| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Introduction

This rotary-blade, riding lawn mower is intended to be used by professional, hired operators. It is designed primarily for cutting grass on well-maintained lawns on residential or commercial properties. Using this product for purposes other than its intended use could prove dangerous to you and bystanders.

Read this information carefully to learn how to operate and maintain your product properly and to avoid injury and product damage. You are responsible for operating the product properly and safely.

Visit www.Toro.com for product safety and operation training materials, accessory information, help finding a dealer, or to register your product.

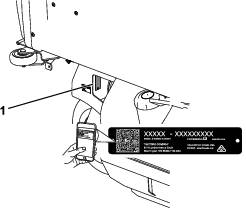

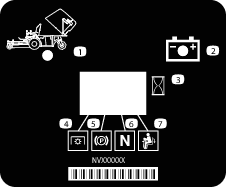

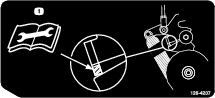

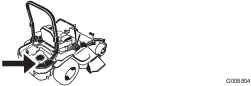

Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product. Write the numbers in the space provided.

Important: With your mobile device, you can scan the QR code on the serial number decal (if equipped) to access warranty, parts, and other product information.

This manual uses 2 words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention.

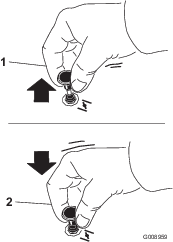

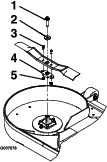

The safety-alert symbol (Figure 2) appears both in this manual and on the machine to identify important safety messages that you must follow to avoid accidents. This symbol will appear with the word Danger, Warning, or Caution.

-

Danger indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

-

Warning indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

-

Caution indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

This product complies with all relevant European directives; for details, please see the separate product specific Declaration of Conformity (DOC) sheet.

Please refer to the engine manufacturer’s information included with the machine.

Gross or Net Torque: The gross or net torque of this engine was laboratory rated by the engine manufacturer in accordance with the Society of Automotive Engineers (SAE) J1940 or J2723. As configured to meet safety, emission, and operating requirements, the actual engine torque on this class of mower will be significantly lower. Please refer to the engine manufacturer’s information included with the machine.

Safety

This machine has been designed in accordance with EN ISO 5395.

General Safety

This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury.

-

Read and understand the contents of this Operator’s Manual before starting the engine.

-

Keep bystanders and children away.

-

Do not allow children or untrained people to operate or service the machine. Allow only people who are responsible, trained, familiar with the instructions, and physically capable to operate or service the machine.

-

Always keep the roll bar in the fully raised and locked position and use the seat belt.

-

Do not operate the machine near drop-offs, ditches, embankments, water, or other hazards, or on slopes greater than 15°.

-

Do not put your hands or feet near moving components of the machine.

-

Do not operate the machine without all guards, safety switches, and other safety protective devices in place and functioning properly.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operator’s position. Allow the machine to cool before servicing, adjusting, fueling, cleaning, or storing it.

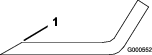

Slope Indicator

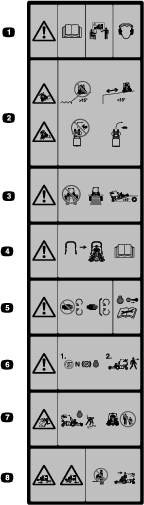

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

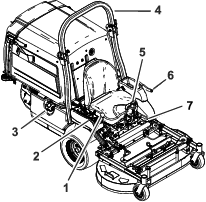

Product Overview

Become familiar with all the controls before you start the engine and operate the machine.

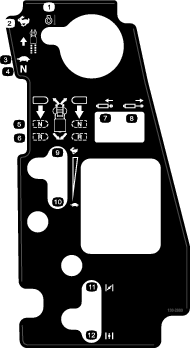

Control Panel

Key Switch

The key switch, used to start and shut off the engine, has 3 positions: OFF, RUN, and START. Refer to Starting the Engine.

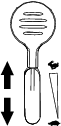

Throttle Control

The throttle controls the engine speed, and it has a continuous-variable setting from the SLOW to FAST position (Figure 5).

Choke Control

Use the choke control to start a cold engine.

PTO-Engagement Lever

Use the PTO-engagement lever to engage the blades and the blower.

Speed-Control Lever

The speed-control lever sets maximum forward speed of the machine (Figure 4). Moving the speed-control lever rearward to the NEUTRAL position places the drive system into neutral.

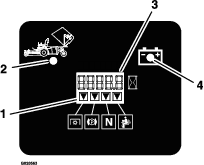

Hour Meter

The hour meter records the number of hours the engine has operated. The hour meter is recording when the decimal point is flashing in the Hour/Voltage display. Use these times for scheduling regular maintenance (Figure 6).

Battery-Indicator Light

If you turn the key switch to the ON position for a few seconds, the battery voltage displays in the area where the hours are normally displayed.

The battery light turns on when the key switch is turned on and when the charge is below the correct operating level (Figure 6).

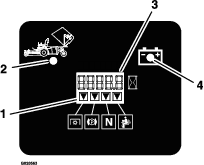

Safety-Interlock Indicators

There are symbols on the hour meter that indicate with a black triangle that the interlock component is positioned correctly (Figure 6).

Engine-Oil-Temperature Light and Buzzer

The engine-oil-temperature light monitors the temperature of the engine oil. An illuminated engine-oil-temperature light and intermittent buzzing sound signals that the engine is overheating.

Motion-Control Levers

Use the motion-control levers to drive the machine forward, reverse, and turn either direction (Figure 4).

Parking-Brake Lever

Whenever you shut off the engine, engage the parking brake to prevent accidental movement of the machine.

Fuel-Shutoff Valve

Close the fuel-shutoff valve when transporting or storing the machine.

Note: Specifications and design are subject to change without notice.

| 122 cm Mower Deck | |

|---|---|

| Without Mower Deck | 108 cm (43 inches) |

| With Mower Deck | 125 cm (49 inches) |

| 122 cm Mower Deck | |

|---|---|

| Without Mower Deck | 171 cm (67 inches) |

| Mower Deck—Up | 208 cm (82 inches) |

| Mower Deck—Down | 240 (95 inches) |

| 122 cm Mower Deck |

|---|

| 130 cm (51 inches) |

| 122 cm Mower Deck |

|---|

| 538 kg (1,185 lb) |

Attachments/Accessories

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved attachments and accessories.

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

Operation

Note: Determine the left and right sides of the machine from the normal operating position.

Before Operation

Before Operation Safety

General Safety

-

Do not allow children or untrained people to operate or service the machine. Local regulations may restrict the age of the operator. The owner is responsible for training all operators and mechanics.

-

Inspect the area where you will use the machine, and remove all objects that could interfere with the operation of the machine or that the machine could throw.

-

Become familiar with the safe operation of the equipment, operator controls, and safety signs.

-

Check that operator-presence controls, safety switches, and guards are attached and working properly. Do not operate the machine unless they are functioning properly.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operator’s position. Allow the machine to cool before servicing, adjusting, fueling, cleaning, or storing it.

-

Before mowing, inspect the machine to ensure that the cutting assemblies are working properly.

-

Evaluate the terrain to determine the appropriate equipment and any attachments or accessories required to operate the machine properly and safely.

-

Wear appropriate clothing, including eye protection; long pants; substantial, slip-resistant footwear; and hearing protection. Tie back long hair and do not wear loose clothing or loose jewelry.

-

Do not carry passengers on the machine.

-

Keep bystanders and pets away from the machine during operation. Shut off the machine and attachment(s) if anyone enters the area.

-

Do not operate the machine unless all guards and safety devices, such as the deflectors and the entire grass catcher, are in place and functioning properly. Replace worn or deteriorated parts when necessary.

Fuel Safety

-

Fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

-

To prevent a static charge from igniting the fuel, place the container and/or machine directly on the ground before filling, not in a vehicle or on an object.

-

Fill the fuel tank outdoors on level ground, in an open area, and when the engine is cold. Wipe up any fuel that spills.

-

Do not handle fuel when smoking or around an open flame or sparks.

-

Do not remove the fuel cap or add fuel to the tank while the engine is running or hot.

-

If you spill fuel, do not attempt to start the engine. Avoid creating a source of ignition until the fuel vapors have dissipated.

-

Store fuel in an approved container and keep it out of the reach of children.

-

-

Fuel is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious injury and illness.

-

Avoid prolonged breathing of vapors.

