| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This rotary-blade, riding lawn mower is intended to be used by residential homeowners or professional, hired operators. It is designed primarily for cutting grass on well-maintained lawns on residential or commercial properties. It is not designed for cutting brush or for agricultural uses.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

You may contact Toro directly at www.Toro.com for product safety and operation training material, accessory information, help finding a dealer, or to register your product.

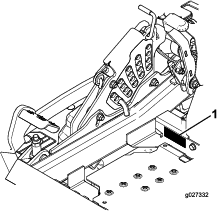

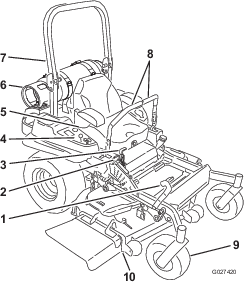

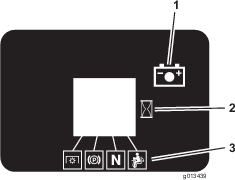

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

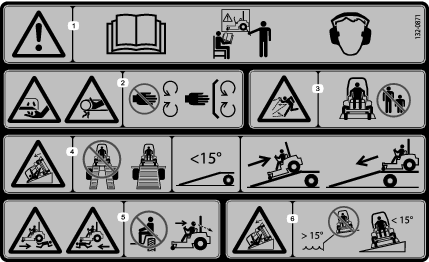

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This spark ignition system complies with Canadian ICES-002

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

The enclosed Engine Owner's Manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

Improper use or maintenance by the operator or owner can result in injury. To reduce the potential for injury, comply with these safety instructions, and pay attention to the safety-alert symbol , which means Caution, Warning, or Danger—personal safety instruction. Failure to comply with the instructions may result in personal injury or death.

This machine was manufactured according to the appropriate regulatory standards in effect at the time of manufacture. Modifying this machine in any way may cause it to be out of compliance with those standards and with the instructions in this Operator’s Manual. Modifications to this machine should only be made by either the manufacturer or an Authorized Toro Dealer.

This product is capable of amputating hands and feet. Follow all safety instructions to avoid serious injury or death.

The owner/user can prevent and is responsible for accidents or injuries occurring to people, or damage to property.

The addition of attachments made by other manufacturers that do not meet American National Standards Institute certification will cause noncompliance of this machine.

Safe Operating Practices

The following instructions are adapted from ANSI B71.4-2012.

Training

-

Read the Operator's Manual and other training material. If the operator(s) or mechanic(s) cannot read or understand the information it is the owner's responsibility to explain this material to them.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

All operators and mechanics should be trained. The owner is responsible for training the users.

-

Never let children or untrained people operate or service the equipment. Local regulations may restrict the age of the operator.

-

The owner/user can prevent and is responsible for accidents or injuries occurring to people or damage to property.

Preparation

-

Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Only use accessories and attachments approved by the manufacturer.

-

Wear appropriate clothing including substantial slip-resistant footwear, safety glasses, and hearing protection. Tie long hair back and do not wear jewelry.

-

Inspect the area where the equipment is to be used and remove all objects such as rocks, toys, and wire which can be thrown by the machine.

-

Check that operator's presence controls, safety switches, and shields are attached and functioning properly. Do not operate unless they are functioning properly.

Operation

-

Lightning can cause severe injury or death. If lightning is seen or thunder is heard in the area, do not operate the machine; seek shelter.

-

Never run an engine in an enclosed area.

-

Only operate in good light, keeping away from holes and hidden hazards.

-

Be sure all drives are in neutral and parking brake is engaged before starting the engine. Only start the engine from the operator's position.

-

Be sure of your traction while using this machine, especially when backing up. Walk; do not run. Never operate on wet grass. Reduced footing could cause slipping.

-

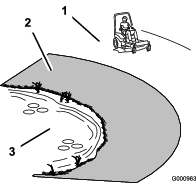

Slow down and use extra care on hillsides. Be sure to travel side to side on hillsides. Turf conditions can affect the stability of the machine. Use caution while operating near drop-offs.

-

Slow down and use caution when making turns and when changing directions on slopes.

-

Never raise deck with the blades running.

-

Never operate with the PTO shield or other guards not securely in place. Be sure all interlocks are attached, adjusted properly, and functioning properly.

-

Never operate with the discharge deflector raised, removed or altered, unless using a grass catcher.

-

Do not change the engine governor setting or overspeed the engine.

-

Stop on level ground, disengage drives, engage the parking brake (if provided), and shut off the engine before leaving the operator's position for any reason, including emptying the catchers or unclogging the chute.

-

Stop equipment and inspect blades after striking objects or if an abnormal vibration occurs. Make necessary repairs before resuming operations.

-

Keep hands and feet away from the cutting unit.

-

Look behind and down before backing up to be sure of a clear path.

-

Never carry passengers on the machine.

-

Keep pets and bystanders away.

-

Slow down and use caution when making turns and crossing roads and sidewalks. Stop blades if not mowing.

-

Be aware of the mower discharge direction and do not point it at anyone.

-

Do not operate the mower while ill, tired, or under the influence of alcohol or drugs.

-

Use care when loading or unloading the machine into or from a trailer or truck.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

Rollover-Protection System (ROPS)

-

The ROPS is an integral and effective safety device. Keep a folding ROPS in the raised and locked position and use the seat belt when operating the machine.

-

Lower a folding ROPS temporarily only when absolutely necessary. Do not wear the seat belt when folded down.

-

Be aware there is no rollover protection when a folded ROPS is in the down position.

-

Be certain that the seat belt can be released quickly in the event of an emergency.

-

Check the area to be mowed and never fold down a folding ROPS in areas where there are slopes, drop offs or water.

-

Check carefully for overhead clearances (i.e., branches, doorways, electrical wires) before driving under any objects and do not contact them.

-

Keep the ROPS in safe operating condition by periodically thoroughly inspecting for damage and keeping all mounting fasteners tight.

-

Replace a damaged ROPS. Do not repair or revise.

-

Do not remove the ROPS.

-

Any alterations to a ROPS must be approved by the manufacturer.

Maintenance and Storage

-

Disengage drives, set the parking brake, Shut off the engine and remove the key or disconnect the spark-plug wire. Wait for all movement to stop before adjusting, cleaning or repairing the machine.

-

Clean grass and debris from the cutting unit, the drives, the mufflers, and the engine to help prevent fires. Clean up oil, fuel, or hydraulic fluid spills.

-

Let the engine cool before storing and do not store near flame.

-

Shut off the fuel while storing or transporting. Do not store fuel near flames.

-

Park the machine on level ground. Set the parking brake. Never allow untrained personnel to service the machine.

-

Use jack stands to support components when required.

-

Carefully release pressure from components with stored energy.

-

Disconnect the battery or the spark-plug wire before making any repairs. Disconnect the negative terminal first and the positive last. Connect the positive first and negative last.

-

Use care when checking the blades. Wrap the blade(s) or wear thickly-padded gloves, and use caution when servicing them. Only replace blades. Never straighten or weld them.

-

Keep hands and feet away from moving parts. If possible, do not make adjustments with the engine running.

-

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

-

To best protect your investment and maintain optimal performance of your Toro equipment, count on Toro genuine parts. When it comes to reliability, Toro delivers replacement parts designed to the exact engineering specifications of our equipment. For peace of mind, insist on Toro genuine parts.

Hauling

-

Use care when loading or unloading the machine into a trailer or truck.

-

Use full-width ramps for loading the machine into a trailer or truck.

-

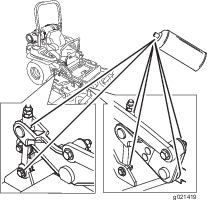

Tie the machine down securely using straps, chains, cable, or ropes. Both front and rear straps should be directed down and outward from the machine.

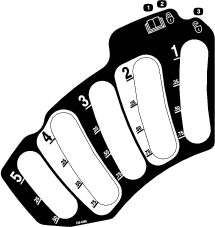

Slope Indicator

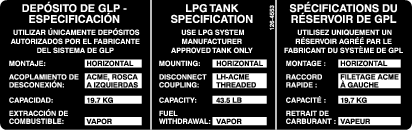

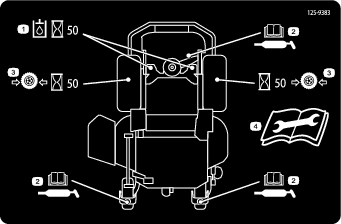

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. |

Product Overview

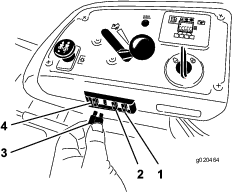

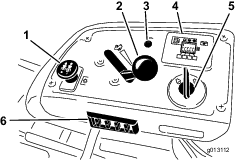

Become familiar with all the controls before you start the engine and operate the machine (Figure 4 and Figure 5).

Battery-Indicator Light

If the ignition key is turned to the ON position for a few seconds, the battery voltage is displayed in the area where the hours are normally displayed.

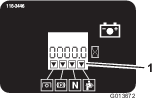

The battery light turns on when the ignition is turned on and when the charge is below the correct operating level (Figure 6).

Hour Meter

The hour meter records the number of hours the engine has operated. It operates when the engine is running. Use these times for scheduling regular maintenance (Figure 5).

