Installation

Installing the Rack

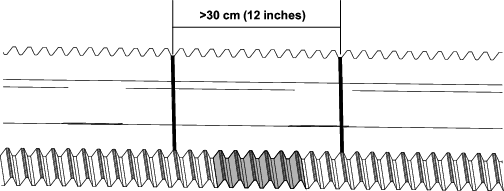

Note: Use a minimum of 30 cm (12 inches) of rack for repair.

-

Move the machine to a level surface, shut off the engine, remove the key, turn the battery disconnect switch to the OFF position, and wait for the engine to cool; refer to the Operator’s Manual.

Note: Remove the pipe box.

-

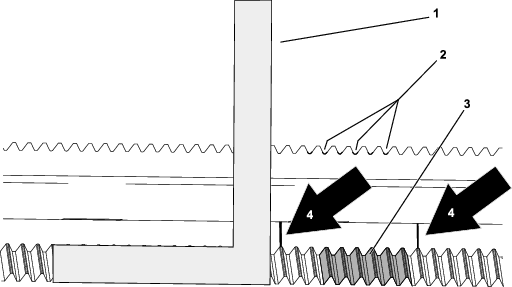

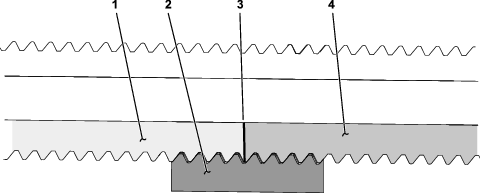

Use a square to line up the cut in the center of the valley of the tooth. Mark the area to be cut.

-

Grind down the existing welds on the top and bottom of the damaged rack area.

-

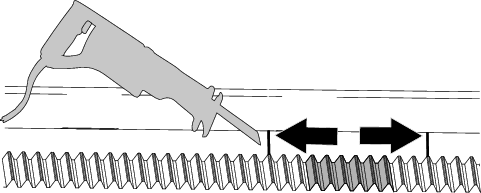

Using a reciprocating or band saw to cut out the damaged rack.

-

Use the cut out section to measure, mark, and cut out a new section of rack.

-

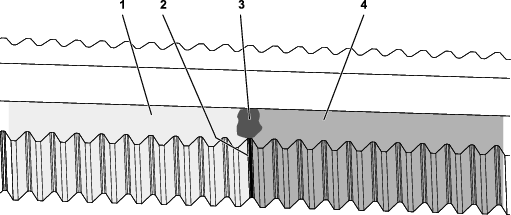

Use a piece of the cut out rack to align the new rack piece and the original rack.

Note: Grind down any damaged or bent teeth that does not allow proper alignment.

-

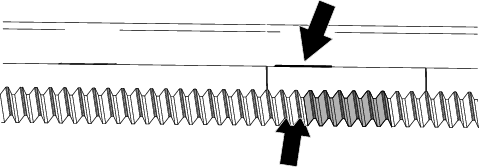

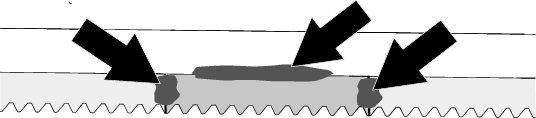

Weld the rack pieces together. Weld the new rack piece to the frame. Grind down the weld areas to make it flush.

Important: Ensure that the welds and tooth root is flat or damage may occur to the rollers.

-

There will be a small gap at the joint of the rack pieces.