| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

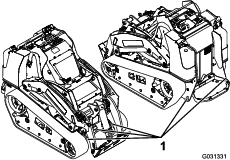

Introduction

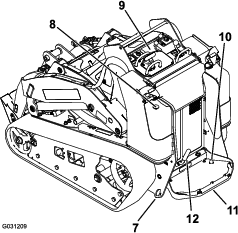

This machine is a compact tool carrier intended to move various earth and materials for landscaping and construction work. It is designed to operate a wide variety of attachments each of which perform a specialized function.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

You may contact Toro directly at www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

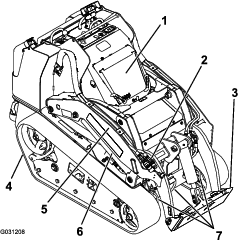

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

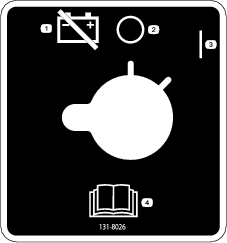

This manual identifies potential hazards and has safety messages identified by the safety-alert symbol (Figure 2), which signals a hazard that may cause serious injury or death if you do not follow the recommended precautions.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

It is a violation of California Public Resource Code Section 4442 or 4443 to use or operate the engine on any forest-covered, brush-covered, or grass-covered land unless the engine is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order or the engine is constructed, equipped, and maintained for the prevention of fire.

The enclosed engine owner's manual is supplied for information regarding the US Environmental Protection Agency (EPA) and the California Emission Control Regulation of emission systems, maintenance, and warranty. Replacements may be ordered through the engine manufacturer.

Warning

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Use of this product may cause exposure to chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

Safety

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury, comply with

these safety instructions and always pay attention to the safety-alert

symbol  , which means: Caution, Warning, or Danger—personal

safety instruction. Failure to comply with the instruction may result

in personal injury or death.

, which means: Caution, Warning, or Danger—personal

safety instruction. Failure to comply with the instruction may result

in personal injury or death.

Safe Operating Practices

This product is capable of amputating hands and feet. Always follow all safety instructions to avoid serious injury or death.

Warning

Engine exhaust contains carbon monoxide, an odorless, deadly poison that can kill you.

Do not run the engine indoors or in an enclosed area.

Training

-

Read the Operator's Manual and other training material. If the operator(s) or mechanic(s) cannot read English, it is the owner's responsibility to explain this material to them.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

All operators and mechanics should be trained. The owner is responsible for training the users.

-

Never let children or untrained people operate or service the equipment. Local regulations may restrict the age of the operator.

-

The owner/user can prevent and is responsible for accidents or injuries occurring to himself or herself, other people or property.

Preparation

-

Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Only use accessories and attachments approved by the manufacturer.

-

Wear appropriate clothing including gloves, safety glasses, long pants, substantial slip-resistant footwear, and hearing protection. Tie back long hair and do not wear jewelry.

-

Inspect the area where the equipment is to be used and remove all objects such as rocks, toys, and wire which can be thrown by the machine.

-

Use extra care when handling fuels. They are flammable and vapors are explosive.

-

Use only an approved container

-

Never remove the fuel cap or add fuel with the engine running. Allow the engine to cool before refueling. Do not smoke.

-

Never refuel or drain the machine indoors.

-

-

Check that the operator's presence controls, safety switches, and shields are attached and functioning properly. Do not operate unless they are functioning properly.

Operation

-

Only operate in good light, keeping away from holes and hidden hazards.

-

Be sure all drives are in neutral and parking brake is engaged before starting the engine. Start the engine only from the operator's position.

-

Slow down and use extra care on hillsides. Be sure to travel in the recommended direction on hillsides. Turf conditions can affect the stability of the machine.

-

Slow down and use caution when making turns, crossing roads and sidewalks, and changing directions on slopes.

-

Never operate without the guards securely in place. Be sure all interlocks are attached, adjusted, and functioning properly.

-

Do not change the engine governor setting or overspeed the engine.

-

Keep hands and feet away from moving attachments.

-

Look behind and down before backing up to be sure of a clear path.

-

Never carry passengers and keep pets and bystanders away.

-

Slow down and use caution when making turns and crossing roads and sidewalks.

-

Do not operate the machine when you are tired, ill, or under the influence of alcohol or drugs.

-

Use care when loading or unloading the machine into a trailer or truck.

-

Use care when approaching blind corners, shrubs, trees, or other objects that may obscure vision.

-

Read all attachment manuals.

-

Ensure that the area is clear of other people before operating the traction unit. Stop the traction unit if anyone enters the area.

-

Never leave a running traction unit unattended. Always lower the loader arms, shut off the engine, set the parking brake, and remove the key before leaving.

-

Do not exceed the rated operating capacity, as the traction unit may become unstable which may result in loss of control.

-

Do not carry a load with the arms raised. Always carry loads close to the ground.

-

Do not overload the attachment and always keep the load level when raising the loader arms. Logs, boards, and other items could roll down the loader arms, injuring you.

-

Never jerk the controls; use a steady motion.

-

Watch for traffic when operating near or crossing roadways.

-

Do not touch parts which may be hot from operation. Allow them to cool before attempting to maintain, adjust, or service.

-

Check for overhead clearances (i.e., branches, doorways, electrical wires) before driving under any objects and do not contact them.

-

Ensure that you operate the traction unit in areas where there are no obstacles in close proximity to the operator. Failure to maintain adequate distance from trees, walls, and other barriers may result in injury. Operate the unit only in areas where there is sufficient clearance for the operator to safely maneuver the product.

-

Before digging, have the area marked for underground utilities, and do not dig in marked areas.

Also, be aware of the location of objects and structures that may not be marked, such as underground storage tanks, wells, and septic systems.

-

Locate the pinch point areas marked on the traction unit and attachments and keep hands and feet away from these areas.

-

Before operating the traction unit with an attachment, ensure that the attachment is properly installed and a genuine Toro attachment.

-

Lightning can cause severe injury or death. If lightning is seen or thunder is heard in the area, do not operate the machine; seek shelter.

Slope Operation

Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death. All slopes require extra caution.

-

Do not operate the traction unit on hillsides or slopes exceeding the angles recommended in Stability Data, and those in the attachment Operator's Manual. See also the .

-

Operate up and down slopes with the heavy end of the traction unit uphill. Weight distribution changes. An empty bucket will make the rear of the traction unit the heavy end, and a full bucket will make the front of the traction unit the heavy end. Most other attachments will make the front of traction unit the heavy end.

-

Raising the loader arms on a slope will affect the stability of the machine. Whenever possible, keep the loader arms in the lowered position when on slopes.

-

Remove or add attachments on level ground.

-

Remove obstacles such as rocks, tree limbs, etc. from the work area. Watch for holes, ruts, or bumps, as uneven terrain could overturn the traction unit. Tall grass can hide obstacles.

-

Use only Toro-approved attachments. Attachments can change the stability and the operating characteristics of the traction unit. Warranty may be voided if used with unapproved attachments.

-

Keep all movements on slopes slow and gradual. Do not make sudden changes in speed or direction.

-

Avoid starting or stopping on a slope. If the traction unit loses traction, proceed slowly, straight down the slope.

-

Avoid turning on slopes. If you must turn, turn slowly and keep the heavy end of the traction unit uphill.

-

Do not operate near drop-offs, ditches, or embankments. The traction unit could suddenly turn over if a track goes over the edge of a cliff or ditch, or if an edge caves in.

-

Use caution when operating on wet grass. Reduced traction could cause sliding.

-

Do not park the traction unit on a hillside or slope without lowering the attachment to the ground and setting the parking brake.

Maintenance and Storage

-

Park on level ground, disengage the auxiliary hydraulics, lower the attachment, set the parking brake, shut off the engine, and remove the key. Wait for all movement to stop and the machine to cool before adjusting, cleaning, storing, or repairing.

-

Clean debris from attachments, drives, mufflers, and engine to help prevent fires. Clean up oil or fuel spillage.

-

Do not store fuel near flames or drain indoors.

-

Never allow untrained personnel to service the machine.

-

Use jack stands to support components when required.

-

Carefully release pressure from components with stored energy.

-

Disconnect the battery before making any repairs; refer to Using the Battery-Disconnect Switch.

-

Keep hands and feet away from moving parts. If possible, do not make adjustments with the engine running.

-

Charge batteries in an open, well-ventilated area, away from spark and flames. Unplug the charger before connecting or disconnecting it from the battery. Wear protective clothing and use insulated tools.