Fuel Gauge

Located on the LPG-fuel tank.

This gauge monitors the amount of liquid LPG in the fuel tank.

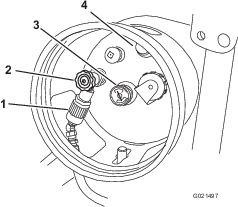

Safety Pressure-Relief Valve

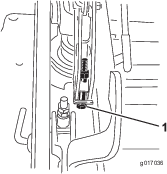

The relief valve is located on the LPG-fuel tank (Figure 7).

The safety pressure-relief valve relieves the excess pressure in the LPG tank.

Important: This valve has a protective-plastic cap that should never be removed. If the cap is damaged or missing, contact trained and qualified personnel immediately.

LPG Cylinder Brackets

The brackets are located on the engine deck.

The LPG-cylinder brackets are used to fasten the removable LPG tank to the mower.

Safety-Interlock Indicators

The symbols on the hour meter indicate with a black triangle that the interlock component is in the correct position (Figure 6).

Throttle Control

The throttle control is variable between the FAST and SLOW positions.

Blade-Control Switch (PTO)

The blade-control switch (PTO) is used to engage the electric clutch and drive the mower blades. Pull the switch up to engage the blades and release. To disengage the blades, push the blade-control switch (PTO) down or move a motion-control lever into the NEUTRAL-LOCK position.

Ignition Switch

This switch is used to start the mower engine and has three positions: START, RUN, and OFF.

Motion-Control Levers

The motion-control levers are used to drive the machine forward, reverse, and turn either direction.

Neutral-Lock Position

The NEUTRAL-LOCK position is used with the safety-interlock system to engage and to determine NEUTRAL position.

Fuel-Shutoff Valve

Close the LPG-shutoff valve on the cylinder tank when transporting or storing the mower.

Electronic Control Unit Malfunction Indicator Light

The electronic-control unit (ECU) continuously monitors the operation of the EFI system.

If a problem or fault within the system is detected, the malfunction-indicator light (MIL) is illuminated.

The MIL is the red light located in the right console panel.

Once the MIL illuminates, initial trouble shooting checks should be made. Refer to the MIL section under Toubleshooting.

If these checks do not correct the problem, further diagnosis and servicing by an Authorized Service Dealer is necessary.

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories.

Note: Specifications and design are subject to change without notice.

| 60-inch Deck | 72-inch Deck | |

|---|---|---|

| Without Deck | 134.6 cm (53.0 inches) | 150.1 cm (59.1 inches) |

| Deflector Up | 156.8 cm (61.7 inches) | 187 cm (73.6 inches) |

| Deflector Down | 192.2 cm (75.7 inches) | 222.4 cm (87.6 inches) |

| 60-inch Deck | 72-inch Deck | |

|---|---|---|

| Roll Bar - Up | 211.1 cm (83.1 inches) | 218.7 cm (86.1 inches) |

| Roll Bar - Down | 215.4 cm (84.8 inches) | 223.0 cm (87.8 inches) |

| Roll Bar - Up | Roll Bar - Down |

|---|---|

| 179.1 cm (70.5 inches) | 118.9 cm (46.8 inches) |

| Model | Weight |

| 60-inch Deck | 593 kg (1,307 lb) |

| 72-inch Deck | 774 kg (1707 lb) |

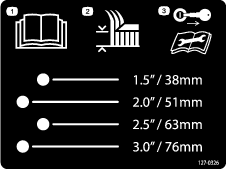

Tank Type and Refilling

Note: The LPG tank used on this mower is a special tank with internal baffles designed for this application.

-

Horizontal Tank Specifications:

-

Tank Material: Aluminum

-

Capacity: 43.5 lb

-

Disconnect coupling: Left hand ACME threaded

-

Fuel Withdrawal: Vapor

-

Fuel Shutoff Valve: Rotate clockwise to close.

-

Type of fuel: HD5 grade propane

-

-

New tanks must be properly filled by trained and qualified personnel.

-

Only use tanks recommended by Toro. Failure to do so will result in improper operation of the fuel system.

Important: Using a liquid-withdrawal tank will result in icing or freezing of the LPG regulator and prevent the engine from operating. This may also result in permanent fuel-system damage and the release of highly-flammable-propane liquid or vapor.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Adding Fuel

LPG (liquefied-petroleum gas) is more commonly called propane. LPG is a liquid fuel that is stored in a tank under pressure. Before the liquid leaves the tank, it is converted into a vapor. Since LPG is stored as both liquid and gas, it may leak from joints or connections that are not sealed properly. LPG becomes flammable when it is mixed with air.

The LPG information in this Operator's Manual is provided only as a guide. Consult the NFPA 58: Liquefied Petroleum Gas Code, 2008 Edition for additional safety information. This National Fire Protection Association (NFPA) code pertains to the handling, storing, transporting, and usage of LPG.

Type of fuel: HD5 grade propane

Caution

Using overfilled tanks may result in the release of highly concentrated and extremely-flammable-liquid propane. Refer to the Adding Fuel section.

Never use propane tanks that are filled beyond 80% capacity.

Danger

LPG vapors and liquid escaping from the tank may cause serious injury or death. Vapors or liquid may cause suffocation, freezing of tissue, or frostbite.

-

Store and service the mower in a well-ventilated area.

-

Install an approved LPG detector in trailers and storage areas.

-

LPG is heavier than air and may accumulate in low lying areas, such as ditches, drains, or pits.

-

Avoid breathing in vapors.

-

Keep LPG vapors and liquid away from vent valves.

-

Keep LPG vapors and liquid away from your eyes and skin.

-

Contact trained and qualified personnel if the tank shows signs of frosted areas, makes a hissing sound, or emits a foul odor.

-

Obtain immediate medical attention if vapors or liquid come in contact with your eyes or skin.

Danger

LPG fuel is extremely flammable and vapors are explosive.

A fire or explosion from LPG fuel can burn you, others, and cause property damage.

-

Never smoke around fuel tank(s) and stay away from an open flame or where fumes may be ignited by a spark.

-

Extinguish all sources of spark or flame when approaching LPG tanks or mowers. The hazard increases for enclosed trailers or storage locations where vapor leakage may occur and collect.

-

LPG is heavier than air and may accumulate in low lying areas, such as ditches, drains, or pits.

-

LPG tank(s) should be filled by trained and qualified personnel only.

-

Never tamper with or repair the tank(s); contact trained and qualified personnel.

-

Do not change the tank(s) when the engine is running.

-

Before disconnecting the hoses, close the fuel valves on all of the tanks and allow the engine to run until it stops to purge all of the LPG vapors from the system.

-

Store the tank(s) away from heat, sparks, or open flames.

-

Do not operate without the entire exhaust system in place and in proper working condition.

Danger

LPG fuel is extremely flammable and vapors are explosive.

-

In case of fire, take the following steps:

-

If you can safely do so, stop the flow of gas as quickly as possible. Never put out the flame unless you can shut off the gas.

-

Notify the fire department and clear the immediate area of all people.

-

When the gas flow has stopped, put out the fire. Usually, when flow of gas is cut off, fire will automatically stop.

-

If you cannot immediate stop the gas flow, direct water on to the tanks to keep them cool, but do not put out the fire.

-

-

Storage locations and trailers should be equipped with at least 1 approved portable fire extinguisher that has a minimum capacity of 8.2 kg (18 lb) dry chemical with a B:C rating. Do not use carbon-tetrachloride extinguishers such as Pyrene.

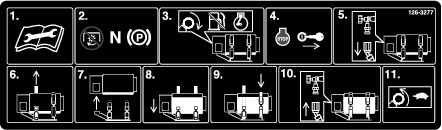

Changing the LPG Tank

Change the LPG tank outdoors in a well-ventilated area.

Important: Only hand tighten tank-connection fitting. Over tightening by the use of tools may cause damage. If hand tightening does not stop a leak, contact trained and qualified personnel immediately.

-

Shut off the machine on level ground, disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Wait for all moving parts to stop before leaving the operating position.

-

With the engine running, close the fuel valve on the tank.

-

Run the engine until it stops.

Note: This purges all vapors from the hose.

-

Remove the key.

-

Carefully disconnect the LPG fuel hose.

-

Unlatch the cylinder brackets and remove the tank.

Warning

Fuel system components are under high pressure. The use of damaged or improper components can cause system failure, fuel leakage, and possible explosion, which may result in serious injury or death.

-

Do not attempt to repair or modify the valves, fittings, or other tank components.

-

Only use the Toro approved LPG tank, fittings, and hoses that were designed for your mower.

-

-

Inspect the filled tank valve and fitting openings for dirt, debris, or damage.

-

Inspect the tank hose connection fitting for damaged or missing o-rings.

-

Ensure that the replacement tank type and size match the tank specification decal.

-

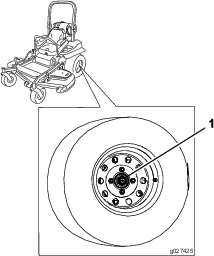

Align the center hole over the mounting pin that points straight up on the mower as shown in .

Important: The valves and gauges may not function properly if the LPG tank is not installed correctly.

-

Latch the cylinder brackets and ensure that the tank is securely fastened to the mower.

