Maintenance

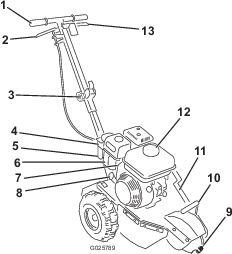

Note: Determine the left and right sides of the machine from the normal operating position.

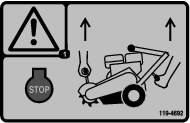

Important: You can tip the machine backward or on its side to clean or service it, but no longer than 2 minutes. If you hold the machine in this position for too long, fuel can drain into the crankcase and damage the engine. Should this happen, perform an extra oil change on the engine, then turn the engine over a few revolutions with the starter handle before starting the engine again.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 300 hours |

|

| Yearly or before storage |

|

Important: Refer to your engine owner’s manual for additional maintenance procedures.

Engine Maintenance

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 300 hours |

|

The cyclone air filter collects the largest contaminant particles, which collect in the container. When you can see a layer of dirt at the bottom of the container, clean the cyclone housing, air channels, and air-intake screen.

Servicing the Cyclone Housing

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine and wait for all moving parts to stop.

-

Remove the 3 screws holding the cyclone housing to the air-cleaner cover.

-

Remove the housing with the air-intake screen and remove the air channels.

Note: The air channels may remain in the upper portion or follow along with the housing when removed.

-

Clean the components with water, detergent, and a brush then dry the components carefully.

-

Place the air channels in the cyclone housing.

-

Insert cyclone housing into position and make sure that it fits in the upper portion.

Important: Do not use force; align it in place before fitting the screws.

-

Secure the cyclone housing using the 3 screws.

Servicing the Air-Cleaner Elements

Removing the Foam and Paper Elements

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine and wait for all moving parts to stop.

-

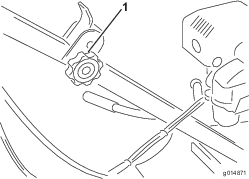

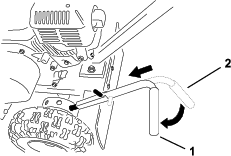

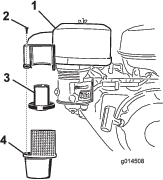

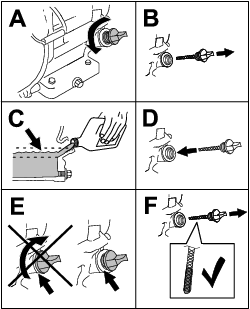

Remove the wing nut and lift off the air-cleaner cover with the air-filter cowling (Figure 13).

-

Remove the foam element (Figure 13).

-

Remove the wing nut on top of the paper element and remove the paper element (Figure 13).

Servicing the Foam Air-Cleaner Element

-

Wash the foam element using a mild detergent and water.

-

Squeeze it dry with a clean cloth.

-

Soak it with new engine oil.

-

Gently squeeze out excess oil from the element in an absorbent cloth.

Servicing the Paper Air-Cleaner Element

-

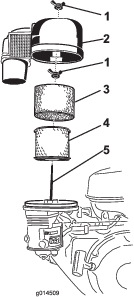

Clean the paper element by tapping it gently to remove dust. If it is very dirty, replace the paper element (Figure 15).

-

Inspect the element for tears, an oily film, or damage to the rubber seal.

-

Replace the paper element if it is damaged.

Important: Do not clean the paper filter.

Installing the Foam and Paper Elements

-

Mount the paper element in the air-cleaner housing and secure it with the wing nut.

-

Position the foam element over the paper element.

-

Install the air-cleaner cover and secure it with the wing nut.

Servicing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Before each use or daily |

|

| Every 100 hours |

|

| Yearly or before storage |

|

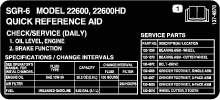

Engine-Oil Specifications

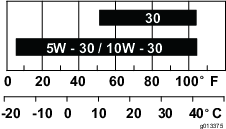

Oil Type: Detergent oil with an API service of SJ or higher.

Crankcase Capacity: 0.6 L (20.3 fl oz)

Viscosity: Refer to the table below.

Checking the Engine-Oil Level

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine and wait for all moving parts to stop.

-

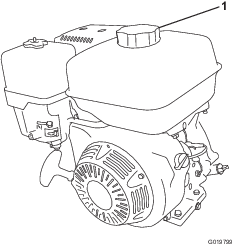

Check the engine-oil level as shown in Figure 15.

