Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Lower the loader arms.

-

Remove any attachments; refer to the Operator’s Manual for the machine.

-

Shut off the engine and remove the key.

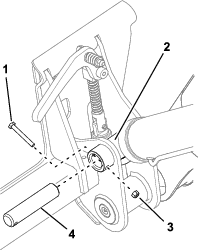

Removing the Existing Pivot Pin

-

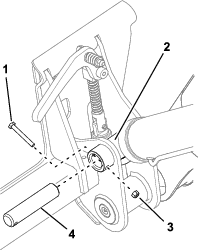

On each side of the attachment mount plate, remove the bolt (5/16 x 2-1/2 inches), locknut (5/16 inch), and link pin securing the hydraulic cylinder rod to the mount plate (Figure 1).

-

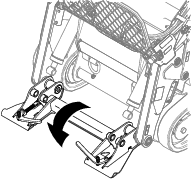

Rotate the attachment mount plate forward so that it is resting on the ground (Figure 2).

-

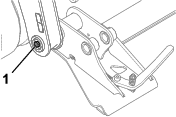

On 1 side of the mount plate, loosen the bolt (1/2 x 3-1/4 inch) securing the pivot pin so that the head of the bolt is at least 6 mm (1/4 inch) out from the original position (Figure 3).

-

Use a hammer to strike the head of the bolt to push the pivot pin toward the middle of the machine.

-

When the pivot pin is removable, remove the bolt, washer, and pivot pin (Figure 4).

-

Repeat steps 4 through 7 for the other pivot pin.

-

Check the pivot bushings of the attachment mount plate for wear or damage. Replace any as necessary.

Installing the New Pivot Pins

-

Install the grease fittings onto the new pins.

-

Align the holes in the loader arms with the holes in the attachment mount plate.

-

On both sides of the attachment mount plate, slide the tapered end of the pivot pin into the holes from the inside of the attachment mount plate.

-

Ensure that the taper on the pins and the holes are clean and free of grease.

-

Apply thread-locking compound to the bolts (1/2 x 3-1/2 inches), and secure each pin with a bolt and washer as shown in Figure 5. Torque the bolts to 127 to 157 N∙m (94 to 116 ft-lb).

-

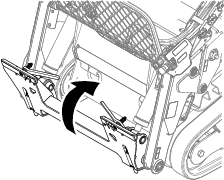

Rotate the attachment mount plate up toward the loader arms (Figure 6).

-

Insert the hydraulic cylinder rods into the attachment mount plate and secure them with the link pins, bolts (5/16 x 2-1/2 inches), and locknuts (5/16 inch) removed previously (Figure 7). Torque the locknuts to 20 to 25 N∙m (15 to 18 ft-lb).

-

Grease the base and rod end of the hydraulic cylinders and the pivot pins.

-

Start the machine and tilt the attachment mount plate forward and rearward to verify that it operates properly.