-

Carefully connect the fuel hose. Ensure the hose is not kinked.

-

Slowly open the fuel valve to equalize the pressure in the tank.

Note: If the fuel valve is opened too quickly, the pressure relief valve is equipped with a back pressure check valve that will shut off the fuel supply. If this happens, close the fuel valve completely and wait 5 seconds.

-

Check for leaks as described in Inspecting the LPG System.

Checking the Engine-Oil Level

Before you start the engine and use the machine, check the oil level in the engine crankcase; refer to Checking the Engine-Oil Level.

Breaking in a New Machine

New engines take time to develop full power. Mower decks and drive systems have higher friction when new, placing additional load on the engine. Allow 40 to 50 hours of break-in time for new machines to develop full power and best performance.

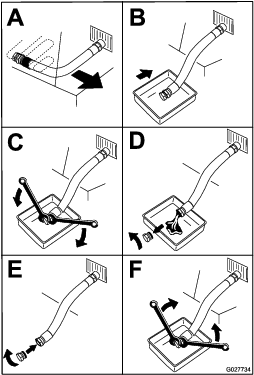

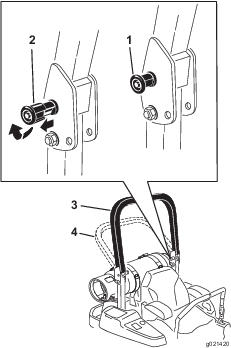

Using the Rollover-Protection System (ROPS)

Warning

There is no rollover protection when the roll bar is in the down position.

-

Lower the roll bar only when absolutely necessary.

-

Do not wear the seat belt when the roll bar is in the down position.

-

Drive slowly and carefully.

-

Raise the roll bar as soon as clearance permits.

-

Check carefully for overhead clearances (i.e., branches, doorways, electrical wires) before driving under any objects, and do not contact them.

Important: Lower the roll bar only when absolutely necessary.

Important: Ensure that the rear part of the seat is secured with the seat latch.

-

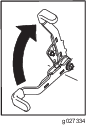

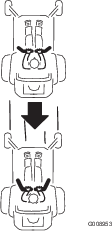

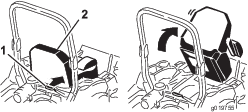

To lower the roll bar, apply forward pressure to the upper part of the roll bar.

-

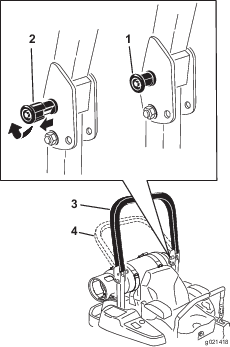

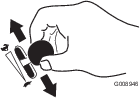

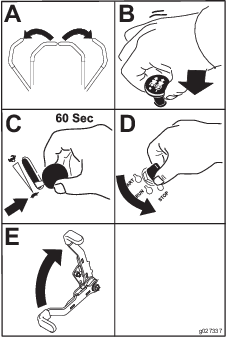

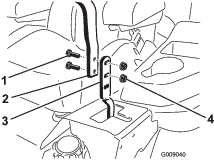

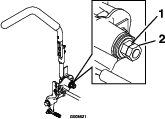

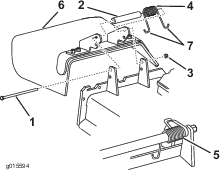

Pull both knobs out and rotate them 90° so they are not engaged (Figure 9).

-

Lower the roll bar to the down position (Figure 9).

-

To raise the roll bar, raise the roll bar to the operate position, rotate the knobs so they move partially into the grooves (Figure 9).

-

Raise the roll bar to the full upright position while pushing on the upper roll bar and the pins will snap into position when the holes align with the pins (Figure 9). Push on the roll bar and ensure that both pins are engaged.

Important: Always use the seat belt with the roll bar in the fully raised position.

Think Safety First

Please read all safety instructions and symbols in the safety section. Knowing this information could help you or bystanders avoid injury.

Danger

Operating the machine on wet grass or steep slopes can cause sliding and loss of control.

-

Do not operate on slopes greater than 15 degrees.

-

Reduce speed and use extreme caution on slopes.

-

Do not operate the machine near water.

Danger

Wheels dropping over edges can cause rollovers, which may result in serious injury, death, or drowning.

Do not operate the machine near drop-offs.

Danger

Operating the machine while the roll bar is down may lead to serious injury or death in the event of a rollover.

Always keep the roll bar in the fully raised and locked position and use the seat belt.

Caution

This machine produces sound levels in excess of 85 dBA at the operator’s ear and can cause hearing loss through extended periods of exposure.

Wear hearing protection when operating this machine.

The use of protective equipment for eyes, ears, hands, feet, and head is recommended.

Operating the Parking Brake

Always set the parking brake when you stop the machine or leave it unattended.

Setting the Parking Brake

Warning

The parking brake may not hold a machine parked on a slope and could cause personal injury or property damage.

Do not park the machine on slopes unless the wheels are chocked or blocked.

Releasing the Parking Brake

Operating the Mower Blade-Control Switch (PTO)

The blade-control switch (PTO) starts and stops the mower blades and any powered attachments.

Operating the Throttle

The throttle control can be moved between FAST and SLOW positions (Figure 14).

Always use the FAST position when turning on the mower deck with the blade-control switch (PTO).

Operating the Ignition Switch

-

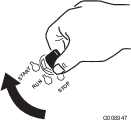

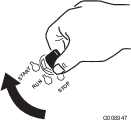

Turn the ignition key to the START position (Figure 15).

-

When the engines starts, release the key.

Important: Do not engage starter for more than 5 seconds at a time. If the engine fails to start, allow a 15-second cool-down period between attempts. Failure to follow these instructions can burn out the starter motor.

-

Turn the ignition key to STOP to shut off the engine.

Starting and Shutting Off the Engine

Starting the Engine

-

Raise the ROPS up and lock into place, sit on the seat, and fasten the seat belt (Figure 16).

-

Slowly open the fuel valve to equalize the pressure in the tank (Figure 16).

Note: The fuel valve is located on the top end of the LPG tank. If the fuel valve is opened too quickly, the pressure relief valve is equipped with a back pressure check valve that will shut off the fuel supply. If this happens, close the fuel valve completely and wait 5 seconds.

-

Move the motion controls to NEUTRAL-LOCK position (Figure 16).

-

Set the parking brake; refer to Setting the Parking Brake.

-

Move the blade-control switch (PTO) to the OFF position (Figure 16).

-

Move the throttle lever to the 3/4 throttle position between the SLOW and FAST positions (Figure 16).

-

Turn the ignition key to the START position (Figure 16). When the engines starts, release the key.

Shutting Off the Engine

Caution

Children or bystanders may be injured if they move or attempt to operate the tractor while it is unattended.

Always remove the ignition key and set the parking brake when leaving the machine unattended, even if just for a few minutes.

Let the engine idle at SLOW throttle (turtle) for 60 seconds before turning the ignition switch OFF.

Important: Ensure that the fuel shut off valve is closed before transporting or storing the machine, as fuel leakage may occur. Set the parking brake before transporting. Ensure to remove the key as the fuel pump may run and cause the battery to lose charge.

Using the Safety-Interlock System

Caution

If the safety-interlock switches are disconnected or damaged, the machine could operate unexpectedly, causing personal injury.

-

Do not tamper with the interlock switches.

-

Check the operation of the interlock switches daily and replace any damaged switches before operating the machine.

Understanding the Safety-Interlock System

The safety-interlock system is designed to prevent the engine from starting unless:

-

The parking brake is engaged.

-

The blade-control switch (PTO) is disengaged.

-

The motion-control levers are in the NEUTRAL-LOCK position.

The safety-interlock system also is designed to shut off the engine when you move the traction controls from the LOCK position with the parking brake engaged or if you rise from the seat when the PTO is engaged.

The hour meter has symbols to notify you when the interlock component is in the correct position. When the component is in the correct position, a triangle lights up in the corresponding square.

Testing the Safety-Interlock System

Test the safety-interlock system before you use the machine each time. If the safety system does not operate as described below, have an Authorized Service Dealer repair the safety system immediately.

-

Sit on the seat, engage the parking brake and move the blade-control switch (PTO) to the ON position. Try starting the engine; the engine should not start.

-

Sit on the seat, engage the parking brake and move the blade-control switch (PTO) to the OFF position. Move either motion-control lever (out of the NEUTRAL-LOCK position). Try starting the engine; the engine should not start. Repeat for other control lever.

-

Sit on the seat, engage the parking brake, move the blade-control switch (PTO) to the OFF position, and move the motion-control levers to the NEUTRAL-LOCK position. Start the engine. While the engine is running, release the parking brake, engage the blade-control switch (PTO), and rise slightly from the seat; the engine should shut off.

-

Sit on the seat, engage the parking brake, move the blade-control switch (PTO) to the OFF position, and move the motion-control levers to NEUTRAL-LOCK position. Start the engine. While the engine is running, center either motion-control lever and move it forward or reverse; the engine should shut off. Repeat for other motion-control lever.

-

Sit on the seat, disengage the parking brake, move the blade-control switch (PTO) to the OFF position, and move the motion-control levers to NEUTRAL-LOCK position. Try starting the engine; the engine should not start.

