Removing the Cutting Unit from the Traction Unit

-

Position the machine on a level surface, raise the

cutting unit, engage the parking brake, ensure that the traction pedal

is in the neutral position and the PTO lever in the OFF position, shut off the engine, and remove the key from the switch.

Caution

The counterbalance spring is in tension when the deck is in

the lower position (200 Series traction units only).

Always raise the deck before adjusting or removing the spring.

-

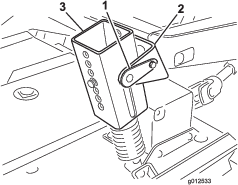

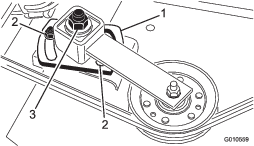

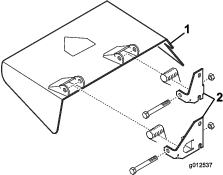

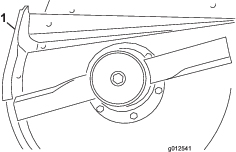

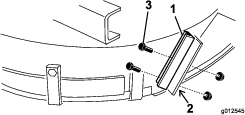

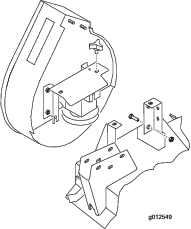

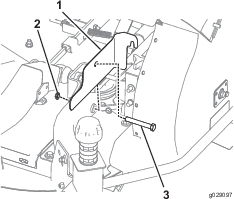

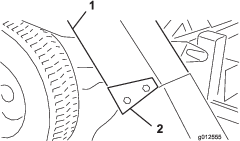

On 200 Series traction units only, disconnect the

counterbalance from the traction unit, remove the lock pins from the

brackets, separate the spring tension assemblies from the brackets,

and lay them down on the deck. Loosely secure the lock pins to the

brackets to prevent losing them (Figure 1).

-

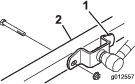

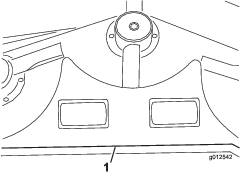

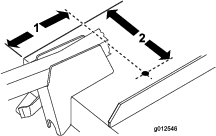

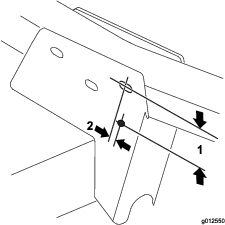

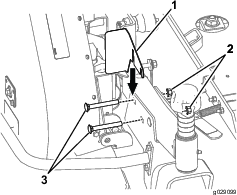

Lower the cutting unit and remove the 4 bolts and

nuts securing lift arm brackets to castor arms (Figure 2).

-

Start the engine and raise the traction unit lift

arms.

-

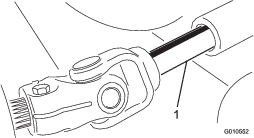

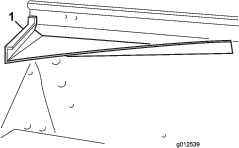

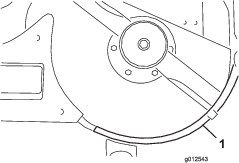

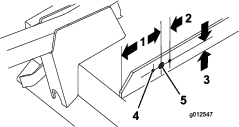

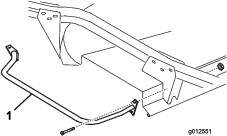

Shut off the engine and slide the cutting unit away

from the traction unit, separating the male and female sections of

PTO shaft (Figure 3).

Caution

If the engine is started and the PTO shaft is allowed to rotate,

serious injury could result.

Do not start the engine and engage the PTO lever when the PTO

shaft is not connected to the gear box on the cutting unit.