-

Keep your hands and face away from the nozzle and the fuel-tank opening.

-

Keep fuel away from your eyes and skin.

-

-

Do not store the machine or fuel container where there is an open flame, spark, or pilot light, such as on a water heater or on other appliances.

-

Do not fill containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always place containers on the ground and away from your vehicle before filling.

-

Remove the equipment from the truck or trailer and refuel it while it is on the ground. If this is not possible, then refuel from a portable container rather than from a fuel-dispenser nozzle.

-

Do not operate the machine without the entire exhaust system in place and in proper working condition.

-

Keep the fuel-dispenser nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete. Do not use a nozzle lock-open device.

-

If you spill fuel on your clothing, change your clothing immediately.

-

Do not overfill the fuel tank. Replace the fuel cap and tighten it securely.

-

Clean grass and debris from the cutting unit, muffler, drives, grass catcher, and engine compartment to help prevent fires. Clean up oil or fuel spills.

Adding Fuel

Recommended Fuel

-

For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with an octane rating of 87 or higher ((R+M)/2 rating method).

-

Ethanol: Gasoline with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. Ethanol and MTBE are not the same. Gasoline with 15% ethanol (E15) by volume is not approved for use. Never use gasoline that contains more than 10% ethanol by volume, such as E15 (contains 15% ethanol), E20 (contains 20% ethanol), or E85 (contains up to 85% ethanol). Using unapproved gasoline may cause performance problems and/or engine damage which may not be covered under warranty.

-

Do not use gasoline containing methanol.

-

Do not store fuel either in the fuel tank or fuel containers over the winter unless you use a fuel stabilizer.

-

Do not add oil to gasoline.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to provide the following benefits:

-

Keeps fuel fresh longer when used as directed by the fuel-stabilizer manufacturer

-

Cleans the engine while it runs

-

Eliminates gum-like varnish buildup in the fuel system, which causes hard starting

Important: Do not use fuel additives containing methanol or ethanol.

Add the correct amount of fuel stabilizer/conditioner to the fuel.

Note: A fuel stabilizer/conditioner is most effective when mixed with fresh fuel. To minimize the chance of varnish deposits in the fuel system, use fuel stabilizer at all times.

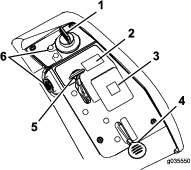

Filling the Fuel Tank

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Clean around the fuel-tank cap.

-

Fill the fuel tank to the bottom of the filler neck (Figure 7).

Note: Do not fill the fuel tank completely full. The empty space in the tank allows the fuel to expand.

Performing Daily Maintenance

Before starting the machine each day, perform the Each Use/Daily procedures listed in .

Breaking in a New Machine

New engines take time to develop full power. Mower decks and drive systems have higher friction when new, placing additional load on the engine. Allow 40 to 50 hours of break-in time for new machines to develop full power and best performance.

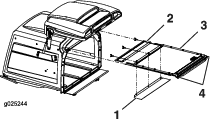

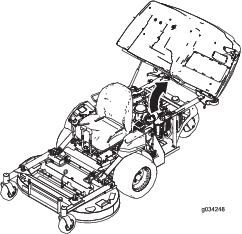

Raising the Mower Deck into the Service Position

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

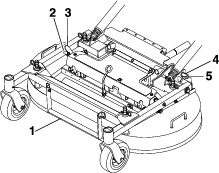

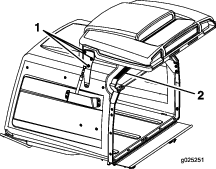

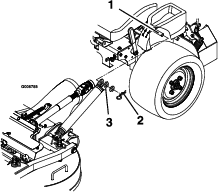

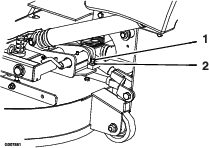

Release the mower deck locking pins on each side (Figure 8).

-

Using the deck-lift handle, lift the deck and latch it in the raised position (latch is located at front center of seat) as shown in Figure 9.

Warning

Engaging the PTO with a deck in the raised position can result in a serious injury or property damage.

Always lower and lock the mower deck in the operation position before engaging the PTO.

Lowering the Mower Deck to the Operating Position

-

While firmly holding onto deck-lift handle, unhook the mower-deck latch from the machine and slowly lower the mower deck to the ground (Figure 9).

-

Push the deck-locking pins inward and rotate them forward to securely lock the mower deck in the lowered position (Figure 8).

Warning

Operating the machine without the locking pins securely latched can result in the mower deck folding up unexpectedly, causing serious injury.

Always operate the machine with the locking pins securely latched.

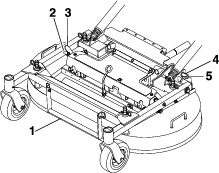

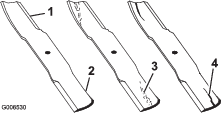

Adjusting the Fill Reduction System (FRS) Baffles

The fill reduction system has been designed to allow you to reduce the amount of clippings collected by varying degrees. The advantages include less frequent emptying of the hopper and the return of nutrients to the soil.

The following are possible configurations:

-

Baffles open with standard blades—maximum collection

-

Baffles closed with standard blades—partial mulching

-

Baffles closed with mulch blades—intermediate mulching

-

Mulch plug installed with mulch blades—complete mulching (requires mulch kit)

Adjust the FRS baffles as follows:

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

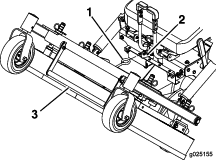

Loosen the bolts attached to the rubber guard (Figure 10).

-

Fold the guard forward.

-

Loosen the locknuts on the rear studs of the FRS baffles.

-

Raise the mower deck; refer to Raising the Mower Deck into the Service Position.

-

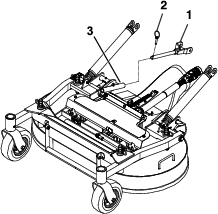

Remove the bolt and washer at the front of each FRS baffle (Figure 12).

-

Rotate the baffles into the desired position and install the bolt and washer.

-

Lower the mower deck; refer to Lowering the Mower Deck to the Operating Position.

-

Slightly tighten the locknuts on the rear studs of the FRS baffles.

Note: The locknuts on the rear studs may be left slightly loose if you anticipate adjusting the baffle frequently.

-

Install the rubber guard using the attached bolts.

Using the Safety-Interlock System

Warning

If the safety-interlock switches are disconnected or damaged, the machine could operate unexpectedly, causing personal injury.

-

Do not tamper with the interlock switches.

-

Check the operation of the interlock switches daily and replace any damaged switches before operating the machine.

Understanding the Safety-Interlock System

The safety-interlock system is designed to prevent the engine from starting unless:

-

The parking brake is engaged.

-

The PTO-engagement lever is disengaged.

-

The speed-control lever is in the NEUTRAL position

The safety-interlock system is designed to shut off the engine when you rise from the seat when the PTO is engaged.

The hour meter has indicators to notify the user when the interlock component is in the correct position. When the component is in the correct position, an indicator displays on the screen.

Testing the Safety-Interlock System

Test the safety-interlock system before you use the machine each time. If the safety system does not operate as described below, have an Authorized Service Dealer repair the safety system immediately.

-

Sit on the seat, engage the parking brake, move the PTO-engagement lever to the ON position, and move the speed-control lever to the NEUTRAL position. Try starting the engine; the engine should not start.

-

Sit on the seat, engage the parking brake, and move the PTO-engagement lever to the OFF position. Move the speed-control lever out of the NEUTRAL position. Try starting the engine; the engine should not start.

-

Sit on the seat, disengage the parking brake, move the PTO-engagement lever to the OFF position, and move the speed-control lever to the NEUTRAL position. Try starting the engine; the engine should not start.

-

Sit on the seat, engage the parking brake, move the PTO-engagement lever to the OFF position, and move the speed-control lever to the NEUTRAL position. Now start the engine. While the engine is running, release the parking brake, engage the PTO-engagement lever, and rise slightly from the seat; the engine should shut off.

-

Sit on the seat, engage the parking brake, move the PTO-engagement lever to the OFF position, and move the speed-control lever to the NEUTRAL position. Now start the engine. Move the speed-control lever forward; the engine should shut off.

Unlatching the Seat

To unlatch the seat, remove the bolt and the pin on the left side of the seat (Figure 14).

During Operation

During Operation Safety

General Safety

-

The owner/operator can prevent and is responsible for accidents that may cause personal injury or property damage.

