Maintenance

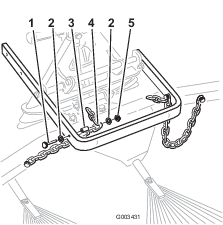

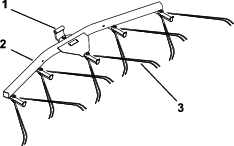

Inspecting and Cleaning the Rake and Traction Unit

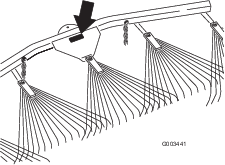

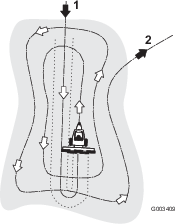

After raking, clean the machine thoroughly. Because you use this machine primarily in sand and sand is extremely abrasive, wash off the sand after each use. If you clean the machine frequently (before the sand has a chance to cake), clean it with a stream of water from a hose with the nozzle removed. A high-pressure stream could drive the sand into wear areas, where it could act as a grinding compound.

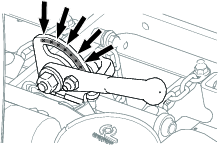

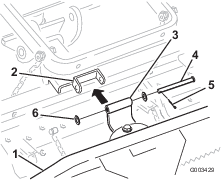

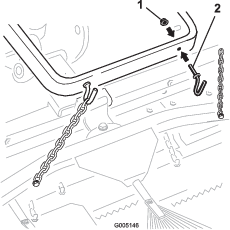

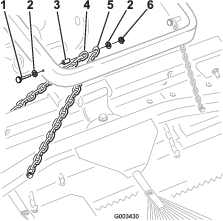

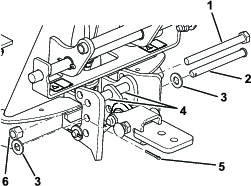

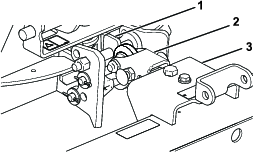

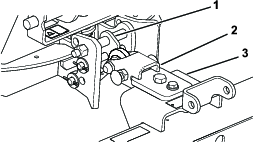

Note: If the attachment adapter sticks to the traction unit adapter, insert a pry bar or screwdriver into the pry slot to disengage the parts (Figure 16).

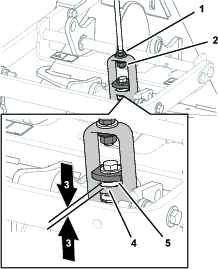

Greasing the Attachment Adapter

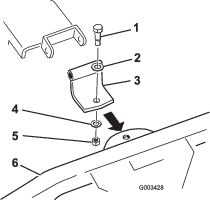

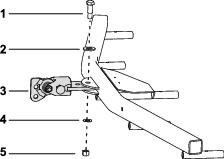

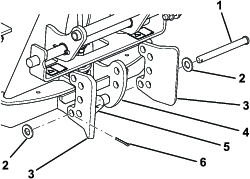

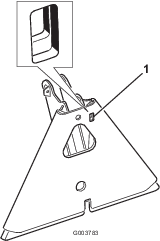

If the locking lever on the attachment adapter does not pivot freely and easily, apply a light coat of grease to the area shown in Figure 17.