Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely. Read your Operator’s Manual for more information.

Monitor

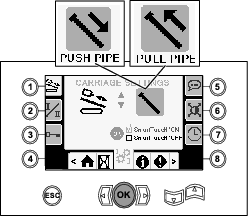

Home Screen Options

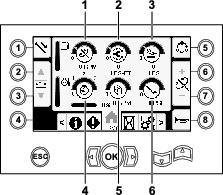

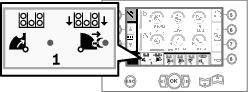

Main Information Screen

This is the first screen that appears after the initial splash screen. To navigate between screens, use the left and right arrows.

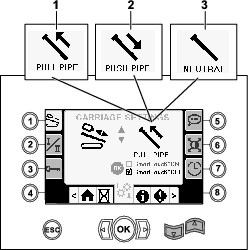

Push button 1 to switch between the pipe functions: pull pipe, push pipe, neutral.

Push button 5 to switch between thrust force, drill speed (rpm), and rotary torque.

Use buttons 6 and 7 to set limits for the drill speed (rpm), rotary torque, and thrust force.

SmartTouch

SmartTouch mode allows the operator to load and unload pipes from the rod box with less joystick operation to reduce operator fatigue.

Use the Carriage Settings Screen to turn SmartTouch mode on and off.

Note: The Push/Pull Icon will have a green background when SmartTouch mode is on and a ribbon will appear at the bottom of the screen showing a sequence of the steps.

Important: Never switch between Push/Pull modes during the chosen operation. Use neutral (manual) mode to switch between Push/Pull; refer to Carriage Settings Screen to turn SmartTouch mode off.

Pulling Pipe in SmartTouch Mode

Start the SmartTouch mode with the cam assembly in the home position (row 3 of the pipe box).

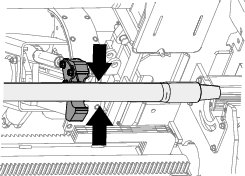

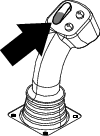

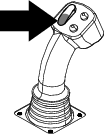

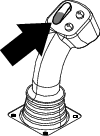

Important: Ensure that you hold the lower section of the cam rocker switch, on the left joystick, completely down until the action is complete in each step (Figure 4).

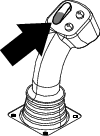

Hold the upper section of the cam rocker switch, on the left joystick, completely down until all actions are complete to go to the previous step in the sequence (Figure 5).

-

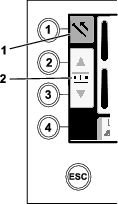

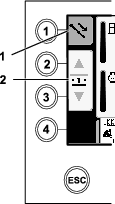

Push button 1 to select the pull pipe option (Figure 6).

-

Push buttons 2 and 3 to select the row where you want to place the pipe (Figure 6).

-

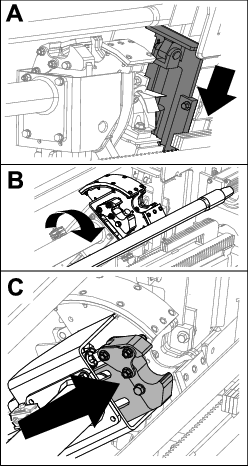

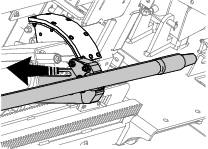

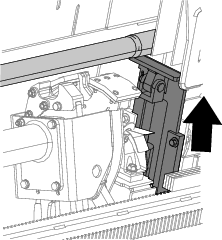

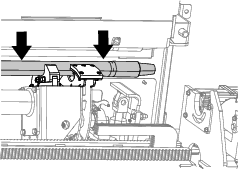

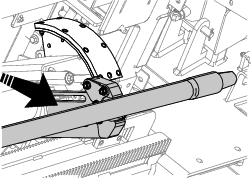

Hold the lower section of the rocker switch (Figure 8) until the elevator lowers, the cam assembly rotates toward the operator station, and the arms fully extend (Figure 9).

-

Release the rocker switch to proceed to the next step in the sequence (Figure 10).

-

Break the pipe connection; refer to Removing Drill Pipes in the Operator’s Manual.

-

Hold the upper button on the joystick to grip the pipe (Figure 11 and Figure 12) and release the button.

-

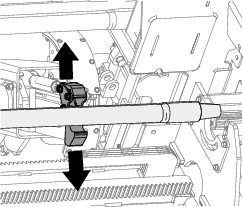

Hold the lower section of the rocker switch (Figure 14) until the arms fully retract (Figure 15).

-

Release the rocker switch to proceed to the next step in the sequence (Figure 16).