Installing the New Spindle Pulley

Parts needed for this procedure:

| Double pulley | 1 |

| Pulley nut | 1 |

| Nut cover | 1 |

-

Unhook the latches securing the right cover to the

top of the cutting unit. Remove the cover from the cutting unit.

-

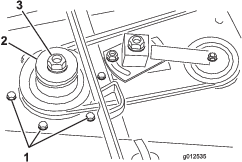

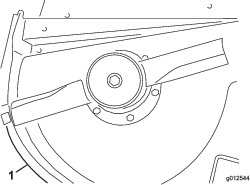

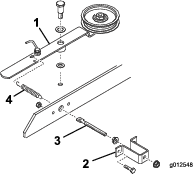

Loosen the 2 nuts securing the idler plate so the

tension of the idler pulley against the belt is released (Figure 4).

-

Remove the belt from the right spindle pulley (Figure 4).

-

Remove the six carriage bolts and flange nuts securing

the spindle housing assembly to the cutting unit (Figure 5). Slide

the spindle housing assembly out of the bottom of the cutting unit.

-

Remove the nut and washer retaining the pulley on

the spindle shaft. Remove the pulley from the shaft.

-

Slide the new double spindle pulley onto the spindle

shaft. Do not install the pulley nut at this time.

-

Slide the pulley end of spindle housing assembly through

the hole in the cutting unit, and loop the belt around the pulley

and idler. Mount the spindle assembly in place with 6 carriage bolts

and flange nuts.

-

Install the original washer and new pulley nut onto

the spindle shaft and tighten it to 100 ft-lb (135.5 N⋅m). Install

the nut cover.

-

Adjust (tighten) the idler adjusting nut to 35 to

40 ft-lb (48 to 54 N⋅m) to achieve the proper belt tension. Tighten

the idler plate nuts.

Installing the New Blades

Parts needed for this procedure:

-

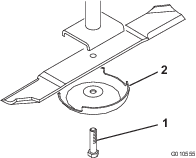

Grasp the end of blade using a thickly padded glove.

Remove the blade bolt, anti-scalp cup, and blade from the spindle

shaft (Figure 6).

-

In sequence, install a new blade (sail facing toward

the cutting unit) and anti-scalp cup. Secure the parts in place with

the blade bolt. Tighten the blade bolt to 85 to 110 ft-lb (115 to

149 N⋅m).

-

Repeat this procedure on all blades.

Removing and Modifying the Grass Deflector

Parts needed for this procedure:

-

Remove the bolts, locknuts, and springs securing the

deflector mounts to the pivot brackets (Figure 7). Remove the deflector.

-

Remove the carriage bolts and flange nuts securing

the pivot brackets to the housing (Figure 7). Remove the pivot brackets.

Retain the fasteners for future use.

-

Remove the 2 carriage bolts, flat washers, and locknuts

securing the reinforcement plate to the under side of the housing

and the stiffener plate to the top of the housing (Figure 7).

-

Using the bolts, locknuts, and springs previously

removed, install the new pivot brackets to the deflector mounts (Figure 8). Do not

over tighten the nuts because the brackets must be allowed to pivot.

Save this assembly for side discharge operation.

Installing the Blower Mounting Brackets

Parts needed for this procedure:

| Blower assembly with mounting brackets | 1 |

| Capscrew, 5/16 x 1 inch | 3 |

| Locknut, 5/16 | 4 |

| Carriage bolt, 3/8 inch x 3/4 inch | 4 |

| Flange nut, 3/8 inch | 3 |

-

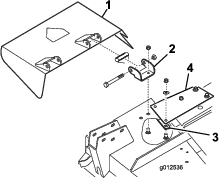

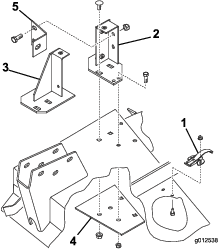

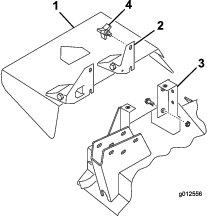

Remove the fasteners securing the right hand deck

cover spring latch to the right side of the cutting deck (Figure 9). Remove

and retain the latch for future use with the right hand cover.