-

Use your full attention while operating the machine. Do not engage in any activity that causes distractions; otherwise, injury or property damage may occur.

-

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs.

-

Contacting the blade can result in serious personal injury. Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. When you turn the key to the OFF position, the engine should shut off and the blade should stop. If not, stop using your machine immediately and contact an Authorized Service Dealer.

-

Operate the machine only in good visibility and appropriate weather conditions. Do not operate the machine when there is the risk of lightning.

-

Keep your hands and feet away from the cutting units. Keep clear of the discharge opening.

-

Do not mow with the discharge door raised, removed, or altered unless there is a grass-collection system or mulch kit in place and working properly.

-

Do not mow in reverse unless it is absolutely necessary. Always look down and behind you before moving the machine in reverse.

-

Use extreme care when approaching blind corners, shrubs, trees, or other objects that may block your view.

-

Stop the blades whenever you are not mowing.

-

If the machine strikes an object or starts to vibrate, immediately shut off the engine, remove the key (if equipped), and wait for all moving parts to stop before examining the machine for damage. Make all necessary repairs before resuming operation.

-

Slow down and use caution when making turns and crossing roads and sidewalks with the machine. Always yield the right-of-way.

-

Before you leave the operating position, do the following:

-

Park the machine on a level surface.

-

Disengage the power takeoff and lower the attachments.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for all moving parts to stop.

-

-

Operate the engine only in well-ventilated areas. Exhaust gases contain carbon monoxide, which is lethal if inhaled.

-

Never leave a running machine unattended.

-

Attach towed equipment to the machine only at the hitch point.

-

Do not operate the machine unless all guards and safety devices, such as the deflectors and the entire grass catcher, are in place and functioning properly. Replace worn or deteriorated parts when necessary.Do not operate the machine unless all guards and safety devices, such as the deflectors and the entire grass catcher, are in place and functioning properly. Replace worn or deteriorated parts when necessary.

-

Use only accessories and attachments approved by Toro.

-

This machine produces sound levels in excess of 85 dBA at the operator’s ear and can cause hearing loss through extended periods of exposure.

-

Clean grass and debris from the cutting unit, drives, muffler, and engine to help prevent fires.

-

Start the engine with your feet well away from the blades.

-

Never raise the mower deck while the blades are moving.

-

Be aware of the mower discharge path and direct the discharge away from others. Avoid discharging material against a wall or obstruction because the material may ricochet back toward you.

-

Stop the blades, slow down the machine, and use caution when crossing surfaces other than grass or when transporting the machine to and from the operating area.

-

Do not change the engine governor speed or overspeed the engine.

-

Children are often attracted to the machine and the mowing activity. Never assume that children will remain where you last saw them.

-

Keep children out of the operating area and under the watchful care of a responsible adult other than the operator.

-

Be alert and shut off the machine if children enter the operating area.

-

Before backing up or turning the machine, look down and all around for small children.

-

Do not carry children on the machine, even when the blades are not moving. Children could fall off and be seriously injured or prevent you from safely operating the machine. Children who have been given rides in the past could appear in the operating area without warning and be run over or backed over by the machine.

Rollover Protection System (ROPS) Safety

-

The ROPS is an integral safety device. Do not remove any of the ROPS components from the machine.

-

Ensure that the seat belt is attached and that you can release it quickly in an emergency.

-

Keep the roll bar in the fully raised and locked position and always wear your seat belt whenever the roll bar is up.

-

Check carefully for overhead objects before you drive under them, and do not contact them.

-

Replace damaged ROPS components. Do not repair or alter them.

-

There is no rollover protection when the roll bar is down.

-

Wheels dropping over edges, over steep banks, or into water can cause a rollover, which may result in serious injury or death.

-

Do not wear the seat belt when the roll bar is down.

-

Lower the roll bar only when absolutely necessary; raise it as soon as clearance permits.

-

In the event of a rollover, take the machine to an Authorized Service Dealer to inspect the ROPS.

-

Use only Toro approved accessories and attachments for the ROPS.

Slope Safety

-

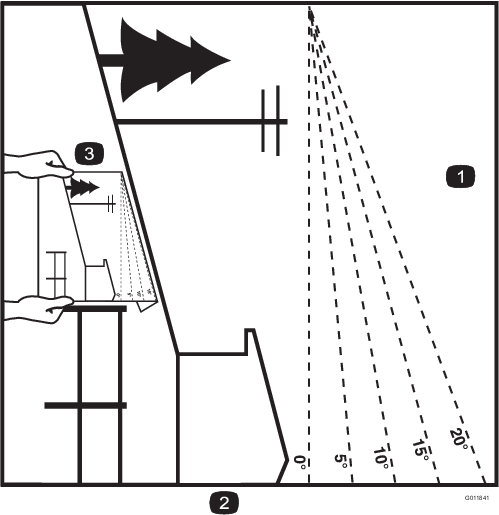

Slopes are a major factor related to loss of control and rollover accidents, which can result in severe injury or death. The operator is responsible for safe slope operation. Operating the machine on any slope requires extra caution. Before using the machine on a slope, do the following:

-

Review and understand the slope instructions in the manual and on the machine.

-

Use an angle indicator to determine the approximate slope angle of the area.

-

Never operate on slopes greater than 15°.

-

Evaluate the site conditions of the day to determine if the slope is safe for machine operation. Use common sense and good judgment when performing this evaluation. Changes in the terrain, such as moisture, can quickly affect the operation of the machine on a slope.

-

-

Identify hazards at the base of the slope. Do not operate the machine near drop-offs, ditches, embankments, water, or other hazards. The machine could suddenly roll over if a wheel goes over the edge or the edge collapses. Keep a safe distance (twice the width of the machine) between the machine and any hazard. Use a walk-behind machine or a hand trimmer to mow the grass in these areas.

-

Avoid starting, stopping, or turning the machine on slopes. Avoid making sudden changes in speed or direction; turn slowly and gradually.

-

Do not operate a machine under any conditions where traction, steering, or stability is in question. Be aware that operating the machine on wet grass, across slopes, or downhill may cause the machine to lose traction. Loss of traction to the drive wheels may result in sliding and a loss of braking and steering. The machine can slide even if the drive wheels are stopped.

-

Remove or mark obstacles such as ditches, holes, ruts, bumps, rocks, or other hidden hazards. Tall grass can hide obstacles. Uneven terrain could overturn the machine.

-

Use extra care while operating with accessories or attachments, such as grass-collection systems. These can change the stability of the machine and cause a loss of control. Follow directions for counterweights.

-

If possible, keep the deck lowered to the ground while operating on slopes. Raising the deck while operating on slopes can cause the machine to become unstable.

Operating the Parking Brake

Always engage the parking brake when you stop the machine or leave it unattended.

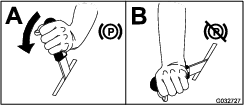

Engaging the Parking Brake

Park the machine on a level surface.

Disengaging the Parking Brake

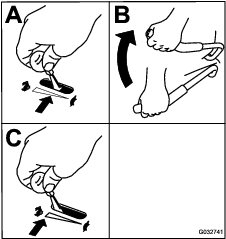

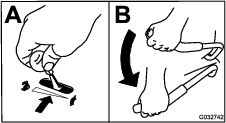

Operating the PTO-Engagement Lever

The PTO-engagement lever starts and stops the mower blades and blower.

Engaging the PTO-Engagement Lever

Disengaging the PTO-Engagement Lever

Operating the Throttle

You can move the throttle control between FAST and SLOW positions (Figure 21).

Always use the FAST position when engaging the PTO.

Operating the Choke

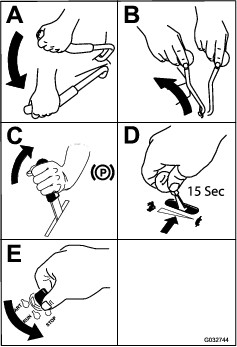

Starting the Engine

-

Move the speed-control lever to the NEUTRAL position.

-

Engage the parking brake; refer to Engaging the Parking Brake.

-

Move the PTO-engagement lever to the OFF position (Figure 23).

-

Move the throttle lever midway between the SLOW and FAST positions.

-

For EFI machines: Move the choke control to the CLOSED/ON position. On a warm engine, leave the choke in the OPEN/OFF position.

-

Turn the key to the START position (Figure 23). When the engine starts, release the key.

