Setup

Adding Fuel to the Machine

Add fuel to the machine before starting it. Refer to your Operator’s Manual for the correct fuel and procedure.

Checking the Engine-Oil Level

Before you start the engine and use the machine, check the oil level in the engine crankcase; refer to the Operator's Manual.

Checking the Tire Pressure

Drive tires air pressure specification: 124 kPa (18 psi)

Note: Check the tire pressure before starting the machine. Refer to your Operator’s Manual for the correct tire type, correct air pressure needed, and procedure.

Checking the Hydraulic-Fluid Level

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Move the motion-control levers to the NEUTRAL-LOCK position and start the engine.

Note: Run the engine at the lowest possible rpm to purge any air in the system.

Important: Do not engage the PTO.

-

Wait until the machine cools before checking the hydraulic fluid.

-

Adjust the seat to the most forward position to access the caps on the left and right hydrostatic drives.

-

Clean the area around the hydraulic-reservoir cap and remove the cap.

-

Remove the dipstick and wipe it with a clean rag.

-

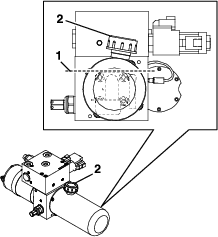

Install the dipstick into the filler neck, thread it fully, remove it, and check the fluid level (Figure 1).

Note: If the level is not within the notched area of the dipstick, add enough high-quality hydraulic fluid to raise the level to within the notched area.

Important: Do not overfill.

-

Install the dipstick and thread the fill cap finger-tight onto the filler neck.

-

Check all hoses and fittings for leaks.

Checking the Deck-Lift Power Unit Fluid Level

Ensure that the fluid level is slightly above the internal gear pump in the tank (Figure 2).

Note: If needed, add Toro Premium Transmission/Hydraulic Tractor Fluid until the fluid level is slightly above the internal gear pump in the tank.

Checking the Battery

Important: The machine is shipped with a filled lead acid battery.

Danger

Charging or jump starting the battery may produce explosive gases. Battery gases can explode causing serious injury.

-

Keep sparks, flames, or cigarettes away from battery.

-

Ventilate when charging or using battery in an enclosed space.

-

Make sure venting path of battery is always open once battery is filled with acid.

-

Always shield eyes and face from battery.

Danger

Battery electrolyte contains sulfuric acid, which is poisonous and can cause severe burns. Swallowing electrolyte can be fatal or if it touches skin can cause severe burns.

-

Wear safety glasses to shield eyes, and rubber gloves to protect skin and clothing when handling electrolyte.

-

Do Not swallow electrolyte.

-

In the event of an accident, flush with water and call a doctor immediately.

Caution

If the ignition is in the “ON” position there is potential for sparks and engagement of components. Sparks could cause an explosion or moving parts could accidentally engage causing personal injury.

Be sure ignition switch is in the “OFF” position before charging the battery.

-

Check the voltage of the battery with a digital voltmeter. Locate the voltage reading of the battery in the table below and charge the battery for the recommended time interval to bring the charge up to a full charge of 12.6 V or greater.

Important: Ensure that the negative battery cable is disconnected and the battery charger used for charging the battery should have an output of 16 V and 7 A or less to avoid damaging the battery (see the chart below for the recommended charger settings). This is especially important on Kohler EFI (Electronic Fuel Injection) units. Failure to do so may damage the ECU (Electronic Control Unit).

Voltage Reading Percent Charge Maximum Charger Settings Charging Interval 12.6 or greater 100% 16 V/7 A No charging required 12.4 to 12.6 75 to 100% 16 V/7 A 30 minutes 12.2 to 12.4 50 to 75% 16 V/7 A 1 hour 12.0 to 12.2 25 to 50% 14.4 V/4 A 2 hours 11.7 to 12.0 0 to 25% 14.4 V/4 A 3 hours 11.7 or less 0% 14.4 V/2 A 6 hours or more -

Connect the negative battery cable.

Note: If the positive cable is also disconnected, connect the positive (red) cable to the positive battery terminal first, then the negative (black) cable to the negative battery terminal. Slip the insulator boot over the positive terminal.

