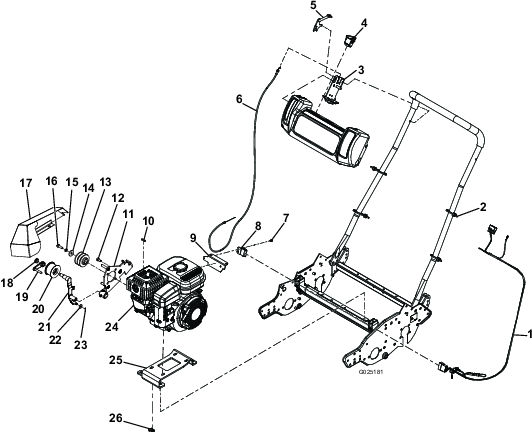

Maintenance

Important: Refer to your engine owner’s manual for additional maintenance procedures.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

Preparing the Machine for Maintenance

Warning

While you are maintaining or adjusting the machine, someone could start the engine. Accidentally starting the engine could seriously injure you or other bystanders.

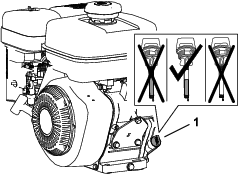

Remove the key from the ignition, engage parking brake, and pull the wire(s) off the spark plug(s) before you do any maintenance. Also push the wire(s) aside so it does not accidentally contact the spark plug(s).

Perform the following before servicing, cleaning, or making any adjustments to the machine.

-

Park the machine on a level surface.

-

Shut off the engine and remove the key from the machine (if equipped).

-

Engage the parking brake.

-

Wait for all moving parts to stop allow the engine to cool before servicing, storing, or making repairs.

-

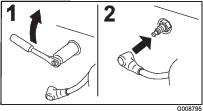

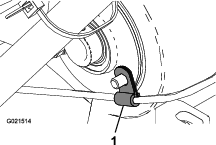

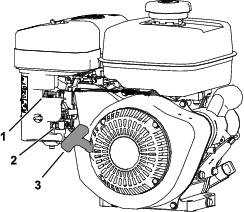

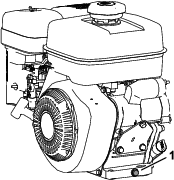

Disconnect the spark-plug wire (Figure 10).

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

Important: Do not apply oil to the foam or paper element.

Removing the Foam and Paper Elements

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

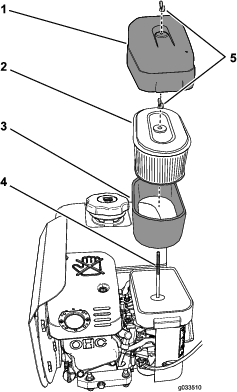

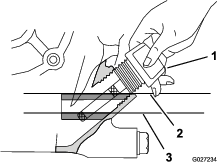

Clean around the air cleaner to prevent dirt from getting into the engine and causing damage (Figure 11).

-

Rotate the wing nut that secures the air-cleaner cover counterclockwise and remove the air-cleaner cover (Figure 11).

-

Rotate the wing nut that secures the paper and foam-filter elements counterclockwise and remove the filter elements from the hold-down rod (Figure 11).

-

Carefully pull the foam element off the paper element (Figure 11).

Note: Inspect the paper and foam-filter elements for damage or an excessive accumulation of dirt. Replace the damaged filters. Clean the foam-filter element if it is dirty. Replace the paper-filter element if it is dirty.

Servicing the Foam Filter Element

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

Inspect the element for tears, an oily film, or damaged (Figure 11).

Important: Replace the foam element if it is worn or damaged.

-

Wash the foam element in liquid soap and warm water. When the element is clean, rinse it thoroughly.

-

Dry the element by squeezing it in a clean cloth.

-

Air dry the foam-filter element.

Installing the Foam and Paper-Filter Elements

Important: To prevent engine damage, always operate the engine with the complete foam and paper air-cleaner assembly installed.

-

Carefully slide the foam-filter element onto the paper-filter element (Figure 11).

-

Align the hole in the top plate of the paper-filter element with the hold-down rod of the carburetor (Figure 11).

-

Secure the filter elements to the carburetor with the wing nut (Figure 11) that you removed in step 4 of Removing the Foam and Paper Elements.

-

Align the hole in the air-cleaner cover with the hold-down rod (Figure 11) and secure the cover to the rod with the wing nut that you removed in step 3 of Removing the Foam and Paper Elements.

Engine Oil Specification

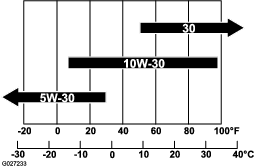

Oil Type: Detergent oil (API service SJ or higher)

Oil viscosity: Refer to the table below.

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Important: Do not operate the engine with the oil level below the Low (or Add) mark on the dipstick, or over the Full mark.

-

Move the machine to a level surface.

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

Allow the engine to cool.

-

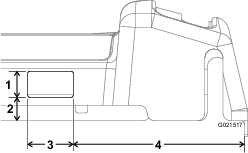

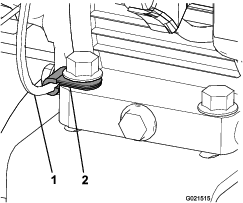

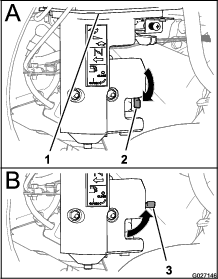

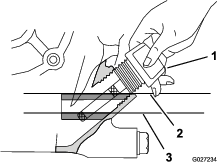

Remove the dipstick from the engine and wipe the dipstick with a clean rag (Figure 13).

-

Insert the dipstick from the engine as shown in Figure 13.

Note: Do not thread the dipstick into the filler neck when checking the engine oil level.

-

Remove the dipstick from the filler neck and look at the oil level in the dipstick (Figure 13).

Note: The engine oil level must cover between the hatch marked areas on the dipstick (Figure 13).

-

If the oil level is low, wipe off the area around the filler neck and add the specified oil until the oil level is between the hatch marked areas on the dipstick.

Important: Do not overfill the engine with oil.

-

Hand tighten the dipstick into the filler neck (Figure 13).

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Every 100 hours |

|

Draining the Engine Oil

Important: Do not operate the engine with the oil level below the Low (or Add) mark on the dipstick, or over the Full mark.

-

Start and run the engine for a few minutes to warm the engine oil.

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

At the rear of the machine, place a drain pan under the drain plug.

-

Remove the drain plug from the engine and allow the oil to drain completely.

-

Push down on the handle to tip the machine and engine backward, allowing all the oil to run into the drain pan.

Important: Do not tip the machine at an angle greater than 25°. Tipping the machine beyond 25° leads to oil leaking into the combustion chamber and/or fuel leaking out of the fuel-tank cap.

-

Install the drain plug and refill the crankcase with the specified oil; refer to Adding Oil to the Engine.

-

Torque the drain plug to 20 to 23 N∙m (15 to 17 ft-lbs).

-

Wipe up any spilled oil and dispose of the used oil properly.

Adding Oil to the Engine

Engine Oil Capacity: 0.6 L (20 fl oz)

Important: Do not operate the engine with the oil level below the Low (or Add) mark on the dipstick, or over the Full mark.

-

Remove the dipstick from the filler neck of the engine and wipe clean the dipstick with a rag (Figure 15).

-

Slowly pour 0.6 L (20 fl oz) of the specified oil into the crank case of the engine through the filler neck (Figure 15).

-

Insert the dipstick from the engine as shown in Figure 16.

Note: Do not thread the dipstick into the filler neck when checking the engine oil level.

-

Remove the dipstick from the filler neck and look at the oil level in the dipstick (Figure 15).

Note: The engine oil level must cover between the hatch marked areas on the dipstick (Figure 15).

-

If the oil level is low, add the specified oil into the engine until the oil level is between the hatch marked areas on the dipstick.

Note: Do not overfill the engine with oil.

-

Hand tighten the dipstick into the filler neck (Figure 15).

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Spark Plug Specification

Spark Plug Type: NGK BR6HS, Champion RTL86C, or equivalent

Removing the Spark Plug

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

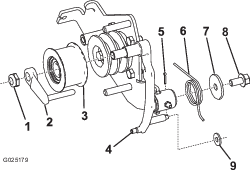

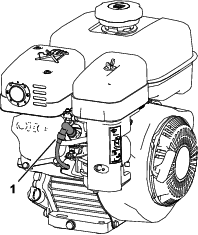

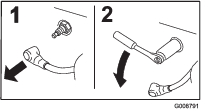

Remove the spark plug as shown in Figure 17.

Checking the Spark Plug

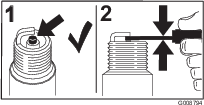

Air Gap: 0.6 to 0.7 mm (0.02 to 0.03 inch)

Important: Do not clean the spark plug(s). Always replace the spark plug(s) when it has a black coating, worn electrodes, an oily film, or cracks.

If you see light brown or gray on the insulator, the engine is operating properly. A black coating on the insulator usually means the air cleaner is dirty.

Use a gapping tool/feeler gauge to check and adjust the air gap to 0.6 to 0.7 mm (0.02 to 0.03 inch).

Installing the Spark Plug

Tighten the spark plug as follows:

-

New spark plug—12 to 15 N∙m (8.7 to 10.8 ft-lb)

-

In-service spark plug—23 to 27 N∙m (16.6 to 19.5 ft-lb)