Important: Do not engage starter for more than 5 seconds at a time. If the engine fails to start, wait 15 seconds between attempts. Failure to follow these instructions can burn out the starter motor.

Note: You may need multiple attempts to start the engine the first time after adding fuel to an empty fuel system.

-

If the choke is in the CLOSED/ON position, gradually return choke to the OPEN/OFF position as the engine warms up.

Shutting Off the Engine

Caution

Children or bystanders may be injured if they move or attempt to operate the machine while it is unattended.

Always remove the key and engage the parking brake when leaving the machine unattended.

-

Disengage the PTO.

-

Move the speed-control lever to the NEUTRAL position.

-

Engage the parking brake.

-

Place the throttle in the middle position.

-

Let the engine idle for 15 seconds, then turn the key switch to the OFF position and remove the key.

Driving the Machine

The throttle control regulates the engine speed as measured in rpm (revolutions per minute). Place the throttle control in the FAST position for best performance. Always operate in the full throttle position when mowing.

Warning

The machine can spin very rapidly. You may lose control of the machine and cause personal injury or damage to the machine.

-

Use caution when making turns.

-

Slow the machine down before making sharp turns.

Driving Forward

Note: To begin movement (forward or backward), sit on the seat and disengage the parking-brake lever before you move the speed-control lever forward, otherwise the engine shuts off.

To stop the machine, pull the speed control lever to the NEUTRAL position.

-

Start the engine.

-

Disengage the parking brake; refer to Disengaging the Parking Brake.

-

To move forward in a straight line move the speed control lever forward.

Note: The machine moves faster the farther that you move the speed control lever away from the NEUTRAL position.

-

To turn left or right, pull 1 of the steering levers back toward neutral in the direction desired.

-

To stop the machine, pull the speed control lever back to the NEUTRAL position.

Driving Backward

-

To move rearward in a straight line, pull both steering levers rearward equally.

To turn left or right, release pressure on the steering lever toward the direction desired.

-

To stop the machine, release the steering levers to the neutral position.

Adjusting the Height of Cut

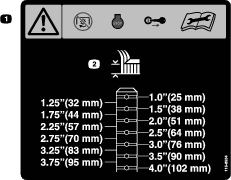

The cutting height of the mower deck is adjusted from 2.5 to 10.2 cm (1 to 4 inches) in 6.3 mm (1/4 inch) increments.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

While keeping the front frame down, lift the deck on 1 side so that the deck-support latch engages the fixed pin in the front frame (Figure 25).

-

Move the cotter pins on the deck-support pins to the proper hole for the desired height of cut.

-

Lift the deck enough to raise and release the deck-support latch and lower the deck.

-

Repeat this procedure on the other side of the mower deck.

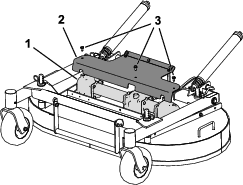

Emptying the Hopper

A full hopper is indicated by a buzzer located behind the seat, in the hopper. Empty the hopper when the buzzer sounds to prevent clogging of the blower or the mower deck.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Lift the rear door up and allow it to rest on top of the hopper.

-

Using the handles at the lower front of the hopper, raise the hopper to dump the contents.

-

Lower the hopper and close the hopper door.

Operating Tips

Using the Fast Throttle Setting

For best mowing and maximum air circulation, operate the engine at the FAST position. Air is required to thoroughly cut grass clippings, so do not set the height-of-cut so low as to totally surround the mower deck in uncut grass. Always try to have 1 side of the mower deck free from uncut grass, which allows air to be drawn into the mower deck.

Cutting a Lawn for the First Time

Cut grass slightly longer than normal to ensure that the cutting height of the mower deck does not scalp any uneven ground. However, the cutting height used in the past is generally the best one to use. When cutting grass longer than 15 cm (6 inches) tall, you may want to cut the lawn twice to ensure an acceptable quality of cut.

Cutting a Third of the Grass Blade

It is best to cut only about a third of the grass blade. Cutting more than that is not recommended unless grass is sparse, or it is late fall when grass grows more slowly.

Alternating the Mowing Direction

Alternate the mowing direction to keep the grass standing straight. This also helps disperse clippings, which enhances decomposition and fertilization.

Mowing at Correct Intervals

Grass grows at different rates at different times of the year. To maintain the same cutting height, mow more often in early spring. As the grass growth rate slows in mid summer, mow less frequently. If you cannot mow for an extended period, first mow at a high cutting height, then mow again 2 days later at a lower height setting.

Using a Slower Cutting Speed

To improve cut quality, use a slower ground speed in certain conditions.

Avoiding Cutting Too Low

When mowing uneven turf, raise the cutting height to avoid scalping the turf.

Stopping the Machine

If you must stop the forward motion of the machine while mowing, a clump of grass clippings may drop onto your lawn. To avoid this, move onto a previously cut area with the blades engaged or you can disengage the mower deck while moving forward.

Keeping the Underside of the Mower Deck Clean

Clean clippings and dirt from the underside of the mower deck after each use. If grass and dirt build up inside the mower deck, cutting quality will eventually become unsatisfactory.

Maintaining the Blade(s)

Maintain a sharp blade throughout the cutting season because a sharp blade cuts cleanly without tearing or shredding the grass blades. Tearing and shredding turns grass brown at the edges, which slows growth and increases the chance of disease. Check the mower blades after each use for sharpness, and for any wear or damage. File down any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade.

After Operation

After Operation Safety

General Safety

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operator’s position. Allow the machine to cool before servicing, adjusting, fueling, cleaning, or storing it.

-

Clean grass and debris from the cutting unit, muffler, drives, grass catcher, and engine compartment to help prevent fires. Clean up oil or fuel spills.

-

Shut off the fuel and remove the key before storing or transporting the machine.

Clearing the Hopper Screen

Remove the screen by firmly lifting the screen handles (Figure 26).

Pull the screen toward the back to remove it. As needed, gently tap the screen to remove debris.

Note: Excessive buildup on the screen can cause the blower to plug.

Note: In conditions where the screen clogs quickly, you can turn and install the front removable screen panel under the primary screen to allow free air flow from the hopper.

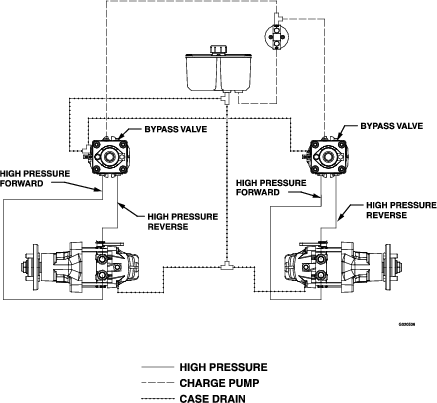

Using the Drive-Wheel Release Valves

Warning

Hands may become entangled in the rotating drive components below the engine deck, which could result in serious injury.

Shut off the engine, remove the key, and allow all moving parts to stop before accessing the drive-wheel-release valves.

Warning

The engine and hydraulic-drive units can become very hot. Touching a hot engine or hydraulic-drive units can cause severe burns.

Allow the engine and hydraulic-drive units to cool completely before accessing the drive-wheel-release valves.

The drive-wheel release valves are located on the top, left, front corner of the hydrostatic pumps.

-

Move the speed-control lever to the NEUTRAL position to stop the machine.

-

Disengage the PTO lever, engage the parking brake, shut off the engine, and wait for all moving parts to stop.

-

Tilt the seat up to gain access to the pumps.

-

Rotate both release valves 1 turn counterclockwise to release the drive system.

Note: This allows the hydraulic fluid to bypass the pump, enabling the wheels to turn.

-

Disengage the parking brake before pushing the machine.

Note: Do not tow the machine.

-

Rotate the valves clockwise to run the machine.

Note: Do not overtighten the valves.

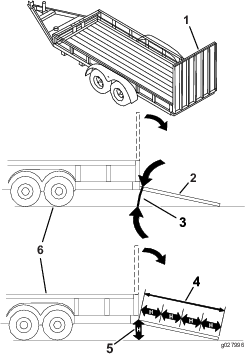

Transporting the Machine

Use a heavy-duty trailer or truck to transport the machine. Use a full-width ramp. Ensure that the trailer or truck has all the necessary brakes, lighting, and marking as required by law. Please carefully read all the safety instructions. Knowing this information could help you or bystanders avoid injury. Refer to your local ordinances for trailer and tie-down requirements.

