Maintenance

Danger

Contact with the reels or other moving parts can result in personal injury.

-

Before making any adjustments to the cutting units, disengage the reels, set the parking brake, shut off the engine, and remove the key.

-

Keep your hands and clothing away from the reels or other moving parts.

Changing the Gearbox Lubricant

| Service Interval |

| After the first 100 hours |

| Every 500 hours / Yearly (Whichever comes first) |

-

Clean the external surfaces of the groomer housing.

Important: Ensure that there is no dirt or clippings on the outside of the groomer housing; if debris gets inside of the groomer it can damage the gearbox.

-

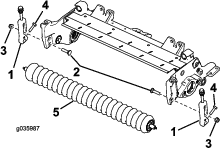

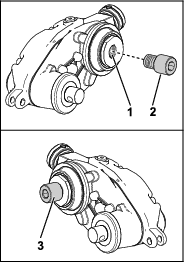

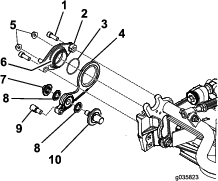

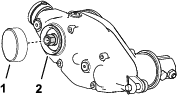

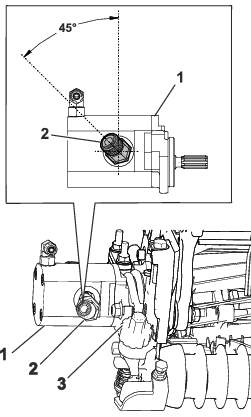

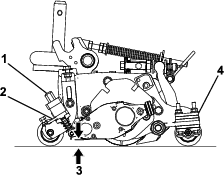

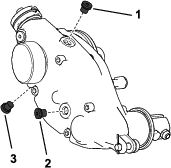

Remove the drain plug on the bottom of the housing (Figure 26).

-

Remove the fill plug on the side of the housing and loosen the air-vent plug on the top so air can pass through (Figure 26).

-

Align a suitable container beneath the oil-drain port to catch drained oil.

-

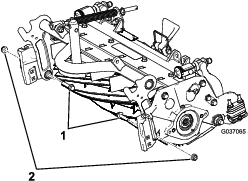

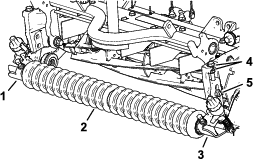

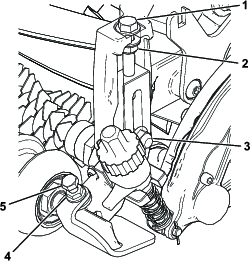

Tip the cutting unit back onto the kickstand until the drain port is at the bottom to ensure complete drainage (Figure 24).

-

Rock the cutting unit back and forth to ensure complete drainage. When the oil is completely drained, place the cutting unit on a level surface.

-

Install the drain plug.

-

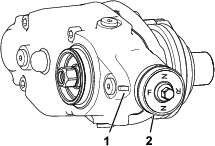

Use a syringe (Part No. 137-0872) to fill the drive box with 80-90W oil. Fill with 50 cc for 5-inch reels or 90 cc for 7-inch reels.

-

Install the fill plug and tighten the air-vent plug.

-

Torque all plugs to 3.62 to 4.75 N∙m (32 to 42 in-lb).

Removing the Groomer Drive Box

Note: Retain all removed parts for later installation unless otherwise stated.

Important: If you have any issues removing the groomer drive box, refer to your traction unit Service Manual or contact your authorized Toro distributor.

-

Remove the cap from the groomer.

-

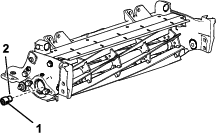

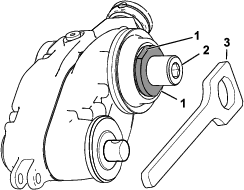

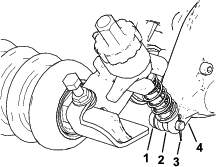

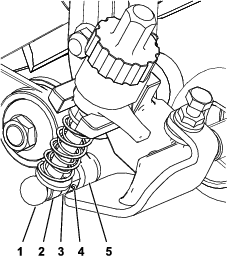

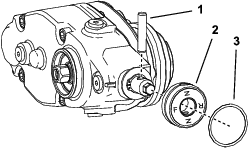

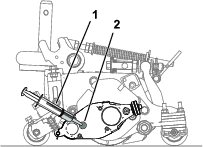

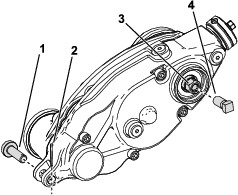

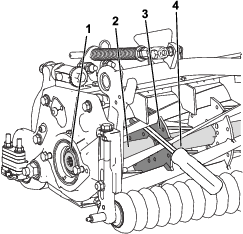

Remove the clamp bolts connecting the groomer to the drive box (Figure 16).

