Maintenance

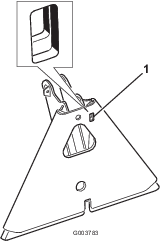

Greasing the Attachment

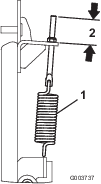

If the locking lever on the attachment adapter does not pivot freely and easily, apply a light coat of grease to the area shown in Figure 6.

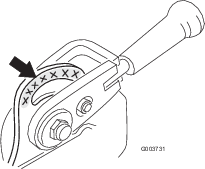

Adjusting the Actuating Rod Springs

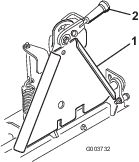

The extension spring length is adjusted at the factory to 5 cm (2 inches) as shown in Figure 7. To increase the aggressiveness of the blade, tighten the springs. Loosen the springs to decrease the aggressiveness of the blade.