Warning

Driving on the street or roadway without turn signals, lights, reflective markings, or a slow-moving-vehicle emblem is dangerous and can lead to accidents, causing personal injury.

Do not drive the machine on a public street or roadway.

Selecting a Trailer

Warning

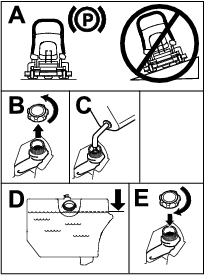

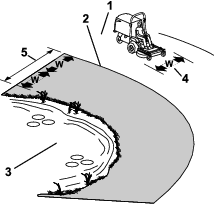

Loading a machine onto a trailer or truck increases the possibility of tip-over and could cause serious injury or death (Figure 27).

-

Use only a full-width ramp; do not use individual ramps for each side of the machine.

-

Do not exceed a 15-degree angle between the ramp and the ground or between the ramp and the trailer or truck.

-

Ensure that the length of the ramp is at least 4 times as long as the height of the trailer or truck bed to the ground. This ensures that the ramp angle does not exceed 15 degrees on flat ground.

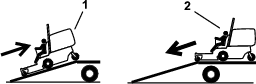

Loading the Machine

Warning

Loading a machine onto a trailer or truck increases the possibility of tip-over and could cause serious injury or death.

-

Use extreme caution when operating a machine on a ramp.

-

Back the machine up the ramp and drive it forward down the ramp.

-

Avoid sudden acceleration or deceleration while driving the machine on a ramp as this could cause a loss of control or a tip-over situation.

-

If using a trailer, connect it to the towing vehicle and connect the safety chains.

-

If applicable, connect the trailer brakes and lights.

-

Lower the ramp, ensuring that the angle between the ramp and the ground does not exceed 15 degrees (Figure 27).

-

Back the machine up the ramp (Figure 28).

-

Shut off the engine, remove the key, and engage the parking brake.

-

Securely fasten the machine to the trailer or truck with straps, chains, cable, or ropes down and outward from the machine. Refer to local regulations for tie-down requirements.

Maintenance

Maintenance Safety

-

If you leave the key in the switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the switch before you perform any maintenance.

-

Before you leave the operator’s position, do the following:

-

Park the machine on a level surface.

-

Disengage the drives.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Allow machine components to cool before performing maintenance.

-

-

Do not allow untrained personnel to service the machine.

-

Keep your hands and feet away from moving parts or hot surfaces. If possible, do not make adjustments with the engine running.

-

Carefully release pressure from components with stored energy.

-

Check the parking brake operation frequently. Adjust and service it as required.

-

Never tamper with safety devices. Check their proper operation regularly.

-

Clean grass and debris from the cutting unit, muffler, drives, grass catcher, and engine compartment to prevent fires.

-

Clean up oil or fuel spills and remove fuel-soaked debris.

-

Do not rely on hydraulic or mechanical jacks to support the machine; support the machine with jack stands whenever you raise the machine.

-

Keep all parts in good working condition and all hardware tightened, especially the blade-attachment hardware. Replace all worn or damaged decals.

-

Disconnect the battery before repairing the machine. Disconnect the negative terminal first and the positive last. Connect the positive terminal first and the negative last.

-

To ensure optimum performance, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

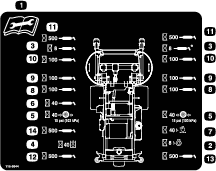

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| After the first 100 hours |

|

| Before each use or daily |

|

| Every 40 hours |

|

| Every 100 hours |

|

| Every 160 hours |

|

| Every 200 hours |

|

| Every 250 hours |

|

| Every 400 hours |

|

| Every 500 hours |

|

| Every 2,000 hours |

|

| Monthly |

|

| Yearly |

|

| Yearly or before storage |

|

Important: Refer to your engine owner's manual for additional maintenance procedures.

Caution

If you leave the key in the switch, someone could accidently start the engine and seriously injure you or other bystanders.

Shut off the engine and remove the key from the switch before you perform any maintenance.

Lubrication

Greasing the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 40 hours |

|

| Every 100 hours |

|

| Yearly |

|

Grease the machine more often in dirty or dusty conditions.

Grease Type: No. 2 lithium or molybdenum grease

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Clean the grease fittings with a rag.

Note: Scrape any paint off the front of the fitting(s).

-

Connect a grease gun to the fitting.

-

Pump grease into the fittings until grease begins to ooze out of the bearings.

-

Wipe up any excess grease.

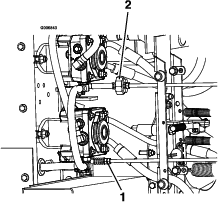

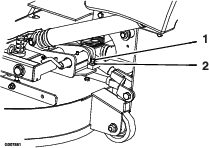

Greasing the Pump-Belt Idler Arm

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

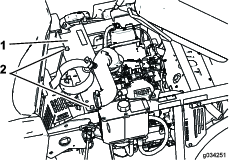

Raise up the hopper (Figure 30).

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

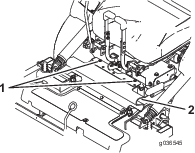

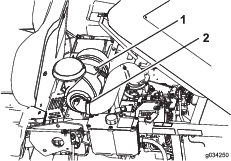

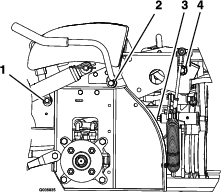

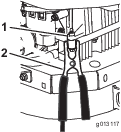

Loosen the bolt holding the air cleaner (Figure 31).

-

Loosen the clamp holding the hose and remove the air cleaner (Figure 31).

-

Remove the bolts and the plate below the air cleaner.

-

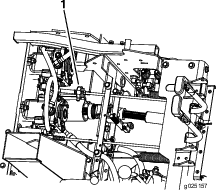

Lubricate the pump-belt idler arm (Figure 32).

-

Install the plate and the air cleaner.

Lubricating the Brake-Handle Pivot

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 160 hours |

|

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

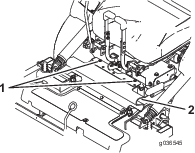

Lubricate the bronze bushings on the brake-handle pivot with a spray type lubricant or light oil (Figure 33).

Lubricating the Brake-Rod Bushings and Steering-Linkage Rod Ends

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 160 hours |

|

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Unlatch the seat latch and tilt the seat up; refer to Unlatching the Seat.

-

Lubricate the bronze bushings on each end of the brake rod shaft with a spray type lubricant or a light oil.

Note: The bushings are located to the inside of the flange bearings.

-

Lubricate each end of both steering linkage rods with a spray lubricant or a light oil.

Changing the Gearbox Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 50 hours |

|

| Every 100 hours |

|

| Every 2,000 hours |

|

-

Park the machine on a level surface, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

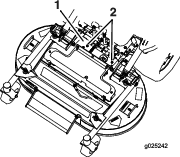

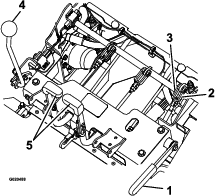

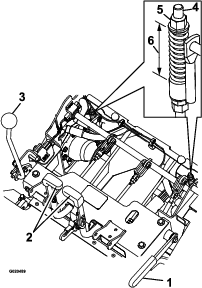

Remove the guard to access the gearbox (Figure 34)

-

Remove the blades that are attached to the gearbox; refer toRemoving the Blades.

-

Remove the gearbox and drive-shaft assembly from the mower deck. Retain the hardware for use later.

-

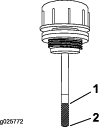

Remove the large oil drain plug on the front of each of the 3 gearbox sections and drain the oil (Figure 35).

-

Remove the small magnetic plugs and wipe away any material accumulated on the plugs.

-

Apply a Teflon® pipe sealant to all small magnetic plugs and install them into the gearbox.

-

Install the gearbox and drive-shaft assembly to the mower deck.

-

Fill the gearbox with Mobil® SHC (synthetic) 75W-90 gear lube oil until level with oil drain/fill plug.

Note: Each of the gearbox sections must be filled separately.

Note: Keep the mower deck level to the ground when filling the gearbox with oil. Do not fill the gearbox with the mower deck raised in the service position.

-

Apply a Teflon pipe sealant to the 3 large oil plugs and install them into the gearbox.

Greasing the Caster Pivots

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 400 hours |

|

| Yearly |

|

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the dust cap and adjust the caster pivots and keep the dust cap off until greasing is done; refer to Greasing the Caster-Wheel Hubs.

