Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

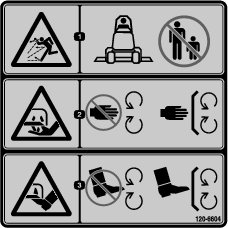

Warning

If you raise the machine using only a jack to support it while you work under the cutting unit, the jack could tip, causing the mower deck to fall, crushing you or bystanders.

Always secure the machine with at least 2 jack stands when you have the mower deck raised.

Caution

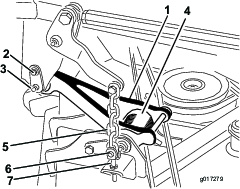

On the top of the cutting unit are 2 links that connect them to the frame. Connected to these links are torsion spring that are under tension (Figure 15). If you disconnect the link, the stored energy in the torsion spring will be released and could cause the links to move, damaging your hands or fingers.

Be careful when removing the cutting unit from the frame and secure the links before disconnecting them from the frame.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

Lubrication

Greasing the Bearings and Bushings

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

The machine has grease fittings that must be lubricated regularly with No. 2 lithium grease. Bearings and bushings must be lubricated daily when operating conditions are extremely dusty and dirty. Dusty and dirty operating conditions could cause dirt to get into the bearings and bushings, resulting in accelerated wear. Lubricate the grease fittings immediately after every washing, regardless of interval specified.

-

Wipe the grease fittings clean so foreign matter cannot be forced into the bearing or bushing.

-

Pump grease into the fittings.

-

Wipe off excess grease.

Note: Bearing life can be negatively affected by improper wash down procedures. Do not wash the unit when it is still hot and avoid directing high-pressure or high volume spray at the bearings or seals.

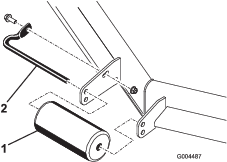

Replacing the Blade Drive Belts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

The blade drive belts, tensioned by the spring loaded idler pulleys, are very durable. However, after many hours of use, the belts will show signs of wear. Signs of a worn belt include squealing when the belt is rotating, blades slipping when cutting grass, poor quality of cut, frayed edges, and burn marks and cracks. Replace the belts if any of these conditions are evident.

-

Lower the cutting unit to the 1 inch height of cut setting, move the throttle lever to the SLOW position, shut off the engine, engage the parking brake, and remove the key.

-

Remove the belt covers from the top of the cutting unit and set the covers aside.

-

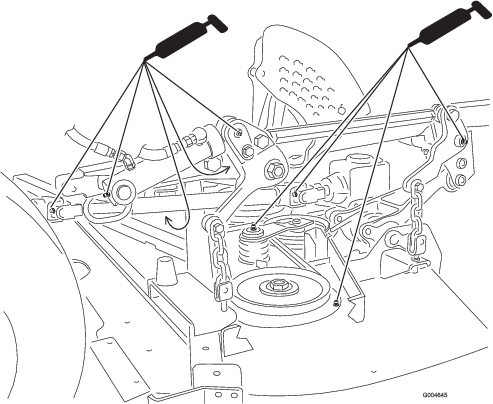

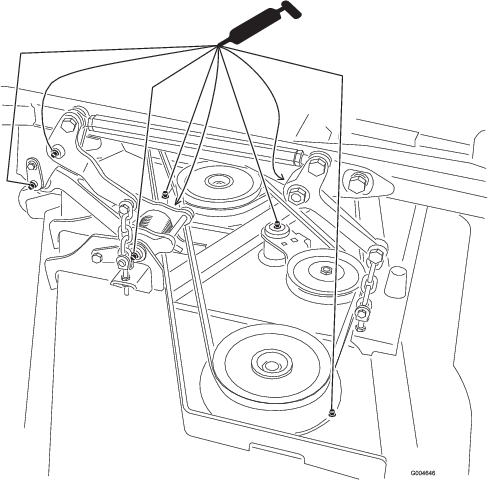

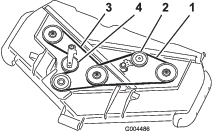

Using a breaker bar or similar tool, move the idler pulley for the top belt (Figure 18) away from the top drive belt to release the belt tension and allow the belt to be slipped off the pulleys.

-

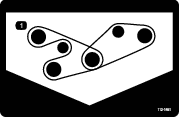

Route a new belt around the gearbox pulley, bottom spindle pulleys, and idler pulley assembly as shown in Figure 18.