-

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

-

If any maintenance or repair requires the loader arms to be in the raised position, secure the arms in the raised position with the hydraulic cylinder lock.

-

Secure the loader arm valve with the loader valve lock anytime you need to stop the machine with the loader arms raised.

-

Keep nuts and bolts tight. Keep equipment in good condition.

-

Never tamper with safety devices.

-

Keep the traction unit free of grass, leaves, or other debris build-up. Clean up oil or fuel spillage. Allow the traction unit to cool before storing.

-

Use extra care when handling fuels. They are flammable and vapors are explosive.

-

Use only an approved container.

-

Never remove the fuel cap or add fuel when the engine is running. Allow the engine to cool before refueling. Do not smoke.

-

Never refuel the traction unit indoors.

-

Never store the traction unit or fuel container inside where there is an open flame, such as near a water heater or furnace.

-

Never fill a container while it is inside a vehicle, trunk, pick-up bed, or any surface other than the ground.

-

Keep container nozzle in contact with the tank during filling.

-

-

Stop and inspect the equipment if you strike an object. Make any necessary repairs before restarting.

-

Use only genuine Toro replacement parts to ensure that original standards are maintained.

-

Battery acid is poisonous and can cause burns. Avoid contact with skin, eyes, and clothing. Protect your face, eyes, and clothing when working with a battery.

-

Battery gases can explode. Keep cigarettes, sparks and flames away from the battery.

-

Keep your body and hands away from pin hole leaks or nozzles that eject high-pressure hydraulic fluid. Use cardboard or paper to find hydraulic leaks; never use your hands. Hydraulic fluid escaping under pressure can penetrate skin and cause injury requiring surgery within a few hours by a qualified surgeon; otherwise gangrene may result.

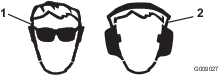

Sound Pressure Level

Sound Pressure Level This unit has a sound pressure level at the operator’s ear of 86 dBA, which includes an Uncertainty Value (K) of 0.6 dBA.

Sound pressure level was determined according to the procedures outlined in ISO 6396.

Sound Power

This unit has a guaranteed sound power level of 101 dBA, based on measurements of identical machines per ISO 6395.

Vibration Level

Hand-Arm

Measured vibration level for right hand = 0.7 m/s2

Measured vibration level for left hand = 0.7 m/s2

Uncertainty Value (K) = 0.3 m/s2

Measured values were determined according to the procedures outlined in EN ISO 20643.

Whole Body

Measured vibration level = 0.29 m/s2

Uncertainty Value (K) = 0.15 m/s2

Measured values were determined according to the procedures outlined in EN ISO 20643.

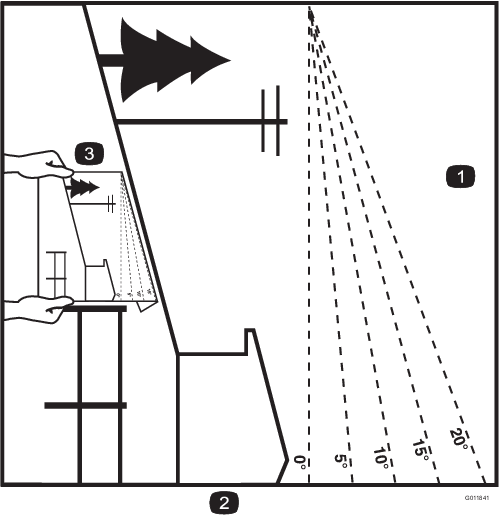

Stability Data

The following tables list the maximum slope recommended for the traction unit in the positions listed in the tables. Slopes over the listed degree may cause the traction unit to become unstable. The data in the tables assume that the loader arms are fully lowered; raised arms may affect the stability.

In each attachment manual is a set of three stability ratings, one for each hill position. To determine the maximum slope you can traverse with the attachment installed, find the degree of slope that corresponds to the stability ratings of the attachment. Example: If the attachment installed on a TX Model 22327 traction unit has a front uphill rating of B, a rear uphill rating of D, and a side uphill rating of C, then you could drive forward up a 19° slope, rearward up a 11° slope, or sideways on a 11° slope, as listed in the following table.

| Model 22327 | |||

| Configuration | Maximum Recommended Slope when Operating with: | ||

| Front Uphill | Rear Uphill | Side Uphill | |

|  |  |

|

| Traction unit without attachment | 15° | 19° | 16° |

| Traction unit with an attachment rated with one of the following stability ratings for each slope position:* | |||

| A | 25° | 25° | 20° |

| B | 19° | 20° | 15° |

| C | 16° | 17° | 11° |

| D | 14° | 11° | 8° |

| E | 5° | 5° | 5° |

| Model 22328 | |||

| Configuration | Maximum Recommended Slope when Operating with: | ||

| Front Uphill | Rear Uphill | Side Uphill | |

|  |  |

|

| Traction unit without attachment | 16° | 19° | 19° |

| Traction unit with an attachment rated with one of the following stability ratings for each slope position:* | |||

| A | 25° | 25° | 23° |

| B | 21° | 19° | 18° |

| C | 18° | 15° | 14° |

| D | 15° | 10° | 10° |

| E | 5° | 5° | 5° |

Slope Indicator

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

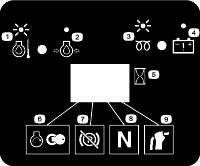

Product Overview

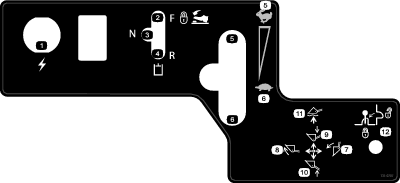

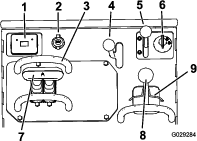

Become familiar with all the controls (Figure 5) before you start the engine and operate the traction unit.

Key Switch

The key switch, used to start and shut off the engine, has 3 positions: OFF, RUN, and START.

To start the engine, rotate the key to the START position. Release the key when engine starts and it moves automatically to the RUN position.

To shut off the engine, rotate the key to the OFF position.

Throttle Lever

Move the control forward to increase the engine speed and rearward to decrease speed.

Reference Bar

When driving the traction unit, use the reference bar as a handle and a leverage point for controlling the traction control and the auxiliary-hydraulics lever. To ensure smooth, controlled operation, do not take both hands off the reference bar while operating the machine.

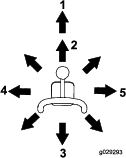

Traction Control

-

To move forward, move the traction control forward (Figure 7).

-

To move rearward, move the traction control rearward (Figure 8).

Important: When reversing, look behind you for obstructions and keep your hands on the reference bar.

-

To turn right, rotate the traction control clockwise (Figure 9).

-

To turn left, rotate the traction control counterclockwise (Figure 10).

-

To stop the machine, release the traction control (Figure 6).

Note: The farther you move the traction control in any direction, the faster the machine moves in that direction.

Loader Arm/Attachment-Tilt Lever

-

To tilt the attachment forward, slowly move the lever to the right (Figure 11).

-

To tilt the attachment rearward, slowly move the lever to the left (Figure 11).

-

To lower the loader arms, slowly move the lever forward (Figure 11).

-

To raise the loader arms, slowly move the lever rearward (Figure 11).

-

To lower the loader arms to a detent (float) position, push the lever fully forward (Figure 11).

Note: This allows attachments such as the leveler and the hydraulic blade to follow the contours of the ground (i.e., float) when grading.

By moving the lever to an intermediate position (e.g., forward and left), you can move the loader arms and tilt the attachment at the same time.

Loader Lock

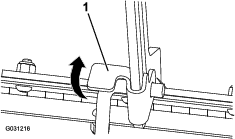

The loader lock secures the loader arm/attachment-tilt lever so that you cannot push it forward. This ensures that no one accidentally lowers the loader arms during maintenance. Secure the loader arms with the lock any time you need to stop the machine with the loader arms raised.

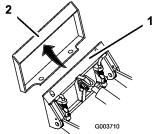

To set the lock, lift up on it so it clears the hole in the control panel and swing it to the left, in front of the loader-arm lever, pushing it down into the locked position (Figure 12).

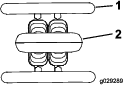

Loader-Control Reference Bar

The loader-control reference bar helps stabilize your hand while operating the loader arm/attachment tilt lever (Figure 4).

Auxiliary-Hydraulics Lever

To operate a hydraulic attachment in the forward direction, move the auxiliary-hydraulics lever forward (Figure 13).

