Maintenance

Greasing the Broom

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Park the machine on a level surface and disengage the auxiliary hydraulics.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

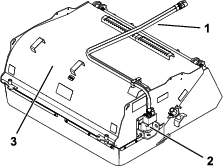

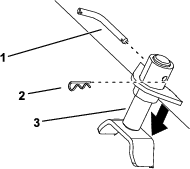

Grease the fittings on the 2 hinges and the bearing (Figure 7).

Replacing the Brushes

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Removing the Brushes

Replace the brushes when the outside diameter of the brushes is 33 cm (13 inches, or half the original diameter).

Note: Replace all bristles at the same time; otherwise, a mix of old and new bristles reduces performance.

-

Park the machine on a level surface and disengage the auxiliary hydraulics.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the hoses from the hose clamp.

-

Remove the 4 nuts securing the motor assembly and remove the assembly.

-

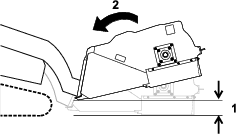

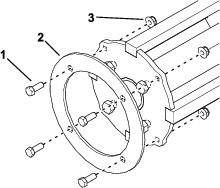

On the right side of the machine, remove the 4 nuts (1/2 inch) securing the bearing mount plate and remove the bearing mount plate (Figure 8).

Note: The broom core should be free from the hood. Push the broom core toward the motor end to allow it to drop from the hood.

-

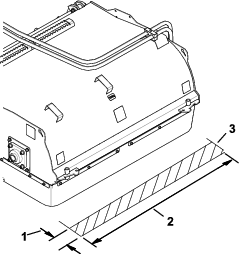

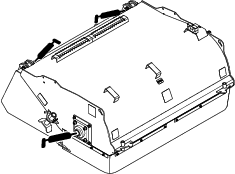

Remove the 4 bolts, 4 nuts, and the retaining plate (Figure 9).

-

Slide the brushes off the broom.

Installing the Brushes

-

Inspect the broom core for damage or excessive wear. Replace it if it is damaged.

-

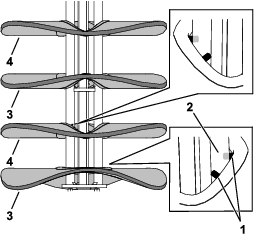

Stand the broom core on end. Starting with a polypropylene brush, install new brushes, ensuring the prongs straddle the rods of the core (Figure 10). Alternate between polypropylene and wire brushes, with each consecutive brush 180° apart.

Note: The last brush installed should be a polypropylene brush.

-

Install the retaining plate (Figure 9).

-

Lay the core on the ground.

Important: Do not move the core using the brushes.

-

Lower the hood over the core.

Note: You may need to push the broom core toward the motor end to bypass the side of the hood when installing it.

-

Install the bearing mount plate (Figure 8).

-

Install the mount plate and secure it with the nuts.

-

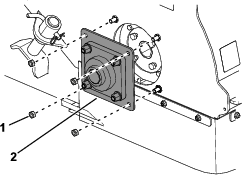

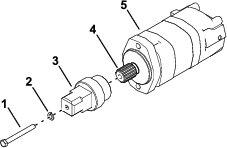

Remove the bolt (3/8 x 3-1/2 inches) and washer securing the drive adapter to the hydraulic motor and apply a thin layer of grease to the splines of the motor (Figure 11).

-

Secure the drive adapter using the bolt (3/8 x 3-1/2 inches) and washer (Figure 11).

-

Install the motor assembly using the 4 bolts removed previously.

-

Install the hoses in the clamp.

Checking the Hydraulic Lines

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury; otherwise, gangrene may result.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.

, which means Caution, Warning,

or Danger—personal safety instruction. Failure to comply with

these instructions may result in personal injury or death.