipment from the truck or trailer and refuel the equipment with its wheels on the ground.

-

If this is not possible, then refuel the equipment on a truck or trailer from a portable container, rather than from a fuel dispenser nozzle.

-

If you must use a fuel-dispenser nozzle, keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

Warning

Fuel is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious injury and illness.

-

Avoid prolonged breathing of vapors.

-

Keep face away from nozzle and gas tank or conditioner bottle opening.

-

Avoid contact with skin; wash off spillage with soap and water.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to provide the following benefits:

-

Keeps fuel fresh during storage of 90 days or less. For longer storage it is recommended that the fuel tank be drained.

-

Cleans the engine while it runs

-

Eliminates gum-like varnish buildup in the fuel system, which causes hard starting

Important: Do not use fuel additives containing methanol or ethanol.

Add the correct amount of gas stabilizer/conditioner to the gas.

Note: A fuel stabilizer/conditioner is most effective when mixed with fresh fuel. To minimize the chance of varnish deposits in the fuel system, use fuel stabilizer at all times.

Fueling the Machine

Note: Refueling the engine is difficult when using a larger refueling container such as a container with a 19 L (5 US gal) capacity.To make fueling the machine easier use the following equipment:

-

a fuel container with approximately a 4 to 8 L (1 to 2 US gal) capacity

-

a funnel

-

Clean around the fuel tank cap.

-

Remove the cap from the tank.

-

Fill the fuel tank with unleaded gasoline to within 6 to 13 mm (1/4 to 1/2 inch) from the top of the tank. Do not fill into the filler neck.

Important: Do not fill the tank more than 6 mm (1/4 inch) from the top of the tank because the gasoline must have room to expand.

-

Install the fuel-tank cap and wipe up any spilled fuel.

Checking the Safety Interlock System

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Caution

If interlock switch is disconnected or damaged the machine could operate unexpectedly causing personal injury.

-

Do not tamper with the interlock switch.

-

Check the operation of the interlock switch daily and replace damaged switch before operating the machine.

Important: It is essential that the safety mechanisms on your machine are connected and in proper operating condition prior to operating your machine.

The safety interlock system is designed to prevent the engine from starting unless the parking brake is set.

Testing the Starter Interlock

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Move the machine to a level surface.

-

Chock the wheels of the machine.

-

Disconnect the spark-plug wires.

-

Release the parking brake.

-

With the motion-control lever in the NEUTRAL position turn the key to the START position.

Note: The starter must not rotate the engine.

-

If the starter rotates the engine of your machine—the machine does not pass this test, do not operate it. Contact your authorized Toro service distributor.

-

If the starter does not rotate the engine—the machine does pass the test: Set the parking brake, connect the spark-plug wire to the spark plug, and remove the chock(s) from the wheels.

-

Checking the Machine for Loose Hardware

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Shut off engine, wait for all moving parts to stop, remove key, and set parking brake.

-

Visually inspect machine for damaged or worn parts, and check for loose hardware.

Note: Replace any damaged parts and tighten all loose hardware before operating the machine.

Operating the Machine

Caution

Chemicals are hazardous and can cause personal injury.

-

Read the chemical manufacture’s directions on the label before handling the chemicals; follow all manufacturer recommendations and precautions.

-

Keep chemicals away from your skin. Should contact occur, wash the affected area thoroughly with soap and clean water.

-

Wear eye protection, gloves, and any other protective equipment recommended by the chemical manufacturer.

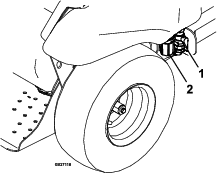

Extending and Retracting the Operator’s Platform

Extending the Operator’s Platform

Extend the platform as follows:

-

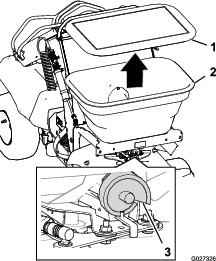

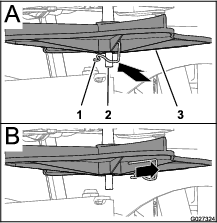

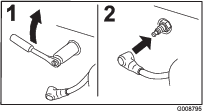

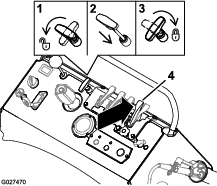

Pull inward the knob for the platform lock until the pin of the lock clears the upper hole in the chassis (Figure 18).

-

Rotate the operator’s platform down until the pin of the platform lock is aligned with the lower hole in the chassis (Figure 18).

-

Move the knob for the platform lock outward until the pin for the lock is protruding through the lower hole (Figure 18).

Retracting the Operator’s Platform

-

Pull inward the knob for the platform lock until the pin of the lock clears the upper hole in the chassis (Figure 18).

-

Rotate the operator’s platform up until the pin of the platform lock is aligned with the upper hole in the chassis (Figure 18).

-

Move the knob for the platform lock outward until the pin for the lock is protruding through the upper hole (Figure 18).

Opening and Closing the Fuel-Shut-Off Valve

Control fuel flow to the engine with the fuel-shut-off valve as follows:

-

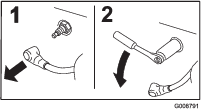

Rotate the handle for the fuel-shut-off valve 90 degrees clockwise to the open the valve.

-

Rotate fuel-shut-off valve handle 90 degrees counterclockwise to close the valve.

Starting the Engine

-

Ensure that the fuel-shut-off valve is open; refer to Opening and Closing the Fuel-Shut-Off Valve.

-

Move the steering-control/motion-control lever in NEUTRAL position and set the parking brake; refer to Steering Control, Motion-Control Lever, and Parking-Brake Lever.