Driving Forward or Backward

The throttle control regulates the engine speed as measured in rpm (revolutions per minute). Place the throttle control in the FAST position for best performance. Always operate in the FULL-THROTTLE position when mowing.

Caution

Machine can spin very rapidly. Operator may lose control of machine and cause personal injury or damage to machine.

-

Use caution when making turns.

-

Slow the machine down before making sharp turns.

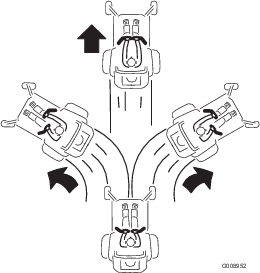

Using the Motion-Control Levers

Driving Forward

Note: The engine will shut off when you move the traction-control levers with the parking brake engaged.

To stop the machine, pull the motion-control levers to the NEUTRAL position.

-

Release the parking brake; refer to Releasing the Parking Brake.

-

Move the levers to the center, unlocked position.

-

To go forward, slowly push the motion-control levers forward (Figure 20).

Driving Backward

-

Move the levers to the center, unlocked position.

-

To go backward, slowly pull the motion-control levers rearward (Figure 21).

Stopping the Machine

To stop the machine, move the traction-control levers to NEUTRAL, and then move them to the locked position, disengage the power take off blade-control switch (PTO), and turn the ignition key to the OFF position.

Set the parking brake when you leave the machine; refer to Setting the Parking Brake. Remove the key from the switch.

Caution

Children or bystanders may be injured if they move or attempt to operate the machine while it is unattended.

Always remove the ignition key and set the parking brake when leaving the machine unattended, even if just for a few minutes.

Adjusting the Height-of-Cut

Using the Transport Lock

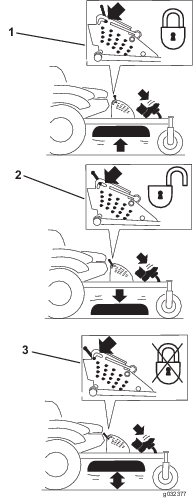

The transport lock has 2 positions and is used with the deck-lift pedal. There is a lock position and an unlock position for the transport position. You use the transport lock with the deck-lift pedal (Figure 22).

Adjusting the Height-of-Cut Pin

You can adjust the height of cut to from 25 to 140 mm (1 to 5-1/2 inches) in 6 mm (1/4 inch) increments by locating the clevis pin into different hole locations.

-

Move the transport lock to the lock position.

-

Push on the deck-lift pedal with your foot, and raise the mower deck to the transport position (also the 140 mm (5-1/2 inches) cutting-height position) as shown in Figure 23.

-

To adjust, rotate the pin 90 degrees and remove the pin from the height-of-cut bracket (Figure 23).

-

Select a hole in the height-of-cut bracket corresponding to the height-of-cut desired, and insert the pin (Figure 23).

-

Push on the deck lift, pull back on the transport lock, and slowly lower the mower deck.

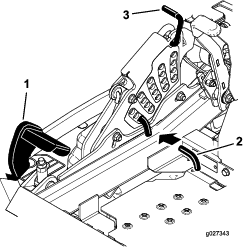

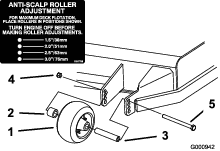

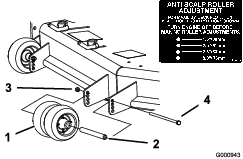

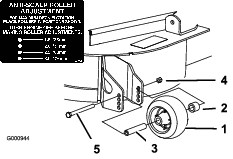

Adjusting the Anti-Scalp Rollers

Whenever you change the height-of-cut, it is recommended to adjust the height of the anti-scalp rollers.

-

Disengage the BLADE-CONTROL switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

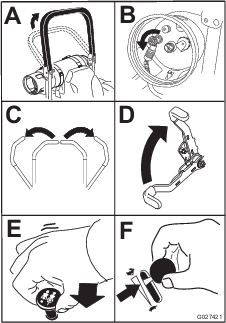

Adjust the anti-scalp rollers as shown in Figure 24, Figure 25, and Figure 26.

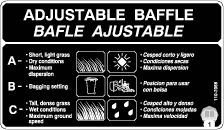

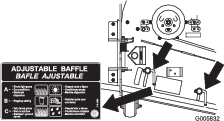

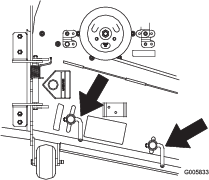

Adjusting the Flow Baffle Cam Locks

This procedure is applicable only to machines with the flow-baffle locks. Certain models have nuts and bolts in place of the flow-baffle locks and can be adjusted the same.

You can adjust the mower-discharge flow for different types of mowing conditions. Position the cam locks and baffle to give the best quality of cut.

-

Disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

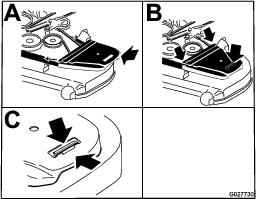

To adjust the cam locks, swing the lever up to loosen the cam lock (Figure 27).

-

Adjust the baffle and cam locks in the slots to the desired discharge flow.

-

Swing the lever back over to tighten the baffle and cam locks (Figure 27).

-

If the cam locks do not lock the baffle into place or it is too tight, loosen the lever and then rotate the cam lock.

Note: Adjust the cam lock until you obtain the desired locking pressure.

Positioning the Flow Baffle

The following figures are only recommendations for use. Adjustments will vary by grass type, moisture content, and the height of the grass.

Note: If the engine power draws down and the mower ground speed is the same, open up the baffle.

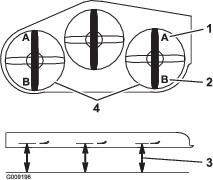

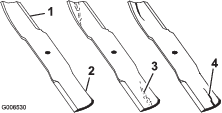

Position A

This is the full rear position. The suggested use for this position is as follows:

-

Short, light grass mowing conditions

-

Dry conditions

-

Smaller grass clippings

-

Propels grass clippings farther away from the mower.

Position B

Use this position when bagging. Always align it with the blower opening.

Position C

This is the full-open position. The suggested use for this position is as follows:

-

Tall, dense grass mowing conditions

-

Wet conditions

-

Lowers the engine-power consumption

-

Allows increased ground speed in heavy conditions

-

This position is similar to the benefits of the Toro SFS mower.

Positioning the Seat

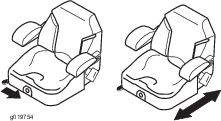

The seat moves forward and backward. Position the seat where you have the best control of the machine and are most comfortable.

To adjust, move the lever sideways to unlock the seat (Figure 31).

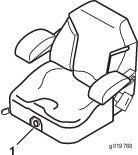

Unlatching the Seat

Changing the Seat Suspension

The seat adjusts to provide a smooth and comfortable ride. Position the seat where you are most comfortable.

To adjust, turn the knob in front either direction to provide the best comfort (Figure 33).

Using the Drive-Wheel-Release Valves

Warning

Hands may become entangled in the rotating drive components below the engine deck, which could result in serious injury.

Shut off the engine, remove the key, and allow all moving parts to stop before accessing the drive-wheel-release valves.

Warning

The engine and hydraulic-drive units can become very hot. Touching a hot engine or hydraulic-drive units can cause severe burns.

Allow the engine and hydraulic-drive units to cool completely before accessing the drive-wheel-release valves.

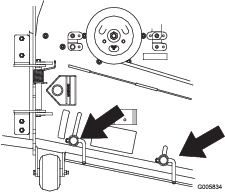

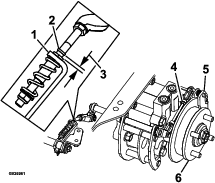

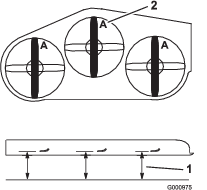

The drive-wheel-release valves are located in the back of each hydraulic-drive unit, under the seat.

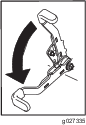

Note: Ensure that the release valves are in the fully horizontal position when operating the machine or severe damage to the hydraulic system can occur.

-

Disengage the PTO (blade-control switch) and turn the ignition key to the OFF position.

-

Move the levers to NEUTRAL-LOCK position, apply the parking brake, and remove the key.

-

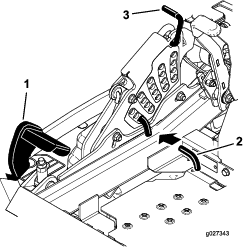

Rotate the release-valve levers vertically to push the machine. This allows hydraulic fluid to bypass the pump enabling the wheels to turn(Figure 34).

-

Disengage the parking brake before pushing the machine.

-

Rotate the release-valve levers horizontally to run the machine (Figure 34).

Using the Side Discharge

The mower has a hinged grass deflector that disperses clippings to the side and down toward the turf.

Danger

Without a grass deflector, discharge cover, or complete grass catcher assembly mounted in place, you and others are exposed to blade contact and thrown debris. Contact with rotating mower blade(s) and thrown debris will cause injury or death.

-

Never remove the grass deflector from the mower because the grass deflector routes material down toward the turf. If the grass deflector is ever damaged, replace it immediately.

