Note: Determine the left and right sides of the cutting unit from

behind the cutting unit.

Important: The Rear Roller Brush Kit is only to be used when cutting in

the height of cut range of 6 to 25 mm (1/4 to 1 inch).

Install the high height-of-cut brush when cutting above 25 mm

(1 inch) height of cut (7 maximum spacers installed below the side

plate pad).:

-

Part 110-1740 for 22-inch cutting units

-

Part 115-0838 for 27-inch cutting units

-

Part 115-0849 for 32-inch cutting units

Install the HD brush for heavy-duty conditions (worm castings,

clay, etc.).:

Refer to Installing the High Height-of-Cut Brush or HD Brush (Optional).

Rear Roller Brush Kit Model 137-5991 may be used on

the following:

Reelmaster 5210 and 5410 Cutting Unit Models 03661, 03694, and

03695

Rear Roller Brush Kit Model 137-5992 may be used on

the following:

-

Reelmaster 5510 and 5610 Cutting Unit Models 03681,

03682, 03693, 03696 and 03697

-

Reelmaster 6500 and 6700 Cutting Unit Models 03863,

03864, 03698 and 03699

Rear Roller Brush Kit Model 137-5993 may be used on

the following:

-

Reelmaster 3100 Cutting Unit Models 03180, 03181,

and 03183 with the 27-inch Lift Arm Kit, Model 03172

-

Reelmaster 7000 Cutting Unit Models 03710 and 03711

Rear Roller Brush Kit Model 137-5994 may be used on

the following:

-

Reelmaster 3100 Cutting Unit Model 03182 with the

32-inch Lift Arm Kit, Model 03173

-

Reelmaster 7000 Cutting Unit Model 03712

Note: If you are installing a groomer kit and a brush kit on the cutting

unit, install the groomer kit first.

Gathering the Appropriate Tools

Acquire the following tools before proceeding with the installation:

-

1/2 deep-well socket

-

9/16 socket

-

5/8 socket

-

1/2 wrench

-

9/16 wrench

-

1/8 Allen wrench

-

5/16 Allen wrench

-

3/8-16 tap

-

12-inch straight edge (optional, Toro Part 114-5446)

-

Torque wrench (foot-pound)

-

Torque wrench (inch-pound)

-

Blue 243 Loctite

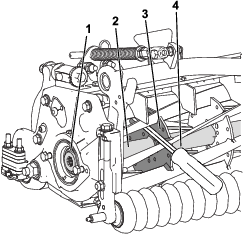

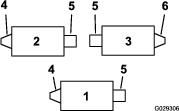

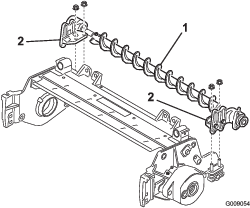

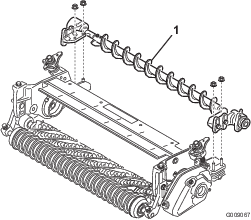

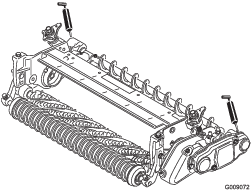

Determining the Orientation of the Roller Brushes

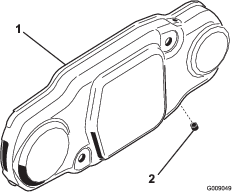

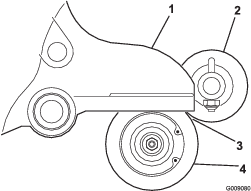

All cutting units are shipped with the counterweight mounted

to the left end of the cutting unit. Use the Figure 1 to determine the position

of the roller brushes and reel motors for Reelmaster 3100-D or Figure 2 for Reelmaster

5210, 5410, 5510, 5610, 6500-D, 6700-D, and 7000-D.

Note: These instructions and illustrations show the installation of

the kit on cutting units with the end weights mounted on the left

end of the cutting unit.