Note: To start the engine, the parking brake must be set. (The operator can start the engine while he or she is off the platform.)

-

Move the throttle lever midway between the SLOW and FAST positions; refer to Throttle Control.

-

If the engine is cold, pull up the choke control to the ON position; refer to Choke Control.

Note: If the engine is warm , push down the choke lever to the OFF position.

-

Rotate the ignition switch to the START position; refer to Ignition Switch.

Note: Release the switch as soon as the engine starts.

Important: Do not crank the engine continuously for more than ten seconds at a time. If the engine does not start, allow a 60 second cool-down period between starting attempts. Failure to follow these guidelines can burn out the starter motor

-

If the choke control is in the ON position, gradually move the lever down, toward the OFF position as the engine warms up.

Shutting Off the Engine

-

Move the steering-control/motion-control lever to the NEUTRAL position and bring the machine to a full stop; refer to Steering Control and Motion-Control Lever.

-

Place the throttle in the midway between the SLOW and FAST positions; refer to Throttle Control.

-

Allow the engine to run for a minimum of 15 seconds, then turn the ignition switch to the OFF position to shut off the engine; refer to Ignition Switch.

Note: You must have the parking brake in the released position to shut off the engine.

-

Set the parking brake; refer to Parking-Brake Lever.

-

Remove the key to prevent children or other unauthorized persons from starting the engine.

-

Close the fuel-shut-off valve when the machine will not be in use for a few days, when transporting, or when the machine is parked inside a building; refer to Opening and Closing the Fuel-Shut-Off Valve.

Driving the Machine

Caution

Machine can turn rapidly by moving the steering control to the far right or left. Operator may lose control of the machine, which may cause damage to the machine or injury.

-

Use caution when making turns.

-

Slow down the machine before making sharp turns.

Important: If the motion-control lever does not return to the NEUTRAL position when you release it, contact an Authorized Service Dealer.

Important: To begin moving the machine (forward or backward), the brake lever must be released (pulled up) before you move the motion-control lever.

Driving the Machine Forward

-

Move the motion-control lever to the NEUTRAL position.

-

Release the parking brake.

-

To drive the machine, perform the following:

-

To move the machine forward in a straight line, center the steering control and move the motion-control lever forward.

Note: The machine will move faster the farther the motion-control lever is moved from the NEUTRAL position.

-

To turn left or right, move the steering control toward the desired turn direction.

-

To stop the machine, move the motion-control lever in the NEUTRAL position.

Note: Stopping distance may vary depending on the spreader-sprayer load.

Note: When you release the motion-control lever, it automatically returns to the NEUTRAL position.

-

Driving the Machine in Reverse

-

Move the motion-control lever to the NEUTRAL position.

-

To move the machine rearward in a straight line, slowly move the motion-control lever rearward.

To turn left or right, move the steering control toward the desired turn direction.

-

To stop the machine, move the motion-control lever to the NEUTRAL position.

Note: Stopping distance may vary depending on the spreader-sprayer load.

Operating the Spreader

Caution

Chemicals are hazardous and can cause personal injury.

-

Read the chemical manufacture’s directions on the label before handling the chemicals; follow all manufacturer recommendations and precautions.

-

Keep chemicals away from your skin. Should contact occur, wash the affected area thoroughly with soap and clean water.

-

Wear eye protection, gloves, and any other protective equipment recommended by the chemical manufacturer.

Use the spreader to disperses free-flowing granular substances such as grass seed, fertilizer, ice melt, etc. When you use the spreader, first fill the granular hopper, then apply the granular materials to the work site, and finally clean the hopper. It is important to complete all three of these steps to avoid damaging the spreader.

Note: When you use your spreader, thoroughly clean it at the end of the day.

Before Operating the Spreader

Before you start using the spreader, ensure that the spreader has been calibrated for the material that you will disperse; refer to Calibrating the Spreader.

Important: Verify that the proper application rate has been set on the spreader prior to filling the hopper.

Calibrating the Spreader

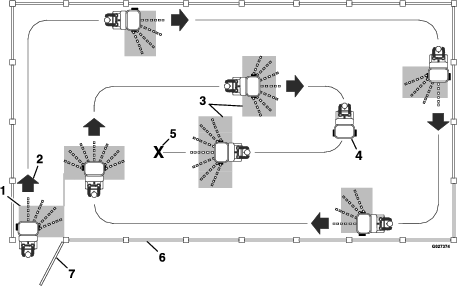

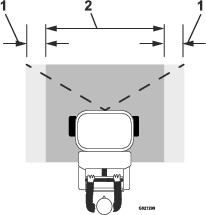

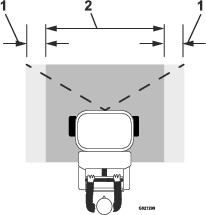

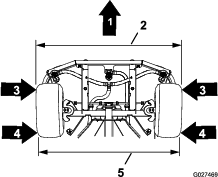

Calibrate the spreader each time a new material is used. The spreader can broadcast material in a pattern 1.5 to 6.7 m (5 to 22 ft) wide depending on the material particle size, volume/density, and rate of travel, and wind conditions.

Refer to the spreading charts along with Determining the Distribution Pattern, Determining the Effective Spreading Width, and Calculating the Application Rate sections to calibrate the machine.