-

Never put your hands or feet under the mower.

-

Never try to clear the discharge area or mower blades unless you move the power take off (PTO) blade-control switch to the OFF position, rotate the ignition key to the OFF position, and remove the key.

-

Ensure that the grass deflector is in the down position.

Transporting the Machine

Use a heavy-duty trailer or truck to transport the machine. Ensure that the trailer or truck has all necessary brakes, lighting, and marking as required by law. Please carefully read all the safety instructions. Knowing this information could help you, your family, pets, or bystanders avoid injury.

Warning

Driving on the street or roadway without turn signals, lights, reflective markings, or a slow-moving vehicle emblem is dangerous and can lead to accidents causing personal injury.

Do not drive the machine on a public street or roadway.

-

Be sure that the fuel valve is closed on the tank(s).

-

Place spare LPG tank(s) in a DOT approved storage cage.

-

Transport the tanks in an upright, vertical, and secure position to minimize movement, tipping, or physical damage relative to other tanks or to the storage cage while in transit.

-

Place tanks so that valves, fittings, or gauges are protected from physical damage during transport.

-

-

Place tank(s) in a well-ventilated trailer.

-

Do not store the tank(s) or machine with tank(s) in an area where the temperature can rise above 120°F (49°C). If the temperature exceeds approximately 160°F (71°C), the tank will release highly flammable propane vapor. See Preparation in the Safety Section.

-

Do not transport LPG tank(s) in the passenger space of a vehicle.

-

Do not transport leaking fuel tanks.

-

Trailers must have appropriate markings to transport LPG.

-

Follow NFPA 58 and state and local regulations for transporting LPG.

-

If using a trailer, connect it to the towing vehicle and connect the safety chains.

-

If applicable, connect the trailer brakes.

-

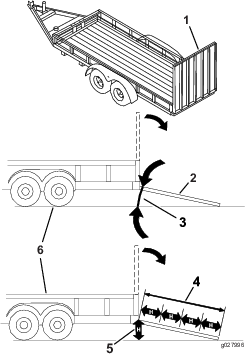

Load the machine onto the trailer or truck.

-

Stop the engine, remove the key, set the brake, and close the fuel valve.

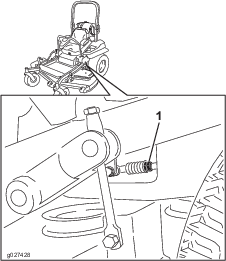

-

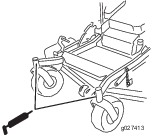

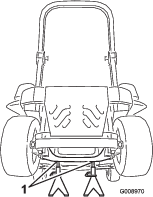

Use the metal tie-down loops on the machine to securely fasten the machine to the trailer or truck with straps, chains, cable, or ropes (Figure 35).

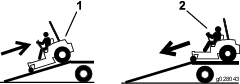

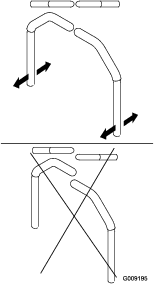

Loading the Machine

Use extreme caution when loading or unloading machines onto a trailer or a truck. Use a full-width ramp that is wider than the machine for this procedure. Back up ramps and drive forward down ramps (Figure 36).

Important: Do not use narrow individual ramps for each side of the machine.

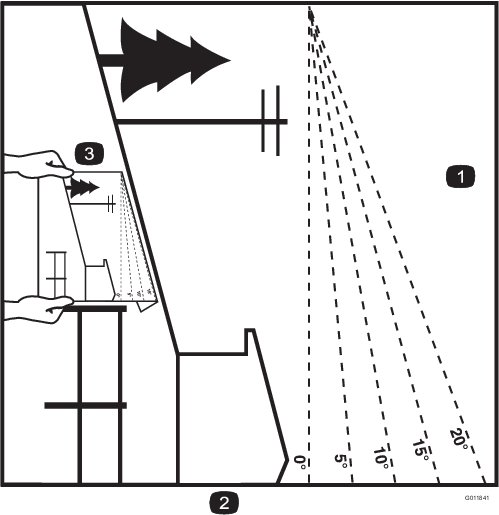

Ensure the ramp is long enough so that the angle with the ground does not exceed 15 degrees (Figure 37). On flat ground, this requires a ramp to be at least 4 times as long as the height of the trailer or truck bed to the ground. A steeper angle may cause mower components to get caught as the unit moves from the ramp to the trailer or truck. Steeper angles may also cause the machine to tip or lose control. If you are loading on or near a slope, position the trailer or truck so that it is on the down side of the slope and the ramp extends up the slope. This will minimize the ramp angle.

Warning

Loading a machine onto a trailer or truck increases the possibility of tip-over and could cause serious injury or death.

-

Use extreme caution when operating a machine on a ramp.

-

Ensure that the ROPS is in the up position and use the seat belt when loading or unloading the machine. Ensure that the ROPS will clear the top of an enclosed trailer.

-

Use only a full-width ramp; do not use individual ramps for each side of the machine.

-

Do not exceed a 15-degree angle between the ramp and the ground or between the ramp and the trailer or truck.

-

Ensure the length of ramp is at least 4 times as long as the height of the trailer or truck bed to the ground. This will ensure that ramp angle does not exceed 15 degrees on flat ground.

-

Back up ramps and drive forward down ramps.

-

Avoid sudden acceleration or deceleration while driving the machine on a ramp as this could cause a loss of control or a tip-over situation.

Operating Tips

Using the Fast Throttle Setting

For best mowing and maximum air circulation, operate the engine at the FAST position. Air is required to thoroughly cut grass clippings, so do not set the height-of-cut so low as to totally surround the mower in uncut grass. Always try to have 1 side of the mower free from uncut grass, which allows air to be drawn into the mower.

Cutting a Lawn for the First Time

Cut grass slightly longer than normal to ensure that the cutting height of the mower does not scalp any uneven ground. However, the cutting height used in the past is generally the best one to use. When cutting grass longer than 15 cm (6 inches) tall, you may want to cut the lawn twice to ensure an acceptable quality of cut.

Cutting a Third of the Grass Blade

It is best to cut only about a third of the grass blade. Cutting more than that is not recommended unless grass is sparse, or it is late fall when grass grows more slowly.

Alternating the Mowing Direction

Alternate the mowing direction to keep the grass standing straight. This also helps disperse clippings which enhances decomposition and fertilization.

Mowing at Correct Intervals

Grass grows at different rates at different times of the year. To maintain the same cutting height, mow more often in early spring. As the grass growth rate slows in mid summer, mow less frequently. If you cannot mow for an extended period, first mow at a high cutting height, then mow again 2 days later at a lower height setting.

Using a Slower Cutting Speed

To improve cut quality, use a slower ground speed in certain conditions.

Avoiding Cutting Too Low

When mowing uneven turf, raise the cutting height to avoid scalping the turf.

Stopping

If you must stop the forward motion of the machine while mowing, a clump of grass clippings may drop onto your lawn. To avoid this, move onto a previously cut area with the blades engaged or you can disengage the mower deck while moving forward.

Keeping the Underside of the Mower Clean

Clean clippings and dirt from the underside of the mower after each use. If grass and dirt build up inside the mower, cutting quality will eventually become unsatisfactory.

Maintaining the Blade(s)

Maintain a sharp blade throughout the cutting season because a sharp blade cuts cleanly without tearing or shredding the grass blades. Tearing and shredding turns grass brown at the edges, which slows growth and increases the chance of disease. Check the mower blades after each use for sharpness, and for any wear or damage. File down any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade.

Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| After the first 100 hours |

|

| After the first 250 hours |

|

| Before each use or daily |

|

| Every 40 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 150 hours |

|

| Every 200 hours |

|

| Every 250 hours |

|

| Every 300 hours |

|

| Every 500 hours |

|

| Every 600 hours |

|

| Monthly |

|

| Yearly |

|

| Yearly or before storage |

|

Important: Refer to your engine operator's manual for additional maintenance procedures.

Caution

If you leave the key in the ignition switch, someone could start the engine and seriously injure you or other bystanders.

Remove the key from the ignition before you do any maintenance.

Lubrication

Greasing and Lubrication

Grease more frequently when operating conditions are extremely dusty or sandy.

Grease Type: No. 2 lithium or molybdenum grease

-

Disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Clean the grease fittings with a rag. Ensure to scrape any paint off the front of the fitting(s).

-

Connect a grease gun to the fitting. Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

Adding Light Oil or Spray Lubrication

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Lubricate the mower-deck-lift pivots.

Greasing the Mower

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

| Yearly |

|

Important: Ensure that the cutting unit spindles are full of grease weekly.

-

Disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

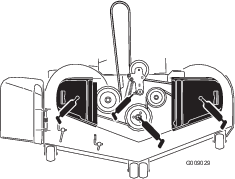

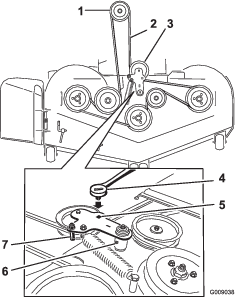

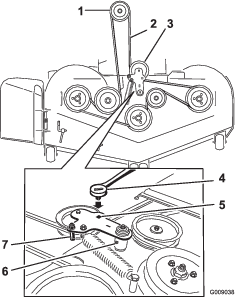

Grease the mower-deck-idler pulley pivot until grease come out the bottom (Figure 39).