To operate a hydraulic attachment in reverse direction, move the hydraulics lever rearward (Figure 13).

If you release the lever while in the FORWARD or REVERSE position, the lever automatically returns to the NEUTRAL position (Figure 13).

Auxiliary-Hydraulics-Lock Switch

Press the auxiliary-hydraulics-lock switch to lock the auxiliary-hydraulics lever in the FORWARD position and free your hand for other controls (Figure 5).

Parking Brake Lever

To set the parking brake, rotate the brake lever to left (Figure 14).

Note: The traction unit may roll slightly before the brakes engage in the drive sprocket.

To release the brake, rotate the brake lever to the right.

Note: You may need to adjust the traction control to release the brake pins and rotate the lever.

Fuel Gauge

This gauge measures the amount of fuel in the fuel tanks (Figure 4).

Message Display

Engine-Coolant Temperature

If the engine coolant becomes too hot, the light on the left flashes and the horn sounds (Figure 15). If this happens, disengage the auxiliary hydraulics and let the machine run at high idle to allow the cooling system to cool the machine. Check the coolant level when the engine has fully cooled.

Important: Do not shut off the engine, as this may cause the machine to overheat.

Engine-Oil Pressure

If the engine-oil-pressure becomes too low, the light on the left illuminates steadily (Figure 16). If this happens, shut off the engine immediately and check the oil. If the oil level is low, add oil and/or look for possible leaks.

Glow Plug

The light on the right flashes while the glow plugs are charged and warming the engine (Figure 17).

Battery-Charge Indicator Light

If the battery charge becomes too low, the light on the right illuminates steadily (Figure 18). If this happens, shut off the engine and charge or replace the battery. Refer to Servicing the Battery

Hour Meter

The hour meter displays the number of hours of operation that have been logged on the traction unit and the following indicators:

-

Engine start—displays when you start the engine

-

Parking brake—displays when you disengage the parking brake

-

Traction neutral—displays when the traction control is in the NEUTRAL position

-

Auxiliary lever neutral—displays when the auxiliary lever is in the NEUTRAL position

Note: Specifications and design are subject to change without notice.

| Model 22327 | |

| Width | 85 cm (33 inches) |

| Length | 256 cm (101 inches) |

| Height | 138 cm (54 inches) |

| Weight | 1234 kg (2,720 lb) |

| Operating capacity (with standard bucket) | 454 kg (1,000 lb) |

| Tipping capacity (with standard bucket) | 1296 kg (2,857 lb) |

| Wheelbase | 104 cm (41 inches) |

| Dump height (with standard bucket) | 155 cm (61 inches) |

| Reach—fully raised (with standard bucket) | 62 cm (25 inches) |

| Height to hinge pin (with standard bucket in highest position) | 206 cm (81 inches) |

| Model 22328 | |

| Width | 103 cm (41 inches) |

| Length | 256 cm (101 inches) |

| Height | 138 cm (54 inches) |

| Weight | 1297 kg (2,860 lb) |

| Operating capacity (with standard bucket) | 454 kg (1,000 lb) |

| Tipping capacity (with standard bucket) | 1296 kg (2,857 lb) |

| Wheelbase | 104 cm (41 inches) |

| Dump height (with standard bucket) | 155 cm (61 inches) |

| Reach—fully raised (with standard bucket) | 62 cm (25 inches) |

| Height to hinge pin (with standard bucket in highest position) | 206 cm (81 inches) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories.

Important: Use only Toro-approved attachments. Other attachments may create an unsafe operating environment or damage the traction unit.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Important: Before operating, check the fuel and oil level, and remove debris from the traction unit. Ensure that the area is clear of people and debris. You should also know and have marked the locations of all utility lines.

Think Safety First

Carefully read all safety instructions and symbols in the safety section. Knowing this information could help you or bystanders avoid injury.

Caution

This machine produces sound levels that can cause hearing loss through extended periods of exposure.

Wear hearing protection when operating this machine.

Use protective equipment for your eyes, ears, hands, feet, and head.

Adding Fuel

Use only clean, fresh diesel fuel or biodiesel fuels with low (<500 ppm) or ultra low (<15 ppm) sulfur content. The minimum cetane rating should be 40. Purchase fuel in quantities that can be used within 180 days to ensure fuel freshness.

Fuel tank capacity: 41 L (11 US gallons)

Use summer-grade diesel fuel (No. 2-D) at temperatures above -7°C (20°F) and winter grade (No. 1-D or No. 1-D/2-D blend) below that temperature. Using winter-grade fuel at lower temperatures provides lower flash point and cold flow characteristics, which eases starting and reduces fuel filter plugging.

Using summer-grade fuel above -7°C (20°F) contributes toward longer fuel pump life and increased power compared to winter-grade fuel.

Important: Do not use kerosene or gasoline instead of diesel fuel. Failure to observe this caution will damage the engine.

Warning

Fuel is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious injury and illness.

-

Avoid prolonged breathing of vapors.

-

Keep face away from nozzle and fuel tank or conditioner opening.

-

Keep fuel away from eyes and skin.

Biodiesel Ready

This machine can also use a biodiesel blended fuel of up to B20 (20% biodiesel, 80% petrodiesel). The petrodiesel portion should be low or ultra low sulfur. Observe the following precautions:

-

The biodiesel portion of the fuel must meet specification ASTM D6751 or EN14214.

-

The blended fuel composition should meet ASTM D975 or EN590.

-

Painted surfaces may be damaged by biodiesel blends.

-

Use B5 (biodiesel content of 5%) or lesser blends in cold weather.

-

Monitor seals, hoses, gaskets in contact with fuel as they may be degraded over time.

-

Fuel filter plugging may be expected for a time after converting to biodiesel blendsd.

-

Contact your distributor if you wish for more information on biodiesel.

Filling the Fuel Tanks

Danger

In certain conditions, fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

-

Fill the fuel tanks outdoors, in an open area, when the engine is cold. Wipe up any fuel that spills.

-

Never fill the fuel tanks inside an enclosed trailer.

-

Never smoke when handling fuel and stay away from an open flame or where fuel fumes may be ignited by a spark.

-

Store fuel in an approved container and keep it out of the reach of children. Never buy more than a 30-day supply of fuel.

-

Do not operate without entire exhaust system in place and in proper working condition.

Danger

In certain conditions during fueling, static electricity can be released, causing a spark that can ignite the fuel vapors. A fire or explosion from fuel can burn you and others and can damage property.

-

Always place fuel containers on the ground away from your vehicle before filling.

-

Do not fill fuel containers inside a vehicle or on a truck or trailer bed, because interior carpets or plastic truck bed liners may insulate the container and slow the loss of any static charge.

-

When practical, remove equipment from the truck or trailer and refuel the equipment with its wheels on the ground.

-

If this is not possible, then refuel such equipment on a truck or trailer from a portable container rather than from a fuel-dispenser nozzle.

-

If you must use a fuel-dispenser nozzle, keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete.

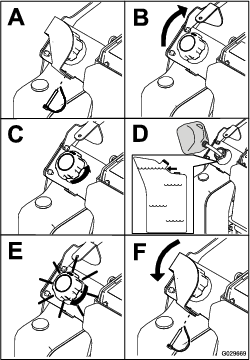

Fill the fuel tanks as shown in Figure 24.

Note: The fuel-tank caps click when you close them securely. Use the brackets to lock the fuel tanks.

Checking the Engine-Oil Level

-

Park the traction unit on a level surface, lower the loader arms, and shut off the engine.

-

Remove the key and allow the engine to cool.

-

Open the hood and secure the hood prop.

-

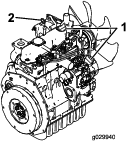

Clean around the oil dipstick and oil-filler cap (Figure 25).

-

Check the oil and add additional oil as needed (Figure 26).

Important: Do not overfill the crankcase with oil because the engine may be damaged.

Checking the Hydraulic-Fluid Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

Hydraulic Tank Capacity: 37.9 L (10 US gallons)

Refer to Changing the Hydraulic Fluid for hydraulic fluid specifications.

Important: Always use the correct hydraulic fluid. Unspecified fluids will damage the hydraulic system.

-

Remove the attachment, if installed; refer to Removing an Attachment.

-

Park the machine on a level surface.

-

Raise the loader arms and install the cylinder locks; refer to Installing the Cylinder Locks.

-

Shut off the engine and remove the key.

-

Open the hood and secure the hood prop.

-

Remove the right side screen; refer to Removing the Side Screens.

-

Clean the area around the filler neck of the hydraulic tank (Figure 27).

