Maintenance

Greasing the Platform

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Grease type: General-purpose grease

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

Clean the grease fittings with a rag.

-

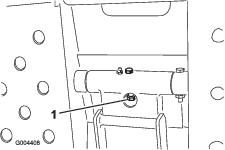

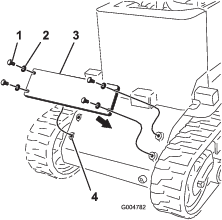

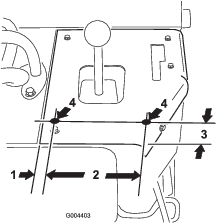

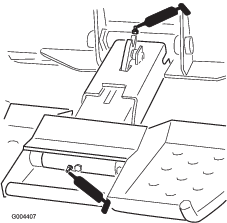

Connect a grease gun to each fitting (Figure 12).

-

Pump grease into the fittings until grease begins to ooze out (approximately 3 pumps).

-

Wipe up any excess grease.

Checking the Shear Bolt

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

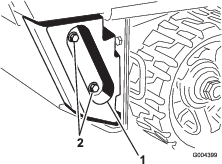

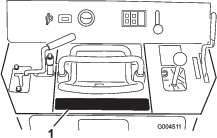

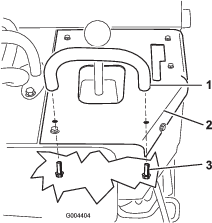

Check the shear bolt for wear, cracks, or damage (Figure 13). Replace it if it is damaged.

Important: Use only a genuine Toro replacement shear bolt and nut. Other bolts may not function correctly and may lead to an unsafe condition.