-

Grease the 3 spindle bearings until grease comes out the lower seals (Figure 39).

-

Grease the drive-belt-idler arm (Figure 39).

-

Remove the dust cap and adjust the caster pivots. Keep the dust cap off until greasing is done. Refer to Adjusting the Caster Pivot Bearing.

-

Remove the hex plug. Thread a grease fitting into the hole.

-

Pump grease into the fitting until it oozes out around the top bearing.

-

Remove the grease fitting in the hole. Install the hex plug and dust cap (Figure 41).

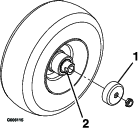

Lubricating the Caster Wheel Hubs

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Shut off the engine, wait for all moving parts to stop, and remove the key. Engage the parking brake.

-

Raise the front of the machine up and support it with jack stands.

-

Remove the caster wheel from the caster forks.

-

Remove the seal guards from the wheel hub.

-

Remove 1 of the spacer nuts from the axle assembly in the caster wheel.

Note: Note that thread-locking adhesive has been applied to lock the spacer nuts to the axle. Remove the axle (with the other spacer nut still assembled to it) from the wheel assembly.

-

Pry out the seals, and inspect the bearings for wear or damage and replace if necessary.

-

Pack the bearings with a general-purpose grease.

-

Insert 1 bearing and 1 new seal into the wheel.

Note: Replace the seals.

-

If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread-locking adhesive to 1 spacer nut and thread it onto the axle with the wrench flats facing outward.

Note: Do not thread the spacer nut all of the way onto the end of the axle. Leave approximately 3 mm (1/8 inch) from the outer surface of the spacer nut to the end of the axle inside the nut.

-

Insert the assembled nut and axle into the wheel on the side of the wheel with the new seal and bearing.

-

With the open end of the wheel facing up, fill the area inside the wheel around the axle full of general-purpose grease.

-

Insert the second bearing and new seal into the wheel.

-

Apply a thread-locking adhesive to the second spacer nut and thread it onto the axle with the wrench flats facing outward.

-

Torque the nut to 8 to 9 N∙m (75 to 80 in-lb), loosen the nut, then torque it to 2 to 3 N∙m (20 to 25 in-lb).

Note: Ensure that the axle does not extend beyond either nut.

-

Install the seal guards over the wheel hub and insert the wheel into the caster fork. Install the caster bolt and tighten the nut fully.

Important: To prevent seal and bearing damage, check the bearing adjustment often. Spin the caster tire. The tire should not spin freely (more than 1 or 2 revolutions) or have any side play. If the wheel spins freely, adjust the torque on the spacer nut until there is a slight amount of drag. Apply thread-locking adhesive.

Engine Maintenance

Warning

Contact with hot surfaces may cause personal injury.

Keep your hands, feet, face, clothing, and other body parts away the muffler and other hot surfaces.

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 150 hours |

|

| Every 300 hours |

|

| Every 600 hours |

|

Note: Check the filters more frequently if the operating conditions are extremely dusty or sandy.

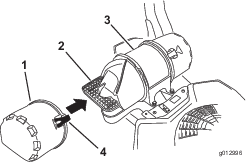

Removing the Filters

-

Disengage the PTO, move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Release the latches on the air cleaner and pull the air-inlet cover off the air-cleaner body (Figure 43).

-

Clean the air-inlet screen and cover.

-

Install the air-inlet cover and secure it with the latches (Figure 43).

-

Release the latches on the air cleaner and pull the air-cleaner cover off the air-cleaner body (Figure 44).

-

Clean the inside of the air-cleaner cover with compressed air.

-

Gently slide the primary filter out of the air-cleaner body (Figure 44).

Note: Avoid knocking the filter into the side of the body.

-

Remove the safety filter only if you intend to replace it.

Important: Never attempt to clean the safety filter. If the safety filter is dirty, then the primary filter is damaged. Replace both filters.

-

Inspect the primary filter for damage by looking into the filter while shining a bright light on the outside of the filter. Holes in the filter will appear as bright spots. If the filter is damaged, discard it.

Servicing the Primary Filter

-

Replace the primary filter if it is dirty, bent, or damaged.

-

Do not clean the primary filter.

Servicing the Safety Filter

Replace the safety filter, never clean it.

Important: Never attempt to clean the safety filter. If the safety filter is dirty, then the primary filter is damaged. Replace both filters.

Installing the Filters

Important: To prevent engine damage, always operate the engine with both air filters and cover installed.

Note: If installing new filters, check each filter for shipping damage. Do not use a damaged filter.

-

To replace the safety filter, carefully slide it into the filter body (Figure 44).

-

Carefully slide the primary filter over the safety filter (Figure 44).

Note: Ensure that the primary filter is fully seated by pushing on its outer rim while installing it.

Important: Do not press on the soft inside area of the filter.

-

Install the air-cleaner cover and secure the latches (Figure 44).

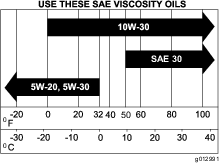

Servicing the Engine Oil

Engine Oil Type: Detergent oil (API service SG, SH, SJ, or SL)

Engine Oil Capacity: with a filter change, 2.3 L (77 oz); without a filter change, 2.1 L (70 oz)

Viscosity: See the table below.

Note: Use of multi-grade oils (5W-20, 10W-30, or 10W-40) will increase oil consumption. Check the oil level more frequently when using them.

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

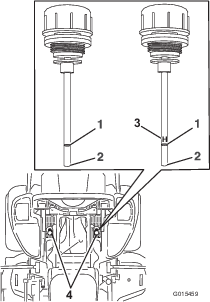

Note: Check the oil when the engine is cold.

Warning

Contact with hot surfaces may cause personal injury.

Keep hands, feet, face, clothing, and other body parts away from the muffler and other hot surfaces.

Important: Do not overfill the crankcase with oil because damage to the engine may result. Do not run engine with oil below the low mark because the engine may be damaged.

-

Disengage the PTO, move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position (Figure 46).

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| Every 100 hours |

|

Note: Dispose of the used oil at a recycling center.

-

Park the machine so that the rear is slightly lower than the front to ensure that the oil drains completely.

-

Disengage the PTO, move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

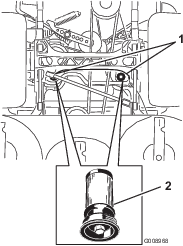

Drain the engine oil (Figure 47).

-

Slowly pour approximately 80% of the specified oil into the filler tube and slowly add the additional oil to bring it to the full mark (Figure 48).

-

Start the engine and drive to a flat area. Check the oil level again.

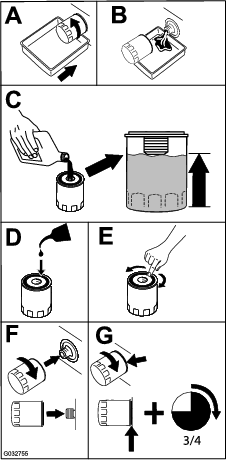

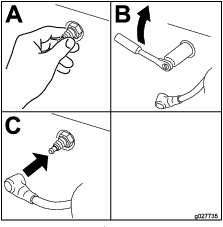

Changing the Engine-Oil Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

Note: Change the engine oil filter more frequently when operating conditions are extremely dusty or sandy.

-

Drain the oil from the engine; refer to Changing the Engine Oil.

-

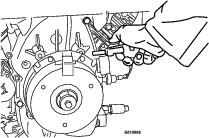

Change the engine-oil filter (Figure 49).

Note: Ensure that the oil filter gasket touches the engine and then turn it an extra 3/4 turn.

-

Fill the crankcase with the proper type of new oil; refer to Changing the Engine Oil.

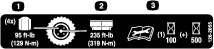

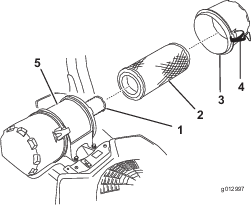

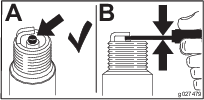

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Ensure that the air gap between the center and side electrodes is correct before installing the spark plug. Use a spark plug wrench for removing and installing the spark plug(s) and a gapping tool/feeler gauge to check and adjust the air gap. Install a new spark plug(s) if necessary.

Type:Champion® XC12YC or equivalent

Air Gap: 0.75 mm (0.030 inch)

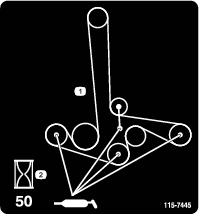

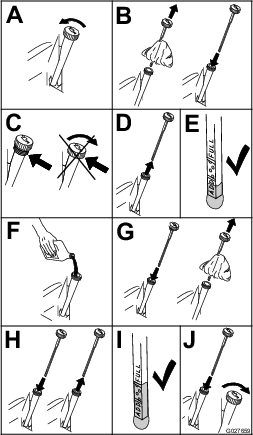

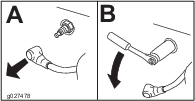

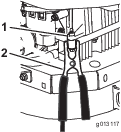

Removing the Spark Plug

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

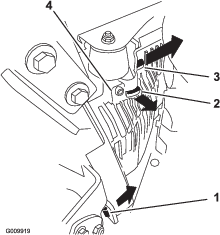

-

Disengage the PTO, move the motion-control levers to the NEUTRAL-LOCK position and set the parking brake.