-

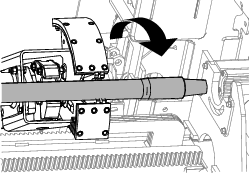

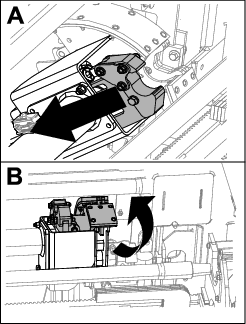

Hold the lower section of the rocker switch (Figure 17) until the cam assembly rotates to the selected row under the pipe box (Figure 18).

-

Release the rocker switch to proceed to the next step in the sequence (Figure 19).

-

Hold the lower section of the rocker switch (Figure 20) until the elevator puts the pipe back in the pipe box and the cam rotates to the home position (Figure 21).

-

Release the rocker switch to start the pull-pipe process again.

Pushing Pipe in SmartTouch Mode

Start the SmartTouch mode with the cam assembly in the home position (row 3 of the pipe box).

Important: Ensure that you hold the lower section of the cam rocker switch, on the left joystick, completely down until the action is complete in each step (Figure 22).

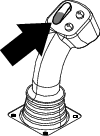

Hold the upper section of the cam rocker switch, on the left joystick, completely down until all actions are complete to go to the previous step in the sequence (Figure 23).

-

Push button 1 to select push pipe (Figure 24).

-

Push buttons 2 and 3 to select the row where you want to get the pipe (Figure 24).

-

Hold the lower section of the rocker switch (Figure 26) until the cam assembly rotates to the selected row and the pipe lowers into the opening (Figure 27).

-

Release the rocker switch to proceed to the next step in the sequence (Figure 28).

-

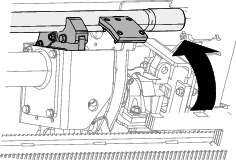

Hold the lower section of the rocker switch (Figure 29) until the cam assembly fully rotates forward to the rack and the elevators lift the remaining pipe into the pipe box (Figure 30).

-

Release the rocker switch to proceed to the next step in the sequence (Figure 31).

-

Hold the lower section of the rocker switch (Figure 32) until the arms extend (Figure 33).

-

Release the rocker switch to proceed to the next step in the sequence (Figure 34).

-

Make the pipe connection; refer to Adding Drill Pipes in the Operator’s Manual.

-

Hold the lower button on the joystick (Figure 35) to release the pipe (Figure 36) and release the button.

-

Hold the lower section of the rocker switch (Figure 38) until the arms retract and the cam assembly returns to the home position (row 3) (Figure 39).

-

Release the rocker switch to start the push-pipe process again. The cam assembly will go to the row picked in step 3 of Pulling Pipe in SmartTouch Mode.

Hours Screen Options

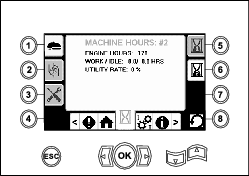

Machine Hours Screen

To access this screen push button 1 on the Hours screen.

This screen shows the operating hours of the machine. Machine 1 cannot be changed. Machine 2 can be reset.

Button 5 shows the total engine hours.

Button 6 shows engine hours that can be reset by pushing button 8.

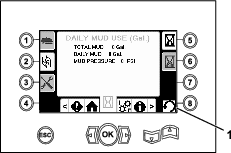

Drilling Fluid (Mud) Use Screen

To access this screen push button 2 on the Hours screen.

This screen shows the drilling fluid (mud) use of the machine. Total drilling fluid (mud) cannot be changed. Daily drilling fluid (mud) can be reset.

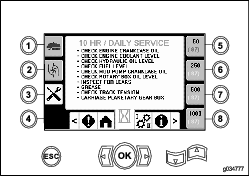

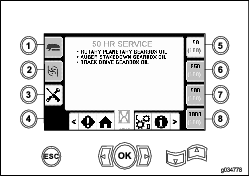

Lubrication and Maintenance Screens

To access this screen, push button 3 on the Hours screen.

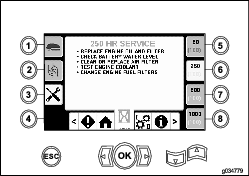

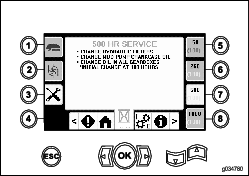

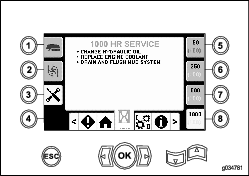

These screens provide the user with the daily maintenance schedules and the 50-hour, 250-hour, 500-hour, and 1,000-hour increments.

To reset the maintenance interval, navigate to the Maintenance and Parameters Options Screen.

