Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Before each use or daily |

|

| Every 100 hours |

|

| Every 800 hours |

|

| Every 1,000 hours |

|

| Every 2,000 hours |

|

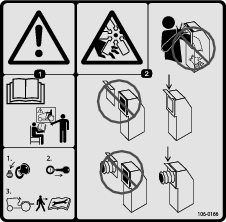

Maintenance Safety

-

Before adjusting, cleaning, servicing, or leaving the machine, do the following:

-

Position the machine on a level surface.

-

Disengage the PTO.

-

Ensure that the traction unit is in neutral.

-

Engage the traction unit parking brake.

-

Shut off the engine of the traction unit and remove the key.

-

Wait for all moving parts to stop.

-

Allow machine components to cool before performing maintenance.

-

-

Perform only those maintenance instructions described in this manual. If major repairs are ever needed or assistance is desired, contact an authorized Toro distributor.

-

Ensure that the machine is in safe operating condition by keeping hardware tightened.

-

If possible, do not perform maintenance while the traction unit engine is running. Keep away from moving parts.

-

Do not check or adjust the belt tension when the traction unit engine is running.

-

Carefully release pressure from components with stored energy.

-

Support the machine with blocks whenever you raise it. Do not rely on a hydraulic system to support the machine.

-

Ensure that all guards are installed after maintaining or adjusting the machine.

Lubricating the Machine

Greasing the Fan Shaft Bearings

Greasing the Drive Shaft

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

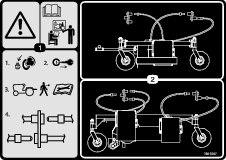

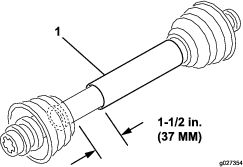

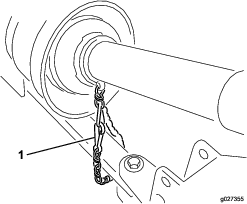

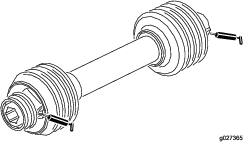

Grease the 2 drive shaft fittings as illustrated in Figure 9 with No. 2 lithium-based grease.

Hydraulic System Safety

-

Seek immediate medical attention if fluid is injected into skin. Injected fluid must be surgically removed within a few hours by a doctor.

-

Ensure that all hydraulic-fluid hoses and lines are in good condition and all hydraulic connections and fittings are tight before applying pressure to the hydraulic system.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks.

-

Before disconnecting or performing any work on the hydraulic system, lower the implement to the ground and shut off the engine to relieve all pressure in the system.

-

To ensure safe, optimal performance of the machine, use only genuine Toro replacement parts. Replacement parts made by other manufacturers could be dangerous, and such use could void the product warranty.

Checking the Hydraulic Lines and Hoses

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Check the hydraulic lines and hoses for leaks, kinked lines, loose mounting supports, wear, loose fittings, weather, deterioration, and chemical deterioration. Make all necessary repairs before operating the machine.

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury.

-

Ensure that all hydraulic fluid hoses and lines are in good condition and all hydraulic connections and fittings are tight before applying pressure to the hydraulic system.

-

Keep body and hands away from pin-hole leaks or nozzles that eject high pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks.

-

Safely relieve all pressure in the hydraulic system before performing any work on the hydraulic system.

-

Seek immediate medical attention if fluid is injected into skin.

Servicing the Hydraulic Fluid and Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 800 hours |

|

| Every 1,000 hours |

|

| Every 2,000 hours |

|

Changing the Hydraulic Fluid

Important: If the fluid becomes contaminated, contact an authorized Toro distributor. Contaminated fluid looks milky or black when compared to clean fluid.

-

Turn the engine off.

-

Disconnect the small hydraulic hose (case drain) from the bottom of the reservoir and let the hydraulic fluid flow into a drain pan.

Note: Install and tighten the hose when the hydraulic fluid stops draining.

-

Fill the reservoir with approximately 38 L (10 US gallons) of hydraulic fluid. Refer to .