-

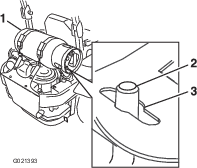

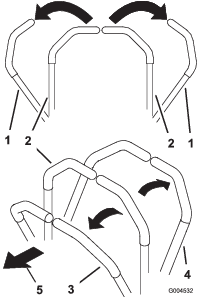

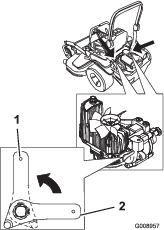

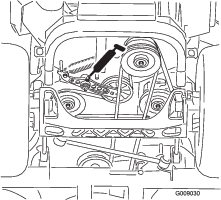

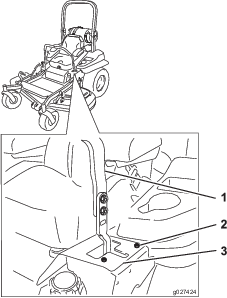

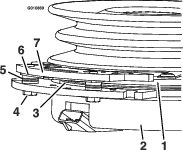

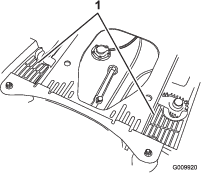

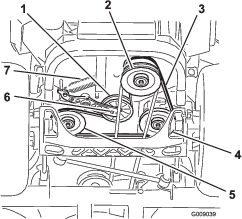

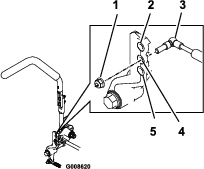

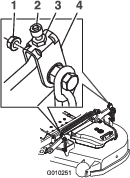

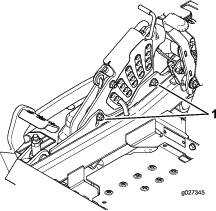

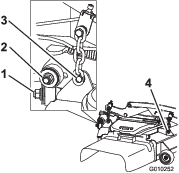

Remove the left-hydraulic-unit shroud in the order listed with Figure 50.

Note: This gives you access to the front spark plug.

-

Remove the spark plug.

-

Install the left-hydraulic-unit shroud (Figure 50).

Checking the Spark Plug

Important: Never clean the spark plug(s). Always replace the spark plug(s) when it has: a black coating, worn electrodes, an oily film, or cracks.

If you see light brown or gray on the insulator, the engine is operating properly. A black coating on the insulator usually means the air cleaner is dirty.

Set the gap to 0.76 mm (0.030 inches).

Installing the Spark Plug

Tighten the spark plug(s) to 22 N∙m (16 ft.-lb).

Checking Spark Arrester

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Warning

Hot particles exhausted during engine operation may ignite flammable materials. Fire may result in personal injury or property damage.

-

Shut off the engine, wait for all moving parts to stop, and remove the key. Engage parking brake.

-

Wait for the muffler to cool.

-

Replace the arrester if there are any breaks in the screen or welds.

-

If the screen is plugged, remove the arrester and shake loose any particles out of the arrester and clean the screen with a wire brush (soak the arrester in solvent if necessary). Install arrester on the exhaust outlet.

Fuel System Maintenance

Inspecting the LPG System

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 40 hours |

|

It is very important to check the LPG tank and components for wear or leaks.

Important: Never check for leaks using an open flame.

Important: Never use bare hands when checking the fitting or valve. Escaping LPG vapor and liquid freezes skin on contact.

-

Inspecting the LPG system before each use:

-

Visually inspect the tank, hose, and fitting and be alert to a foul odor coming from the tank.

-

The LPG tank should be free of dents or damage. If the tank show signs of dents or damage, replace it immediately.

-

Check the valve and fitting openings for dirt and debris.

-

Slowly open the valve all the way and listen for a continuous hiss from the regulator, it may indicate a leak.

-

LPG has a rotten egg or skunk smell added to it to help detect a gas leak. If you detect a gas leak:

-

Turn off the LPG valve if you can safely do so.

-

Leave the area.

-

Contact trained and qualified personnel immediately.

-

-

Do not use if the hoses are abraded, damaged, kinked, or flattened.

-

Ensure that the tank is securely mounted to the mower. If the tank is loose, the hose or fittings may leak.

-

-

Inspecting the LPG system with each tank change:

-

Check all gauges, fittings, and valves for damage.

-

Look for deterioration, worn or missing O-rings on the tank connection fitting.

-

Inspect the LPG tank and the fuel connection joint for leaks. Use the following procedure below to detect leaks:

-

Apply an approved leak detector solution, obtained from a trained and qualified LPG distributor, or a thick non-ammonia soapy water solution (50% non-ammonia soap and 50% water). (A leak detector solution that contains ammonia will cause the fittings to corrode and leak.)

-

Using a small brush or spray bottle, apply the solution around all the fittings of the LPG tank and the fuel connection joint.

-

Slowly open the gas valve a half-turn.

-

If bubbles are detected, the joint or fitting has a leak. Shut off the valve, tighten the leaking connection, and slowly open the valve again. If bubbles still appear, do not use the tank. If it is safe to do so, remove the tank from your mower; otherwise, contact trained and qualified personnel immediately.

-

If no bubbles are detected, the LPG tank may be used.

-

-

-

Inspecting the LPG system weekly:

-

Check the LPG hoses, regulator, and connections for damage or deterioration.

-

Check the LPG hoses, regulator, and connections for leaks at all joints using the same method as described in the previous section.

-

Follow all the inspection checks as specified in the 2 previous inspection sections.

-

-

Tank Requalification:

-

USDOT (United States Department of Transportation) regulations require LPG tanks to be inspected, requalified, and marked within 12 years of the manufacture date and on a regular basis thereafter. Typically this occurs when the tank is refilled; contact a trained and qualified LPG tank provider for more details.

-

Do not fill the LPG tank if it is beyond the requalification period.

-

Do not fill damaged or rusted LPG tanks.

-

Servicing the Electronic Fuel Injection System

This machine contains an electronic-fuel-injection (EFI) system. It controls the fuel flow under different operating conditions.

The electronic control unit (ECU) continuously monitors the operation of the EFI system.

If a problem or fault within the system is detected, the malfunction indicator light (MIL) is illuminated. The MIL is the red light located in the right console panel.

Once the MIL illuminates, initial trouble shooting checks should be made. Refer to the MIL section in .

If these checks do not correct the problem, further diagnosis and servicing by an Authorized Service Dealer is necessary.

Electrical System Maintenance

Servicing the Battery

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Monthly |

|

Danger

Battery electrolyte contains sulfuric acid, which is a deadly poison and causes severe burns.

Do not drink electrolyte and avoid contact with skin, eyes or clothing. Wear safety glasses to shield your eyes and rubber gloves to protect your hands.

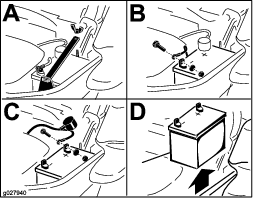

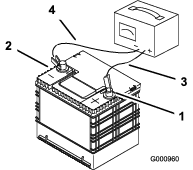

Removing the Battery

Warning

Battery terminals or metal tools could short against metal machine components causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

When removing or installing the battery, do not allow the battery terminals to touch any metal parts of the machine.

-

Do not allow metal tools to short between the battery terminals and metal parts of the machine.

Warning

Incorrect battery cable routing could damage the machine and cables causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

Always disconnect the negative (black) battery cable before disconnecting the positive (red) cable.

-

Always reconnect the positive (red) battery cable before reconnecting the negative (black) cable.

-

Disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

First disconnect the negative battery cable (black) from the negative (-)(black) battery terminal (Figure 54).

-

Slide the red terminal boot off the positive (red) battery terminal and remove the positive (+)(red) battery cable (Figure 54).

-

Remove the wing nut securing the battery clamp (Figure 54).

-

Remove the clamp (Figure 54).

-

Remove the battery.

Installing the Battery

-

Position battery in the tray with the terminal posts opposite from the hydraulic tank (Figure 54).

-

First, install the positive (red) battery cable to positive (+) battery terminal.

-

Then install the negative (black) battery cable and ground wire to the negative (-) battery terminal.

-

Secure the cables with 2 bolts, 2 washers, and 2 locknuts (Figure 54).

-

Slide the red terminal boot onto the positive (red) battery post.

-

Install the clamp and secure it with the wing nut (Figure 54).

Charging the Battery

Warning

Charging the battery produces gasses that can explode.

Never smoke near the battery and keep sparks and flames away from battery.

Important: Always keep the battery fully charged (1.265 specific gravity). This is especially important to prevent battery damage when the temperature is below 32°F (0°C).

-

Charge battery for 10 to 15 minutes at 25 to 30 amps or 30 minutes at 10 A.

-

When the battery is fully charged, unplug the charger from the electrical outlet, then disconnect the charger leads from the battery posts (Figure 55).

-

Install the battery in the machine and connect the battery cables, refer to Installing the Battery.

Note: Do not run the machine with the battery disconnected, electrical damage may occur.