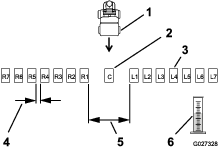

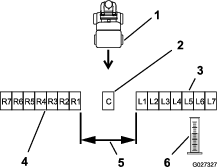

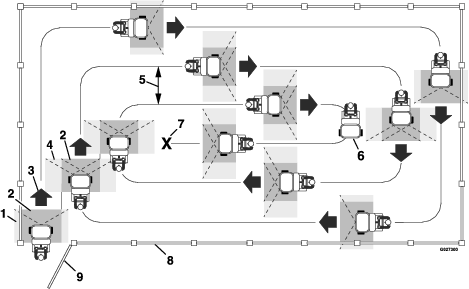

Determining the Distribution Pattern

Operator supplied equipment: 15 shallow collection pans and 15 graduated measuring cylinders

The most accurate method to measure the distribution is to use shallow collection pans and graduated measuring cylinders. In the example below, 15 shallow collection pans approximately 30 cm (12 inches) wide, 91 cm (36 inches) long, and 5 cm (2 inches) tall are used.

-

Allow ample driving distance before the area where the collection pans are located to ensure that the machine is traveling at the desired speed (for spreading) before the machine reaches the collection pans.

-

Place one pan in the center of the drive path. Arrange the next two pans, one on each side, far enough apart to allow adequate room for the drive tires of the machine to pass around the center pan.

-

Place the remaining pans in a straight line as shown in Figure 22 or Figure 23.

-

Set the drop rate cam to the recommended application rate; refer toSpreading Charts to determine the appropriate drop-rate cam setting.

-

Fill the hopper approximately half-full with the desired material; refer to Filling the Spreader Hopper.

-

Set the spreader pattern control to the middle of its travel; refer to Adjusting the Spreader Pattern.

-

Set the impeller speed to the appropriate broadcasting rate.

-

Pull the wide distribution granular gate control to the open position and drive the spreader, at the appropriate speed, over the center pan.

Note: Repeat broadcasting over the test site several times, moving in the same direction each time, until enough material is dispensed to the collection pan to fill a graduated cylinder half full

-

Label each graduated measuring cylinder to correspond with the distribution pans (i.e. ...L2, L1, Center, R1, R2...); refer to Figure 22 and Figure 23.

-

One at a time, take a collection pan and dump the contents into the corresponding graduated cylinder. Record the amount of material collected and return the pan to its location. Repeat this until all pan contents have been emptied.

-

With the graduated measuring cylinder in the same straight line as the pans, evaluate the volume of material in each cylinder to determine the quality of the distribution from the spreader.

-

To adjust the spreader pattern, refer to the Adjusting the Spreader Pattern.

-

Repeat steps 5 through 12 until an uniform pattern is achieved.

Determining the Effective Spreading Width

The effective width is used to determine the uniform distribution of the material.

Note: The spreading width range is 6 to 8 m (20 to 25 ft).

-

After the spreader pattern is correctly adjusted, evaluate the amount of material in the center graduated measuring cylinder.

-

Locate the two tubes, one each side of center, that contain 1/2 the measured amount of the material that you observed in the center graduated cylinder.

-

Go to the two corresponding pans. Starting from the outer edge, measure and record the distance between left pan, through the center pan, to the outer edge of the right pan.

Note: This measurement is the effective spreading width.

Calculating the Application Rate

-

Determine the area and amount of material that you are applying to the job site.

-

Determine the calibration course length as follows:

-

Initially, use the recommended rate indicated in theSpreading Charts section or the rate recommended on the product manufacturer’s label as a guide to help determine the amount of material that you would spread over a 93 m2 (1,000 ft2) area.

-

Determine a course length by dividing 93 m2 (1,000 ft2) by the effective spread width.

Note: For example, if the effective width is 1.8 meters (6 feet), then the calibration course length equals 51 m (167 ft).

Course Length

93 m2(1,000 ft2) = 51 m (167 ft) 1.8 m (6 ft) -

The calibration course is 1.8 m (6 ft) by 51m (167 ft).

-

Measure and visibly mark the course length. Ensure that you allow enough distance before the starting marker so that the spreader moving forward at full speed when crossing the first mark of the course.

-

-

Set the appropriate drop-rate cam setting; refer to the Spreading Charts as a starting point.

-

Add material to the hopper (for example, add 11.3 kg (25 lb) add of material).

-

Drive the spreader over the calibration course while applying the material.

-

Empty the remaining material of the hopper into a clean bucket; refer to Emptying the Hopper.

-

Weigh the bucket containing the material and record the weight. Pour the contents back into the hopper and then weigh the empty bucket. Subtract these two amounts to determine the amount of material remaining in the hopper—for example, 9 kg (20 lb) of material is remained in the hopper after applying the material to the test course.

-

Subtract the amount remaining in the hopper (step 7) from the amount originally added (step 4); the result is the amount applied to the course.

Amount Applied

11.3 kg (25 lb) – 9 kg (20 lb) = 2.3 kg (5 lb)

For this example, 2.3 kg (5 lb) of material was applied to the 93 m2 (1,000 ft2) test course.

-

If necessary, adjust the drop-rate cam to achieve the recommended application rate. Once the correct application rate is achieved, repeat this procedure an additional time to verify your results.

Important: Designate a new calibration course each time, so the turf is not damaged by excessive application of material.

Using the Spreader

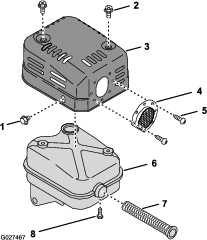

Filling the Spreader Hopper

Maximum hopper weight capacity: 79 kg (175 lb)

-

Drive the machine to the work site.

-

Move the machine to a level surface, move motion-control lever to the NEUTRAL position, shut off the engine, and set the parking brake.