-

Position the blower and mounting brackets on the deck,

aligning the mounting holes with the holes previously used for mounting

the grass deflector. Figure 9 is shown with the blower removed from the brackets.

Make sure there is no gap between the blower and cutting deck.

-

Position the new reinforcement plate under the deck

aligning the mounting holes with the holes previously used for mounting

the grass deflector (Figure 9).

-

Mount the front and rear brackets and reinforcement

plate to the deck with 2 previously removed carriage bolts (3/8 -16

x 7/8 inch) and flange nuts each (Figure 9). The bolt heads must be on

top of the deck.

-

Remove the 2 knobs securing the blower to the mounting

brackets. Remove the blower.

-

Using each bracket as a template, mark the location

and drill 2 additional 11/32 inch diameter holes. (2 holes for the

rear bracket and 1 for the front bracket. Use the reinforcement plate

for a template to drill one of the 11/32 inch diameter holes for the

rear bracket.

Note: Use caution when drilling the holes so that the castor arm is

not damaged.

-

Secure the brackets and reinforcement plate to the

deck with bolts (5/16-18 x 3/4 inch) and locknuts (Figure 9). The bolt

heads must be on top of the deck.

-

Mount the blower brace to the rear mounting bracket

with 2 bolts (3/8-16 x 1 inch) and locknuts (Figure 9) and to the castor arm with

a bolt (3/8-16 x 1 inch).

-

When mounting the lift arm brackets to the castor

arms, mount other side of the blower brace to the lift arm bracket

and the right castor arm with the bolt and nut previously removed.

Installing the Deck Deflectors

Parts needed for this procedure:

| Front deflector | 1 |

| Rear deflector | 1 |

| Rear shelf | 1 |

| Left shelf | 1 |

| Right shelf | 1 |

| Capscrew, 5/16 x 5/8 inch | 6 |

| Locknut, 5/16 inch | 6 |

| Capscrew, 3/8 x 1 inch | 4 |

| Lockwasher, 3/8 inch | 4 |

| Capscrew, 1/4 x 1 inch | 3 |

| Capscrew, 1/4 x 3/4 inch | 3 |

| Locknut, 1/4 inch | 6 |

-

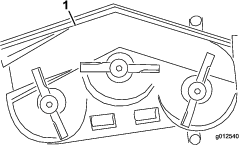

Insert the front deflector into the deck, aligning

the end of the deflector with the edge of the discharge opening (Figure 11 and Figure 12).

-

Using the deflector as a template, mark and drill

three 11/32 inch diameter holes through front and top of deck.

-

Secure the 2 front mounting tabs of deflector to the

deck with bolts (5/16-18 x 5/8 inch) and locknuts (5/16-18 inch).

-

Secure the front right corner of the front mounting

bracket and the top tab of the deflector to the deck with a bolt (5/16-18

x 1 inch) and locknut.

-

Using the deflector as a template, mark and drill

three 11/32 inch diameter holes through the deck.

-

Secure the deflector to the deck with 3 bolts (5/16-18

x 5/8 inch) and locknuts (5/16-18 inch).

-

Before mounting the left and right shelves to the

deck, you must grind the welds off of the bottom edge of the deck.

Paint the deck after grinding.

-

Using the existing holes, mount the rear shelf to

the deck with 4 bolts (3/8-16 x 1 inch) and lock washers (3/8 inch)

(Figure 14).

-

Align the left shelf with the left end of the rear

shelf and the edge of the deck (Figure 12 and Figure 14).

-

Secure the left shelf to the deck with 2 bolts (1/4-20

x 1 inch), 1 bolt (1/4-20 x 3/4 inch), and 3 locknuts (Figure 15). Position

the bolt heads to the inside of the deck.

