Introduction

The bucket is a load-bearing attachment intended to be used on a Toro tool carrier. It is designed primarily for moving rock, dirt, sand, or other materials. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

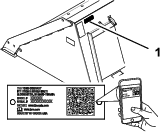

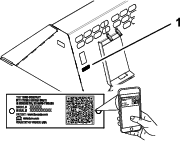

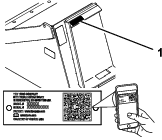

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1, Figure 2, or Figure 3 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 4), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

Warning

CALIFORNIA

Proposition 65 Warning

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

Danger

There may be buried utility lines in the work area. Digging into them may cause a shock or an explosion.

Have the property or work area marked for buried lines and do not dig in marked areas. Contact your local marking service or utility company to have the property marked (for example, in the US, call 811 or in Australia, call 1100 for the nationwide marking service).

General Safety

Always follow all safety instructions to avoid serious injury or death.

-

Do not transport an attachment with the arms raised or extended; always transport the attachment close to the ground, with the loader arms retracted; refer to Transport Position.

-

Have the property or work area marked for buried lines and other objects, and do not dig in marked areas.

-

Read and understand the content of this Operator’s Manual before starting the engine.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Never allow children or untrained people to operate the machine.

-

Keep your hands and feet away from the moving components and attachments.

-

Do not operate the machine without the guards and other safety protective devices in place and working on the machine.

-

Keep bystanders and pets a safe distance away from the machine.

-

Stop the machine, shut off the engine, and remove the key before servicing, fueling, or unclogging the machine.

Improperly using or maintaining this machine can result in injury.

To reduce the potential for injury, comply with these safety instructions

and always pay attention to the safety-alert symbol  , which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

You can find additional safety information where needed throughout this Operator’s Manual.

Slope Safety

-

Operate the machine up and down slopes with the heavy end of the machine uphill. Weight distribution changes with attachments. An empty load-bearing attachment makes the rear of the machine the heavy end, and a full load-bearing attachment makes the front of the machine the heavy end. Most other attachments make the front of machine the heavy end.

-

Keep the attachment in the lowered position with the loader arms retracted when on slopes. Raising the attachment or extending the loader arms on a slope affects the stability of the machine.

-

Slopes are a major factor related to loss of control and tip-over accidents, which can result in severe injury or death. Operating the machine on any slope or uneven terrain requires extra caution.

-

Establish your own procedures and rules for operating on slopes. These procedures must include surveying the site to determine which slopes are safe for machine operation. Always use common sense and good judgment when performing this survey.

-

Slow down and use extra care on hillsides. Ground conditions can affect the stability of the machine.

-

Avoid starting or stopping on a slope. If the machine loses traction, proceed slowly, straight down the slope.

-

Avoid turning on slopes. If you must turn, turn slowly and keep the heavy end of the machine uphill.

-

Keep all movements on slopes slow and gradual. Do not make sudden changes in speed or direction.

-

If you feel uneasy operating the machine on a slope, do not do it.

-

Watch for holes, ruts, or bumps, as uneven terrain could overturn the machine. Tall grass can hide obstacles.

-

Use caution when operating on wet surfaces. Reduced traction could cause sliding.

-

Evaluate the area to ensure that the ground is stable enough to support the machine.

-

Use caution when operating the machine near the following:

-

Drop-offs

-

Ditches

-

Embankments

-

Bodies of water

The machine could suddenly roll over if a track goes over the edge or the edge caves in. Maintain a safe distance between the machine and any hazard.

-

-

Do not remove or add attachments on a slope.

-

Do not park the machine on a hillside or slope.

Bucket Safety

-

Wear gloves, eye protection, long pants, substantial slip-resistant footwear, and hearing protection during operation or while adjusting or repairing the machine.

-

After striking a foreign object, shut off the engine, remove the key, thoroughly inspect the attachment for any damage, and repair the damage before starting and operating the attachment.

-

Always lower the attachment and shut off the machine each time you leave the operating position.

-

When lifting the attachment, keep it level and prevent the load from spilling backward.

Maintenance and Storage Safety

-

Check fasteners at frequent intervals for proper tightness to ensure that the equipment is in safe operating condition.

-

Refer to the Operator’s Manual for important details if you store the attachment for an extended period of time

-

Maintain or replace safety and instruction labels, as necessary.

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

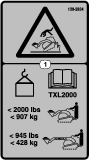

Decal 139-2834 is for Model 22576.

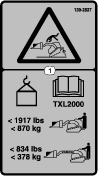

Decal 139-2836 is for Model 22547.

Decal 139-2837 is for Model 22546.

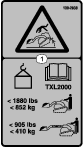

Decal 139-2838 is for Model 22548.

Product Overview

Note: Specifications and design are subject to change without notice.

| Width | 185 cm (73 inches) |

| Length | 124 cm (49 inches) |

| Height | 74 cm (29 inches) |

| Weight | 385 kg (849 lb) |

| Capacity (SAE struck capacity) | 0.8 m3 (29.0 ft3) |

| Width | 140 cm (55 inches) |

| Length | 107 cm (42 inches) |

| Height | 64 cm (25 inches) |

| Weight | 276 kg (609 lb) |

| Capacity (SAE struck capacity) | 0.4 m3 (12.8 ft3) |

| Width | 140 cm (55 inches) |

| Length | 99 cm (39 inches( |

| Height | 51 inches |

| Weight | 239 kg (527 lb) |

| Capacity (SAE struck capacity) | 0.3 m3 (9.3 ft3) |

| Width | 140 cm (55 inches) |

| Length | 107 cm (42 inches) |

| Height | 64 cm (25 inches) |

| Weight | 243 kg (535 lb) |

| Capacity (SAE struck capacity) | 0.4 m3 (12.8 ft3) |

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Maximum Material Density at Capacity