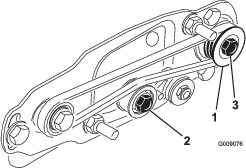

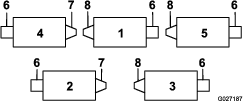

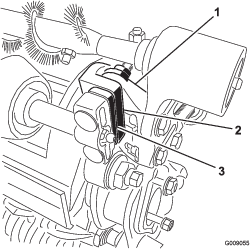

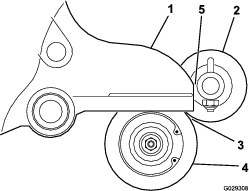

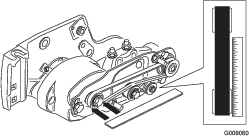

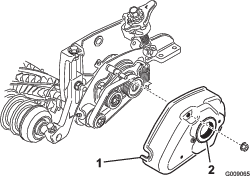

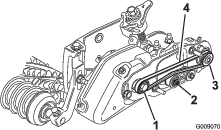

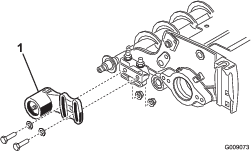

Adjusting the Position of the Idler Pulley Assembly

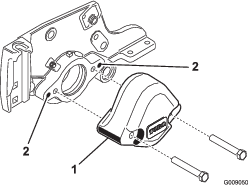

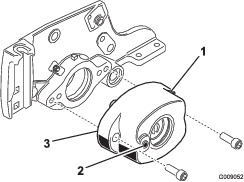

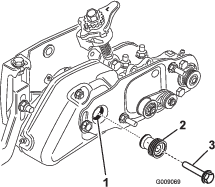

On the left front and left rear cutting units, reverse the idler

pulley assembly to mount on the right end of

the cutting unit (Figure 3), as follows:

-

Remove the idler pulley assembly from the left end

of the cutting unit and mount it to the lower hole in the brush plate

on the right end of the cutting unit (Figure 3).

Note: The idler pulley must pivot freely; do not overtighten the locknut

on the idler pivot bolt.

-

Remove the carriage bolt and nut and relocate them

to the upper hole previously occupied by the idler pulley assembly

(Figure 3).

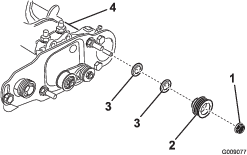

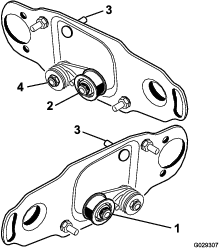

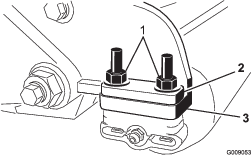

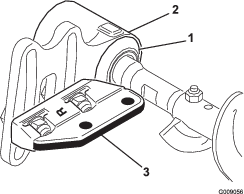

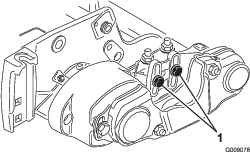

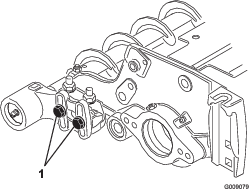

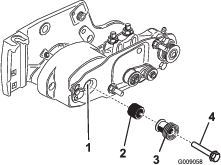

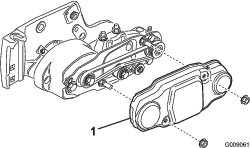

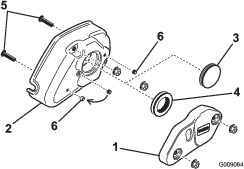

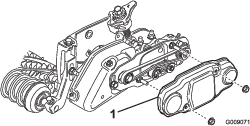

Removing the Brush Cover Drain Plug

Remove only the bottom drain plug (Figure 4) from the brush covers. This

allows moisture to drain from the belt area.

