Maintenance

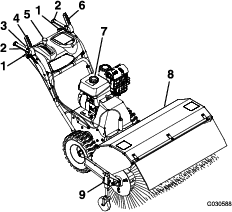

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| After the first 5 hours |

|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Every 300 hours |

|

| Yearly |

|

| Yearly or before storage |

|

Important: You can find more information about maintaining and servicing your machine at www.Toro.com.

Important: Refer to your engine operator's manual for additional maintenance procedures. For engine adjustments, repairs, or warranty service not covered in this manual, contact the authorized engine service dealer.

Preparing for Maintenance

-

Move the machine to a level surface.

-

Shut off the engine and allow it to cool.

-

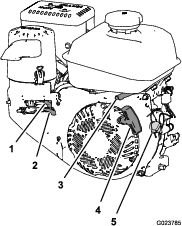

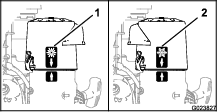

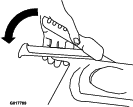

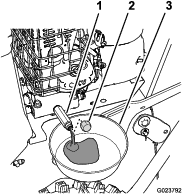

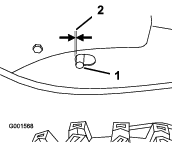

Disconnect the spark-plug wire from the spark plug and keep the wire away from the plug, to prevent accidental starting (Figure 19).

Lubrication

Lubricating the Broom-Angle-Lock Pin and the Hex Shaft

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Yearly |

|

-

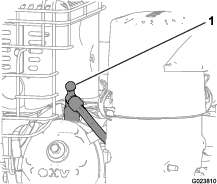

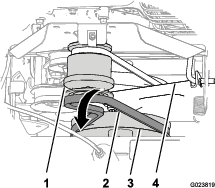

Lubricate the broom-angle-lock pin fitting with No. 2 lithium grease (Figure 20).

-

Remove the belt cover and the engine shield.

-

Move the speed-selector lever to the R2 position.

-

Dip a long, clean, small-tipped paint brush in automotive engine oil and lightly lubricate the hex shaft (Figure 21).

Important: Do not get oil on the rubber wheel or the aluminum friction-drive plate as the traction drive will slip (Figure 21).

Note: Rock the machine forward and rearward to rotate the hex shaft.

-

Move the speed selector lever to position 6.

-

Lubricate the other end of the hex shaft.

-

Move the speed selector lever forward and rearward a few times.

-

Install the belt cover and the engine shield.

Engine Maintenance

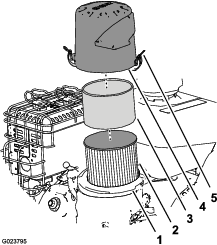

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

| Every 200 hours |

|

| Every 300 hours |

|

Important: Do not operate the engine without the air filter assembly; extreme engine damage may occur.

-

Release the latches on the cover for the air cleaner.

-

Remove the cover and clean it thoroughly ().

Note: Be careful to prevent dirt and debris from falling into the base.

-

Remove the foam pre-cleaner, wash it with a mild detergent and water, and then blot it dry (Figure 22).

-

Remove and inspect the paper air filter (); discard it if it is excessively dirty.

Important: Do not try to clean a paper filter.

-

Wipe dirt away from the base and the cover with a moist rag.

Note: Be careful to prevent dirt and debris from entering the air duct leading to the carburetor.

-

Install the foam pre-cleaner onto the paper air filter (Figure 22).

Note: Use a new paper air filter if you discarded the old one.

-

Install the air filter assembly to the air-filter base (Figure 22).

-

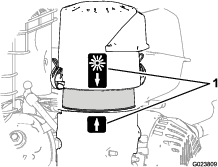

Align the arrow decal on the air-cleaner cover and the arrow decal on the base (Figure 23).

-

Secure the air-filter cover to the base with the latches.

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

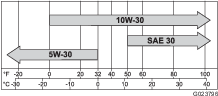

Engine Oil Type: Toro 4-Cycle Premium Engine Oil

Use high-quality detergent oils (including synthetic) of API (American Petroleum Institute) service class SJ or higher. Select the viscosity based on the air temperature at time of operation as shown in the table below.

Check the oil level when the engine is cold.

-

Clean the area around the dipstick.