-

Align the right shelf with the right end of the rear

shelf and the edge of the deck (Figure 12 and Figure 16). Using the left shelf as

a template, locate, mark, and drill three 9/32 inch diameter holes

in the deck.

-

Secure the right shelf to the deck with 1 bolt (1/4-20

x 1 inch), 2 bolts (1/4-20 x 3/4 inch), and 3 locknuts. Position the

bolt heads to the inside of the deck.

Mounting the New Deflector Stop

Parts needed for this procedure:

| Deflector stop | 1 |

| Capscrew, 1/4 x 3/4 inch | 2 |

| Locknut, 1/4 inch | 2 |

-

Using the new deflector stop as a template, set it

on the original flat deflector stop (Figure 17). Ensure that the new deflector

stop is flush at the bottom, contacting the side of the deck, and

parallel with the outside edge of the deflector support.

-

Locate, mark and drill two 9/32 inch diameter holes

through the old deflector support.

-

Mount the new deflector support to the old deflector

stop with 2 bolts (1/4-20 x 3/4 inch) and locknuts (1/4-20 inch),

as shown in Figure 17.

Mounting the Idler Assembly

Parts needed for this procedure:

| Idler arm assembly | 1 |

| Pivot screw | 1 |

| Bushing | 1 |

| Washer | 2 |

| Locknut, 3/8 inch | 1 |

| Spring | 1 |

| Threaded rod | 1 |

| Flange nut, 5/16 inch | 2 |

| Spring bracket | 1 |

| Capscrew, 1/4 x 1 inch | 2 |

| Locknut, 1/4 inch | 2 |

-

Using the dimensions shown in Figure 18, locate, mark, and drill a

13/32 inch diameter hole in the deck. The dimensions shown are from

the right front corner of the deck and from the edge of the discharge

opening. The blower brackets are removed for clarity.

-

Using the dimensions shown in Figure 19, locate, mark, and drill a

13/16 inch diameter hole and two 13/32 inch diameter holes in the

right bridge bar.

-

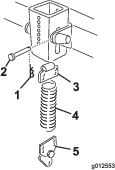

Thread a flange nut (5/16-18 inch) approximately

2 inches (5 cm) onto the threaded rod (Figure 20).

-

Insert the end of the threaded rod through the large

hole in the spring bracket and loosely secure it with another flange

nut (5/16-18 inch) (Figure 20). Do not tighten the flange nuts.

-

Insert the other end of the threaded rod through the

hole in the bridge bar and secure the spring bracket to the bridge

with 2 bolts and locknuts (Figure 20).

-

Hook the short loop of the spring into the hole in

the threaded rod and the long loop in the hole in the idler arm (Figure 20).

-

Mount the idler pulley arm to the deck with a pivot

screw (3/8-16 inch), a thrust washer (1/2 inch), the idler arm, a

thrust washer (3/8 inch), and a locknut (3/8-16 inch) beneath the

deck (Figure 20).

Important: Do not tighten the flange nuts on the threaded rod at this time.

Adjust the spring tension after the blower assembly and belt have

been installed.

Mounting the Blower

Parts needed for this procedure:

-

Route the belt around the small deck spindle pulley.

-

Slide the blower onto the mounting bracket alignment

studs (Figure 21) while routing the belt around the blower pulley.

Note: If the blower does not easily slide onto the mounting brackets,

loosen the alignment bolts slightly.

-

Secure the blower to the brackets with 2 knobs.

-

Adjust the spring length to 4-7/8 inches (12.4 cm)

for proper belt tension by adjusting the flange nuts on the threaded

rod.

Install the Bumper

Parts needed for this procedure:

| Bumper | 1 |

| Capscrew, 5/16 x 3 inch | 4 |

| Locknut, 5/16 inch | 4 |

-

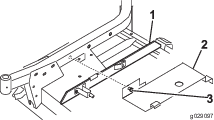

Using dimensions shown in Figure 22, locate, mark and drill a

11/32 inch diameter hole through both walls of the right front castor

arm bracket.