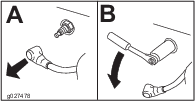

Changing the Engine Oil

-

Start the engine and let it run for 5 minutes.

Note: This warms the oil so that it drains better.

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine and wait for all moving parts to stop.

-

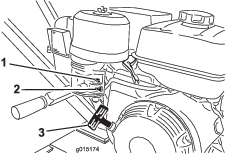

Change the oil as shown in (Figure 16).

-

Slowly pour approximately 80% of the specified oil into the filler tube and slowly add the additional oil to bring it to the Full mark (Figure 17).

-

Dispose of the used oil at a recycling center.

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Every 300 hours |

|

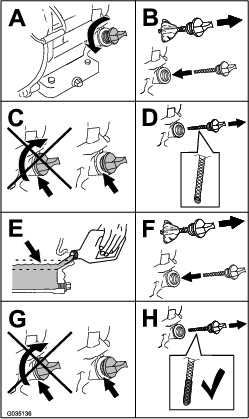

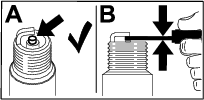

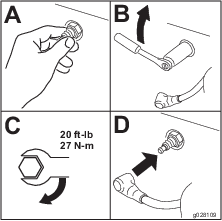

Ensure that the air gap between the center and side electrodes is correct before installing the spark plug. Use a spark plug wrench for removing and installing the spark plug and a gapping tool/feeler gauge to check and adjust the air gap. Install a new spark plug if necessary.

Type: BPR6ES (NKG) or equivalent

Air Gap: 0.70 to 0.80 mm (0.28 to 0.031 inch)

Removing the Spark Plug

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine, wait for all moving parts to stop, and allow the engine to cool.

-

Locate and remove the spark plug (Figure 18).

Checking the Spark Plug

Important: Do not clean the spark plug(s). Always replace the spark plug(s) when it has: a black coating, worn electrodes, an oily film, or cracks.

If you see light brown or gray on the insulator, the engine is operating properly. A black coating on the insulator usually means the air cleaner is dirty.

Set the gap to 0.70 to 0.80 mm (0.28 to 0.031 inch).

Installing the Spark Plug

Fuel System Maintenance

Cleaning the Sediment Cup

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Yearly or before storage |

|

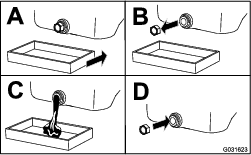

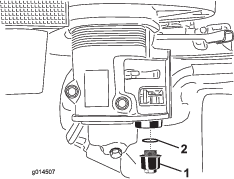

Underneath the fuel valve is a sediment cup to catch dirt in the fuel.

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine and wait for all moving parts to stop.

-

Move the fuel valve to the OFF position, all the way to the left.

-

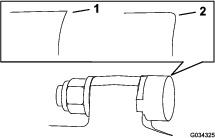

Unscrew the sediment cup (Figure 21).

-

Clean the reservoir and the O-ring using a cleaning solvent and dry carefully.

Note: Make sure not to misplace the O-ring.

-

Place the O-ring in the groove of the cup and replace the sediment cup.

-

Turn the fuel valve to the ON position, all the way to the right, and check for leaks.

Note: If it leaks, replace the O-ring.

Cooling System Maintenance

Cleaning the Engine Screen

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

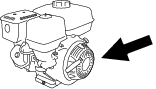

Before each use, remove any buildup of grass, dirt, or other debris from the engine screen. This helps ensure adequate cooling and correct engine speed and reduces the possibility of overheating and mechanical damage to the engine.

Belt Maintenance

Checking the Drive-Belt Tension

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

Note: Replace the belt if it shows any signs of wear, cracks, or damage.

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine and wait for all moving parts to stop.

-

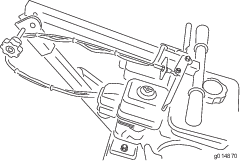

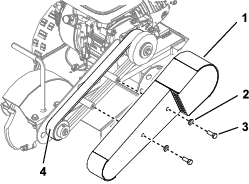

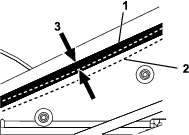

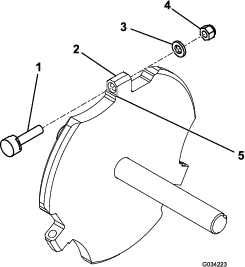

Remove the 2 bolts, 2 washers, and belt guard (Figure 23).