Installing the Roller Brush

Parts needed for this procedure:

| Roller-brush housing | 1 |

| Allen-head bolt, 3/8 x 1 inch | 2 |

| Roller-brush assembly | 1 |

| Shoulder bolt | 1 |

| Belt cover/plate assembly | 1 |

| Bolt, 5/16 x 5/8 inch | 2 |

| Spacer | 1 |

| Drive pulley | 1 |

| Flange-head bolt, 3/8 x 2 inches | 1 |

| Belt | 1 |

| Shim washer (as required) | 1 |

Installing the Brush on Cutting Units not Equipped with Groomers

-

Park the traction unit on a level surface and engage

the parking brake.

-

Ensure that the cutting units are disengaged. Shut

off the engine off and remove the key. Remove all cutting units from

the traction unit.

Important: Check the cutting unit for the desired height of cut and attitude.

Reset it according to the Operator’s Manual, if required, before installing the Rear Roller Brush Kit.

-

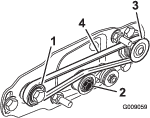

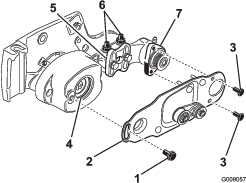

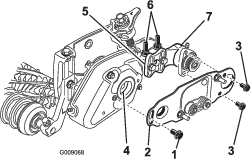

Remove the 2 bolts securing the counterweight to the

left end of the cutting unit. Remove the counterweight (Figure 5).

-

Using a 3/8-16 tap, remove the paint in the outer

mounting holes in the side-plate (Figure 5).

-

Mount the roller-brush housing to the reel-bearing

housing with 2 Allen-head bolts (3/8 x 1 inch) (Figure 6). Position the roller-brush

housing so that the threaded hole is toward the front of the cutting

unit.

Note: Make sure that the O-ring is properly positioned in the roller-brush

housing.

-

Remove the 2 flange locknuts securing each roller

bracket to the side-plates (Figure 7). Do not remove the bolts. Also, remove any 6 mm (1/4 inch) spacers from the top side of the

side-plate mounting flange.

-

Position the roller-brush mounting brackets onto the

roller-bracket bolts (Figure 8).

Important: The roller-brush mounting brackets must be mounted directly

to the top surface of the cutting-unit side-plate mounting flange. Do not put spacers between the roller-brush mounting brackets and

the side-plate mounting flanges. Install additional 6 mm

(1/4 inch) spacers on the top side of the roller-brush mounting bracket

(Figure 9).

-

Secure the roller-brush mounting brackets to the cutting-unit

side plates with the nuts previously removed.

-

Slide each excluder seal outward until the lip seals

are in light contact with each bearing housing (Figure 10).

-

Apply a coating of grease to the inner diameter of

the grommet in the bearing housing (Figure 11).

-

Loosen, but do not remove, the bolts securing the

roller-brush-bearing housing to the roller-brush mounting bracket

(Figure 11).

-

Install the roller-brush pivot plate (Figure 11).

Note: When you insert the protrusion on the pivot plate into the grommet

in the bearing housing, ensure that the grommet stays properly seated

in the housing.

Note: The roller-brush pivot plate is properly seated when there is

no resistance from the rubber grommet and it pivots freely.

-

Apply 243 Loctite (blue) to the 2 bolts (5/16 x 5/8

inch) and use them to mount the brush plate to the roller-brush-bearing

housing (Figure 11).

Note: Torque the bolts to 20 to 25 N∙m (15 to 19 ft-lb).

-

Check to make sure that the roller-brush plate is

parallel to the cutting-unit side plate. If it is not parallel, proceed

as follows:

-

Loosen the 2 flange locknuts securing the roller-brush

mounting bracket to the cutting unit side plate (Figure 11).

-

Rotate the roller-brush-bearing housing until the

brush plate is parallel to the cutting-unit side plate (Figure 11).

-

Tighten the 2 flange locknuts securing the roller-brush

mounting bracket to the cutting-unit side plate (Figure 11).

-

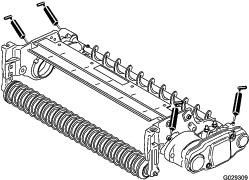

Loosen the 2 bolts securing each roller-brush-bearing

housing to the roller-brush mounting bracket (Figure 12 and Figure 13).