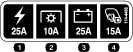

Servicing the Fuses

The electrical system is protected by fuses. It requires no maintenance, however, if a fuse blows check the component/circuit for a malfunction or short.

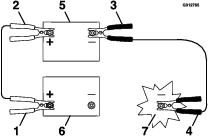

Jump-Starting the Machine

-

Check and clean corrosion from the battery terminals before jump-starting. Ensure that the connections are tight.

Caution

Corrosion or loose connections can cause unwanted electrical voltage spikes at any time during the jump-starting procedure.

Do not attempt to jump-start with loose or corroded battery terminals, or damage to the engine or EFI may occur.

Danger

Jump-starting a weak battery that is cracked or frozen, or has a low electrolyte level or an open/shorted battery cell can cause an explosion resulting in serious personal injury.

Do not jump-start a weak battery if these conditions exist.

-

Ensure that the booster battery is a good and fully charged lead-acid battery at 12.6 V or greater.

Note: Use properly sized jumper cables with short lengths to reduce voltage drop between systems. Ensure that the cables are color coded or labeled for the correct polarity.

Caution

Connecting the jumper cables incorrectly (wrong polarity) can immediately damage the EFI system.

Be certain of battery terminal polarity and jumper cable polarity when hooking up batteries.

Warning

Batteries contain acid and produce explosive gases.

-

Shield the eyes and face from the batteries at all times.

-

Do not lean over the batteries.

Note: Ensure that the vent caps are tight and level. Place a damp cloth, if available, over any vent caps on both batteries. Also ensure that the vehicles do not touch and that both electrical systems are off and at the same rated system voltage. These instructions are for negative ground systems only.

-

-

Connect the positive (+) cable to the positive (+) terminal of the discharged battery that is wired to the starter or solenoid as shown in Figure 57.

-

Connect the other end of the positive cable to the positive terminal of the booster battery.

-

Connect the black negative (–) cable to the other terminal (negative) of the booster battery.

-

Make the final connection on the engine block of the stalled vehicle (not to the negative battery post) away from the battery and stand back (Figure 59).

-

Start the vehicle and remove the cables in the reverse order of connection (the engine block (black) connection is the first to disconnect).

Drive System Maintenance

Checking the Seat Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Visually inspect seat belt for wear, cuts, and proper operation of retractor and buckle. Replace before operating if damaged.

Checking the Knobs on the Rollover Protection System (ROPS)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Check that both the mounting hardware and the knobs are in good working condition. Ensure that the knobs are fully engaged with the ROPS in the fully raised position. The upper hoop of the roll bar may need to be pushed forward or pulled rearward to get both knobs fully engaged.

Adjusting the Tracking

-

Disengage the blade-control switch (PTO).

-

Drive to an open flat area, move the motion-control levers to the NEUTRAL-LOCK position.

-

Move the throttle midway between FAST and SLOW.

-

Move both motion-control levers all the way forward until they both hit the stops in the T-slot.

-

Check which way the machine tracks.

-

If it tracks to the right, loosen the bolts and adjust the left stop plate rearward on the left T-slot until the machine tracks straight (Figure 61).

-

If it tracks to the left, loosen the bolts and adjust the right stop plate rearward on the right T-slot until the machine tracks straight (Figure 61).

-

Tighten the stop plate (Figure 61).

Checking the Tire Pressure

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

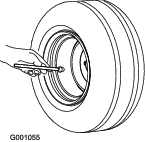

Maintain the air pressure in the rear tires at 13 psi (90 kPa). Uneven tire pressure can cause uneven cut. Check the tires when they are cold to get the most accurate pressure reading.

Note: The front tires are semi-pneumatic tires and do not require air-pressure maintenance.

Checking the Wheel Lug Nuts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 500 hours |

|

Check and torque the wheel lug nuts to 122-129 N-m (90-95 ft-lb).

Checking the Wheel Hub Slotted Nut

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 500 hours |

|

Check and ensure that the torque of the slotted nut is 286 to 352 N∙m (211 to 260 ft-lb).

Note: Do not use anti-seize compound on the wheel hub.

Adjusting the Caster Pivot Bearing

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 500 hours |

|

-

Disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position, and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

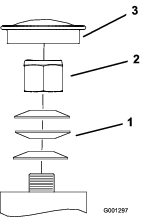

Remove the dust cap from caster and tighten the locknut (Figure 64).

-

Tighten the locknut until the spring washers are flat and then back off a 1/4 turn to properly set the pre-load on the bearings (Figure 64).

Important: Ensure the spring washers are installed correctly as shown in Figure 64.

-

Install the dust cap (Figure 64).

Using the Clutch Shim

Some later model year units have clutches that contain a brake shim. When the clutch brake has worn to the point where the clutch no longer engages consistently, you can remove the shim to extend the clutch life.

Removing the Clutch Shim

-

Shut off the engine, wait for all moving parts to stop, and remove the key.

-

Engage the parking brake and allow the machine to cool down completely.

-

Using an air compressor, blow out any debris from under the brake pole and around the brake spacers.

-

Check the condition of the wire-harness leads, connectors, and terminals. Clean or repair as necessary.

-

Verify that 12 V is present at the clutch connector when you engage the PTO switch.

-

Measure the gap between the rotor and armature. If the gap is greater than 1 mm (.04 inch), proceed with the following steps:

-

Loosen both brake mounting bolts a half to a full turn as shown below.

Note: Do not remove the brake pole from the field shell/armature. The brake pole has worn to match the armature and needs to continue to match after you remove the shim to ensure proper brake torque.

-

Take hold of the tab and remove the shim.

Note: Do not discard the shim until the clutch is functioning properly.

-

Using a pneumatic line, blow out any debris from under the brake pole and around the brake spacers.

-

Torque each bolt (M6 x 1) to 13 N∙m (10 ft-lb) +/- 0.7 N∙m (0.5 ft-lb).

-

Using a 0.010 inch thick feeler gauge, verify that a gap is present between the rotor and armature face on both sides of the brake pole as shown.

Note: Due to the way the rotor and armature faces wear (peaks and valleys) it is sometimes difficult to measure the true gap.

-

If the gap is less than 0.010 inch, then install the shim and refer to .

-

If the gap is sufficient, proceed to the safety check in step 6.

-

-

Perform the following safety check:

-

Sit on the seat and start the engine.

-

Ensure the blades do not engage with the PTO switch in the off position and the clutch disengaged.

If the clutch does not disengage, install the shim and refer to .

-

Engage and disengage the PTO switch 10 consecutive times to ensure that the clutch is functioning properly. If the clutch does not engage properly, refer .

-

-

Cooling System Maintenance

Cleaning the Engine Screen and Engine Oil Cooler

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

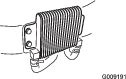

Remove any build-up of grass, dirt, or other debris from the oil cooler (Figure 71).

Before each use, remove any build-up of grass, dirt, or other debris from the engine screen. This helps to ensure adequate cooling, correct engine speed, and reduces the possibility of overheating and mechanical damage to the engine.

Cleaning the Engine Cooling Fins and Shrouds

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

-

Disengage the PTO and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

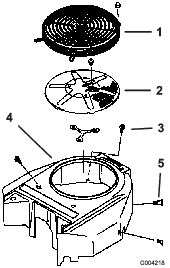

-

Remove the cooling shrouds and fan housing.

-

Clean the debris and grass from the engine parts.

-

Install the cooling shrouds and fan housing (Figure 74).

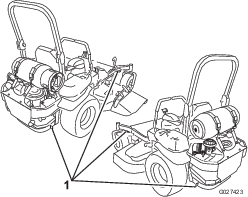

Check and Clean the Hydraulic Unit Shrouds

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Disengage the PTO and set the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Raise the seat.

-

Clean the debris and grass from the hydraulic-unit shrouds (Figure 73).

-

Lower the seat.

Brake Maintenance

Adjusting the Parking Brake

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 500 hours |

|

Ensure that the brake calipers are adjusted properly before adjusting the parking brake.

Note: Perform this procedure also when a brake component has been removed or replaced.

Danger

Mechanical or hydraulic jacks may fail to support machine and cause a serious injury.

-

Use jack stand when supporting machine.

-

Do not use hydraulic jacks.

-

Drive the machine onto a level surface.

-

Disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL-LOCK position and engage the parking brake.

-

Shut off the engine, wait for all moving parts to stop, and remove the key.

-

Raise the back of the machine up and support the machine with jack stands.

-

Remove the rear tires from the machine.

-

Remove any debris from the brake area.

-

Rotate the wheel-release handle to the released position. Refer to Using the Drive-Wheel-Release Valves.

-

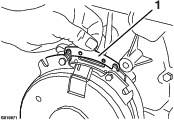

Check to see if there is a visible gap between the L-bracket and the linkage stop (Figure 74).

-

Disengage the parking brake, the lever should be in the down position.

-

Turn the wheel hub by hand in both directions relative to the caliper; the wheel hub should move freely between the caliper.

-

If a gap is needed or the wheel hub does not move freely:

-

Disengage the parking brake.

-

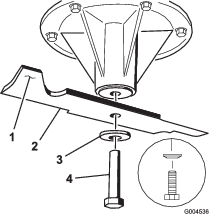

Disconnect and fine-tune the rear linkage assembly: