Maintenance

Determine the left and right sides of the machine from the normal operating position.

Greasing the Power Rake

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Grease Type: General-purpose grease

-

Park the machine on a level surface, disengage the auxiliary hydraulics, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

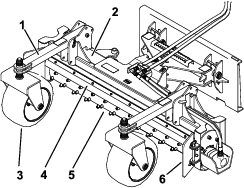

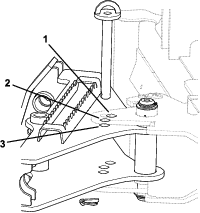

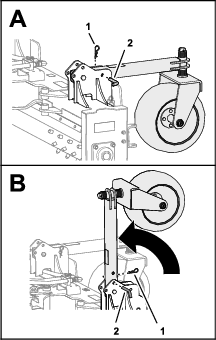

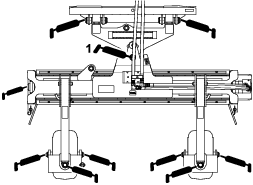

Clean the grease fittings with a rag (Figure 10).

-

Connect a grease gun to the fitting.

-

Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Grease the caster wheels and roller bearing (Figure 10).

-

Wipe up any excess grease.

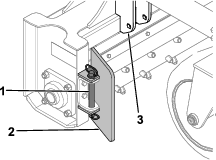

Checking the Hydraulic Lines

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury; otherwise, gangrene may result.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.