-

Route a new belt around the top spindle pulleys and idler pulley assembly as shown in Figure 18.

-

Grease all mower and cutting unit drive grease points.

-

Install the belt covers.

Servicing the Cutting Blades

Maintain sharp blades throughout the cutting season because sharp blades cut cleanly without tearing or shredding the grass blades. Tearing and shredding turns grass brown at the edges, which slows growth and increases the chance of disease.

Check the blades daily for sharpness, and for any wear or damage. Sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade.

Danger

A worn or damaged blade can break, and a piece of the blade could be thrown toward you or bystanders, resulting in serious personal injury or death.

-

Inspect the blade periodically for wear or damage.

-

Replace a worn or damaged blade.

Inspect and check the blades every 8 hours.

Inspecting the Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Disengage the PTO, release the traction pedal, and engage the parking brake.

-

Move the throttle lever to the SLOW position, shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

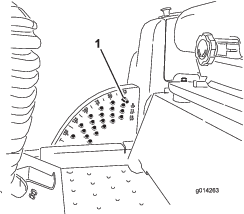

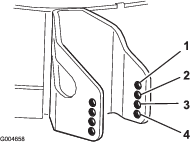

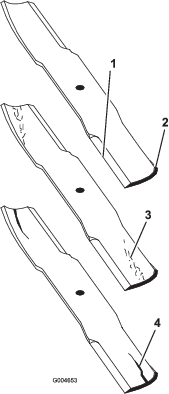

Inspect the cutting edges (Figure 19). If the edges are not sharp or have nicks, remove and sharpen the blades. Refer to Sharpening the Blades (Sharpening the Blades).

-

Inspect the blades, especially the sail area (Figure 19). If you notice any damage, wear, or a slot forming in this area (Figure 19), immediately install a new blade.

Danger

If you allow the blade to wear, a slot will form between the sail and flat part of the blade. Eventually a piece of the blade may break off and be thrown from under the housing, possibly resulting in serious injury to you or bystanders.

-

Inspect the blade periodically for wear or damage.

-

Never try to straighten a blade that is bent or weld a broken or cracked blade.

-

Replace a worn or damaged blade.

-

Checking for Bent Blades

-

Disengage the PTO, release the traction pedal, and engage the parking brake.

-

Move the throttle lever to the SLOW position, shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

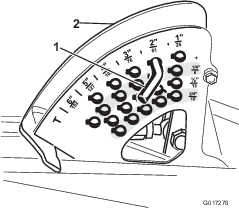

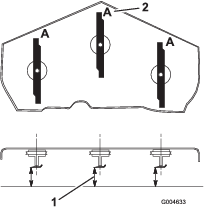

Rotate the blades until the ends face forward and backward (Figure 20). Measure from a level surface to the cutting edge, position A, of the blades (Figure 20). Note this dimension.

-

Rotate the opposite ends of the blades forward.

-

Measure from a level surface to the cutting edge of the blades at the same position as in step 3 above. The difference between the dimensions obtained in steps 3 and 4 must not exceed 3 mm (1/8 inch). If this dimension exceeds 3 mm (1/8 inch), the blade is bent and must be replaced; refer to Removing the Blades and Installing the Blades.

Warning

A blade that is bent or damaged could break apart and could seriously injure or kill you or bystanders.

-

Always replace bent or damaged blade with a new blade.

-

Never file or create sharp notches in the edges or surfaces of blade.

-

Removing the Blades

Blades must be replaced if a solid object is hit, if the blade is out of balance or is bent. To ensure optimum performance and continued safety conformance of the machine, use genuine Toro replacement blades. Replacement blades made by other manufacturers may result in non-conformance with safety standards.

Warning

Contact with a sharp blade can cause serious injury.

Wear gloves or wrap sharp edges of the blade with a rag.

-

Disengage the PTO, release the traction pedal, and engage the parking brake.

-

Move the throttle lever to the SLOW position, shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Hold the blade end using a rag or thickly-padded glove.

-

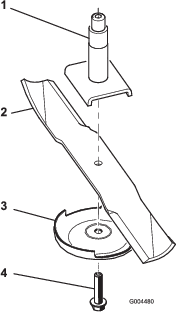

Remove the blade bolt, anti-scalp plate, and blade from the spindle shaft; refer to Figure 23 in Installing the Blades.