Push buttons 5 through 8 for the corresponding service interval and then push the OK button 3 times.

Push the following buttons to attain the subsequent maintenance schedule:

-

Button 3—10-hour/Daily maintenance schedule (Figure 42)

-

Button 5—50-hour maintenance schedule (Figure 43)

-

Button 6—250-hour maintenance schedule (Figure 44)

-

Button 7—500-hour maintenance schedule (Figure 45)

-

Button 8—1,000-hour maintenance schedule (Figure 46)

Settings Screen Options

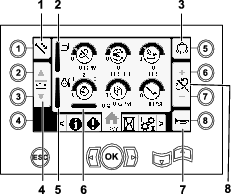

Carriage Settings Screen

Push button 1 on the Settings screen.

Use this screen to change the carriage settings. Push the up and down arrows to rotate between: push pipe, pull pipe, and neutral.

Push the OK button to turn SmartTouch mode on and off.

Push Pipe: refer to Starting the First Pipe and Adding Drill Pipes in the Drilling the Bore section in your Operator’s Manual for full instructions.

Pull Pipe: refer to Removing Drill Pipes in the Drilling the Bore section in your Operator’s Manual for full instructions.

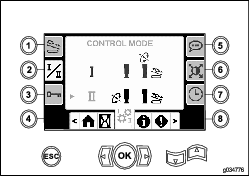

Control Mode Screen

Push button 2 on the Settings screen.

Use this screen to select between the 2 joystick control options. Push the up and down buttons to switch between Mode I and Mode II.

-

Mode I—The right joystick controls the thrust and the rotation functions. The left joystick controls the wrench and pipe loader functions.

-

Mode II—The right joystick controls the thrust and the pipe loader elevator function. The left joystick controls the rotation, wrench, and pipe loader functions.

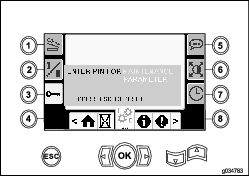

Maintenance and Parameters Options Screen

Push button 3 on the Settings screen.

Push the up and down arrows to switch between Maintenance and Parameters.

The Maintenance pin number is 12356.

The Parameters pin number is 73236531.

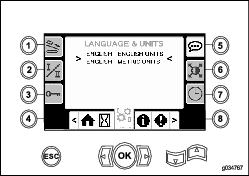

Language and Units Options Screen

Push button 5 on the Settings screen to access the screen to switch between English and metric units. Use the up and down arrow keys to change the language and unit options.

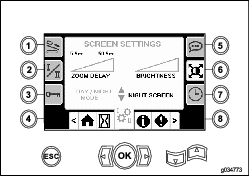

Screen Settings Screen

Push button 6 on the Settings screen to switch between zoom delay, brightness, and day or night mode. Use the up and down arrows to adjust the parameters.

The Main Drilling Screen zooms into the drilling functions. These settings adjust the delay on how long it takes to zoom.

Note: The SmartTouch ribbon sequence will be hidden when the screen is zoomed in.

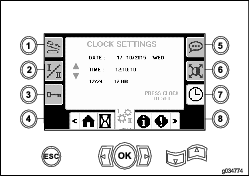

Clock Settings Screen

Push button 7 on the Settings screen to switch between the clock options. Use the up and down arrows to adjust the parameters.

I/O Screens

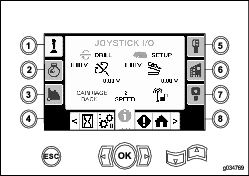

Joystick I/O Screen

Push button 1 on the I/O screen to access the Joystick I/O screen.

When the rocker switch on the left control panel is in the Drill position, the upper left icon turns green and you can check the joystick voltages as well as verify the 2–Speed and Exit Side Lockout.

When the rocker switch is in the Setup position, the upper right icon is green. The setup position allows you to move the machine and prepare for drilling.

-

The rotary voltage ranges from 0.0 to 8.5 V and be present for either make (upper icon) or break (lower icon) as the selected rotary joystick is moved.

-

The carriage indicates a range from 0.0 to 10.0 volts in the joystick selected direction for thrust or pullback.

-

The lower left icon indicates the carriage position of wrench, load, or carriage back as the carriage moves to the most rearward positions.

-

The lower center icon indicates if the 2-speed selection of the carriage speed has been selected.

-

The lower right icon indicates the status of the Exit Side Lockout (ESL). If the indicator is black, the carriage and rotary actions are inhibited.

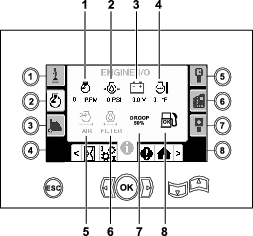

Engine I/O Screen

To access this screen push button 2 on the I/O screen.

