Maintenance

Determine the left and right sides of the machine from the normal operating position.

Caution

If you leave the key in the switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the switch before you perform any maintenance.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

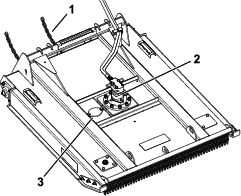

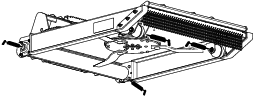

Greasing the Brush Cutter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Grease type: General-purpose grease

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

Clean the grease fittings with a rag.

-

Grease the 2 rear roller bearings and 2 front caster fittings.

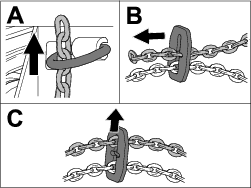

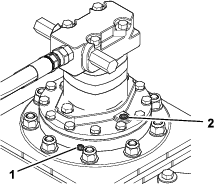

Checking the Planetary Fluid Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Fluid Type: 80W-90 Gear Oil, API-GL-5 approved

Capacity: 0.41 L (14 fl oz)

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

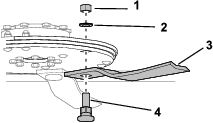

Remove the plug on the side of the bearing housing (Figure 7).

-

If no lubricant comes out of the hole, remove the top plug and add fluid until it comes out of the hole.

-

Install the plugs.

Servicing the Cutting Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Blade Safety

A worn or damaged blade can break, and a piece of the blade could be thrown at you or bystanders, resulting in serious personal injury or death.

-

Inspect the blades periodically for wear or damage.

-

Use care when checking the blades. Wrap the blade or wear gloves, and use caution when servicing the blades. Only replace or sharpen the blades; never straighten or weld them.

Before Inspecting or Servicing the Blades

-

Park the machine on a level surface and disengage the auxiliary hydraulics.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Disconnect the attachment hydraulic couplers from the traction unit and connect the couplers together.

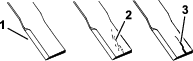

Inspecting the Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Inspect the cutting edges (Figure 8).

-

If the edges are not sharp or have nicks, remove and sharpen the blade; refer to Sharpening the Blades.

-

Inspect the blade.

-

If you notice any crack or wear, immediately install a new blade (Figure 8).

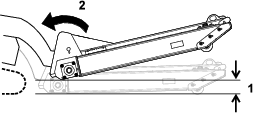

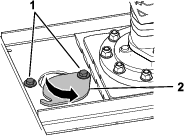

Replacing the Blades

Replace the blades if they hit a solid object, are out of balance, or are bent.

Important: Replace all the blades at the same time to maintain consistent wear and weight balance.

-

Loosen the 2 bolts securing the blade-access cover and move the cover out of the way (Figure 9).

-

Turn the flywheel until you see the blade nut. Remove the blade nut.

Note: The square neck on the bolt prevents the bolt from spinning. The blade will drop after you remove the nut.

-

With assistance from another person, install a new blade, nut, washer, and bolt (Figure 10).

Important: Use new hardware when installing a new blade.

-

Repeat the procedure for the other blades.

-

Close the access cover and tighten the bolts (Figure 9).

Sharpening the Blades

Remove the blades as described in Replacing the Blades and use a file to sharpen the cutting edge at the end of the blade (Figure 11).

Note: Maintain the original angle. Ensure the cutting edge is 0.8 to 1.6 mm (1/32 to 1/16 inch) thick.

Checking the Hydraulic Lines

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury; otherwise, gangrene may result.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

Removing Debris

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

Regular cleaning and washing increases the lifespan of the machine. Clean the machine directly after use.

Use care when using a high-pressure sprayer, because it can damage decals, the planetary, and the hydraulic system.

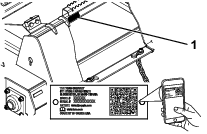

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.