The density of the materials moved by the bucket varies and, therefore, so does the amount of material that the bucket can carry before reaching the maximum load rating. The first 2 tables lists the density of material that can be carried, both heaped and struck (i.e., leveled off), in the bucket. The Material Density table lists common materials and their densities.

| Bucket Capacity | Maximum Density—Loader arms retracted | Maximum Density—Loader arms extended |

| Heaped bucket | 910 kg/m3 | 441 kg/m3 |

| (57 lb/ft3) | (28 lb/ft3) | |

| Struck (leveled) bucket | 1105 kg/m3 | 536 kg/m3 |

| (69 lb/ft3) | (33 lb/ft3) |

| Bucket Capacity | Maximum Density—Loader arms retracted | Maximum Density—Loader arms extended |

| Heaped bucket | 1922 kg/m3 | 881 kg/m3 |

| (120 lb/ft3) | (55 lb/ft3) | |

| Struck (leveled) bucket | 2419 kg/m3 | 1121 kg/m3 |

| (151 lb/ft3) | (70 lb/ft3) |

| Bucket Capacity | Maximum Density—Loader arms retracted | Maximum Density—Loader arms extended |

| Heaped bucket | 2280 kg/m3 | 1010 kg/m3 |

| (142 lb/ft3) | (63 lb/ft3) | |

| Struck (leveled) bucket | 3186 kg/m3 | 1412 kg/m3 |

| (199 lb/ft3) | (88 lb/ft3) |

| Bucket Capacity | Maximum Density—Loader arms retracted | Maximum Density—Loader arms extended |

| Heaped bucket | 1970 kg/m3 | 913 kg/m3 |

| (123 lb/ft3) | (57 lb/ft3) | |

| Struck (leveled) bucket | 2499 kg/m3 | 1,153 kg/m3 |

| (156 lb/ft3) | (72 lb/ft3) |

| Material | Density (Approximate) |

| Caliche | 1250 kg/m3 (78 lb/ft3) |

| Clay: | |

| Natural bed | 1600 kg/m3 (104 lb/ft3) |

| Dry | 1480 kg/m3 (93 lb/ft3) |

| Wet | 1660 kg/m3 (104 lb/ft3) |

| With gravel, dry | 1420 kg/m3 (89 lb/ft3) |

| With gravel, wet | 1540 kg/m3 (96 lb/ft3) |

| Coal: | |

| Anthracite, broken | 1100 kg/m3 (69 lb/ft3) |

| Bituminous, broken | 830 kg/m3 (52 lb/ft3) |

| Earth: | |

| Dry, packed | 1510 kg/m3 (94 lb/ft3) |

| Wet, packed | 1600 kg/m3 (100 lb/ft3) |

| Loam | 1250 kg/m3 (78 lb/ft3) |

| Granite, broken or large crushed | 1660 kg/m3 (104 lb/ft3) |

| Gravel: | |

| Dry | 1510 kg/m3 (94 lb/ft3) |

| Pit run (graveled sand) | 1930 kg/m3 (120 lb/ft3) |

| Dry, 13 to 51 mm (1/2 to 2 inch) | 1690 kg/m3 (106 lb/ft3) |

| Wet, 13 to 51 mm (1/2 to 2 inch) | 2020 kg/m3 (126 lb/ft3) |

| Limestone, broken or crushed | 1540 kg/m3 (96 lb/ft3) |

| Sand: | |

| Dry | 1420 kg/m3 (89 lb/ft3) |

| Wet | 1840 kg/m3 (115 lb/ft3) |

| With gravel, dry | 1720 kg/m3 (107 lb/ft3) |

| With gravel, wet | 2020 kg/m3 (126 lb/ft3) |

| Sandstone, broken | 1510 kg/m3 (94 lb/ft3) |

| Shale | 1250 kg/m3 (78 lb/ft3) |

| Slag, broken | 1750 kg/m3 (109 lb/ft3) |

| Stone, crushed | 1600 kg/m3 (100 lb/ft3) |

| Topsoil | 950 kg/m3 (59 lb/ft3) |

Operation

Determine the left and right sides of the machine from the normal operating position.

Installing and Removing the Attachment

Refer to the Operator’s Manual for the traction unit for the installation and removal procedure.

Important: Before installing the attachment, position the machine on a level surface, ensure that the mount plates are free of any dirt or debris, and ensure that the pins rotate freely. If the pins do not rotate freely, grease them.

Note: Always use the traction unit to lift and move the attachment.

Warning

If you do not fully seat the quick-attach pins through the attachment mount plate, the attachment could fall off the machine, crushing you or bystanders.

Ensure that the quick-attach pins are fully seated in the attachment mount plate.

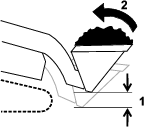

Filling the Bucket

-

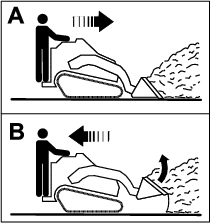

Position the bucket level to the ground.

-

Drive forward and insert the bucket into the pile of material.

-

When the bucket is full, drive the machine in reverse and gently tilt the bucket rearward to decrease the lifting resistance when you lift the load.

Important: Always carry loads close to the ground with the arms retracted (if applicable); refer to Transport Position.

Transport Position

When transporting a load, keep the attachment as close to the ground as possible, no more than 15 cm (6 inches) above the lowest position. Tilt it rearward to keep the load level.

Storage

-

Before long-term storage, wash the attachment with mild detergent and water to remove dirt and grime.

-

Paint all scratched or bare metal surfaces.

Note: Paint is available from your Authorized Service Dealer.

-

Store the attachment in a clean, dry garage or storage area. Cover it to protect it and keep it clean.