Sharpening the Blades

Warning

When sharpening blade, pieces of blade could be thrown and cause serious injury.

Wear proper eye protection when sharpening blades.

-

Sharpen the cutting edge at both ends of the blade (Figure 21). Maintain the original angle. The blade retains its balance if the same amount of material is removed from both cutting edges.

-

Check the balance of the blade by putting it on a blade balancer (Figure 22). If the blade stays in a horizontal position, the blade is balanced and can be used. If the blade is not balanced, file some metal off the end of the sail area only (Figure 23). Repeat this procedure until the blade is balanced.

Installing the Blades

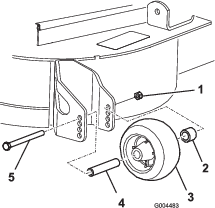

Correcting Cutting Unit Mismatch

If the cut is uneven across the cutting unit swath, correct it as follows:

-

Position the machine on a level surface.

-

Set the cutting unit to the desired height of cut, move the throttle lever to the SLOW position, shut off the engine, engage the parking brake, and remove the key.

-

Check and adjust front and rear traction-unit tire pressure; refer to the traction unit Operator’s Manual.

-

Check for bent blades.

-

Remove the covers from the top of the cutting units.

-

Rotate the blade on each spindle until the ends face forward and backward.

-

Measure from the floor to the front tip of the cutting edge.

-

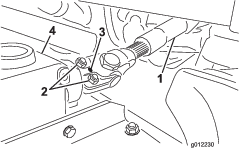

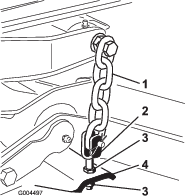

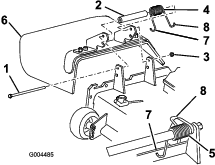

Adjust the jam nuts securing the cutting unit yokes/chains to the mower until the cutting unit is level (Figure 24).

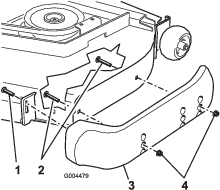

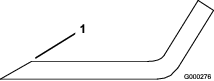

Replacing the Grass Deflector

Warning

An uncovered discharge opening allows the machine to throw objects toward you or bystanders, which can result in serious injury. Contact with the blade can also occur.

-

Never operate the machine without a mulch kit or grass deflector installed.

-

Ensure that the grass deflector is lowered.

-

Lower the cutting unit to the ground, move the throttle lever to the SLOW position, shut off the engine, engage the parking brake, and remove the key.

-

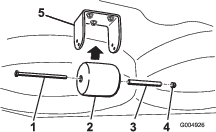

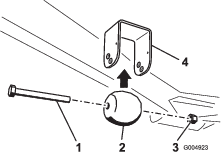

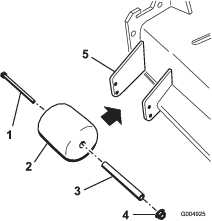

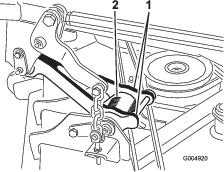

Remove the locknut, bolt, spring and spacer holding the deflector to the pivot brackets (Figure 25). Remove damaged or worn grass deflector.

-

Place the spacer and spring between the replacement grass deflector brackets (Figure 25). Place the left hand J hook end of the spring behind the cutting unit edge.

Note: Ensure that the left-hand hook end of the spring is installed behind the cutting unit edge before installing the bolt as shown in Figure 25.

-

Install the bolt and nut. Place the right-hand hook end of the spring around the grass deflector (Figure 25).

Important: The grass deflector must be able to lower down into position. Lift the deflector up to test that it lowers into the full down position.

Cleaning Under the Cutting Unit

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Remove the grass buildup under the cutting unit daily.

-

Disengage the PTO, release the traction pedal to the neutral position, and engage the parking brake.

-

Move the throttle lever to the SLOW position, shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operator’s position.

-

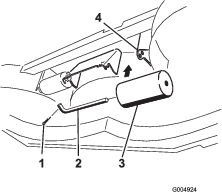

Raise the cutting unit to the TRANSPORT position.

-

Use a jack to raise the front of the machine and support it with jack stands.

-

Thoroughly clean the underside of the cutting unit with water.

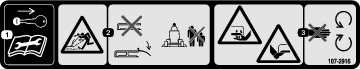

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.