Note: If time does not permit charging the battery, or if charging equipment is not available, connect the negative battery cable and run the machine continuously for 20 to 30 minutes to sufficiently charge the battery.

Checking the Wheel Lug Nut Torque

Before you start the engine and use the machine, check the wheel lug nut torque; refer to Checking the Wheel Lug Nuts in the Operator's Manual.

Raising the Rollover Protection System (ROPS)

-

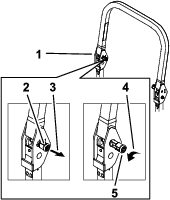

Pull the knob and rotate 90° to the unlatched position (Figure 3).

-

Raise the roll bar to the operate position, and rotate the knobs so that they move partially into the grooves (Figure 3).

-

Raise the roll bar to the full upright position while pushing on the upper roll bar and the pins snap into position when the holes align with the pins (Figure 3).

Important: Always use the seat belt with the roll bar in the raised position.

-

Push on the roll bar and ensure that both pins are engaged (Figure 4).

Checking the Machine Before Delivery to the Customer (All Machines)

Before delivering the machine to the customer, ensure that you perform or have performed the procedures listed in the following table and initial each when finished. Refer to the Operator's Manual for instructions on performing these procedures.

| Initial | Check Procedure |

| Check the tire pressure. | |

| Check the level of the machine. | |

| Check that all spindles are greased. | |

| Check the engine-oil level. | |

| Check the hydraulic-fluid level. | |

| Check ROPS is secure. | |

| On liquid cooled machines, check the level of the coolant in the radiator and overflow bottle. | |

| Check the adjustment of the parking brake. | |

| Ensure that the machine tracks correctly; refer to the Operator's Manual for the adjustment procedure. | |

| Check the safety interlock system; refer to the Operator's Manual. | |

| Ensure that the PTO works. | |

| Check all fasteners that you installed to ensure that they are tight. |

When you finish setting up the machine, sign and date in the space provided below:

Delivering the Machine to the Customer

Parts needed for this procedure:

| Operator's Manual | 1 |

| Engine owner's manual | 1 |

| Registration card | 1 |

| Operator training material | 1 |

| Key | 2 |

At delivery, fill in the model and serial number, complete the items listed in the following table, and initial each when finished.

| Dealer Initial | Customer Initial | Check Procedure | ||

|---|---|---|---|---|

| Show the customer where the following features are located and how they function: | ||||

| • | Fuel tank | |||

| • | Oil fill cap/Oil dipstick | |||

| • | Engine-oil filter | |||

| • | Engine-oil drain | |||

| • | Fuel gauge, valve and hose | |||

| • | Air filter | |||

| • | Radiator coolant (if applicable) | |||

| • | Hydraulic-fluid reservoir | |||

| • | Hydraulic filter | |||

| • | Battery | |||

| • | Key switch | |||

| • | Throttle lever | |||

| • | Choke (if applicable) | |||

| • | Power take off switch (PTO) | |||

| • | Motion-control levers | |||

| • | Parking brake | |||

| • | Height of cut | |||

| • | Lift-assist lever (if applicable) | |||

| • | Adjustable seat | |||

| • | Hydraulic-bypass valves | |||

| • | Rollover Protection System (ROPS) | |||

| • | Deck-flow baffle | |||

| Refer to theOperator's Manual to point out safety procedures, operation, and maintenance procedures. | ||||

| Review the warranty statement as shown in the Operator's Manual. | ||||

| Describe the post sale service procedures for your store. | ||||

| Assist the customer in filling out and mailing the registration card or register online at www.Toro.com | ||||

| Ensure that the customer receives the Operator's Manual, engine owner’s manual, Setup Instructions, and operator training material. | ||||

| Ensure that the customer knows the Parts Catalog is available at www.Toro.com. | ||||

| Assist the customer in loading the machine using a full-width trailer ramp. | ||||

Note: When you, the dealer representative, have finished delivering the machine to the customer, sign and date in the space provide below and keep a copy of this page for dealer records. Also, the dealer must remind the customer to use a full-width trailer ramp to load the machine.