-

Secure the top mounting hole of the front mounting

plate of the bumper to the castor arm bracket with a bolt (5/16 -18

x 3 inch) and locknut (Figure 23).

-

Using both mounting plates of the bumper as templates,

locate, mark, and drill 3 additional 11/32 inch diameter holes through

both walls of the front and rear castor arm brackets.

Installing the New Deck Cover

Parts needed for this procedure:

| Trim molding | 1 |

| Deck cover | 1 |

-

Insert a trim molding onto the right bridge bar, so

the side of the spring bracket is 10 cm (4 inches) to the far edge

of the trim molding (Figure 24).

-

Hook the rear of the deck cover (Figure 24) onto the

rear channel pin while aligning the cover mounting bolt with the hole

in the right castor arm. The cover is to rest on the trim molding.

Adjust the molding as required.

-

Secure the cover to the right castor arm with the

bolt.

Installing the New Safety Guards

Parts needed for this procedure:

| Belt guard | 1 |

| Pulley guard | 1 |

-

Install the belt guard onto the machine (Figure 25).

Note: Use existing hardware on the machine by removing it and using

it to install the guard.

-

Install the pulley guard onto the machine (Figure 26).

Note: Use existing hardware on the machine by removing it and using

it to install the guard.

Installing the New Counterbalance Spring

Parts needed for this procedure:

To compensate for the additional weight of the blower assembly,

the original light counterbalance spring at the right side of the

machine, must be replaced with the heavier spring included (Figure 27).

-

Remove the hair pin cotter and clevis pin and slide

the spring assembly out of the retaining bracket.

-

Screw the spring off of the top and bottom mounting

brackets.

-

Screw the new heavy spring onto both mounting brackets.

Ensure that the spring is completely threaded through all holes and

it contacts the flat side of the bracket.

-

Install the spring assembly into the retaining bracket

with a clevis pin and hairpin cotter.

Installing the Cutting Unit to the Traction Unit

-

Engage the parking brake, ensure that the traction

pedal is in neutral and the PTO lever is in the Off position. Start

the engine and raise the lift arms. Shut off the engine.

-

Position the cutting unit in front of the traction

unit and align the gear case input shaft with the PTO shaft; install

the shaft.

-

Carefully lower the lift arms while aligning the lift

arm brackets with the castor arms. Align the PTO shaft hole with the

gear case input shaft hole and install the roll pin.

-

Secure the lift arm brackets and the side of the blower

brace to the castor arms with 4 bolts and nuts.

-

Start the engine and raise the cutting unit. Secure

the counterbalance springs to the cutting unit with shoulder bolts

and locknuts.

Installing the New Decal

Parts needed for this procedure:

Install the Danger Decal (Part Number 66-1340 or 93-7824 for

CE) on the front edge of the deck, inside the right castor arm.

Mounting the Blower Housing Chute

Parts needed for this procedure:

Important: When the chute in the Blower Kit is used with a 15 cubic foot

Hopper Kit, you must cut off a section of the chute to ensure proper

fit between the blower and the hopper. If used with another kit, proceed

to step 3.

-

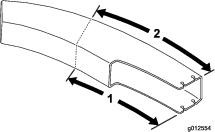

Using the dimensions shown in Figure 28, use a tape measure and mark

the chute.

Note: For convenience, some chutes may have a light scribe mark where

the chute must be cut off.

-

Draw lines around all sides of the chute and cut off

with a saw.

-

Set the deck to the desired height-of-cut setting.

-

Slide the chute over the blower opening and onto the

mounting studs (Figure 29).

-

Lower the hopper hood and align the chute with the

hood snout. Secure the chute in position with 4 locknuts (5/16 inch)

and chute brackets. Position the wide end of brackets to the rear.