-

Ensure that the wide-distribution impeller-gate lever is in the fully forward (closed) position; refer to Wide-distribution Impeller-Gate Lever.

-

Use the Spreading Charts to determine the setting for the drop-rate cam (Figure 24).

Note: If the setting is not listed for the type of material that you are using, set the cam to the setting with a lower value then adjust as needed.

-

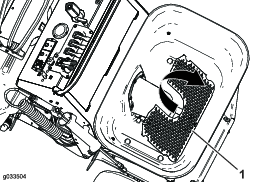

Remove the cover from the hopper, add the material to be spread, and install the cover onto the hopper (Figure 24).

Note: Do not overload the hopper; the maximum weight capacity of the hopper is 79 kg (175 lb).

Note: One extra bag of granular product may be placed on top of the sprayer tank; however, this is not recommended if the operator is heavy.

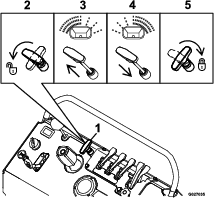

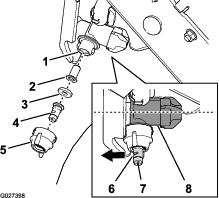

Emptying the Hopper

-

Move the machine to a level surface, move motion-control lever to the NEUTRAL position, shut off the engine, and set the parking brake.

-

Empty the hopper by scooping out as much of the material as possible.

-

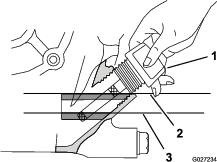

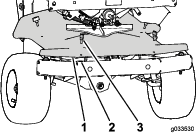

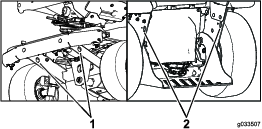

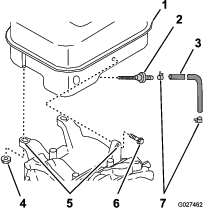

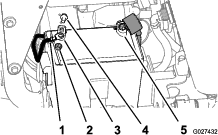

Remove the 4 thumb screws that secure the front cover ( below the impeller) to the chassis and remove the cover (Figure 25).

-

Remove the drive pin that secure the impeller to the shaft of the impeller motor and remove the impeller from the shaft (Figure 26 and Figure 27).

-

Place a shallow pan under the shaft of the impeller motor (Figure 27).

-

Open the hopper gate as follows:

-

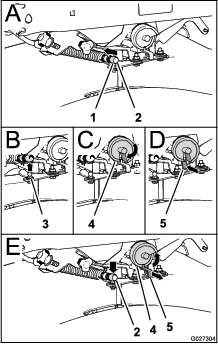

Push the locking sleeve for the gate cable rearward and lift the cable up from the ball stud of the rate-gate linkage (Figure 28).

-

Pull the cable off the ball stud (Figure 28).

-

Rotate the drop-rate cam past the position 9 so that the slot in the cam is aligned with the linkage (Figure 28).

-

Fully push the linkage rearward (Figure 28).

-

-

Allow the remaining material in the hopper to pour into the shallow pan and then remove the pan.

-

Connect the hopper-gate cable as follows:

-

Assemble impeller onto the impeller shaft and secure the impeller with the drive pin.

-

Align the holes in the front cover with the clip nuts in the chassis and secure the cover with the 4 thumb nuts that you removed in 3.

Spreading Charts

Note: The cam setting tables for pellet material and the grass seed are provided with permission from the Brinly-Hardy Company; reference the Brinly-Hardy Company website for more information.

These charts are to be used as an approximate guideline only. Other factors, such as weather conditions, spreader operation, and the condition of material, will affect your results.

| Type | kg per 93 m2 (lb per 1,000 ft2) | Cam Setting — One Pass | Cam Setting — Two Passes |

| Fine Pellets | 0.5 (1) | 3.6 | 3.1 |

| 0.9 (2) | 4.0 | 3.5 | |

| 1.4 (3) | 4.2 | 3.7 | |

| Mixed Fine Pellets | 0.9 (2) | 3.7 | 3.2 |

| 1.8 (4) | 4.7 | 4.1 | |

| 2.7 (6) | 5.2 | 4.5 | |

| Small Pellets | 0.9 (2) | 3 | 2.2 |

| 1.8 (4) | 4.2 | 3.7 | |

| 2.7 (6) | 4.5 | 4 | |

| Nitrogen Pellets Medium Size | 0.5 (1) | 3.5 | 3 |

| 0.9 (2) | 4.2 | 3.7 | |

| 1.4 (3) | 4.7 | 4 | |

| Medium Pellets and Granules | 0.9 (2) | 3.5 | 3 |

| 1.8 (4) | 4.2 | 3.8 | |

| 2.7 (6) | 5.2 | 4.5 | |

| Large Heavy Pellets | 0.9 (2) | 3.8 | 3.3 |

| 1.8 (4) | 4.9 | 4.1 | |

| 2.7 (6) | 5.9 | 4.9 |

The chart below is for reference only. When spraying and spreading at the same time, set the spread pattern to twice the width of the spray; this will help avoid striping and streaking. For example, standard spray width = 2.7 m (9 ft) and spread width = 5.4 m (18 ft).