-

Remove the adjuster pin and cotter pin connecting the groomer drive box to the adjuster arms (Figure 27).

-

Restrain the reel for removal; refer to Restraining the Reel for Removing Threaded Inserts.

-

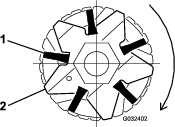

Install the reinforcement screw (Part No. 1-803022—sold separately) to the internal threads of the groomer drive hex head and torque to 13.5 N⋅m (120 in-lbs) as shown in Figure 27.

-

Remove the groomer drive box from the cutting reel by turning the groomer drive hex-head (Figure 27).

Important: If the groomer drive box is installed on the right side of a cutting unit, turn the groomer drive hex-head counter-clockwise (right-hand thread) to remove the drive-box shaft from cutting unit.

Important: If the groomer drive box is installed on the left side of a cutting unit, turn the groomer drive hex-head clockwise (left-hand thread) to remove drive-box shaft from cutting unit

Important: You must use a 6-point socket with heavy wall.

Cleaning the Grooming Reel

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After each use |

Clean off the grooming reel after using it by spraying it with water. Do not direct the water stream directly at the groomer bearing seals. Do not permit the grooming reel to stand in water so that the components rust.

Inspecting the Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

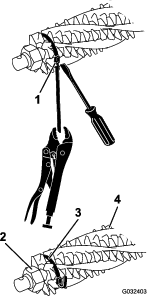

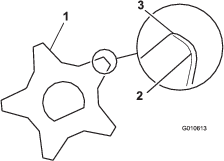

Inspect the grooming-reel blades frequently for damage and wear. Straighten bent blades with a pliers and replace worn blades. When inspecting the blades, check to see that nuts on the right and left blade-shaft ends are tight.

Restraining the Reel

Warning

The cutting reel blades are sharp and capable of amputating hands and feet.

-

Keep your hands and feet outside of the reel.

-

Ensure that the reel is restrained before servicing it.

Restraining the Reel for Removing Threaded Inserts

-

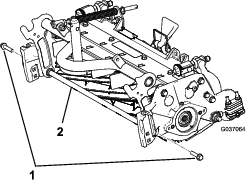

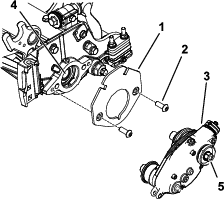

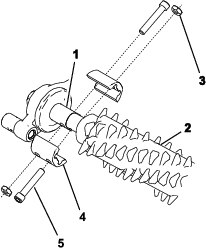

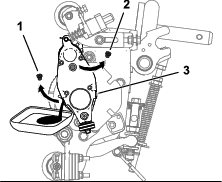

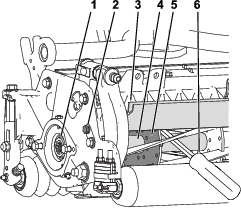

Loosen the shield-bolt on the left side of the cutting unit and raise the rear shield (Figure 29).

-

Insert a long-handled pry bar (recommended 3/8" x 12" with screwdriver handle) through the back of the cutting reel, closest to the side of the cutting unit that you will be torquing (Figure 29).

-

Place the pry bar against the weld side of the reel support plate (Figure 29).

Note: Insert the pry bar between the top of the reel shaft and the backs of 2 reel blades so that the reel will not move.

Important: Do not contact the cutting edge of any blades with the pry bar; this may damage the cutting edge and/or cause a high blade.

Important: The insert on the left side of the cutting unit has left-hand threads. The insert on the right side of the cutting unit has right-hand threads.

-

Rest the handle of the pry bar against the rear roller.

-

Complete the removal of the threaded insert while ensuring that the pry bar stays in place, then remove the pry bar.

-

Lower the rear shield and tighten the shield-bolt.

Restraining the Reel for Installing Threaded Inserts

-

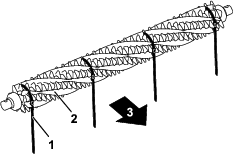

Insert a long-handled pry bar (recommended 3/8" x 12" with screwdriver handle) through the front of the cutting reel, closest to the side of the cutting unit that you will be torquing (Figure 30).

-

Place the pry bar against the weld side of the internal cutting reel reinforcement (Figure 30).

Note: The pry bar should contact a blade at the front, the reel shaft, and a blade at the back of the back of the reel, locking it in place.

Important: Do not contact the cutting edge of any blades with the pry bar; this may damage the cutting edge and/or cause a high blade.

Important: The insert on the left side of the cutting unit has left-hand threads. The insert on the right side of the cutting unit has right-hand threads.

-

Rest the handle of the pry bar against the roller

-

Per the insert’s installation instructions and torque requirements, complete the installation of the threaded insert while ensuring that the pry bar stays in place, then remove the pry bar.