-

Remove the hex plug.

-

Thread a grease fitting into the hole.

-

Pump grease into the fitting until it oozes out around the top bearing.

-

Remove the grease fitting from the hole. Install the hex plug and cap.

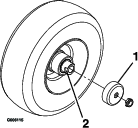

Greasing the Caster-Wheel Hubs

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Yearly |

|

-

Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Raise the mower for access.

-

Remove the caster wheel from the caster forks.

-

Remove the seal guards from the wheel hub.

-

Remove a spacer nut from the axle assembly in the caster wheel.

Note: Thread-locking compound has been applied to lock the spacer nuts to the axle.

-

Remove the axle (with the other spacer nut still assembled to it) from the wheel assembly.

-

Pry out seals and inspect bearings for wear or damage and replace if necessary.

-

Pack the bearings with a general-purpose grease.

-

Insert 1 bearing and 1 new seal into the wheel.

-

If the axle assembly is missing both spacer nuts, apply a thread-locking compound to 1 spacer nut and thread it onto the axle with the wrench flats facing outward.

Note: Do not thread the spacer nut all of the way onto the end of the axle. Leave approximately 3 mm (1/8 inch) from the outer surface of the spacer nut to the end of the axle inside the nut.

-

Insert the assembled nut and axle into the wheel on the side with the new seal and bearing.

-

With the open end of the wheel facing up, fill the area inside the wheel around the axle full of general-purpose grease.

-

Insert the second bearing and new seal into the wheel.

-

Apply a thread-locking compound to the second spacer nut, and thread it onto the axle with the wrench flats facing outward.

-

Torque the nut to 8 to 9 N∙m (75 to 80 in-lb), loosen the nut, then torque it to 2 to 3 N∙m (20 to 25 in-lb).

Note: Make sure that the axle does not extend beyond either nut.

-

Install the seal guards over the wheel hub, and insert the wheel into the caster fork.

-

Install the caster bolt and tighten the nut fully.

Important: To prevent seal and bearing damage, check the bearing adjustment often. Spin the caster tire. The tire should not spin freely (more than 1 or 2 revolutions) or have any side play. If the wheel spins freely, adjust the torque on the spacer nut until there is a slight amount of drag. Apply another layer of thread-locking compound.

Engine Maintenance

Engine Safety

-

Keep your hands, feet, face, clothing, and other body parts away from the muffler and other hot surfaces. Allow engine components to cool before performing maintenance.

-

Do not change the engine governor speed or overspeed the engine.

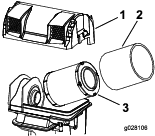

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 250 hours |

|

| Every 500 hours |

|

Note: Service the air cleaner more frequently if operating conditions are extremely dusty or sandy.

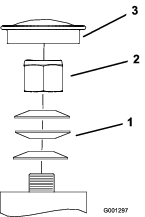

Removing the Filters

-

Park the machine on a level surface, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Release the latches on the air cleaner and pull the air-inlet cover off the air-cleaner body (Figure 37).

-

Clean the air-inlet screen and cover.

-

Install the air-inlet cover and secure it with the latches (Figure 37).

-

Release the latches on the air cleaner and pull the air-cleaner cover off the air-cleaner body (Figure 38).

-

Clean the inside of the air-cleaner cover with compressed air.

-

Gently slide the primary filter out of the air-cleaner body (Figure 38).

Note: Avoid knocking the filter into the side of the body.

-

Remove the inner filter only if you intend to replace it.

Important: Never attempt to clean the inner filter. If the safety filter is dirty, then the primary filter is damaged. Replace both filters.

-

Inspect the primary filter for damage by looking into the filter, while shining a bright light on the outside of the filter.

Note: Holes in the filter will appear as bright spots. If the filter is damaged, discard it.

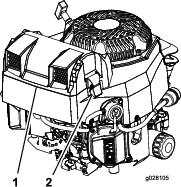

Servicing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 100 hours |

|

| Every 200 hours |

|

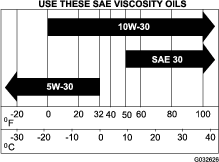

Engine Oil Specifications

Oil Capacity: with a filter change—1.8 L (61 fl oz); without a filter change—1.6 L (54 fl oz)

Viscosity: See the table below.

Checking the Engine-Oil Level

Note: Check the oil when the engine is cold.

Important: Do not overfill the crankcase with oil because damage to the engine may result. Do not run engine with oil below the low mark because the engine may be damaged.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

Note: Ensure that the engine is cool so that the oil has had time to drain into the sump.

-

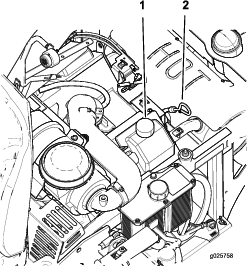

Raise the hopper

-

To keep dirt, grass clippings, etc., out of the engine, clean the area around the oil-fill cap and dipstick before removing it (Figure 40).

-

Remove the dipstick and wipe the oil off.

-

Insert the dipstick and push it all the way down into the tube.

-

Remove the dipstick and read the oil level.

-

If the oil level is low, wipe off the area around the oil-fill cap, remove cap and fill to the full mark on the dipstick (Figure 40).

Important: Do not operate the engine with the oil level below the low (or add) mark on the dipstick or over the full mark.

Changing the Engine Oil

Note: Dispose of the used oil at a recycling center.

-

Park the machine so that the rear is slightly lower than the front to ensure that the oil drains completely.

-

Move the speed-control lever to the NEUTRAL position to stop the machine.

-

Move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Slowly pour approximately 80% of the specified oil into the filler tube and slowly add the additional oil to bring it to the full mark on the dipstick (Figure 40).

-

Start the engine and drive to a flat area. Check the oil level again (Figure 40).

-

If needed, add oil to the full mark on the dipstick.

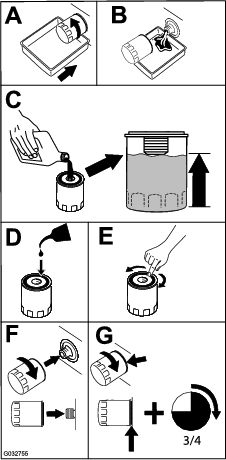

Changing the Engine-Oil Filter

-

Drain the oil from the engine; refer to Changing the Engine Oil.

-

Change the engine-oil filter (Figure 42).

Note: Ensure that the oil-filter gasket touches the engine, and then turn the oil filter an extra 3/4 turn.

-

Fill the crankcase with the proper type of new oil; refer to Engine Oil Specifications.

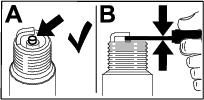

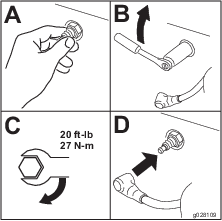

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

| Every 500 hours |

|

Type: Champion XC12YC

Air Gap: 0.76 mm (0.03 inch)

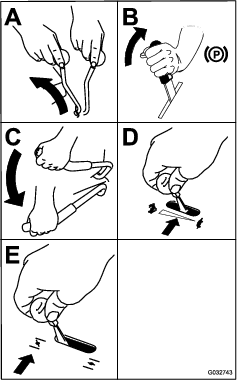

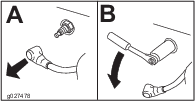

Removing the Spark Plug

-

Park the machine on a level surface, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Clean the area around the base of the plug(s) to keep dirt and debris out of the engine.

-

Locate and remove the spark plug(s) as shown in Figure 43.

Checking the Spark Plug

Important: Do not clean the spark plug(s). Always replace the spark plug(s) when it has a black coating, worn electrodes, an oily film, or cracks.

If you see light brown or gray on the insulator, the engine is operating properly. A black coating on the insulator usually means the air cleaner is dirty.

Set the gap to 0.76 mm (0.03 inch).

Installing the Spark Plug

Fuel System Maintenance

Danger

In certain conditions, fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property.

Refer to Fuel Safety for a complete list of fuel related precautions.

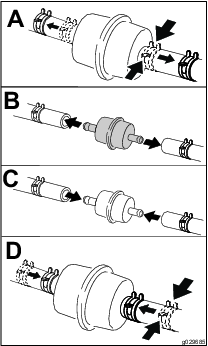

Replacing the Fuel Filter

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 200 hours |

|

The fuel filter is located near the engine on the front or rear side of the engine.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Allow the machine to cool down.

-

Clamp the hose on the fuel tank side of the fuel filter.