| Type | Bag Weight | Coverage - m2 (ft2) | Cam Setting – Full Rate | Cam Setting – Half Rate | Spreader Width |

|---|---|---|---|---|---|

| Blue Grass or Red Top | 0.23 kg (0.5 lb) | 93 (1,000) | 1.25 | 4 | |

| 0.45 kg (1 lb) | 93 (1,000) | 2.0 | 4 | ||

| 0.9 kg (2 lb) | 93 (1,000) | 2.5 | 4 | ||

| Park, Merion, Delta, or Kentucky Bluegrass | 2.27 kg (.5 lb) | 93 (1,000) | 2.5 | 4 | |

| 0.45 kg (1 lb) | 93 (1,000) | 3.0 | 4 | ||

| 0.9 kg (2 lb) | 93 (1,000) | 3.5 | 4 | ||

| Hulled Bermuda | 0.9 kg (2 lb) | 93 (1,000) | 2.75 | 2.25 | 6 |

| 1.36 kg (3 lb) | 93 (1,000) | 3.0 | 2.5 | 6 | |

| 1.81 kg (4 lb) | 93 (1,000) | 3.25 | 2.75 | 6 | |

| Mixtures Including Coarse Seeds | 0.9 kg (2 lb) | 93 (1,000) | 6.0 | 6 | |

| 1.81 kg (4 lb) | 93 (1,000) | 7.0 | 6 | ||

| 2.72 kg (6 lb) | 93 (1,000) | 7.0 | 6 | ||

| Rye Grasses or Tall Fescue | 0.9 kg (2 lb) | 93 (1,000) | 6.0 | 6 | |

| 1.81 kg (4 lb) | 93 (1,000) | 7.0 | 6 | ||

| 2.72 kg (6 lb) | 93 (1,000) | 7.75 | 6 | ||

| Dichondra | 113 kg (4 oz) | 93 (1,000) | 1.9 | 8 | |

| 227 g (8 oz) | 93 (1,000) | 2.1 | 8 | ||

| 340 g (12 oz) | 93 (1,000) | 2.5 | 8 | ||

| Pensacola Bahia | 1.81 kg (4 lb) | 93 (1,000) | 4.5 | 3.75 | 7 |

| 2.27 kg (.5 lb) | 93 (1,000) | 4.75 | 4.0 | 7 | |

| 2.72 kg (6 lb) | 93 (1,000) | 5.0 | 4.25 | 7 |

Adjusting the Spreader Pattern

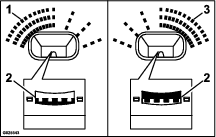

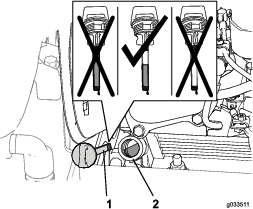

If the spreader is casting material in a unequal side-to side—too light/heavy to one side—(see Figure 29 and Figure 30), adjust the spreader-pattern control as follows:

Note: Do not adjust the ramps that split the product flow. Adjust only the front or rear ramp positions.

Using the Deflector Gate

Use the deflector-gate control to temporarily stop or deflect granular material away from sidewalks, parking lots, patios, or anywhere the granular chemicals are not desired.

Note: The deflector gate changes the discharged of materials from the left side of the spreader only.

Push the knob for the deflector-gate control down to lower the deflector and temporarily deflect the granular material.

Pull the knob up to raise the deflector for normal casting of materials at the left side of the machine.

Spreading Tips

-

To ensure uniform application, broadcast the material in an overlapping pattern as shown in Figure 32. The highest amount of material will dispense from the front of the hopper and less material from each side. You can adjust the distribution pattern to achieve the desired results.

-

Watch for changes in the distribution pattern; unequal distribution may lead to striping.

Note: Ensure that you calibrate the spreader before you start using the spreader.

-

Start the engine and place the throttle midway between the SLOW and the FAST positions.

-

Set the impeller-speed control to appropriate broadcast rate and then press the impeller On/Off switch to the ON position (Figure 33).

-

To lock the impeller speed control, press and hold the impeller On/Off switch for 5 seconds (Figure 33).

Note: The indicator light above the impeller On/Off switch will flash at a constant rate.

Note: As long as the impeller-speed control is locked (indicated by the flashing indicator light) the impeller motor will start and run at the last locked speed.

-

To unlock the impeller-speed control, start the impeller motor and then press and hold press and hold the On/Off switch for 5 seconds (the indicator light will illuminate steady).

-

-

Move the throttle to the FAST position and drive the machine forward.

-

Open the either the narrow or wide impeller-gate lever to begin spreading (Figure 35).

Note: Use the narrow-spreader distribution flow-rate knob to control the discharge rate of the granular material from the hopper onto the impeller when the narrow-distribution impeller-gate lever is in the OPEN position.

-

Evaluate the spread pattern.

Note: If adjustments to the spreading pattern are needed, refer to Calibrating the Spreader.

-

When you are finished spreading, close the wide-distribution impeller-gate lever.

Note: Only the wide-distribution impeller-gate lever will close the impeller gate. Pushing the wide-distribution impeller-gate lever forward will also reset the narrow-distribution impeller-gate lever to the forward position.

-

Clean the hopper after each spreading session; refer to Cleaning and Lubricating the Spreader.

Important: Always empty and clean the spreader immediately after each use. Failure to do so may cause the chemicals to corrode the spreader and other components.

Cleaning and Lubricating the Spreader

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

-

Drive the machine to a designated cleaning area with a level surface.

-

Move the motion-control lever in the NEUTRAL position, shut off the engine, and set the parking brake.

-

Empty the hopper; refer to steps 2 through 6 in Emptying the Hopper.

-

Using a hose to spray the inside and outside of the entire spreader with clean water.

Note: Do not use a power washer to clean the machine. The high-pressure water can force residual-corrosive materials into spreader-spreader components.

-

Tilt the screen at the bottom of the hopper forward to clean the bottom components of hopper (Figure 36).

-

When the hopper and screen have been thoroughly rinsed and drained, perform the following:

-

Rotate the hopper screen down.

