Maintenance

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 300 hours |

|

Servicing a Subaru

Preparing the Machine for Maintenance

Warning

While you are maintaining or adjusting the machine, someone could start the engine. Accidentally starting the engine could seriously injure you or other bystanders.

Remove the key from the ignition (if equipped), engage parking brake, and pull the wire(s) off the spark plug(s) before you do any maintenance. Also push the wire(s) aside so it does not accidentally contact the spark plug(s).

Perform the following before servicing, cleaning, or making any adjustments to the machine.

-

Park the machine on a level surface.

-

Shut off the engine and remove the key from the machine (if equipped).

-

Engage the parking brake.

-

Wait for all moving parts to stop allow the engine to cool before servicing, storing, or making repairs.

-

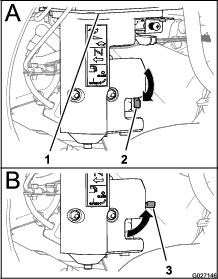

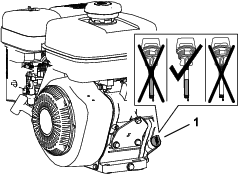

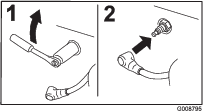

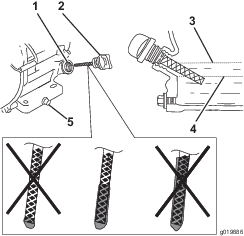

Disconnect the spark-plug wire (Figure 5).

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

Important: Do not apply oil to the foam or paper element.

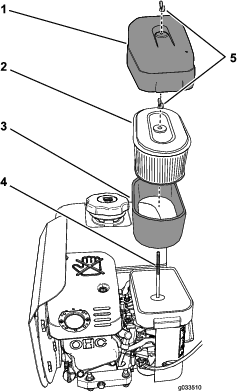

Removing the Foam and Paper Elements

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

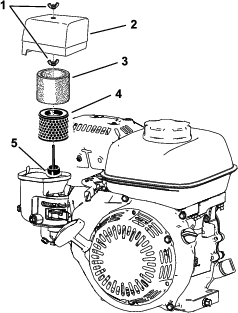

Clean around the air cleaner to prevent dirt from getting into the engine and causing damage (Figure 6).

-

Rotate the wing nut that secures the air-cleaner cover counterclockwise and remove the air-cleaner cover (Figure 6).

-

Rotate the wing nut that secures the paper and foam-filter elements counterclockwise and remove the filter elements from the hold-down rod (Figure 6).

-

Carefully pull the foam element off the paper element (Figure 6).

Note: Inspect the paper and foam-filter elements for damage or an excessive accumulation of dirt. Replace the damaged filters. Clean the foam-filter element if it is dirty. Replace the paper-filter element if it is dirty.

Servicing the Foam Filter Element

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

Inspect the element for tears, an oily film, or damaged (Figure 6).

Important: Replace the foam element if it is worn or damaged.

-

Wash the foam element in liquid soap and warm water. When the element is clean, rinse it thoroughly.

-

Dry the element by squeezing it in a clean cloth.

-

Air dry the foam-filter element.

Installing the Foam and Paper-Filter Elements

Important: To prevent engine damage, always operate the engine with the complete foam and paper air-cleaner assembly installed.

-

Carefully slide the foam-filter element onto the paper-filter element (Figure 6).

-

Align the hole in the top plate of the paper-filter element with the hold-down rod of the carburetor (Figure 6).

-

Secure the filter elements to the carburetor with the wing nut (Figure 6) that you removed in step 4 of Removing the Foam and Paper Elements.

-

Align the hole in the air-cleaner cover with the hold-down rod (Figure 6) and secure the cover to the rod with the wing nut that you removed in step 3 of Removing the Foam and Paper Elements.

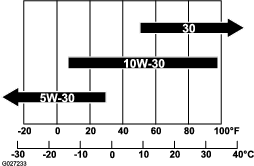

Engine Oil Specification

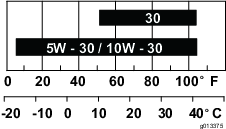

Oil Type: Detergent oil (API service SJ or higher)

Oil viscosity: Refer to the table below.

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Important: Do not operate the engine with the oil level below the Low (or Add) mark on the dipstick, or over the Full mark.

-

Move the machine to a level surface.

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

Allow the engine to cool.

-

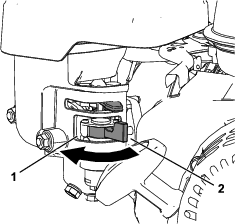

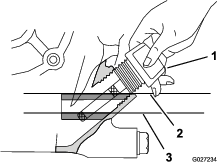

Remove the dipstick from the engine and wipe the dipstick with a clean rag (Figure 8).