-

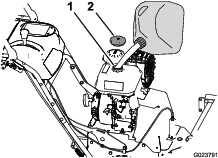

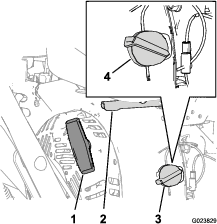

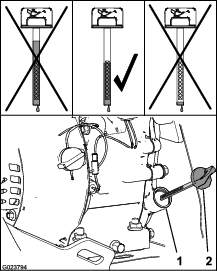

Remove the dipstick and read the oil level (Figure 25).

-

Remove the dipstick and wipe off the oil with a clean rag.

-

Insert the dipstick into the filler neck, rest it on the oil filler neck, and turn it counterclockwise until the cap drops down to lowest point of the thread leads.

Note: Do not thread the cap onto the tube.

-

Remove dipstick and check oil level.

Note: Do not operate the engine with the oil level below the Add mark or above the Full mark on the dipstick.

Note: The oil level should be at top of the indicator on the dipstick (Figure 25).

-

If the oil level is low, perform the following:

-

Pour the specified oil into the filler neck (Figure 25).

Note: Do not overfill the engine with oil.

-

Repeat steps 3 through 5.

-

-

If the oil level is high, preform the following:

-

Remove the cap from the drain fitting.

-

Drain the oil until the oil level is at the top of the indicator on dipstick; refer to steps 1 of Changing the Engine Oil.

-

Install the cap onto the drain fitting; refer to step 2 of Changing the Engine Oil.

-

-

-

Insert the dipstick into the filler neck and tighten the dipstick by hand.

Changing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 100 hours |

|

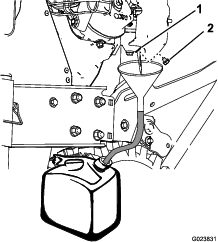

Oil capacity: 0.60 L (0.63 qt)

Note: Drain the engine oil while the engine is warm.

-

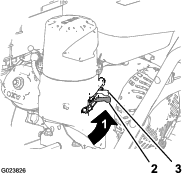

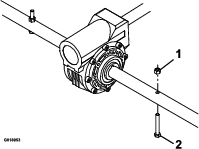

Place a pan under drain fitting and remove the oil-drain cap (Figure 26).

-

Allow the oil to drain and then install the oil-drain cap.

-

Clean around the filler neck and remove the dipstick.

-

Fill to the specified capacity with the specified oil and replace the dipstick; refer to Checking the Engine-Oil Level.

Note: Do not overfill the engine with oil.

-

Wipe up any spilled oil.

-

Start the engine and check for leaks.

-

Shut off the engine and check the oil level; refer to Checking the Engine-Oil Level.

Checking the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

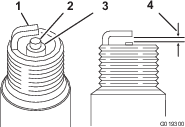

Spark plug type: Champion® RC12YC, Kohler® 12 132 02-S, or Koher 25 132 14-S (RFI compliant)

Spark-plug gap: 0.76 mm (0.030 inch)

-

Disconnect the spark-plug wire from the terminal of the spark plug (Figure 19).

-

Clean the area around the base of the spark plug.

-

Remove the spark plug from the cylinder head by rotating the plug counterclockwise.

-

Examine the plug for wear and damage (Figure 27).

Important: Replace a cracked, fouled, or dirty spark plug. Do not clean the electrodes, because grit entering the cylinder can damage the engine.

-

Check the spark-plug gap with a wire gauge (Figure 27).

Note: If necessary, adjust the gap to 0.76 mm (0.030 inch) by carefully bending the ground electrode.

-

Install the spark plug by threading it into the cylinder head and torquing the plug to 20 N∙m (14 lb-ft).

-

Connect the spark-plug wire to the terminal of the spark plug.

Fuel System Maintenance

Draining the Fuel System

-

Locate the drain bolt that is in the side port of the carburetor bowl (Figure 28).

-

Align the equipment that you will use to collect the fuel beneath the drain screw.

-

Remove the drain screw from the carburetor and allow the fuel to drain from the fuel tank and the carburetor.

Note: Do not remove the bowl-retaining screw from carburetor.

-

Install the drain bolt into the side port of the carburetor.

Drive System Maintenance

Checking the Tire Pressure

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

Shut off the engine, wait for all moving parts to stop, and leave engine switch in the OFF position.

-

Check the tire pressure in the drive tires.

-

Inflate the drive tires to 117 to 138 kPa (17 to 20 psi).

Checking the Traction Cable

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

-

Shut off the engine, wait for all moving parts to stop, and disconnect the spark-plug wire.