-

Place the rate gate dial to a setting lower than the maximum open position and allow the spreader-sprayer to completely dry.(Figure 28).

-

Connect the hopper gate cable; refer to step 8 in Emptying the Hopper.

-

-

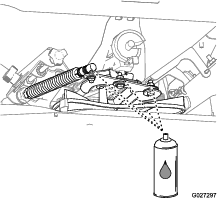

Apply water-displacing lubricant to the components as shown in Figure 37.

Operating the Sprayer

Caution

Chemicals are hazardous and can cause personal injury.

-

Read the chemical manufacture’s directions on the label before handling the chemicals; follow all manufacturer recommendations and precautions.

-

Keep chemicals away from your skin. Should contact occur, wash the affected area thoroughly with soap and clean water.

-

Wear eye protection, gloves, and any other protective equipment recommended by the chemical manufacturer.

Use the sprayer to disperse liquid herbicides, pesticides, fertilizers, and other substances. Before using the sprayer ensure that you have cleaned the tank, plumbing, and nozzles before adding any chemicals. When you use the sprayer, you first fill the spray tank, then apply the chemical solution to the work site, and then when you are finished spraying, clean the tank. It is important to complete all three of these steps to avoid damaging the sprayer. For example, Do not mix and add chemicals in the spray tank the night before and then spray in the morning. This could lead to separation of the chemicals and possible cause damage to components of the sprayer.

Calibrating the Sprayer

Note: Before you use the sprayer for the first time or change the nozzles or when the sprayer is out of adjustment—calibrate the sprayer for ground speed and flow rate.

Note: The left and right sprayer boom nozzles are wide pattern (white)nozzles and the center nozzle is narrow pattern (red) nozzle.

Note: Refer to the chemical product label for output recommendations.

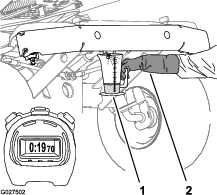

The method to calibrate the sprayer flow involves driving a preset distance, recording the time, and then measuring the amount of liquid applied during that time.

Calculating the Ground Speed

Operator supplied equipment: Stop watch capable of measuring ± 1/10 second.

-

Measure and visibly mark a course length to use to calculate your the average ground speed.

Record your course length here .

Note: Allow ample distance ahead of the starting marker to ensure the machine is at full ground speed when you cross the first marker of the course.

Note: Example: the course length equals 45.7 m (150 ft).

-

Add clean water into the spray tank 1/2 full; refer to Filling the Spray Tank.

-

Drive the sprayer to an area far enough away from the course so that the machine will be traveling at the desired ground speed for spraying before the it reaches the first marker.

-

Use a stop watch to measure the time (in seconds) that it takes the machine to travel the marked course (45.7 m (150 ft) in this example) while maintaining the desired ground speed.

Note: Record your course time in the course time worksheet.

Course Time Worksheet

Time Test 1 seconds Test 2 seconds Test 3 seconds -

Repeat steps 2 through 4 2-additional times.

-

Move the sprayer to a level surface, leave the motion-control lever in the NEUTRAL position, and shut off the engine.

-

Average the 3 test run times (in seconds) using the average course time formula below:

Record your the average course speed here .

Average Course Time Formula

Formula time 1 + time 2 + time 3 = The average time to drive the course 3 Example 21.6 + 19.1+ 18.4seconds = 19.7 seconds 3 -

Use the ground speed formula below to determine the average ground speed.

Record your the average ground speed here .

Note: 1 kph = 16.6 m/minute (1 mph = 88 ft/minute)

Ground Speed Formula

Formula Distance traveledm (ft) x 60 seconds = Speed (mph) Time (seconds) x16.7 m/minute (88 ft/minute) Example 45.7 m (150 ft) x 60 seconds = 8.4 kph(5.2 mph) 19.7 seconds x 16.6 m/minute (88 ft/minute)

Understanding the Effective Spray Pattern Width

Testing the Sprayer Nozzle Discharge

Operator supplied equipment: Stop watch capable of measuring ± 1/10 second and a container graduated in 50 ml (1 fl-oz) increments.

Note: Ensure that there is enough clean water in the tank to complete the calibration.

-

Set the parking brake and turn the engine on.

-

Set the pump/tank agitation switch to the ON position.

-

Pull the agitation lever rearward to turn on the tank agitation.

-

Place the throttle to the FAST position.

-

Push the agitation control lever down to the OFF position.

Note: Shut off the agitation to ensure proper spray pressure and distribution.

-

Use the spray-pressure control to adjust the pressure-sprayer system to 40 psi (2.8 bar).

Note: The red and white nozzles installed on this unit have a normal operating pressure of 40 psi (2.8 bar).

-

Align the graduated container under each nozzle for 19.7 seconds.

Note: Record the amount of water collected from each nozzle in the collection worksheet below.

Collection Worksheet

Left sprayer nozzle Center sprayer nozzle Right sprayer nozzle Test 1 ml (fl oz) ml (fl oz) ml (fl oz) Test 2 ml (fl oz) ml (fl oz) ml (fl oz) Test 3 ml (fl oz) ml (fl oz) ml (fl oz) -

Repeat test step 7 for each nozzle 2-additional times.

-

Turn off the pump/tank agitation switch.

-

Calculate the average quantity of water discharged using the average discharge formula for each nozzle.

Average Discharge Formula

Formula test 1 + test 2 + test 3 = The average spray nozzle discharge in 19.7 seconds 3 Example center nozzle—narrow pattern (red) 475 ml (16.05 fl oz) + 507 ml (17.15 fl oz) + 504 ml (17.05 fl oz) = 0.49 L (16.75 fl oz) 3 -

Record the average quantity of water collected from the right nozzle here .