-

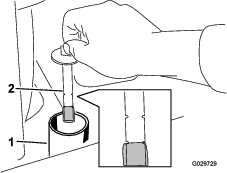

Remove the cap from the filler neck and check the fluid level on the dipstick (Figure 28).

Note: The fluid level should be between the 2 notches of the dipstick while the arms are lowered or at the lower notch while the arms are raised.

-

If the level is low, add enough fluid to raise it to the proper level.

-

Install the cap on the filler neck.

-

Install the side screen.

-

Close the hood.

Checking the Engine Coolant

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

The cooling system is filled with a 50/50 solution of water and permanent ethylene-glycol antifreeze.

Danger

If the engine has been running, the pressurized, hot coolant can escape and cause severe burns.

-

Do not remove the radiator cap when the engine is hot. Always allow the engine to cool at least 15 minutes or until the radiator cap is cool enough to touch without burning your hand before removing the radiator cap.

-

Do not touch radiator and surrounding parts that are hot.

-

Use a rag when opening the radiator cap and open the cap slowly to allow steam to escape.

Danger

Rotating shaft and fan can cause personal injury.

-

Do not operate the machine without the covers in place.

-

Keep fingers, hands, and clothing clear of rotating fan and drive shaft.

-

Shut off the engine and remove the ignition key before performing maintenance.

-

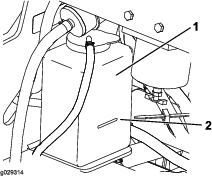

Check the level of coolant in the expansion tank (Figure 29).

Note: The coolant level should be at or above the mark on the side of the tank.

-

If the coolant level is low, remove the expansion tank cap and add a 50/50 mixture of water and permanent ethylene-glycol antifreeze.

Important: Do not overfill.

-

Install the expansion-tank cap.

Bleeding the Fuel System

You must bleed the fuel system before starting the engine if any of the following situations have occurred:

-

Initial start up of a new machine.

-

Engine has ceased running due to lack of fuel.

-

Maintenance has been performed upon fuel-system components (e.g., filter replaced).

Danger

Under certain conditions, diesel fuel and fuel vapors are highly flammable and explosive. A fire or explosion from fuel can burn you and others and can cause property damage.

-

Use a funnel and fill the fuel tanks outdoors, in an open area, when the engine is off and is cold. Wipe up any fuel that spills.

-

Do not fill the fuel tanks completely full. Add fuel to each fuel tank until the level is 6 to 13 mm (1/4 to 1/2 inch) below the bottom of the filler neck. This empty space in the tank allows the fuel to expand.

-

Never smoke when handling fuel and stay away from an open flame or where fuel fumes may be ignited by a spark.

-

Store fuel in a clean, safety-approved container and keep the cap in place.

-

Ensure that the fuel tanks are at least half full.

-

Open the hood and secure the hood prop.

-

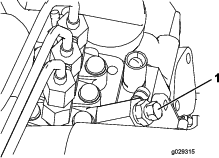

Open the air-bleed screw on the fuel-injection pump (Figure 30).

-

Turn the key in the ignition switch to the ON position.

Note: The electric fuel pump will begin operation, thereby forcing air out around the air-bleed screw. Leave the key in the ON position until a solid stream of fuel flows out around the screw.

-

Tighten the screw and turn the key to the OFF position.

Note: Normally, the engine should start after you follow the above bleeding procedure. However, if engine does not start, air may be trapped between injection pump and injectors; contact your Authorized Service Dealer.

Starting and Shutting Off the Engine

Starting the Engine

-

Ensure that the auxiliary-hydraulics lever and traction-control lever are in neutral.

-

Move the throttle lever midway between the SLOW and FAST positions.

-

Turn the ignition key to the ON position.

-

Wait for the glow-plug indicator light to stop blinking.

-

Turn the ignition key to the START position. When the engines starts, release the key.

Important: Do not engage the starter for more than 10 seconds at a time. If the engine fails to start, wait 30 seconds between attempts. Failure to follow these instructions can burn out the starter motor.

-

Move the throttle lever to desired setting.

Important: If you run the engine at high speeds when the hydraulic system is cold (i.e., when the ambient air temperature is near freezing or lower), hydraulic system damage could occur. When starting the engine in cold conditions, run the engine in the middle throttle position for 2 to 5 minutes before moving the throttle to the FAST position.

Note: If the outdoor temperature is below freezing, store the traction unit in a garage to keep it warmer and aid in starting.

Shutting Off the Engine

-

Move the throttle lever to the SLOW position.

-

Lower the loader arms to the ground.

-

Turn the ignition key off.

Note: If the engine has been working hard or is hot, let it idle for a minute before turning the ignition key off. This helps cool the engine before it is shut off. In an emergency, the engine may be shut off immediately.

Stopping the Machine

Stop the machine on level ground, release the traction control, move the throttle lever to the SLOW position, lower the loader arms to the ground, and shut off the engine. Set the parking brake and remove the key.

Caution

A child or untrained bystander could attempt to operate the traction unit and be injured.

Remove the key from the switch when leaving the traction unit, even if just for a few seconds.

Moving a Non-functioning Machine

Important: Do not tow or pull the traction unit without first opening the tow valves or the hydraulic system will be damaged.

-

Shut off the engine.

-

Open the hood and secure the hood prop.

-

Remove the side screens; refer to Removing the Side Screens.

-

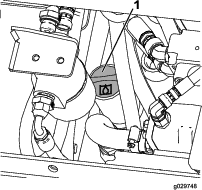

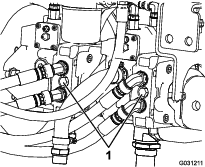

Using a wrench, turn the tow valves on the hydraulic pumps twice counter-clockwise (Figure 31).

-

Tow the traction unit as required.

-

After repairing the machine, close the tow valves before operating it.

Using Attachments

Installing an Attachment

Important: Use only Toro-approved attachments. Attachments can change the stability and the operating characteristics of the traction unit. The warranty of the traction unit may be voided if used with unapproved attachments.

Important: Before installing the attachment, ensure that the mount plates are free of any dirt or debris and that the pins rotate freely. If the pins do not rotate freely, grease them.

-

Position the attachment on a level surface with enough space behind it to accommodate the traction unit.

-

Start the engine.

-

Tilt the attachment mount plate forward.

-

Position mount plate into the upper lip of the attachment receiver plate (Figure 32).

-

Raise the loader arms while tilting back the mount plate at the same time.

Important: Raise the attachment enough to clear the ground and tilt the mount plate all the way back.

-

Shut off the engine.

-

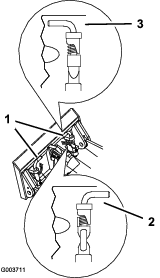

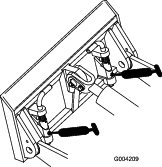

Engage the quick-attach pins, ensuring that they are fully seated in the mount plate (Figure 33).

Important: If the pins do not rotate to the engaged position, the mount plate is not fully aligned with the holes in the attachment receiver plate. Check the receiver plate and clean it if necessary.

Warning

If you do not fully seat the quick-attach pins through the attachment mount plate, the attachment could fall off the traction unit, crushing you or bystanders.

Ensure that your quick-attach pins are fully seated in the attachment mount plate.

Connecting the Hydraulic Hoses

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury; otherwise gangrene may result.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

Caution

Hydraulic couplers, hydraulic lines/valves, and hydraulic fluid may be hot. If you contact hot components, you may be burned.

-

Wear gloves when operating the hydraulic couplers.

-

Allow the traction unit to cool before touching hydraulic components.

-

Do not touch hydraulic fluid spills.

If the attachment requires hydraulics for operation, connect the hydraulic hoses as follows:

-

Shut off the engine.

-

Move the auxiliary-hydraulics lever forward, backward, and back to neutral to relieve pressure at the hydraulic couplers.

-

Remove the protective covers from the hydraulic couplers on the traction unit.

-

Ensure that all foreign matter is cleaned from the hydraulic connectors.

-

Push the attachment male connector into the female connector on the traction unit.

Note: When you connect the attachment male connector first, you relieve any pressure built up in the attachment.

-

Push the attachment female connector onto the male connector on the traction unit.

-

Confirm that the connection is secure by pulling on the hoses.

Removing an Attachment

-

Move the machine to level ground.

-

Lower the attachment to the ground.

-

Shut off the engine.

-

Disengage the quick-attach pins by turning them to the outside.

-

If the attachment uses hydraulics, move the auxiliary-hydraulics lever forward, backward, and back to neutral to relieve pressure at the hydraulic couplers.