-

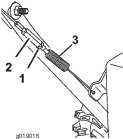

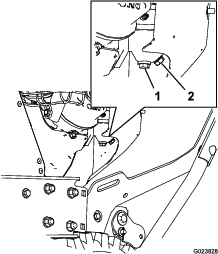

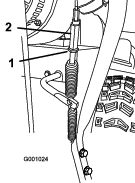

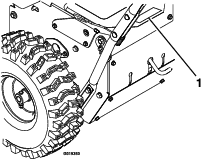

With the traction lever disengaged, check the pin in the elongated slot in the left side of the machine above the tire (Figure 30).

Note: There should be a gap of 6 mm (1/4 inch) from the front of the slot to the front edge of the pin (Figure 30).

Note: If adjustment is necessary, refer to (Figure 30).

Adjusting the Traction Cable

If the machine does not drive in the forward or reverse speeds or it drives when you release the traction lever, adjust the traction cable.

With the traction lever disengaged, check the pin in the elongated slot in the left side of the machine above the tire. There should be a gap of 6 mm (1/4 inch) from the front of the slot to the front edge of the pin; refer to Checking the Traction Cable.

If the left hand traction cable is not properly adjusted, do the following steps:

Adjusting the Wheel-Clutch Cable

-

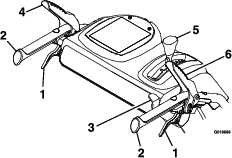

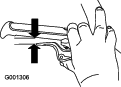

Squeeze the lever fully, then check the gap between the bottom of the handle and the wheel-clutch lever end (Figure 32).

Note: The gap should be approximately the thickness of a pencil (6 mm or 1/4 inch). If it is greater, loosen the cable clamp nut, slide the cable jacket up slightly, tighten the cable clamp nut, and check the gap again.

-

Repeat for the other cable (Figure 32).

Broom Maintenance

Checking the Broom-Shaft Shear Pin

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Move the machine to a level surface.

-

Shut off the engine, wait for all moving parts to stop, and disconnect the spark-plug wire.

-

Check the shear pin located on the broom shaft on either side of the gearbox.

-

If the shear pin is damaged, remove the pin, replace it, and secure the it with a nut.

Replacing Worn or Damaged Broom Segments

Service Interval: As required.

-

Raise the broom by setting the caster positions.

-

On both sides of the unit, remove and retain the carriage bolts, washers, and locknuts that secure the end bearings to the broom support.

-

Manually pull the power unit rearward to remove the broom assembly from the unit.

-

Support the spline shaft on either side of the gearbox.

-

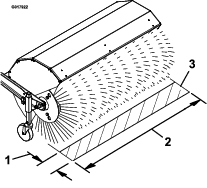

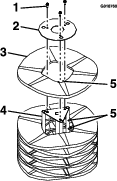

Stand the broom core assembly on end so that the removable end retainer plate faces upward (Figure 35).

-

Remove and retain the hardware from the end-retainer plate (Figure 35).

-

Remove the damaged broom segment(s).

-

Install the new segment(s) by staggering the metal ring alignment fingers as shown in Figure 35.

Important: You may damage the broom assembly if you do not properly install the broom segments.

-

Install the broom assembly onto the unit.

Important: Make sure that the bearing setscrews are tightened before operating the broom.

Checking the Broom Cable

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 2 hours |

|

| Yearly |

|

-

Shut off the engine, wait for all moving parts to stop, and disconnect the spark-plug wire.

-

Remove the belt cover and engine shield.

-

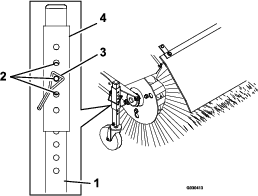

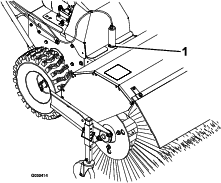

With the broom lever disengaged, ensure the gap between the broom-clutch assembly and the tab is 3 mm (1/8 inch).

Note: If the broom is not properly adjusted, refer to Adjusting the Broom Drive.

Adjusting the Broom Drive

If the broom cable is not properly adjusted; refer to Checking the Broom Cable, and then perform the following steps:

-

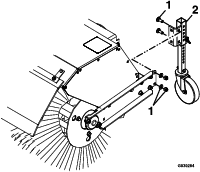

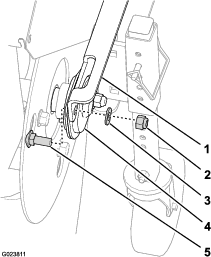

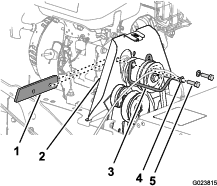

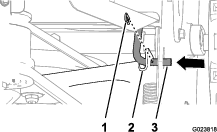

Loosen the jam nut (Figure 37).