-

Insert the dipstick from the engine as shown in Figure 8.

Note: Do not thread the dipstick into the filler neck when checking the engine oil level.

-

Remove the dipstick from the filler neck and look at the oil level in the dipstick (Figure 8).

Note: The engine oil level must cover between the hatch marked areas on the dipstick (Figure 8).

-

If the oil level is low, wipe off the area around the filler neck and add the specified oil until the oil level is between the hatch marked areas on the dipstick.

Important: Do not overfill the engine with oil.

-

Hand tighten the dipstick into the filler neck (Figure 8).

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Every 100 hours |

|

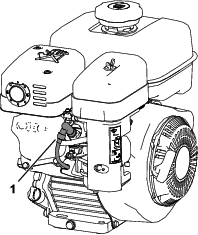

Draining the Engine Oil

Important: Do not operate the engine with the oil level below the Low (or Add) mark on the dipstick, or over the Full mark.

-

Start and run the engine for a few minutes to warm the engine oil.

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

At the rear of the machine, place a drain pan under the drain plug.

-

Remove the drain plug from the engine and allow the oil to drain completely.

-

Push down on the handle to tip the machine and engine backward, allowing all the oil to run into the drain pan.

Important: Do not tip the machine at an angle greater than 25°. Tipping the machine beyond 25° leads to oil leaking into the combustion chamber and/or fuel leaking out of the fuel-tank cap.

-

Install the drain plug and refill the crankcase with the specified oil; refer to Adding Oil to the Engine.

-

Torque the drain plug to 20 to 23 N∙m (15 to 17 ft-lbs).

-

Wipe up any spilled oil and dispose of the used oil properly.

Adding Oil to the Engine

Engine Oil Capacity: 0.6 L (20 fl oz)

Important: Do not operate the engine with the oil level below the Low (or Add) mark on the dipstick, or over the Full mark.

-

Remove the dipstick from the filler neck of the engine and wipe clean the dipstick with a rag (Figure 10).

-

Slowly pour 0.6 L (20 fl oz) of the specified oil into the crank case of the engine through the filler neck (Figure 10).

-

Insert the dipstick from the engine as shown in Figure 11.

Note: Do not thread the dipstick into the filler neck when checking the engine oil level.

-

Remove the dipstick from the filler neck and look at the oil level in the dipstick (Figure 10).

Note: The engine oil level must cover between the hatch marked areas on the dipstick (Figure 10).

-

If the oil level is low, add the specified oil into the engine until the oil level is between the hatch marked areas on the dipstick.

Note: Do not overfill the engine with oil.

-

Hand tighten the dipstick into the filler neck (Figure 10).

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Spark Plug Specification

Spark Plug Type: NGK BR6HS, Champion RTL86C, or equivalent

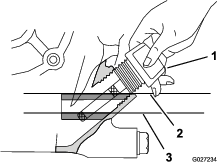

Removing the Spark Plug

-

Prepare the machine for maintenance; refer to Preparing the Machine for Maintenance.

-

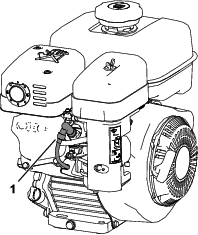

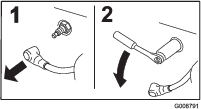

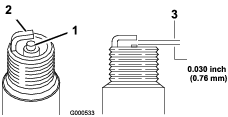

Remove the spark plug as shown in Figure 12.

Checking the Spark Plug

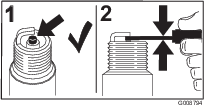

Air Gap: 0.6 to 0.7 mm (0.02 to 0.03 inch)

Important: Do not clean the spark plug(s). Always replace the spark plug(s) when it has a black coating, worn electrodes, an oily film, or cracks.

If you see light brown or gray on the insulator, the engine is operating properly. A black coating on the insulator usually means the air cleaner is dirty.

Use a gapping tool/feeler gauge to check and adjust the air gap to 0.6 to 0.7 mm (0.02 to 0.03 inch).

Installing the Spark Plug

Tighten the spark plug as follows:

-

New spark plug—12 to 15 N∙m (8.7 to 10.8 ft-lb)

-

In-service spark plug—23 to 27 N∙m (16.6 to 19.5 ft-lb)

Servicing a Honda

Preparing the Machine for Maintenance

Warning

While you are maintaining or adjusting the machine, someone could start the engine. Accidentally starting the engine could seriously injure you or other bystanders.

Remove the key from the ignition (if equipped), engage parking brake, and pull the wire(s) off the spark plug(s) before you do any maintenance. Also push the wire(s) aside so it does not accidentally contact the spark plug(s).

Perform the following before servicing, cleaning, or making any adjustments to the machine.

-

Park the machine on a level surface.