-

If the attachment uses hydraulics, slide the collar back on the hydraulic couplers and disconnect them.

Important: Connect the attachment hoses together to prevent hydraulic system contamination during storage.

-

Install the protective covers onto the hydraulic couplers on the traction unit.

-

Start the engine, tilt the mount plate forward, and back the traction unit away from the attachment.

Transporting the Machine

Use a heavy-duty trailer or truck to transport the machine. Use full-width ramps. Ensure that the trailer or truck has all the necessary brakes, lighting, and marking as required by law. Please carefully read all the safety instructions. Knowing this information could help you, your family, pets, or bystanders avoid injury. Refer to your local ordinances for trailer and tie-down requirements.

Warning

Driving on the street or roadway without turn signals, lights, reflective markings, or a slow-moving-vehicle emblem is dangerous and can lead to accidents causing personal injury.

Do not drive the machine on a public street or roadway.

Selecting a Trailer

Warning

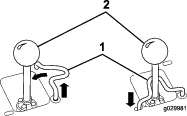

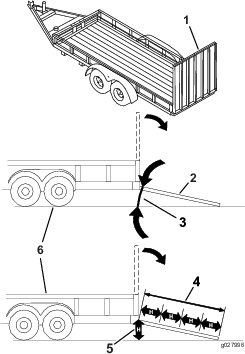

Loading a machine onto a trailer or truck increases the possibility of tip-over and could cause serious injury or death (Figure 34).

-

Use only a full-width ramp; do not use individual ramps for each side of the machine.

-

Do not exceed a 15-degree angle between the ramp and the ground or between the ramp and the trailer or truck.

-

Ensure that the length of ramp is at least 4 times as long as the height of the trailer or truck bed to the ground. This ensures that ramp angle does not exceed 15 degrees on flat ground.

Loading the Machine

Warning

Loading a machine onto a trailer or truck increases the possibility of tip-over and could cause serious injury or death.

-

Use extreme caution when operating a machine on a ramp.

-

Load and unload the machine with the heavy end up the ramp.

-

Avoid sudden acceleration or deceleration while driving the machine on a ramp as this could cause a loss of control or a tip-over situation.

-

If using a trailer, connect it to the towing vehicle and connect the safety chains.

-

If applicable, connect the trailer brakes.

-

Lower the ramp, ensuring that the angle between the ramp and the ground does not exceed 15 degrees (Figure 34).

-

Lower the loader arms.

-

Load the machine onto the trailer with the heavy end up the ramp, carrying loads low (Figure 35).

-

If the machine has a full load-carrying attachment (e.g., bucket or adjustable forks) or a non-load-carrying attachment (e.g., stump grinder), drive the machine forward up the ramp.

-

If the machine has an empty load-carrying attachment or no attachment, back the machine up the ramp.

-

-

Lower the loader arms all the way down.

-

Shut off the engine, remove the key, and engage the parking brake.

-

Use the metal tie-down loops on the machine to securely fasten the machine to the trailer or truck with straps, chains, cable, or ropes (Figure 36). Refer to local regulations for tie-down requirements.

Unloading the Machine

-

Lower the ramp, ensuring that the angle between the ramp and the ground does not exceed 15 degrees (Figure 35).

-

Unload the machine from the trailer with the heavy end up the ramp, carrying loads low (Figure 37).

-

If the machine has a full load-carrying attachment (e.g., bucket or adjustable forks) or a non-load-carrying attachment (e.g., stump grinder), back it down the ramp.

-

If the machine has an empty load-carrying attachment or no attachment, drive it forward down the ramp.

-

Lifting the Machine

You can lift the machine using the tie-down/lift loops as lift points indicated in Figure 36.

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| After the first 50 hours |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 400 hours |

|

| Every 500 hours |

|

| Every 1,500 hours |

|

| Yearly |

|

| Yearly or before storage |

|

| Every 2 years |

|

Important: Refer to your engine owner’s manual for additional maintenance procedures.

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders.

Remove the key from the ignition before you do any maintenance.

Pre-Maintenance Procedures

Before opening any of the covers, shut the engine and remove the key. Allow the engine to cool before opening any covers

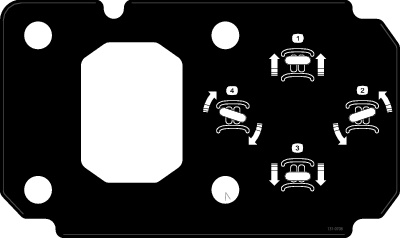

Using the Cylinder Locks

Warning

The loader arms may lower when in the raised position, crushing anyone under them.

Install the cylinder lock before performing maintenance that requires raised loader arms.

Installing the Cylinder Locks

-

Remove the attachment.

-

Raise the loader arms to the fully raised position.

-

Shut off the engine.

-

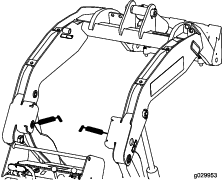

Remove the 2 cotterless pins securing the cylinder lock to the posts on the sides of the machine.

-

Slide the cylinder locks over the lift-cylinder rod (Figure 38).

-

Repeat for the other side of the machine.

-

Slowly lower the loader arms until the cylinder lock contacts the cylinder body and rod end.

Removing/Storing the Cylinder Locks

Important: Remove the cylinder locks from the rod and fully secured in the storage position before operating the traction unit.

-

Start the engine.

-

Raise the loader arms to the fully raised position.

-

Shut off the engine.

-

Remove the cotterless pins securing the cylinder locks.

-

Place the cylinder locks on the posts on the sides of the machine and secure with the lynch pins.

-

Lower the loader arms.

Opening the Hood

Closing the Hood

Opening the Rear-Access Cover

Removing the Front Screen

-

Open the hood and secure the hood prop.

-

Loosen the 2 top bolts and 2 front bolts.

-

Remove the screen.

Removing the Side Screens

-

Open the hood and secure the hood prop.

-

Slide the side screens (Figure 43) up and out of the slots in the front screen and frame.

Lubrication

Greasing the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Grease Type: General-purpose grease.

-

Lower the loader arms and shut off the engine. Remove the key.

-

Clean the grease fittings with a rag.

-

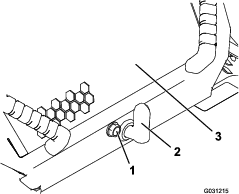

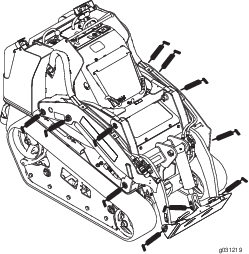

Connect a grease gun to each fitting (Figure 44, Figure 45, and Figure 46).

Note: Raise the loader arms before greasing the fittings in Figure 46.

-

Pump grease into the fittings until grease begins to ooze out of the bearings (approximately 3 pumps).

-

Wipe up any excess grease.

Engine Maintenance

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 100 hours |

|

| Yearly |

|

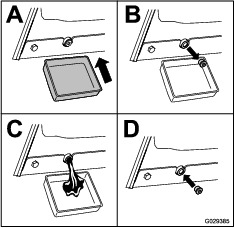

Servicing the Air Cleaner Cover and Body

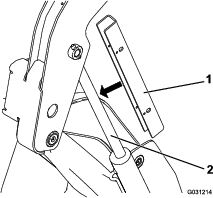

Important: Service the air-cleaner filter only when the service indicator shows red (Figure 47). Changing the air filter before it is necessary only increases the chance of dirt entering the engine when the filter is removed.

-

Lower the loader arms, shut off the engine, and remove the key.

-

Open the hood and secure the hood prop.

-

Check the air-cleaner body for damage that could cause an air leak. Check the whole intake system for leaks, damage, or loose hose clamps. Replace or repair and damaged components.

-

Release the latches on the air cleaner and pull the air-cleaner cover off the air-cleaner body (Figure 47).

Important: Do not remove the air filter.

-

Squeeze the dust cap sides to open it and knock the dust out.

-

Clean the inside of the air-cleaner cover with compressed air that is under 205 kPa (30 psi).

-

Check the air-filter service indicator.

-

If the service indicator is clear, clean any debris from cover and install cover.

Ensure that the cover is seated correctly and seals with the air-cleaner body.

-

If the service indicator is red, replace the air filter as described in Replacing the Filter.

-

-

Install the air-cleaner cover.

Note: Ensure that the dust cap is oriented downward.

Replacing the Filter

Important: To prevent engine damage, always operate the engine with the air filter and cover installed.