This screen displays engine information.

Engine speed (rpm): displays, in steps of 100, the engine speed (rpm).

Engine oil pressure: displays the engine oil pressure (bar or psi).

Battery voltage: displays the battery voltage.

If the engine is off, the voltage is measured by the Toro controller.

Engine temperature: displays the engine coolant temperature. The temperature drops to 40°F when the engine is off.

Air filter: the air filter icon is green unless the filter is plugged then the indicator is red.

Hydraulic fluid filter: the hydraulic fluid filter icon is green unless the filter is plugged then the indicator is red.

Engine droop: use the up and down arrows to select the maximum allowable engine droop in the range of 50, 75, and 80 percent. The droop value is the lowest point below low-load speed (rpm) (under 75 percent load) that the engine may decrease before the drive to the rotary head is decreased to maintain the lowest value.

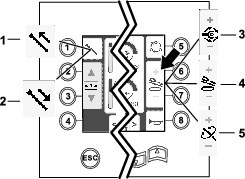

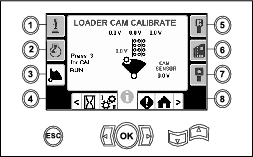

Cam Arm I/O Screen

To access this screen push button 3 on the I/O screen.

Use this screen to adjust the cam calibration options.

Push the up and down buttons to select the load position and the pipe-row position.

The voltage on the bottom indicates the cam raw sensor voltage. The voltages range from 1.0 to 4.0 V. Any voltage higher or lower indicates either sensor failure or incorrect calibration.

The other voltages are calibrated voltages.

Push button 3 to toggle the calibration on and off.

Push the OK button 3 times on the desired row to save the calibration.

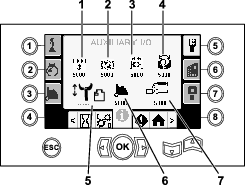

Auxiliary I/O Screen

To access this screen push button 5 on the I/O screen.

All icons change from black to green when you operate the associated functions.

The breakout wrench icon will show arrows above the icon to indicate when the rotating wrench is open or closed.

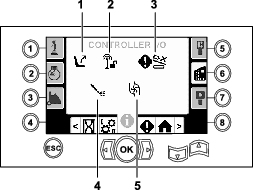

Controller I/O Screen

To access this screen push button 6 on the I/O screen.

Seat switch: shows an arrow out when nobody is in the seat and a person in while you are in the seat.

Exit side lockout: changes from black to green when in operation.

Carriage crash warning: a warning screen (Figure 59) will appear if:

-

the carriage is in the drill area and you try to operate the loader arm or pipe cam or

-

you try to operate the carriage when the loader arm or pipe cam is not in the home position.

Mud pump status:

-

Black icon: mud pump is off

-

Yellow icon: mud pump is in standby

-

Green icon: mud pump is in on

-

Green icon with 100: mud pump is in max flow

Mud pump flow: turns green when you actuate the mud flow rocker switch.

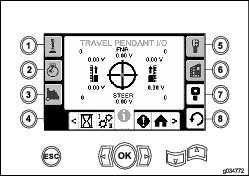

Travel Pendant I/O Screen

To access this screen push button 7 on the I/O screen.

The travel pendant screen shows the voltage and position of the joystick located on the pendant.

The red dot is in the center of the target and the FNR (forward, neutral, reverse) and Steer voltage shows 2.5 V prior to allowing the drill to move. If the red dot travels outside of the outermost black ring, service or replace the pendant. The indicators to the right and left of the circle show the direction of the track travel. The voltages show a range from 0 to 10.0 V.

Errors and Machine Information Screens

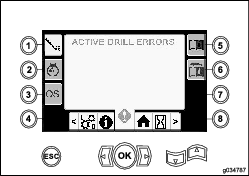

Drill Errors Screens

To access this screen push button 1 on the Errors and Machine Information screen.

This screen displays any drill errors.

Push buttons 5 and 6 to page through the errors.

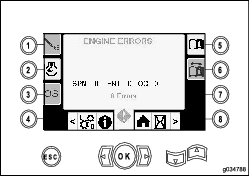

Engine Errors Screen

To access this screen push button 2 on the Errors and Machine Information screen.

This screen displays any engine errors.

Push buttons 5 and 6 to page through the errors.

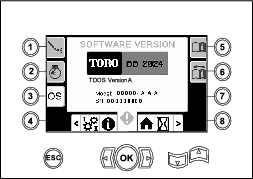

Machine Information Screen

To access this screen push button 3 on the Errors and Machine Information screen.

This screen displays the machine information including the model, serial number, and software version.