For replacement line, you can purchase either a new, pre-wound

spool of line (Model 88185 or 88045) or bulk line (0.065 inch diameter

x 10 ft) that you can wind onto the old spool. Both are available

from an Authorized Service Dealer.

Caution

If you use line other than Toro 0.065 inch diameter nylon monofilament,

it could cut through clothes and skin causing injury and/or overload

the motor, possibly causing a fire or electrical shock.

Do not use metal wire, rope, plastic knives, or any cutting

line or material other than Toro 0.065 inch diameter nylon monofilament,

10 ft. maximum line length.

The spool may wear during normal use and require occasional

replacement.

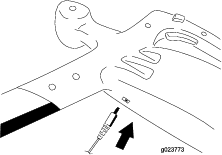

Note: If the line should tangle or break at the eyelet, stop the trimmer,

remove the spool as described below, feed the line through the eyelet,

and reassemble the spool to the cutting head.

Caution

If you do not fully install the spool and cap, the trimmer could

throw them during operation, causing injury to the operator or bystanders.

Ensure that you fully install the spool and cap, with the two

locking tabs on the cap secured in the spool housing.

-

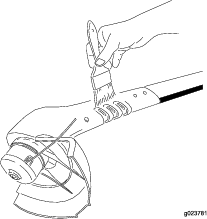

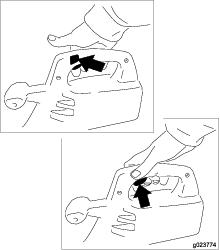

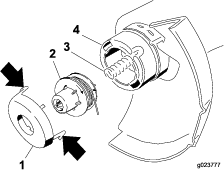

Press in the tabs on each side of the cap (Figure 7).

Note: You may need a screwdriver to press in the tabs on the cap of

a new trimmer.

Note: If the spring falls off the trimmer head, install the spring

before installing the spool and cap.

-

If there is any cutting line left (there should be

a short piece), remove and discard it.

-

Thoroughly clean the trimmer head. Inspect for any

damaged or worn parts.

-

If you are winding a new line onto the old spool,

complete the following steps:

-

Hook one end of line into the slot on the spool, allowing no more than 3 mm (1/8 inch) to protrude, and

push the end of the line all the way to the inner

end of the slot.

-

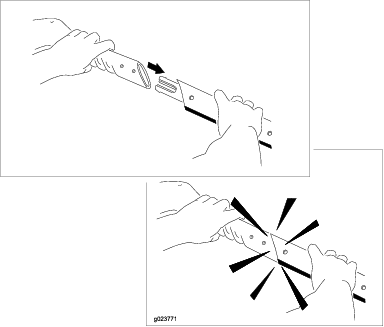

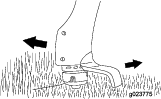

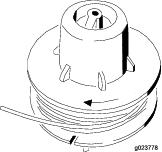

Wind the line in the direction of the arrow on the

spool, in level rows, between the spool flanges (Figure 8).

The trimmer will not function properly if the line is wound

in the wrong direction, the end of the line protrudes more than 3

mm (1/8 inch), or the line is wound beyond the outer edges of the

spool.

-

Unwind no more than 7.6 cm (3 inches) of line from

spool (either new or re-wound) and hold the line and spool to prevent

the line from unraveling.

-

While holding the line and spool, place the cap on

the spool.

-

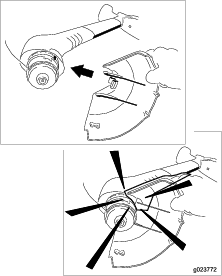

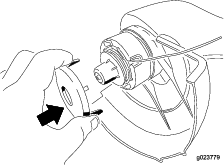

Insert the line into the eyelet, aligning the cap

tabs with the slots in the cutter head.

-

Press in the tabs and push down the cap and spool

to lock the cap in place (Figure 9).

Note: You may need to rotate the spool to fully install it.

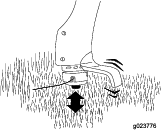

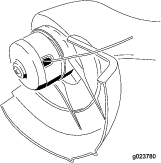

The fully installed cutting head should appear as shown in Figure 10.