-

Position the roller brush so that it just touches

the rear roller (Figure 14).

Important: The roller-brush shaft must not contact the cutting-unit side-plate.

Important: Heavy brush contact on the roller causes premature brush wear.

Note: The roller brush shaft must be parallel to the rear roller.

Note: The orientation of the non-drive roller-brush-bearing housing

should be the same as drive-side bearing housing.

-

Tighten the 2 bolts securing each roller-brush-bearing

housing to the roller-brush mounting brackets.

-

Apply 243 Loctite (blue) to the shoulder bolt (Figure 11). Secure

the brush plate to the roller-brush housing with the shoulder bolt.

(Figure 11).

Note: Torque the bolt to 20 to 25 N∙m (15 to 19 ft-lb).

Note: The shoulder bolt should not clamp the plate to the housing.

-

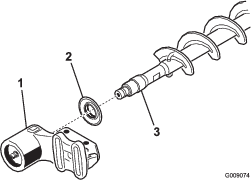

Install the spacer onto the shaft in the bearing housing

(Figure 15).

-

Insert the drive pulley into the spacer and onto the

driveshaft (Figure 15). Make sure that the pulley tabs are positioned in

the slot in the drive shaft.

-

Secure the pulley and spacer to the driveshaft with

a flange-head bolt (3/8 x 2 inch) (Figure 15).

Note: Torque the bolt to 47 to 54 N∙m (35 to 40 ft-lb).

Important: If the bolt is not properly torqued, the bolt will come loose.Restrain the reel for installation; refer to Restraining the Reel for Installing Threaded Inserts.

-

Install the belt onto the pulleys as follows:

-

Loop the belt around the driven pulley and then over the top of the idler pulley (Figure 16).

-

Start the belt on the drive pulley

(Figure 16).

-

While guiding the belt onto the drive pulley, rotate the reel forward to draw the belt onto the drive

pulley.

Note: Wear a padded glove or use a heavy rag to rotate the reel.

Important: Make sure that the ribs on the belt are properly seated in the

grooves in each pulley. Also, make sure that the belt is in the center

of the idler pulley.

-

Push down on the idler pulley to ensure that the idler

pulley assembly pivots freely.

-

Check the alignment of the belt/pulleys as follows:

-

The belt must be properly tensioned (installed) prior

to checking alignment.

-

Lay a straightedge along the outer face of the drive pulley (Figure 17). Do not lay the straightedge across both the drive and driven pulleys.

-

The outer faces of the drive and driven pulleys should

be in line within 0.76 mm (0.030 inch).

-

If the pulleys are not aligned, Refer to Aligning the Pulleys.

-

If the pulleys are aligned, continue with the installation.

-

Do not use the idler pulley to

check alignment.

Important: The belt may fail prematurely if the pulleys are not properly

aligned.

-

Slide the belt cover onto the mounting bolts and secure

with 2 flange nuts (Figure 18).

Important: Do not overtighten the flange nuts, as damage to the cover may

occur.

-

Lubricate the grease fittings on each of the roller-brush-bearing

housings and on the remainder of the cutting unit with No. 2 lithium

grease (Figure 19).

Note: Wipe off any excess grease, specifically around the excluder

seals.

Installing the Brush on Cutting Units Equipped with Groomers

Note: If a groomer kit and a brush kit are going to be installed on

the cutting unit, install the groomer kit first.

-

Remove the 2 groomer cover mounting nuts and remove

the cover (Figure 20).

-

Remove the 2 flange nuts (5/16 inch) securing the

groomer weight to the groomer cover and remove the weight (Figure 21).

-

Remove the solid grommet from the cover and replace

it with the rubber grommet ring included with the groomer (Figure 21).

-

Remove the 2 screws (5/16 x 1-1/4 inch) threaded into

the cover (Figure 21).

-

Remove the setscrew from the center hole in the groomer

cover (Figure 21).

-

Install the previously removed setscrew and the setscrew

included with the Groomer Kit, into the holes previously used for

the cover mounting screws. Apply 243 Loctite (blue) to the setscrews

prior to installation.