-

Replace the fuel filter (Figure 46).

Note: Ensure that the markings on the filter follow the fuel flow direction.

Note: Install the fuel-line hoses and secure them with plastic ties the same as they were originally installed at the factory to keep the fuel line away from components that could cause fuel line damage.

Servicing the Fuel Tank

Do not attempt to drain the fuel tank. Ensure that an Authorized Service Dealer drains the fuel tank and services any components of the fuel system.

Electrical System Maintenance

Electrical System Safety

-

Disconnect the battery before repairing the machine. Disconnect the negative terminal first and the positive last. Connect the positive terminal first and the negative last.

-

Charge the battery in an open, well-ventilated area, away from sparks and flames. Unplug the charger before connecting or disconnecting the battery. Wear protective clothing and use insulated tools.

Servicing the Battery

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Monthly |

|

Danger

Battery electrolyte contains sulfuric acid which is fatal if consumed and causes severe burns.

Do not drink electrolyte and avoid contact with skin, eyes or clothing. Wear safety glasses to shield your eyes and rubber gloves to protect your hands.

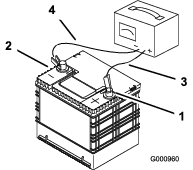

Removing the Battery

Warning

Incorrectly removing the cables from battery could damage the machine and cables, causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

Always disconnect the negative (black) battery cable before disconnecting the positive (red) cable.

-

Always connect the positive (red) battery cable before connecting the negative (black) cable.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Disconnect the negative battery cable (black) from the negative (-) battery terminal (Figure 47).

-

Slide the red terminal boot off the positive (red) battery terminal and remove the positive (+) battery cable (Figure 47).

-

Remove the wing nuts securing the J-hooks (Figure 47).

-

Remove the clamp (Figure 47).

-

Remove the battery.

Charging the Battery

Warning

Charging the battery produces gasses that can explode.

Never smoke near the battery and keep sparks and flames away from the battery.

Important: Always keep the battery fully charged (1.265 specific gravity). This is especially important to prevent battery damage when the temperature is below 0°C (32°F).

-

Remove the battery from the chassis; refer to Removing the Battery.

-

Charge the battery for 10 to 15 minutes at 25 to 30 A or for 30 minutes at 10 A.

Note: Do not overcharge the battery.

-

When the battery is fully charged, unplug the charger from the electrical outlet, then disconnect the charger leads from the battery posts (Figure 48).

-

Install the battery in the machine and connect the battery cables; refer to Installing the Battery.

Note: Do not run the machine with the battery disconnected; electrical damage may occur.

Installing the Battery

-

Position the battery in the tray with the terminal posts opposite from the hydraulic tank (Figure 47).

-

Install the positive (red) battery cable to the positive (+) battery terminal.

-

Install the negative (black) battery cable and ground wire to the negative (-) battery terminal.

-

Secure the cables with 2 bolts, 2 washers, and 2 locknuts (Figure 47).

-

Slide the red terminal boot onto the positive (red) battery post.

-

Install the clamp and secure it with the wing nuts and J-hooks (Figure 47).

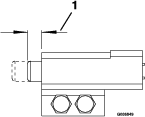

Adjusting the Safety Switches

Adjust all safety switches so that the plunger extends 4.8 mm to 6.4 mm (3/16 inch to 1/4 inch) from the switch body when the plunger is compressed (Figure 49).

Servicing the Fuses

The electrical system is protected by fuses. It requires no maintenance; however, if a fuse blows check the component/circuit for a malfunction or short.

-

The fuses are located on right side behind the seat.

-

To replace the fuses, pull out on the fuse to remove it.

-

Install a new fuse.

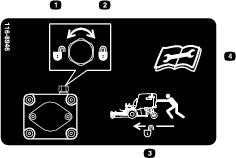

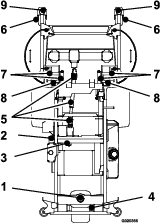

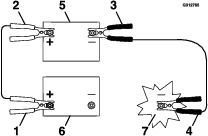

Jump-Starting the Machine

-

Check and clean corrosion from the battery terminals before jump-starting. Ensure that the connections are tight.

Caution

Corrosion or loose connections can cause unwanted electrical voltage spikes at any time during the jump-starting procedure.

Do not attempt to jump-start the machine with loose or corroded battery terminals, or damage to the engine or EFI may occur.

Danger

Jump-starting a weak battery that is cracked or frozen or has a low electrolyte level or an open/shorted battery cell can cause an explosion, resulting in serious personal injury.

Do not jump-start a weak battery if these conditions exist.

-

Make sure that the booster battery is a good and fully charged lead-acid battery at 12.6 V or greater.

Note: Use properly sized jumper cables with short lengths to reduce voltage drop between systems. Make sure that the cables are color coded or labeled for the correct polarity.

Caution

Connecting the jumper cables incorrectly (wrong polarity) can immediately damage the EFI system.

Be certain of battery-terminal polarity and jumper-cable polarity when hooking up the batteries.

Warning

Batteries contain acid and produce explosive gases.

-

Shield your eyes and face from the batteries at all times.

-

Do not lean over the batteries.

Note: Ensure that the vent caps are tight and level. Place a damp cloth, if available, over any vent caps on both batteries. Also ensure that the machines do not touch and that both electrical systems are off and at the same rated system voltage. These instructions are for negative ground systems only.

-

-

Connect the positive (+) cable to the positive (+) terminal of the discharged battery that is wired to the starter or solenoid as shown in Figure 50.

-

Connect the other end of the positive cable to the positive terminal of the booster battery.

-

Connect the black negative (–) cable to the other terminal (negative) of the booster battery.

-

Make the final connection on the engine block of the stalled machine (not to the negative battery post), away from the battery, and stand back (Figure 51).

-

Start the machine and remove the cables in the reverse order of connection (disconnect the negative cable from the engine block first).

Drive System Maintenance

Adjusting the Tracking

Note: The tracking knob is located under the seat.

Note: Rotating this knob allows fine tuning adjustments so that the machine tracks straight with the drive levers in the full forward position.

-

Run the machine at 3/4 speed for at least 5 minutes to bring hydraulic fluid up to operating temperature.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Tilt the seat forward to gain access to the tracking knob.

-

Rotate the knob toward the right to steer right and rotate it toward the left to steer left.

-

Adjust in 1/8 turn increments until the machine tracks straight.

-

Check and ensure that the machine does not creep when in neutral with the parking brakes disengaged (Figure 52).

Checking the Tire Pressure

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 40 hours |

|

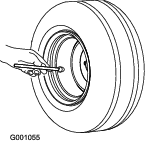

Maintain the air pressure in the rear tires at 103 kPa (15 psi). Uneven tire pressure can cause uneven cut. Check the tires when they are cold, to get the most accurate pressure reading.

Note: The front tires are semi-pneumatic tires and does not require air pressure maintenance.

Note: Do not add any type of tire liner or foam fill material to the tires.

Checking the Wheel Lug Nuts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 500 hours |

|

Check and torque the wheel lug nuts to 122 to 129 N∙m (90 to 95 ft-lb).

Checking the Wheel-Hub Slotted Nuts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 500 hours |

|

Check and ensure that the torque of the slotted nut is 373 to 475 N∙m (275 to 350 ft-lb).

Adjusting the Caster-Pivot Bearings

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 500 hours |

|

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

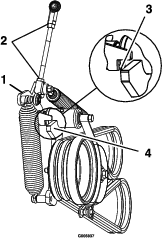

Remove the dust cap from the caster and tighten the locknut until the spring washers are flat, then back off 1/4 turn to properly set the pre-load on the bearings (Figure 54 and Figure 55).

Important: Make sure that the spring washers are installed correctly as shown in Figure 54 and Figure 55.

-

Install the dust cap.

Cooling System Maintenance

Cooling System Safety

-

Swallowing engine coolant can cause poisoning; keep out of reach from children and pets.

-

Discharge of hot, pressurized coolant or touching a hot radiator and surrounding parts can cause severe burns.

-

Always allow the engine to cool at least 15 minutes before removing the radiator cap.

-

Use a rag when opening the radiator cap, and open the cap slowly to allow steam to escape.

-

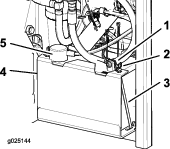

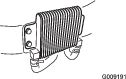

Cleaning the Engine Screen and Engine-Oil Cooler

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Remove any buildup of grass, dirt, or other debris from the oil cooler and the engine screen (Figure 56).