-

Gently slide the filter out of the air-cleaner body (Figure 47).

Note: Avoid knocking the filter into the side of the body.

Important: Do not attempt to clean the filter.

-

Inspect the new filter for damage by looking into the filter while shining a bright light on the outside of the filter.

Note: Holes in the filter appear as bright spots.

-

Inspect the element for tears, an oily film, or damage to the rubber seal. If the filter is damaged do not use it.

-

Carefully install the filter (Figure 47).

Note: Ensure that the filter is fully seated by pushing on the outer rim of the filter while installing it.

Important: Do not press on the soft inside area of the filter.

-

Install the air-cleaner cover with the side indicated as TOP facing up and secure the latches (Figure 47).

-

Close the hood.

Servicing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

Note: Change the oil and oil filter more frequently when operating conditions are extremely dusty or sandy.

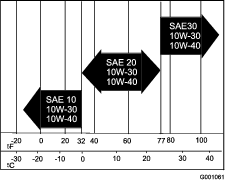

Oil Type: Detergent diesel engine oil (API service CH-4 or higher)

Crankcase Capacity: with filter 5.7 L (1.5 US gallons)

Viscosity: See the table below.

Changing the Engine Oil

-

Start the engine and let it run for 5 minutes.

Note: This warms the oil so that it drains better.

-

Park the traction unit so that the drain side is slightly lower than the opposite side to ensure that the oil drains completely.

-

Raise the loader arms and secure with the cylinder locks; refer to Installing the Cylinder Locks.

-

Set the parking brake, shut off the engine, and remove the key.

-

Drain the oil beneath the platform (Figure 49).

Caution

Components will be hot if the traction unit has been running. If you touch hot components you may be burned.

Allow the traction unit to cool before performing maintenance or touching components under the hood.

-

Remove the oil-fill cap and slowly pour approximately 80% of the specified amount of oil in through the valve cover.

-

Check the oil level; refer to Checking the Engine-Oil Level.

-

Slowly add additional oil to bring the level to the upper hole on the dipstick.

-

Replace the fill cap.

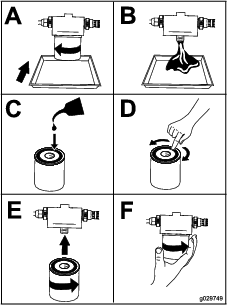

Changing the Oil Filter

-

Raise the loader arms and secure with the cylinder locks; refer to Installing the Cylinder Locks.

-

Shut off the engine and remove the key.

-

Open the hood and secure the hood prop.

-

Remove the right side screen; refer to Removing the Side Screens.

-

Drain the oil from the engine; refer to Changing the Engine Oil.

-

Place a shallow pan or rag under the filter to catch oil.

-

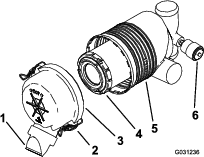

Change the oil filter (Figure 50).

-

Fill the crankcase with the proper type of new oil; refer to Changing the Engine Oil.

Fuel System Maintenance

Danger

Under certain conditions, diesel fuel and fuel vapors are highly flammable and explosive. A fire or explosion from fuel can burn you and others and can cause property damage.

-

Use a funnel and fill the fuel tanks outdoors, in an open area, when the engine is off and is cold. Wipe up any fuel that spills.

-

Do not fill the fuel tanks completely full. Add fuel to each fuel tank until the level is 6 to 13 mm (1/4 to 1/2 inches) below the bottom of the filler neck. This empty space in the tank allows the fuel to expand.

-

Never smoke when handling fuel and stay away from an open flame or where fuel fumes may be ignited by a spark.

-

Store fuel in a clean, safety-approved container and keep the cap in place.

Checking the Fuel Lines and Connections

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 400 hours |

|

Inspect the fuel lines and connections for deterioration, damage, or loose connections. Tighten any loose connections and contact your Authorized Service Dealer for assistance in fixing damaged fuel lines.

Draining the Fuel Filter/Water Separator

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

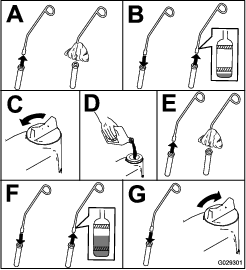

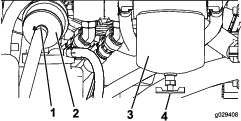

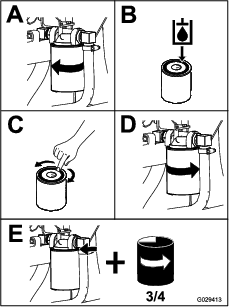

Locate the fuel filter on the rear side of the engine (Figure 51) and place a clean container under it.

-

Loosen the drain valve on the bottom of the filter canister and allow the water to drain.

-

When finished, tighten the drain valve.

Replacing the Fuel Filter Canister and In-Line Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 400 hours |

|

-

Locate the fuel filters on the right side of the engine (Figure 51) and place a clean container under it.

-

Clean the area where the filter canister mounts (Figure 51).

-

Remove the filter canister and clean the mounting surface (Figure 51).

-

Lubricate the gasket on the new filter canister with clean oil.

-

Install the filter canister by hand until the gasket contacts the mounting surface, then rotate it an additional 1/2 turn (Figure 51).

-

Locate the in-line filter behind the fuel filter canister (Figure 51) and note the direction of flow arrow on the side of the in-line filter.

-

Open the clamps on each end of the in-line filter and slide the hoses off it (Figure 51). Discard the filter.

-

Slide the hoses over the end of a new filter (Figure 51), ensuring that the arrow on the filter is pointing in the same direction as the one on the old filter.

-

Secure the hoses with the hose clamps.

Draining the Fuel Tanks

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 2 years |

|

Have an Authorized Service Dealer drain and clean the fuel tanks.

Electrical System Maintenance

Servicing the Battery

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Important: Before welding on the machine, disconnect the negative cable from the battery.

Using the Battery-Disconnect Switch

-

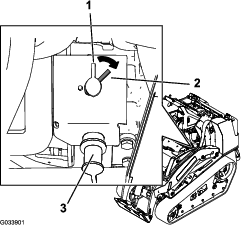

Open the hood, secure the hood prop, and remove the left side screen.

-

Turn the battery-disconnect switch to the ON or OFF position to perform the following:

-

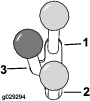

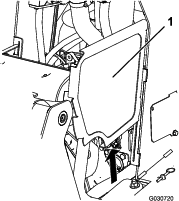

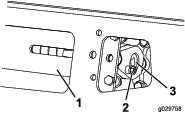

To energize the machine electrically, rotate the battery-disconnect switch clockwise to the ON position (Figure 52).

-

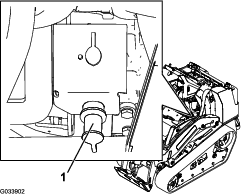

To de-energize the machine electrically, rotate the battery-disconnect switch counterclockwise to the OFF position (Figure 53).

-

Charging and Connecting the Battery

Danger

Battery electrolyte contains sulfuric acid, which is a deadly poison and causes severe burns.

-

Do not drink electrolyte and avoid contact with skin, eyes or clothing. Wear safety glasses to shield your eyes and rubber gloves to protect your hands.

-

Fill the battery where clean water is always available for flushing the skin.

Warning

Battery terminals or metal tools could short against metal components causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

When removing or installing the battery, do not allow the battery terminals to touch any metal parts of the machine.

-

Do not allow metal tools to short between the battery terminals and metal parts of the machine.

Warning

Incorrect battery cable routing could damage the machine and cables causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

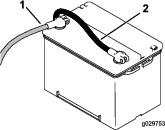

Always disconnect the negative (black) battery cable before disconnecting the positive (red) cable.

-

Always connect the positive (red) battery cable before connecting the negative (black) cable.

-

Remove the front screen; refer to Removing the Front Screen.

-

Connect a 3 to 4 A battery charger to the battery posts.

-

Charge the battery at a rate of 3 to 4 A for 4 to 8 hours.

-

When the battery is charged, disconnect the charger from the electrical outlet and battery posts.

Warning

Charging the battery produces gasses that can explode.

Never smoke near the battery and keep sparks and flames away from battery.

-

Install the positive cable (red) to the positive (+) terminal and the negative cable (black) to the negative (-) terminal of the battery (Figure 53).

Important: Secure cables to posts with capscrews and nuts. Make sure that the positive (+) terminal is all of the way onto the post and the cable is positioned snug to the battery. The cable must not contact the battery cover. Slide the rubber boot over the positive terminal to prevent a possible short from occurring.