Note: The setscrews should be flush with the groomer cover.

-

Install the groomer cover and secure it with 2 flange

nuts (5/16 inch) (Figure 22).

Important: Do not overtighten the nuts.

-

Apply grease to the inside diameter of the grommet

in the groomer cover (Figure 22).

-

Remove the 2 nuts securing each roller bracket to

the side plates (Figure 23). Do not remove the bolts.

Note: Remove any 6 mm (1/4 inch) spacers positioned on the top side

of the side plate mounting flange.

-

Position the roller brush assembly mounting brackets

onto the roller bracket bolts (Figure 24). Secure the brush assembly

mounting brackets to the cutting unit side plates with the nuts previously

removed.

Important: The roller brush assembly mounting brackets must be mounted

directly to the top surface of the cutting unit side plate mounting

flange. Do not put spacers on the roller brush mounting brackets and

the side plate mounting flanges. Install additional 6 mm (1/4 inch)

spacers on the top side of the roller brush mounting bracket (Figure 25).

-

Slide each excluder seal outward until the lip seals

are in light contact with each bearing housing (Figure 26).

-

Loosen but do not remove the bolts securing the roller

brush bearing housing to the roller brush mounting bracket (Figure 27).

-

Install the roller brush pivot plate (Figure 27). Ensure

that the grommet stays properly seated on the cover when the protrusion

on the pivot plate is inserted into the grommet on the groomer cover.

Note: The roller brush pivot plate is properly seated when there is

no resistance from the rubber grommet and it pivots freely.

-

Apply 243 Loctite (blue) to the 2 bolts (5/16 x 5/8

inch) and use them to mount the brush plate to the roller brush bearing

housing (Figure 27). Torque the bolts to 20 to 25 N∙m (15 to 19 ft-lb).

-

Check to make sure that the roller brush plate is

parallel to the cutting unit side plate. If it is not parallel, do

the following:

-

Loosen the 2 flange locknuts securing the roller brush

mounting bracket to the cutting unit side plate (Figure 27).

-

Rotate the roller brush bearing housing until the

brush plate is parallel to the cutting unit side plate (Figure 27).

-

Tighten the 2 flange locknuts securing the roller

brush mounting bracket to the cutting unit side plate (Figure 27).

-

Loosen the 2 bolts securing each roller brush bearing

housing to the roller brush mounting bracket (Figure 12 and Figure 13).

-

Position the roller brush so it is in light contact

with (i.e., just touching or resting on) the rear roller (Figure 14).

Important: The roller brush shaft must not contact the cutting unit side

plate.

Important: Heavy brush contact on the roller will cause premature brush

wear.

Note: The roller brush shaft must be parallel to the rear roller.

Note: The orientation of the non–drive roller brush bearing

housing should be the same as drive side bearing housing.

-

Tighten the 2 bolts securing each roller brush bearing

housing to the roller brush mounting brackets.

-

Apply 243 Loctite (blue) to the shoulder bolt (Figure 27). Secure

the brush plate to the groomer cover with the shoulder bolt. (Figure 27). Torque

the bolt to 20 to 25 N∙m (15 to 19 ft-lb).

Note: The shoulder bolt should not clamp the plate to the housing.

-

Remove the bolt securing the groomer pulley to the

drive shaft (Figure 31).

-

Insert the brush drive pulley into the groomer drive

pulley and onto the drive shaft (Figure 31). Make sure that the pulley

tabs are positioned in the slot in the drive shaft.

-

Secure the drive pulley to the shaft with a flange-head

bolt (3/8 x 2 inch) (Figure 31). Torque the bolt to 47 to 54 N∙m (35 to

40 ft-lb).

Important: If the bolt is not properly torqued, the bolt will come loose.Restrain the reel for installation; refer to Restraining the Reel for Installing Threaded Inserts.

-

Install the belt onto the pulleys as follows:

-

Loop the belt around the driven pulley and then over the top of the idler pulley (Figure 32).