-

Loosen or tighten the turnbuckle that adjusts the tension on the cable (Figure 37).

-

Adjust the turnbuckle until the gap between the broom clutch assembly and the tab is 3 mm (1/8 inch) (Figure 36).

-

Tighten the jam nut.

-

If the broom cable is properly adjusted but a problem remains, contact your Authorized Toro Service Dealer.

Maintaining the Belts

Checking the Condition of the Belts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

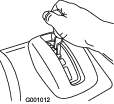

Remove the knob and washer that secures the engine cover and the belt cover to machine (Figure 38).

-

Check the 2 belts for damage or wear.

Note: Replace any damaged or excessively worn belt(s).

-

Align the belt cover and the engine cover to the machine and the plate nut (Figure 38).

-

Secure the belt cover and the engine cover to the machine with the knob and washer (Figure 38).

Removing the Broom-Drive Belt

-

Remove the engine cover and the belt cover from the machine; refer to step 1 of Checking the Condition of the Belts.

-

Remove the 2 bolts and 2 washers that secure the belt guide to the machine, and remove the belt guide and the spacer (Figure 39).

Note: The spacer is located between the engine and the pulley shield.

-

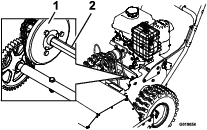

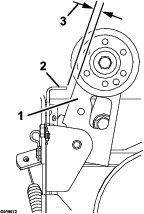

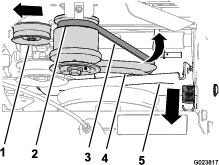

Slip the belt forward over the forward groove of the engine pulley (Figure 40).

-

Slip the belt off of the broom-gearbox pulley, move the belt rearward between the pulley and the traction-control bracket, and remove the belt from the machine (Figure 40).

Installing the Broom-Drive Belt

-

Align the replacement belt between the pulley and the traction-control bracket (Figure 40).

-

Slip the belt onto the groove at the bottom of the broom-gearbox pulley (Figure 40).

-

Slip the belt onto the forward groove of the engine pulley (Figure 40).

Note: Ensure that the belt is not twisted.

-

Align the spacer between the engine and the pulley shined and align the holes in the spacer, engine, and shield (Figure 39).

-

Secure the pulley guide to the machine with the bolts and washers (Figure 39) that you removed in step 2 of Removing the Broom-Drive Belt.

Removing the Traction Belt

-

Remove the broom-drive belt; refer to Removing the Broom-Drive Belt.

-

Remove the hairpin from the traction-control rod (Figure 41).

-

Remove traction-control rod from the traction-control bracket by moving the rod inward (Figure 41).

-

Pivot the traction-control bracket and traction pulley forward (Figure 42).

-

Pull the tension pulley outward (Figure 42).

-

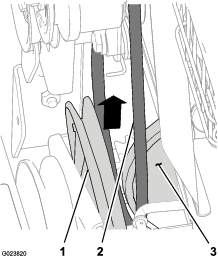

Slip the traction belt out of the groove of the traction pulley and up between the pulley and the friction wheel (Figure 43).

-

Slip the belt off the rear groove of the engine pulley and remove the belt from the machine (Figure 42).

Installing the Traction Belt

-

Align the traction belt between the friction wheel and the traction pulley (Figure 43).

-

Align the belt into the groove at the bottom of the traction pulley (Figure 42).

-

Pull the tension pulley outward (Figure 42).

-

Align the belt into the rear groove of the engine pulley (Figure 42).

Note: Release the tension pulley.

-

Move the traction-control bracket rearward and align the hole in the bracket with the traction-control rod (Figure 41).

-

Slip the rod through the bracket and secure the rod with the hairpin (Figure 41).

-

Install the broom-drive belt; refer to Installing the Broom-Drive Belt.

-

Install the engine cover and the belt cover; refer to step 1 of Checking the Condition of the Belts.

Maintaining the Chassis

Checking for Loose Hardware

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Visually inspect the machine for any loose missing hardware or any other possible problem.

-

Tighten all loose hardware before operating the machine.

-

Replace all missing hardware before operating the machine.

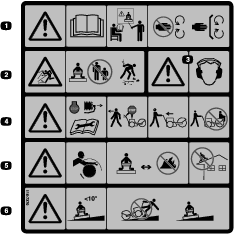

This is the safety-alert symbol. It is used

to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

This is the safety-alert symbol. It is used

to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.