Important: Use only the hydraulic fluids specified. Other fluids could damage the system. To prevent over filling, do not fill if the fluid is cold. Do not over fill.

-

Install the reservoir cap.

-

Start the traction unit engine, use all the hydraulic controls to distribute the hydraulic fluid throughout the system, and check for leaks.

-

Shut off the engine

-

With the fluid warm, look into the sight gauge.

Note: If the hydraulic fluid level is low, add enough fluid to raise the level to the middle (maximum) of the sight gauge.

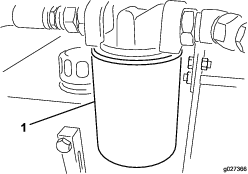

Replacing the Hydraulic Filter

Use only the Toro replacement filter (Part No. 54-0110) in the hydraulic system.

Important: Use of any other filter may void the warranty on some components.

-

Turn the traction unit engine off and remove the key from the ignition.

-

Clean the area around the filter mounting area.

-

Place a drain pan under the filter and remove the filter (Figure 10).

-

Lubricate the new filter gasket and fill the filter with hydraulic fluid.

-

Ensure that the filter mounting area is clean.

-

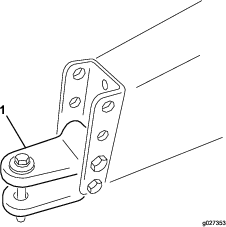

Screw the filter on until the gasket contacts the mounting plate, then tighten the filter one–half turn.

-

Start the traction unit engine and operate the hydraulic controls to purge air from the system.

-

Shut off the engine and check the fluid level and for any leaks.

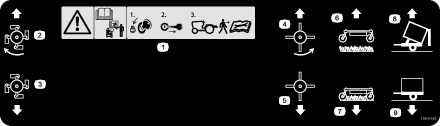

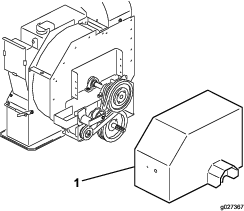

Adjusting the Impeller Belt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Before each use or daily |

|

Make sure that the belt is properly tensioned to ensure proper operation of the machine and prevent unnecessary wear.

-

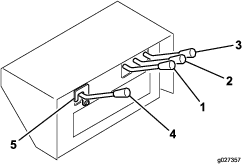

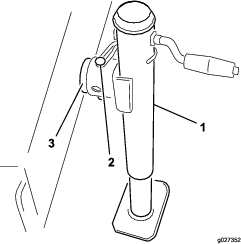

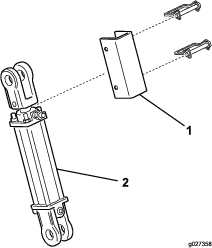

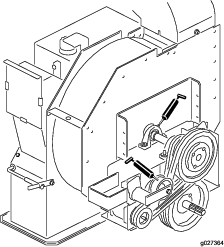

Loosen the bolts and nuts securing the drive shield to the impeller housing (Figure 11) and remove the shield.

Note: The drive shaft does not have to be disconnected to adjust the belt.

-

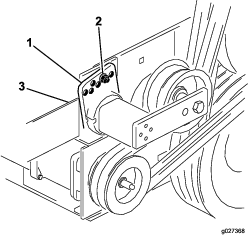

On back side of the frame, loosen the bolt securing the belt tensioner to the frame (Figure 11).

-

Remove the bolt and nut securing the tensioner guide to the drive mount to release the belt tension (Figure 12).

-

Using a large wrench, rotate the tensioner clockwise until the decal is aligned with 15° on the tensioner tube.

Important: Align the tensioner as close to 15° as possible without going under.Rotating the tensioner too far over 15° can overtension the belt, rotating it under 15° will leave the belt too loose; both can damage the machine.

-

Insert the bolt into the aligned guide holes and secure it with the nut.

Important: If the holes are not exactly aligned, rotate the guide to the next higher hole until it is aligned.

-

Tighten the bolt on the back side of the frame to lock the tensioner.

-

Install the drive shield to the impeller housing with the bolts and nuts removed previously.

, which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.

, which means

Caution, Warning, or Danger—personal safety instruction. Failure

to comply with these instructions may result in personal injury or

death.