Safety

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Installation

Determine the left and right sides of the machine from the normal operating position.

Preparing the Machine

-

Park the machine on a level surface.

-

Disengage the power takeoff and lower the attachments.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for all movement to stop.

-

Allow machine components to cool.

Updating the Machine Software

Update the machine software to the latest version in ToroDiag.

Note: This ensures the software is updated for calibration and use of the slope sensor.

Installing the Kit

Parts needed for this procedure:

| Sensor module | 1 |

| Bolt (1/2 x 1 inch) | 2 |

| Nut (1/4 inch) | 2 |

| Bolt (1/4 x 1-1/4 inch) | 2 |

| Mounting bracket | 1 |

| Wire harness | 1 |

| Alarm | 1 |

| Cable tie | 4 |

Installing the Sensor Module

-

Disconnect the battery. Refer to the Operator’s Manual for the procedure.

-

Move the seat forward.

-

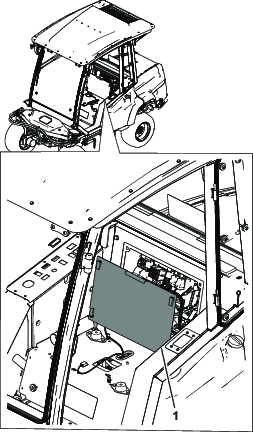

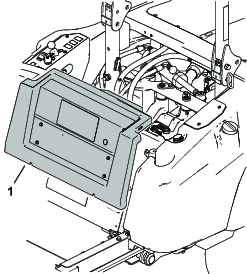

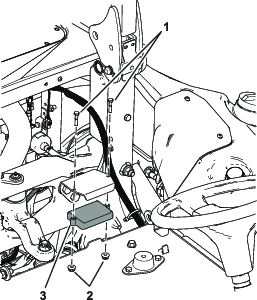

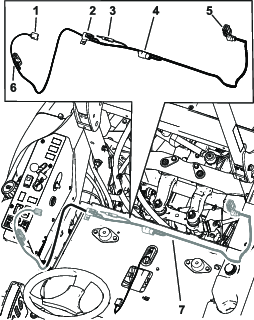

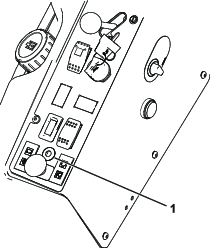

Tilt the back cover forward or remove to gain access to the wires (Figure 1 or Figure 2).

-

Install the sensor bracket to the frame with 2 bolts (1/2 x 1 inch); refer to Figure 3.

Note: The holes in the frame are threaded.

-

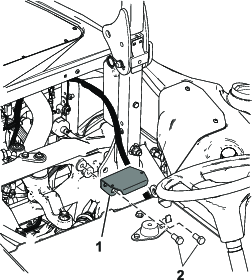

Install the sensor to the sensor bracket with 2 bolts (1/4 x 1-1/4 inch) and 2 nuts (1/4 inch); refer to Figure 4.

-

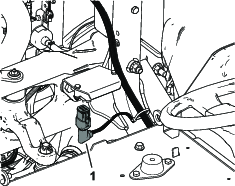

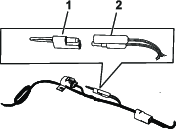

Plug the 90° connector into the sensor (Figure 5 and Figure 8).

-

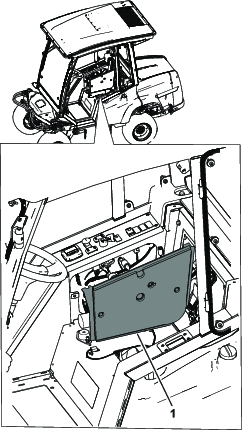

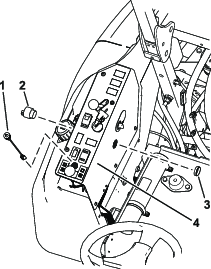

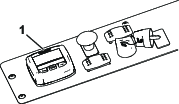

Remove the control panel on the console or loosen and raise up the control panel (Figure 6 or Figure 7).

-

Remove the knockout for the alarm.

-

Install the alarm (Figure 7).

Note: Installing the light and removing the decal area is for machines without an InfoCenter only.

-

Remove the area in the console decal for the light.

-

Install the light from the top of the console (Figure 7).

Routing the Wire Harness

-

Route the wire harness under the seat pan and along the along the existing wire harness in the cross channel (Figure 8).

-

Route the wire harness to the controls.

-

Install the middle connector to the machine wire harness connector labled TELEMATICS port or EXPANSION port (Figure 8).

-

Connect the wire harness to the light and the alarm (Figure 8).

-

Secure the harness away from any hot or moving parts with cable ties.

-

Install the control panel to the console for machines with a cab or install the control panel for machines with a rollbar (Figure 6 or Figure 7).

-

Connect the battery. Refer to the Operator’s Manual for the procedure.

Calibrating the Sensor

-

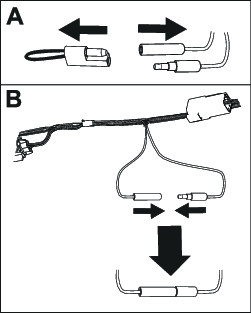

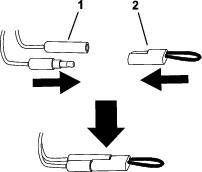

While on a flat surface, remove the plug from the calibration connectors (Figure 9).

-

Plug the calibration connectors together as shown in Figure 9.

-

Turn the ignition key to the ON position, but do not start the engine.

-

Use the following processes depending what your machine has installed.

-

Infocenter display:

-

The InfoCenter shows advisory 195, Slope Sensor Calibrating.

Note: The LED light at the top of the display screen (Figure 10) blinks as the sensor calibrates.

-

When the InfoCenter shows advisory 196, Slope Sensor Calibrated, the light no longer blinks, and the alarm beeps once, turn the ignition key to the OFF position.

-

-

Console light:

-

The LED light (Figure 11) blinks as the sensor calibrates.

-

When the LED light turns off and the alarm beeps once, the sensor is calibrated.

-

Turn the ignition key to the OFF position.

-

-

-

Disconnect the calibration connectors and install the plug onto the connectors (Figure 12).

Installing the Decal

Operation

Use the following procedures depending what your machine has installed.

Warning

Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death.

Use extreme caution when operating the machine on a slope.

Using the Slope Sensor with an InfoCenter

The light and alarm indicates the severity of the slope (Figure 10):

-

No light—normal operating conditions

-

Slow, flashing red light and Advisory 196 displaying on the screen—moderate slope

-

Fast, flashing red light, audible alarm, and Advisory 197 displaying on the screen—steep slope; proceed to a more shallow slope.

Using the Slope Sensor with the LED Light

The light and alarm indicates the severity of the slope(Figure 11):

-

No light—normal operating conditions

-

Slow, flashing red light—moderate slope

-

Fast, flashing red light and audible alarm—steep slope; proceed to a more shallow slope.