-

Start the belt on the drive pulley

(Figure 32).

-

While guiding the belt onto the drive pulley, rotate the reel forward to draw the belt onto the drive

pulley.

Note: Wear a padded glove or use a heavy rag to rotate the reel.

Important: Make sure that the ribs on the belt are properly seated in the

grooves in each pulley. Also, make sure the belt is in the center

of the idler pulley.

-

Push down on the idler pulley to ensure that the idler

pulley assembly pivots freely.

-

Check the alignment of the belt/pulleys as follows:

-

The belt must be properly tensioned (installed) prior

to checking alignment.

-

Lay a straight edge along the outer face of the drive pulley (Figure 33). Do not lay the straight edge across both the drive and driven pulleys.

-

The outer faces of the drive and driven pulleys should

be in line within 0.76 mm (0.030 inch).

-

If the pulleys are not aligned, Refer to the section

on Pulley Alignment.

-

If the pulleys are aligned, continue with the installation.

-

Do not use the idler pulley to

check alignment.

Note: The belt may fail prematurely if the pulleys are not properly

aligned.

-

Slide the belt cover onto the mounting bolts and secure

with 2 flange nuts (Figure 34).

Important: Do not overtighten nuts as damage to cover may occur.

-

Lubricate the grease fittings on each of the roller

brush bearing housings and on the remainder of the cutting unit with

No. 2 general-purpose, lithium-based grease (Figure 35).

Note: Wipe off any excess grease, specifically around the excluder

seals.

Installing the High Height-of-Cut Brush or HD Brush (Optional)

Parts needed for this procedure:

| High height of cut brush (optional) | – |

| HD brush (optional) | – |

Install the high height-of-cut brush when cutting from 2.5 to

5.1 cm (1 to 2 inches) height of cut (7 maximum spacers installed

below the side plate pad).:

-

Part 110-1740 for 22 inch cutting units

-

Part 115-0838 for 27 inch cutting units

-

Part 115-0849 for 32 inch cutting units

Install the HD brush for heavy-duty conditions (worm castings,

clay, etc.).:

-

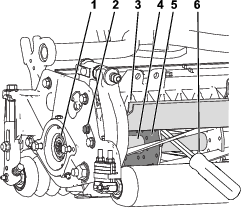

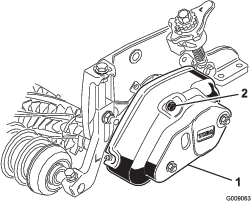

If a roller brush is installed on the cutting unit,

remove the 2 bolts, washers and nuts securing the non-drive-bearing

housing to the bearing-housing mounting bracket (Figure 36 and Figure 37).

-

Slide the non-drive-bearing housing and the excluder

seal off the brush shaft (Figure 37).

-

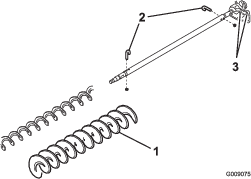

Remove the 2 J-bolts and nuts (Figure 38).

-

Slide the existing brush off the brush shaft (Figure 38).

-

Loosen the 2 bolts, washers, and nuts securing the

drive-bearing housing to the bearing-housing mounting bracket (Figure 38).

-

Slide the high height-of-cut brush or HD brush onto

the brush shaft (Figure 38).

-

Clamp the brush onto the shaft with the 2 J-bolts

and nuts previously removed (Figure 38).

Important: Insert the threaded end of the J-bolts thru the outer holes

of the brush shaft while hooking the curved ends of the J-bolts into

the inner holes.

-

Torque the J-bolt locknuts to 2 to 3 N∙m (20 to 25

in-lb).

-

Install the excluder seal and the non-drive-bearing

housing onto the brush shaft (Figure 37).

-

Mount the non-drive-bearing housing to the bearing-housing

mounting bracket with the 2 bolts, washers, and nuts previously removed.

Note: Be careful not to knock the seal spring off.

-

Tighten the 2 bolts, washers, and nuts securing the

drive-bearing housing to the bearing-housing mounting bracket.