-

Record the average quantity of water collected from the center nozzle here .

-

Record the average quantity of water collected from the left nozzle here .

-

Converting the Time and Collection Results to Flow Rate

-

Convert the milliliters (fluid ounce) quantities that you calculated in step 10 of Testing the Sprayer Nozzle Discharge to liters (US gallons) using the quantity conversion formula.

Note: 1 US gallon = 128 fl oz

Quantity Conversion Formula

Formula Result (X) ml (fl oz) = (X) L (US gallon) .1 L (128 fl oz) Example center nozzle—narrow pattern (red) 490 ml (16.75 fl oz) = 0.49 L (0.13 US gallon) .1 L (128 fl oz) -

Record the converted quantity of water collected for the right nozzle here .

-

Record the converted quantity of water collected for the center nozzle here .

-

Record the converted quantity of water collected for the left nozzle here .

-

-

Calculate the flow rate of each nozzle using the flow rate formula.

-

Flow Rate Formula

Formula Result (X) L (US gallon) x 60 seconds = (X) L (US gallon) 19.7 seconds Example center nozzle—narrow pattern (red) .49 L (0.13 US gallon) x 60 seconds = 3.07 L (0.40 US gallon) per minute 19.7 seconds -

Record the flow rate of water collected for the right nozzle here .

-

Record the flow rate of water collected for the center nozzle here .

-

Record the flow rate of water collected for the left nozzle here .

Note: If the collected nozzle spray does not meet the quantity in the Nozzle Flow Rate Chart, check the nozzles, hoses, and fittings for leaks or damage; clean or replace if needed.

-

Nozzle Flow Rate Chart

The following chart is based on the nozzle capacity information chart provided with permission from TeeJet® Technologies. Use the chart below or reference the TeeJet® Technologies website to determine if the flow rate of the sprayer nozzle is within the specified flow rate (+/– 10%).

Note: The chart information below is based on the machine spraying water at 70°F (21°C).

| Pressure | Flow Rate—New | Flow Rate—In Service Nozzle | ||

| 0.7 bar(10 psi) | 769 ml (26 fl oz)/min | 0.76 L (0.20 US gallon)/min | 0.68 to 0.75 L (0.18 to 0.22 US gallon)/min | |

| 1.4 bar(20 psi) | 1065 ml (36 fl oz)/min | 1.06 L (0.28 US gallon)/min | 0.95 to 1.17 L (0.25 to 0.31 US gallon)/min | |

| 2.1 bar(30 psi) | 1331 ml (45 fl oz)/min | 1.32 L (0.35 US gallon)/min | 1.19 to 1.45 L (0.32 to 0.39 US gallon)/min | |

| 2.8 bar(40 psi) | 1508 ml (51 fl oz)/min | 1.51 L (0.40 US gallon)/min | 1.36 to 1.66 L (0.36 to 0.44 US gallon)/min | |

| Pressure | Flow Rate—New | Flow Rate—In Service Nozzle | ||

| 0.7 bar(10 psi) | 1508 ml (51 fl oz)/min | 1.51 L (0.40 US gallon)/min | 1.36 to 1.66 L (0.36 to 0.44 US gallon)/min | |

| 1.4 bar(20 psi) | 2159 ml (73 fl oz)/min | 2.16 L (0.57 US gallon)/min | 1.94 to 2.38 L (0.51 to 0.63 US gallon)/min | |

| 2.1 bar(30 psi) | 2602 ml (88 fl oz)/min | 2.61 L (0.69 US gallon)/min | 2.35 to 2.87 L (0.62 to 0.76 US gallon)/min | |

| 2.8 bar(40 psi) | 3017 ml (102 fl oz)/min | 3.03 L (0.80 US gallon)/min | 2.73 to 3.33 L (0.72 to 0.88 US gallon)/min | |

Determining Application Rate

Use the example results of the calculated speed, spray width, and nozzle capacity to determine the application rate.

Note: The application rate may also be determined by using the Nozzle Flow Rate Chart, along with the chemical manufacturer’s label of recommendation.

The examples below are based on the following information:

-

Average ground speed = 8.4 kph (5.2 mph)

-

Spray width = 2.7 m (108 inches)

-

Number of nozzles = 2

-

Nozzle capacity = 3.0 L/min (.79 gpm)

Note: The numbers 6 and 600 are constants used in the formulas shown below.

| Single nozzle capacity (Lpm) x Number of nozzles x 6 | = | L |

| Speed (kph) x Spray width (m) | 100 m2 |

| 2.99 Lpm x 2 x 6 | = | 1.563 L/100 m2(1.5 qt/1,000 ft2) |

| 8.369 kph x 2.743 m |

| Single nozzle capacity (Lpm) x Number of nozzles x 600 | = | L |

| Speed (kph) x Spray width (m) | hectar |

| 2.99 Lpm x 2 x 600 | = | 156 L/hectar(16.7 gal/acre) |

| 8.369 kph x 2.743 m |

Note: The numbers 544; 136; and 5,940 are constants used in the formulas shown below.

| Single nozzle capacity (gpm) x Number of nozzles x 544 | = | qt |

| Speed (mph) x Spray width (inches) | 1,000 ft2 |

| 0.79 gpm x 2 x 544 | = | 1.5 qt/1,000 ft2(1.5 L/100 macre2) |

| 5.2 mph x 108 inches |

| Single nozzle capacity (GPM) x Number of nozzles x 136 | = | gal |

| Speed (mph) x Spray width (inches) | 1,000 ft2 |

| 0.79 gpm x 2 x 136 | = | 0.38 gal/1,000 ft2(1.5 L/100 m2) |

| 5.2 mph x 108 inches |

| Single nozzle capacity (gpm) x Number of nozzles x 5,940 | = | gal |

| Speed (mph) x Spray width (inches) | acre |

| 0.79 gpm x 2 x 5,940 | = | 16.7 gal/acre(156.1 L/ha) |

| 5.2 mph x 108 inches |

Using the Sprayer

Before Operating the Sprayer

Some chemicals are more aggressive than others and each chemical interacts differently with various materials. Some consistencies of sprayer chemicals (e.g. wettable powders, charcoal) are more abrasive and lead to higher-wear rates. If a chemical is available in a formulation that would provide increased life to the sprayer, use this alternative formulation.