-

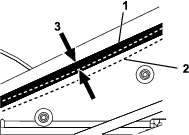

Push down on the belt to check the tension. You should be able to push the new belt down 5.6 mm (0.22 inch) using 2.9 kg (6.5 lb) of force (Figure 24).

Important: To extend the belt life, maintain proper tension. A loose belt can cause excessive cutting wheel slippage and early belt failure. A belt that is too tight can cause bearing and shaft failure and rapid belt wear.

-

If the belt needs adjustment, refer to Adjusting the Drive Belt. If the belt does not need adjustment, install the belt guard as shown in Figure 23.

Adjusting the Drive Belt

-

Park the machine on a level surface and engage the parking brake.

-

Shut off the engine and wait for all moving parts to stop.

-

Remove the belt guard (Figure 23).

-

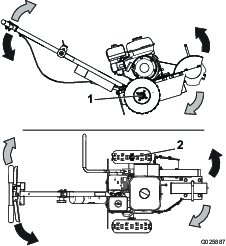

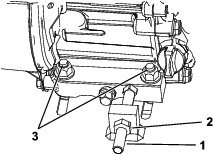

Loosen the 4 engine mounting bolts, and jam nuts holding the adjustment bolt (Figure 25).

-

Turn the square head adjusting bolt on the frame clockwise to tighten the belt; turn it counter clockwise to loosen the belt.

Important: Important: Make sure to tighten all engine bolts after proper belt adjustment is achieved.

-

Install the belt guard and secure with previously removed hardware.

Replacing the Drive Belt

-

Remove the 2 bolts, 2 washers, and belt guard (Figure 23).

-

Loosen the 4 engine mounting bolts, and jam nuts holding the adjustment bolt (Figure 25).

-

Remove the belt.

-

Install the new belt around the pulleys.

-

Tighten the jam nut on the tensioner bolt.

-

Push down on the belt to check the tension. You should be able to push the new belt down 5.6 mm (0.22 inch) using 3.4 kg (7.4 lb) of force. Adjust the tensioner bolt as necessary to tighten or loosen the belt.

-

Tighten the fasteners securing the engine to the frame (Figure 25).

Note: Ensure that the engine does not twist in the chassis and the clutch pulley is aligned with the belt.

-

Install the belt guard (Figure 23).

Grinder Maintenance

Replacing the Teeth

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

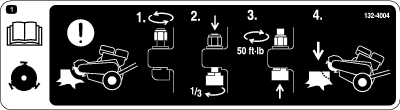

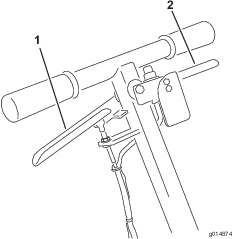

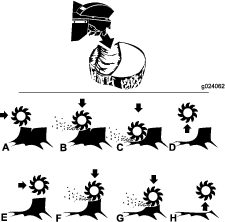

Due to the high amount of wear placed on the teeth, you need to rotate and replace them periodically (Figure 27). Before you rotate or replace them, inspect each tooth holder on the wheel, including the flat lands that prevent the teeth from rotating. If the tooth holder is damaged, replace the wheel. Torque the nuts 68 N∙m (50 ft-lb) for any teeth that you are not rotating or replacing.

Each tooth is indexed with 3 positions so you can rotate it twice, exposing a new sharp edge before replacing the tooth. To rotate a tooth, loosen the nut securing the tooth (Figure 28). Push the tooth forward and rotate it 1/3 of a turn, bringing an unused edge to the outside. Torque the nut securing the tooth to 68 N∙m (50 ft-lb).

To replace a tooth, remove the nut securing the tooth, then install a new tooth, washer, and nut in the same position (Figure 28). Torque the nut securing the tooth to 68 N∙m (50 ft-lb).

Cleaning

Removing Debris from the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Regular cleaning and washing increases the life span of the machine. Clean the machine directly after use, before the dirt hardens.

Before cleaning, check that the fuel-tank cap is properly in place to avoid getting water in the tank.

Use care when using a high-pressure sprayer, because it can damage warning decals, instruction signs, and the engine

Important: Lubricate the cutting wheel bearings after cleaning.

, which means: Caution, Warning, or Danger—personal safety instruction. Failure to comply with the instruction

may result in personal injury or death.

, which means: Caution, Warning, or Danger—personal safety instruction. Failure to comply with the instruction

may result in personal injury or death.