-

Shut off the engine and remove the key from the machine (if equipped).

-

Engage the parking brake.

-

Wait for all moving parts to stop allow the engine to cool before servicing, storing, or making repairs.

-

Disconnect the spark-plug wire (Figure 5).

Servicing the Engine Oil

Fill the crankcase with approximately 0.56 L (19 fl oz) of the proper viscosity oil before starting. The engine uses a high-quality oil that has the American Petroleum Institute (API) service classification of SJ or higher. Select the proper oil viscosity (weight) based on the ambient temperature. Figure 16 illustrates the temperature/viscosity recommendations.

Note: Multi-grade oils (5W-20, 10W-30 and 10W-40) increase oil consumption. Check the engine-oil level more frequently when you use these oils.

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

The ideal time to check the engine-oil level is when the engine is cool or before you have started the engine for the day. If you have already ran the engine, allow the oil to drain back down to the sump for at least 10 minutes before you check the engine-oil level.

-

Shut off the engine and wait for all moving parts to stop; refer to Preparing the Machine for Maintenance.

-

Position the machine so that the engine is level, and clean the area around the oil-fill tube (Figure 17).

-

Remove the dipstick by rotating it counterclockwise.

-

Remove the dipstick and wipe the end clean.

-

Insert the dipstick fully into the oil-fill tube, but do not thread it in.

-

Remove the dipstick and check the engine-oil level (Figure 18).

-

If the engine-oil level is incorrect, add or drain oil to correct the level; refer to Changing the Engine Oil.

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 20 hours |

|

| Every 100 hours |

|

Warning

Oil may be hot after the engine has been run, and contact with hot oil can cause severe personal injury.

Avoid contacting the hot engine oil when you drain it.

-

Shut off the engine and wait for all moving parts to stop; refer to Preparing the Machine for Maintenance.

-

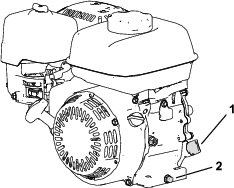

Raise the engine off the ground and place a pan under the drain plug to catch the oil.

-

Remove the drain plug (Figure 17).

-

When the oil has drained completely, lower the engine to the ground, replace the drain plug and washer, and torque the plug to 18 N⋅m (13 ft-lb).

Note: Dispose of the used oil at a certified recycling center.

-

Remove the dipstick, and slowly pour oil into the oil-fill hole until the oil is at the correct level.

-

Ensure that the oil is at the correct level on the dipstick; refer to Checking the Engine-Oil Level.

-

Replace and secure the dipstick.

-

Wipe up any spilled oil.

-

Connect the wire to the spark plug.

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 300 hours |

|

Important: Do not operate the engine without the air filter assembly; extreme engine damage will occur.

-

Shut off the engine and wait for all moving parts to stop; refer to Preparing the Machine for Maintenance.

-

Remove the wingnut securing the air-cleaner cover (Figure 19).

-

Remove the air-cleaner cover.

Note: Ensure that no dirt or debris from the air-cleaner cover fall into the base.

-

Remove the foam and paper elements from the base.

-

Remove the foam element from the paper element.

-

Inspect the foam and paper elements; replace them if they are damaged or excessively dirty.

-

Clean the paper element by tapping it gently to remove the dirt.

Note: Do not try to brush dirt off the paper element; brushing forces the dirt into the fibers. Replace the element if tapping it fails to remove the dirt.

-

Clean the foam element in warm, soapy water or in a nonflammable solvent.

Note: Do not use gasoline to clean the foam element because it could create a risk of fire or explosion.

-

Rinse and dry the foam element thoroughly.

-

Wipe dirt from the base and the cover with a moist rag.

Note: Ensure that dirt and debris do not enter the air duct leading to the carburetor.

-

Install the air-cleaner elements and ensure that they are properly positioned. Install the lower wing nut.

-

Install the cover and install the upper wing nut to secure it.

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Every 300 hours |

|

Use an NGK BPR6ES spark plug or equivalent.

-

Shut off the engine and wait for all moving parts to stop; refer to Preparing the Machine for Maintenance.

-

Clean around the spark plug.

-

Remove the spark plug from the cylinder head.

Important: Replace a cracked, fouled, or dirty spark plug. Do not sand blast, scrape, or clean the electrodes because engine damage could result from grit entering the cylinder.

-

Set the gap on the plug to 0.7 to 0.8 mm (0.028 to 0.031 inch)

-

Carefully install the spark plug by hand (to avoid cross threading) until it is hand tight.

-

Tighten the spark plug an additional 1/2 turn if it is new; otherwise, tighten it an additional 1/8 to 1/4 turn.

Important: A loose spark plug can become very hot and can damage the engine; overtightening a spark plug may damage the threads in the cylinder head.

-

Connect the wire to the spark plug.