Remove any buildup of grass, dirt, or other debris from the engine screen. This helps ensure adequate cooling and correct engine speed and reduces the possibility of overheating and mechanical damage to the engine (Figure 56).

Servicing the Engine-Oil Cooler

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the fuel-tank mounting nuts and swing out the fuel tank.

-

Keep the oil-cooler free of debris by cleaning the fins with a brush.

-

Swing the fuel tank in and secure it with the mounting nuts.

-

Back the mounting nuts off 1/2 turn to allow for tank expansion.

Cleaning the Engine Cooling Fins and Shrouds

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the air-intake screen and fan housing.

-

Clean the debris and grass from the engine parts.

-

Install air-intake screen and fan housing.

Brake Maintenance

Adjusting the Parking Brake

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 100 hours |

|

| Every 500 hours |

|

Make sure that the brake is adjusted properly. Follow this procedure when you remove or replace a brake component.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Release the parking brake.

-

Tilt the seat forward.

-

Check and ensure that there is no slack between the parking-brake handle and the linkage.

-

If an adjustment is necessary, remove the clevis pin and rotate the linkage counterclockwise to lengthen it or clockwise to shorten it.

-

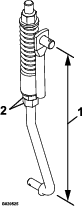

Measure the compressed spring length on both vertical spring assemblies.

Note: The spring should measure between 6 to 7 cm (2.35 to 2.85 inches). If necessary, adjust the nut at the top of the vertical spring assembly to achieve this distance.

-

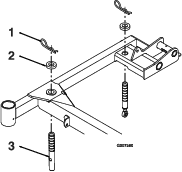

Adjust the linkage length with the 2 nuts at the bottom of the vertical spring assembly (Figure 59).

Note: The linkage should measure 22.7 to 23.3 cm (8.92 to 9.16 inches).

-

Engage and disengage the brakes to check for proper engagement and disengagement. Adjust if necessary.

Note: When the brakes are disengaged, there should be little to no free play in the brake linkage with no dragging in the brakes.

Belt Maintenance

Inspecting the Belts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 40 hours |

|

Replace the belt if it is worn. The signs of a worn belt include squealing while the belt is rotating; the blades slipping while cutting grass; and frayed edges, burn marks, and cracks on the belt.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

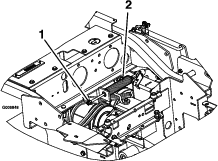

Tilt the hopper up and check the pump and PTO drive belts for wear, cracking, or contamination.

Note: The belts are spring tensioned and no adjustment is necessary unless the belts are replaced.

Replacing the PTO Belts

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

With the engine off, engage the PTO lever, then remove the hairpin cotter and clevis pin at the bottom of the PTO-brake band.

-

Rotate the brake band upward and out of the way of the belts keeping clear of the belt drive.

-

Disengage the PTO lever.

-

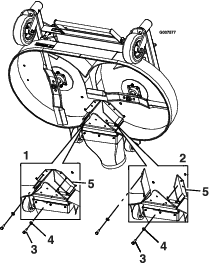

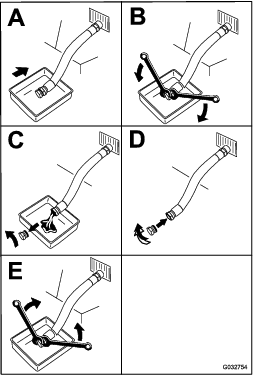

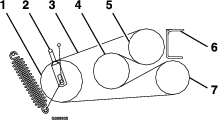

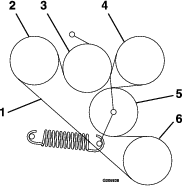

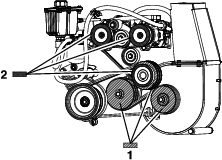

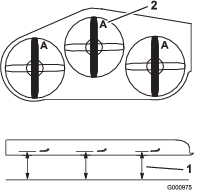

Loosen belt guides A and B (Figure 60).

-

Remove the belts.

-

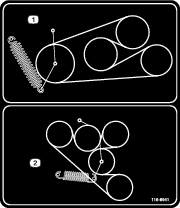

Route the new belts onto the pulleys as shown in Figure 60.

-

Engage the PTO lever.

-

Rotate the brake band down into the original position.

-

Install the clevis pin and hairpin cotter to secure the brake band.

-

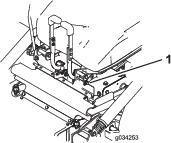

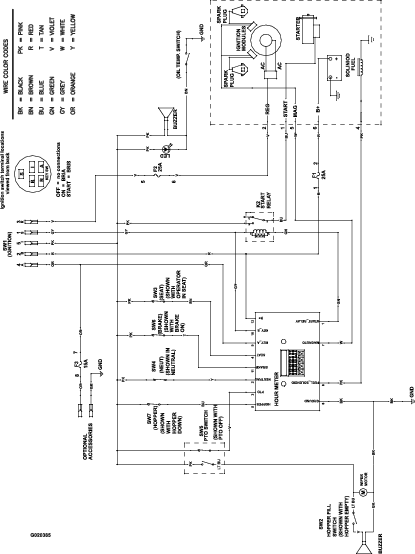

Loosen the jam nuts and adjust the linkage until the top of the idler arm is aligned with the bottom of the notch on the tension arm as shown in Figure 61.

-

Tighten the jam nuts and disengage the PTO lever.

-

Engage the PTO lever and check the alignment.

-

Check and adjust the belt guides as stated in Adjusting the Belt Guides.

Replacing the Pump-Drive Belt

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Remove the PTO Belts; refer to Replacing the PTO Belts.

-

Pull the spring idler or remove the spring to relieve the tension of the pump-drive belt.

-

Remove the old belt.

-

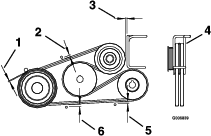

Route the new belt onto the sheaves as shown in the decal located on the back of the left drive shield (Figure 62).

-

Install the PTO belts; refer to Replacing the PTO Belts.

Adjusting the Belt Guides

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the PTO, and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

With the engine off, engage the PTO lever.

-

Adjust the belt guides as shown in Figure 63.

Controls System Maintenance

Adjusting the Reverse-Stop Rod

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

Check the movement of the steering levers as follows:

-

If the levers move slightly forward up to 3 mm (1/8 inch) then no adjustment is necessary.

-

If the levers do not move, then proceed with the following steps:

-

Flip the seat up or remove the seat-frame assembly (with the seat attached) to obtain a clear view of the steering-control shaft to complete this adjustment.

-

Place the speed-control lever in the NEUTRAL position.

-

Release the parking brake.

-

Slightly adjust the length of the rod by loosening the jam nut and by rotating the rod.

-

Engage the parking brake and check the steering levers.

-

Repeat steps 3 through 5 until you achieve up to 3 mm (1/8 inch) movement.

-

Install the seat frame assembly, if removed in step 1.

-

-

Adjusting the Speed-Control Lever Tension

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the blade-control switch (PTO), and engage the parking brake.

-

Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

-

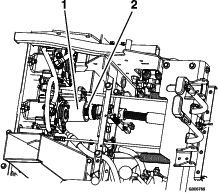

Adjust the pivot nut, which is located at the end of the motion-control shaft in front of the right console (Figure 65).

Note: Set the tension high enough that the speed-control lever position is maintained during operation and loose enough to be moved comfortably.

Adjusting the Speed-Control Linkage

Warning

The engine must be running and the drive wheels must be turning to adjust the motion controls. Contact with moving parts or hot surfaces may cause personal injury.

Keep your fingers, hands, and clothing clear of rotating components and hot surfaces.

Caution

Raising the mower deck for service or maintenance relying solely on mechanical or hydraulic jacks could be dangerous. The mechanical or hydraulic jacks may not be enough support or may malfunction allowing the unit to fall, which could cause injury.

Do not rely solely on mechanical or hydraulic jacks for support. Use adequate jack stands or equivalent support.

-

Park the machine on a level surface, move the speed-control lever to the NEUTRAL position, disengage the blade-control switch (PTO), and engage the parking brake.

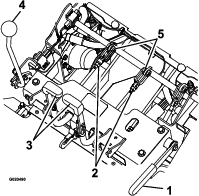

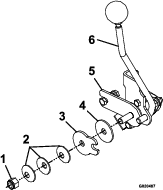

-