-

Coat both battery connections with Grafo 112X (skin-over) grease (Toro Part No. 505-47), petroleum jelly, or light grease to prevent corrosion. Slide the rubber boot over the positive terminal.

-

Install the front screen.

Cleaning the Battery

Note: Keep the terminals and the entire battery case clean, because a dirty battery discharges slowly.

-

Remove the front screen; refer to Removing the Front Screen.

-

Remove the battery from the machine.

-

Wash the entire case with a solution of baking soda and water.

-

Rinse the battery with clear water.

-

Coat the battery posts and cable connectors with Grafo 112X (skin-over) grease (Toro Part No. 505-47) or petroleum jelly to prevent corrosion.

-

Install the front screen.

Jump Starting the Machine

Warning

Jump starting the battery can produce gasses that can explode.

Do not smoke near the battery, and keep sparks and flames away from battery.

-

Open the hood, secure the hood prop, and remove the left side screen.

-

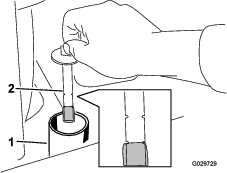

Remove the cover from the jump post (Figure 54).

-

Connect an end of the positive (+) jumper cable to the jump post (Figure 54).

-

Connect the other end of the positive (+) jumper cable to the positive terminal of the battery in the other machine.

-

Connect an end of the negative (-) jumper cable to the negative post of the battery in the other machine.

-

Connect the other end of the negative (-) jumper cable to a ground point, such as an unpainted bolt or chassis member.

-

Start the engine in the other machine. Let it run a few minutes, then start your engine.

-

Remove the cables in the reverse order of connection.

-

Install the cover to the jump post.

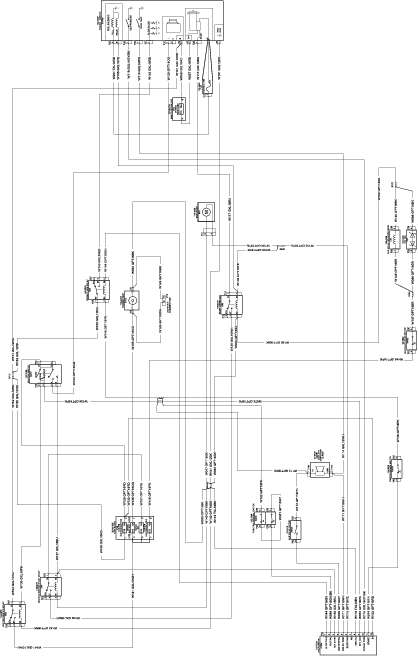

Servicing the Fuses

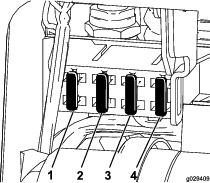

The electrical system is protected by fuses. It requires no maintenance; however, if a fuse blows, check the component/circuit for a malfunction or a short. Figure 55 illustrates the fuse block and identifies the fuse positions.

Note: If the traction unit does not start, either the main circuit or the control panel/relay fuse could be blown.

Drive System Maintenance

Servicing the Tracks

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Before each use or daily |

|

| Every 100 hours |

|

Cleaning the Tracks

-

Park the machine on a level surface and engage the parking brake.

-

With the bucket installed and pointing down, lower it into the ground so that the front of the traction unit lifts off the ground a few centimeters (inches).

-

Shut off the engine and remove the key.

-

Using a water hose or pressure washer, remove dirt from each track system.

Important: Ensure that you use high-pressure water to wash only the track area. Do not use a high-pressure washer to clean the rest of the traction unit. Do not use high pressure water between the drive sprocket and the traction unit or you may damage the motor seals. High-pressure washing can damage the electrical system and hydraulic valves or deplete grease.

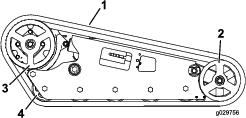

Important: Ensure that you fully clean the road wheels, the front wheel, and the drive sprocket (Figure 56). The road wheels should rotate freely when clean.

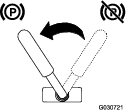

Adjusting the Track Tension

The tension nut should be 1.3 cm (1/2 inch) away from the rear of the tension tube slot (Figure 57). If it is not, adjust the track tension using the following procedure:

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

Lift/support the side of the machine to be worked on so that the track is 7.6 to 10 cm (3 to 4 inches) off the ground.

-

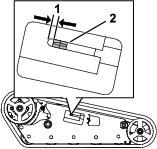

Remove the locking bolt and nut (Figure 58).

-

Using a 1/2 inch drive ratchet, turn the tensioning screw counter-clockwise until the tension nut is 1.3 cm (1/2 inch) away from the rear of the tension tube slot, as shown in Figure 57.

-

Align the closest notch in the tension screw to the locking-bolt hole and secure the screw with the locking bolt and nut (Figure 58).

-

Lower the machine to the ground.

Replacing Narrow-Width Tracks

Replace the tracks when they are badly worn.

Note: You have narrow-width tracks if the tracks are less than 15.5 cm (6 inches) wide.

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

Lift/support the side of the machine to be worked on so that the track is 7.6 to 10 cm (3 to 4 inches) off the ground.

-

Remove the locking bolt and nut (Figure 58).

-

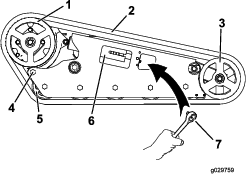

Using a 1/2-inch drive ratchet, release the drive tension by turning the tensioning screw clockwise (Figure 58 and Figure 59).

-

Loosen the rear bolt, near the drive wheel (Figure 59).

Note: This enables the drive wheel to pivot forward and release the tension of the track. If it does not pivot, turn on the engine and briefly move the traction control forward.

-

Remove the track at the top of the front wheel, peeling it off the wheel while rotating the track forwards.

-

When the track is off the front wheel, remove it from the drive sprocket and road wheels (Figure 59).

-

Beginning at the drive sprocket, coil the new track around the sprocket, ensuring that the lugs on the track fit between the spacers on the sprocket (Figure 59).

-

Push the track under and between the road wheels (Figure 59).

-

Starting at the bottom of the front wheel, install the track around the wheel by rotating the track rearward while pushing the lugs into the wheel.

-

Using a 1/2 inch drive ratchet, turn the tensioning screw counter-clockwise until the tensioning screw bottoms out (Figure 58).

-

Align the closest notch in the tension screw to the locking bolt hole and secure the screw with the locking bolt and nut.

-

Torque the rear bolt to 108 to 122 N∙m (80 to 90 ft-lb).

-

Lower the machine to the ground.

-

Repeat the procedure to replace the other track.

-

Drive the machine, then park the machine on a level surface, engage the parking brake, shut off the engine, and remove the key.

-

Verify that the tension screw is bottomed out.

Note: The track tension will loosen after some use.

-

Adjust the track tension so that the tension nut is 1.3 cm (1/2 inch) away from the rear of the tension tube slot; refer to Adjusting the Track Tension.

Replacing Wide-Width Tracks

Replace the tracks when they are badly worn.

Note: You have wide-width tracks if the tracks are more than 23 cm (9 inches) wide.

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

Lift/support the side of the unit to be worked on so that the track is 7.6 to 10 cm (3 to 4 inches) off the ground.

-

Remove the locking bolt and nut (Figure 58).

-

Using a 1/2-inch drive ratchet, release the drive tension by turning the tensioning screw clockwise (Figure 58 and Figure 59).

-

Loosen the rear bolt, near the drive wheel (Figure 59).

-

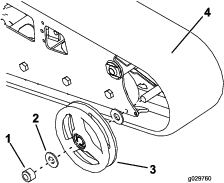

Remove the nut securing the outer front wheel and remove the wheel (Figure 60).

-

Remove the track (Figure 60).

-

Pull the 2 large washers out of the outer wheels, 1 on each side of each wheel (Figure 60).

-

Clean the old grease and dirt out of the area between where the washers were installed and the bearings inside the wheels, then fill this area on each side of each wheel with grease.

-

Install the large washers on the wheels over the grease.

-

Install the new track. (Figure 60).

Note: Ensure that the lugs in the track fit between the spacers in the middle of the drive sprocket.

-

Install the outer front wheel and secure it with the nut removed previously (Figure 60).

-

Torque the nut to 300 ft-lb (407 N∙m).

-

Turn the tensioning screw counter-clockwise until the tensioning screw bottoms out.

-

Align the closest notch in the tension screw to the locking bolt hole and secure the screw with the locking bolt and nut.