Ensure that the sprayer is calibrated before you start using the machine; refer to Calibrating the Sprayer.

Filling the Spray Tank

Important: Ensure that the chemicals that you are using in the sprayer are compatible for use with O-rings and seals made from fluoroelastomer material (refer to the chemical manufacturer's label; it should indicate if it is not compatible). If you use a chemical that is not compatible with fluoroelastomer material, the O-rings and seals in the sprayer can degrade and leak.

Important: Before applying chemicals to the job site, verify that you have set the proper application rate prior to filling the tank.

-

Move the machine to a level surface, move motion-control lever to the NEUTRAL position, shut off the engine, and set the parking brake.

-

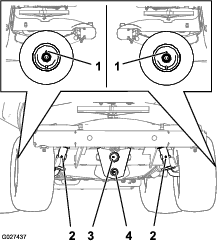

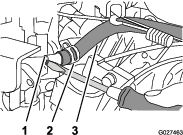

Ensure that the handle for the drain valve for the tank rotated 90 degrees counterclockwise to the is closed position (Figure 41).

-

Determine the amount of water needed to mix the amount of chemical needed as specified by the chemical manufacturer.

-

Open the tank cap on the spray tank (Figure 41).

-

Add 3/4 of the required water to the sprayer tank through the filler neck.

Important: Always use fresh, clean water in the spray tank. Do not pour chemical concentrate into an empty tank.

-

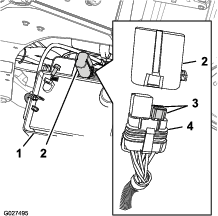

Rotate the pump-shutoff valve clockwise to the OPEN position (Figure 42).

-

Start the engine and set the throttle midway between the SLOW and FAST positions.

-

Set the sprayer-pump switch to the ON position (Figure 43).

-

Move the throttle to the FAST position.

-

Pull rearward on the tank-agitation lever to the ON position.

Note: The water in the tank will circulate.

-

Add the specified amount of chemical concentrate to the tank as directed by the chemical manufacturer.

Important: If you are using a wettable-powder chemical, mix the powder with a small amount of water to form a liquid slurry before adding the chemical mixture to the tank.

-

Add remaining water to the tank and install cap onto the filler neck of the tank.

Note: Allow the content of the sprayer tank to mix thoroughly.

Emptying the Sprayer Tank

Operator supplied equipment: Drain hose with a 1/2–14 inch NPT male coupling and a drain container (capacity varies with remaining sprayer tank content).

-

Move the machine to a level surface at the designated area for emptying and cleaning the sprayer tank, move motion-control lever to the NEUTRAL position, shut off the engine, and set the parking brake.

-

Remove the plug from the drain valve for the sprayer tank (Figure 44).

Note: The drain valve is located at the left side of the machine.

-

Thread a drain hose (operator provided) into the end of the drain valve.

-

Put the free end of the drain hose into a container with enough capacity to hold the remaining content of the sprayer tank.

Note: Use the quantity marks at the front, left side of the sprayer tank for determine the quantity of chemical solution in the tank.

-

Rotate the handle for the drain valve clockwise 90° to drain the tank (Figure 44).

Note: Allow the sprayer tank to drain completely.

-

Close the tank-drain valve, remove the drain hose and install the drain plug into the valve (Figure 44).

Note: Dispose of the sprayer chemicals according to local codes and the chemical manufacturer's instructions.

Cleaning the Sprayer Tank

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

|

Warning

Swallowing or inhaling chemicals could cause serious injury or death.

-

Do not clean sprayer nozzles using your mouth or blowing through the nozzles.

-

Replace all worn and damaged sprayer nozzles.

-

Ensure that the nozzles are installed correctly.

Important: Always empty and clean the sprayer immediately after each use. Failure to do so may cause the chemicals to dry or thicken in the lines, clogging the pump and other components.

-

Empty the sprayer tank; refer to Emptying the Sprayer Tank.

-

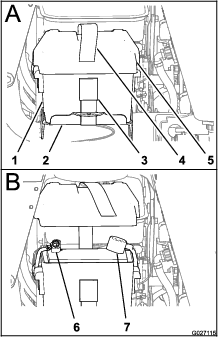

Fill the sprayer tank with 19 L (5 US gallons) or more of clean water and install the cap; refer to Filling the Spray Tank.

-

Start the engine (Figure 45) and ensure that the motion-control lever in NEUTRAL position; refer to Starting the Engine.

-

Set the sprayer-pump switch to the ON position, and set the engine throttle to FAST position (Figure 45).

-

Move the tank-agitation lever to the ON position (Figure 45).

-

Pull back both narrow and wide-spray pattern levers to the ON position (Figure 45).

Note: The sprayer nozzles will to begin spraying.

-

Allow the rinse water in the tank to spray through the nozzles.

-

Check that all 3 nozzles are spraying correctly.

-