-

Torque the rear bolt to 108 to 122 N∙m (80 to 90 ft-lb).

-

Lower the machine to the ground.

-

Repeat the procedure to replace the other track.

-

Drive the machine, then park the machine on a level surface, engage the parking brake, shut off the engine, and remove the key.

-

Verify that the tension screw is bottomed out.

Note: The track tension will loosen after some use.

-

Adjust the track tension so that the tension nut is 1.3 cm (1/2 inch) away from the rear of the tension tube slot; refer to Adjusting the Track Tension.

Cooling System Maintenance

Servicing the Cooling System

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 100 hours |

|

| Yearly |

|

Danger

If the engine has been running, the pressurized, hot coolant can escape and cause severe burns.

-

Do not remove the radiator cap when the engine is hot. Always allow the engine to cool at least 15 minutes or until the radiator cap is cool enough to touch without burning your hand before removing the radiator cap.

-

Do not touch radiator and surrounding parts that are hot.

-

Use a rag when opening the radiator cap, and open the cap slowly to allow steam to escape.

Danger

Rotating shaft and fan can cause personal injury.

-

Do not operate the machine without the covers in place.

-

Keep your fingers, hands and clothing clear of rotating fan and drive shaft.

-

Shut off the engine and remove the ignition key before performing maintenance.

Caution

Swallowing engine coolant can cause poisoning.

-

Do not swallow engine coolant.

-

Keep out of reach from children and pets.

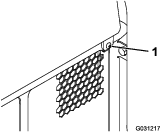

Cleaning the Radiator Screen

Before each use, check and clean the radiator screen, located in front of the operator platform. Remove any buildup of grass, dirt or other debris from the radiator screen with compressed air.

Changing the Engine Coolant

Have an Authorized Service Dealer change the engine coolant yearly.

If you need to add engine coolant, refer to Checking the Engine Coolant.

Belt Maintenance

Checking the Alternator/Fan Belt Tension

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Every 500 hours |

|

Controls System Maintenance

The factory adjusts the controls before shipping the traction unit. However, after many hours of use, you may need to adjust the traction-control alignment, the NEUTRAL position of the traction control, and the tracking of the traction control in the full forward position.

Contact your Authorized Service Distributor to adjust the controls of your machine.

Hydraulic System Maintenance

Replacing the Hydraulic Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 8 hours |

|

| Every 200 hours |

|

Important: Do not substitute an automotive oil filter or severe hydraulic system damage may result.

-

Park the machine on a level surface, engage the parking brake, and lower the loader arms.

-

Shut off the engine and remove the key.

-

Open the hood and secure the hood prop.

-

Place a drain pan under the filter and replace the filter (Figure 61).

-

Clean up any spilled fluid.

-

Start the engine and let it run for about 2 minutes to purge air from the system.

-

Shut off the engine and check for leaks.

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury; otherwise, gangrene may result.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

-

-

Check the fluid level in the hydraulic tank; refer toChecking the Hydraulic-Fluid Level and add fluid to raise the level to mark on dipstick.

Important: Do not over fill the tank.

-

Close the hood.

Changing the Hydraulic Fluid

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 400 hours |

|

Hydraulic Fluid Specification:

Use only one of the following fluids in the hydraulic system:

-

Toro Premium Transmission/Hydraulic Tractor Fluid (refer to your Authorized Toro Dealer for more information)

-

Toro Premium All Season Hydraulic Fluid (refer to your Authorized Toro Dealer for more information)

-

If either of the above Toro fluids are not available, you may use another Universal Tractor Hydraulic Fluid (UTHF), but they must be only conventional, petrolium-based products. The specifications must fall within the listed range for all of the following material properties and the fluid should meet the listed industry standards. Check with your oil supplier to determine if the oil meets these specifications.

Note: Toro will not assume responsibility for damage caused by improper substitutions, so use only products from reputable manufacturers who will stand behind their recommendations.

Material Properties Viscosity, ASTM D445 cSt at 40°C: 55 to 62 cSt at 100°C: 9.1 to 9.8 Viscosity index, ASTM D2270 140 to 152 Pour Point, ASTM D97 -37 to -43°C (-35 to -46°F) Industry Standards API GL-4, AGCO Powerfluid 821 XL, Ford New Holland FNHA-2-C-201.00, Kubota UDT, John Deere J20C, Vickers 35VQ25 and Volvo WB-101/BM. Note: Many hydraulic fluids are almost colorless, making it difficult to spot leaks. A red dye additive for the hydraulic system oil is available in 20 ml (2/3 oz) bottles. One bottle is sufficient for 15 to 22 L (4 to 6 US gallons) of hydraulic fluid. Order Part No. 44-2500 from your Authorized Toro Dealer.

-

Park the machine on a level surface.

-

Raise the loader arms and install the cylinder locks; refer to Installing the Cylinder Locks.

-

Shut off the engine, remove the key, and allow the traction unit to cool completely.

-

Open the hood and secure the hood prop.

-

Remove the right side screen; refer to Removing the Side Screens.

-

Remove the hydraulic-tank cap and dipstick (Figure 62).

-

Place a large drain pain (capable of holding 57 or 15 US gallons) under the drain plug on the front of the traction unit (Figure 63).

-

Remove the drain plug and allow the oil to drain into the pan (Figure 63).

-

When the oil is finished draining, install and tighten the drain plug.

Note: Dispose of the used oil at a certified recycling center.

-

Fill the hydraulic tank with approximately 38 L (10 US gallons) of hydraulic fluid as specified previously in this section.

-

Start the engine and let it run for a few minutes.

-

Shut off the engine.

-

Check the hydraulic-fluid level and top it off if necessary; refer to Checking the Hydraulic-Fluid Level.

-

Close the hood.

Checking the Hydraulic Lines

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Every 1,500 hours |

|

Warning

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid injected into the skin must be surgically removed within a few hours by a doctor familiar with this form of injury; otherwise, gangrene may result.

-

Keep your body and hands away from pinhole leaks or nozzles that eject high-pressure hydraulic fluid.

-

Use cardboard or paper to find hydraulic leaks; never use your hands.

Cleaning

Removing Debris

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Important: Operating the engine with blocked screens and/or cooling shrouds removed will result in engine damage from overheating.

-

Park the machine on a level surface and lower the loader arms.

-

Shut off the engine, remove the key, and allow the engine to cool.

-

Open the hood and secure the prop rod.

-

Clean any debris from the front and side screens.

-

Wipe away debris from the air cleaner.

-

Clean any debris buildup on the engine and in the oil cooler fins with a brush or blower.

Important: Operating the engine with blocked screens and/or cooling shrouds removed will result in engine damage due to overheating.

-

Clean debris from the hood opening, muffler, heat shields, and radiator screen (if applicable).

-

Close the hood.

Cleaning the Chassis

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

Over time, the chassis under the engine collects dirt and debris that must be removed. Using a flashlight, open the hood and inspect the area under the engine on a regular basis. When the debris is 2.5 to 5.1 cm (1 to 2 inches) deep, clean the chassis.

-

Lower the loader arms, shut off the engine, and remove the key.

-

Raise the front of the machine so that the machine is angled backward.

-

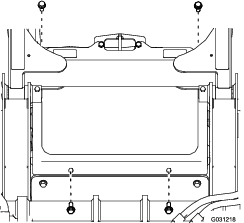

Remove the 2 bolts securing the bottom plate and remove the bottom plate (Figure 64).

-

Remove the front screen; refer to Removing the Front Screen.

-

Spray water into the chassis to clean out the dirt and debris.

Note: The water will drain at the back of the machine.

Important: Do not spray water into the engine.

-

Grease the machine; refer to Greasing the Machine.

-

Install the bottom plate (Figure 64).

-

Install the front screen.

-

Lower the machine.

Storage

-

Lower the loader arms, shut off the engine, and remove the key.

-

Remove dirt and grime from the entire traction unit.

Important: You can wash the traction unit with mild detergent and water. Do not pressure wash the traction unit. Avoid excessive use of water, especially near the control panel, engine, hydraulic pumps, and motors.

-

Service the air cleaner; refer to Servicing the Air Cleaner.

-

Grease the traction unit; refer to Greasing the Machine.

-

Change the crankcase oil; refer to Changing the Engine Oil.

-

Charge the battery; refer to Charging and Connecting the Battery.

-

Check and adjust the track tension; refer to Adjusting the Track Tension.

-

Check and tighten all bolts, nuts, and screws. Repair or replace any part that is damaged.

-