Maintenance

Maintenance Safety

-

Before adjusting, cleaning, or repairing the machine do the following:

-

Park the machine on a level surface.

-

Disengage the drives.

-

Shut off the engine.

-

Wait for all moving parts to stop.

-

Engage the parking brake.

-

Raise the blades.

-

Disconnect the spark-plug wire.

-

-

Clean grass and debris from the blades, drives, muffler, and engine to help prevent fires. Clean up oil or fuel spillage.

-

Clean up oil or fuel spills.

-

Do not allow untrained personnel to service the machine.

-

Use jack stands to support the machine and/or components when required.

-

Carefully release pressure from components with stored energy.

-

Remove the spark-plug wire before making any repairs.

-

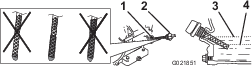

Use care when checking the blades. Wrap the blade(s) or wear thickly padded gloves, and use caution when servicing them. Only replace blades; do not straighten or weld them.

-

Keep your hands and feet away from moving parts. If possible, do not make adjustments with the engine running.

-

Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged decals.

-

Never interfere with the intended function of a safety device or reduce the protection provided by a safety device. Check their proper operation regularly.

-

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the product warranty.

-

Check the parking brake operation frequently. Adjust and service as required.

Recommended Maintenance Schedule(s)

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Before each use or daily |

|

| Every 25 hours |

|

| Every 50 hours |

|

| Every 100 hours |

|

| Every 200 hours |

|

| Yearly or before storage |

|

Pre-Maintenance Procedures

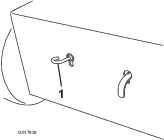

Disconnecting the Spark-Plug Wire

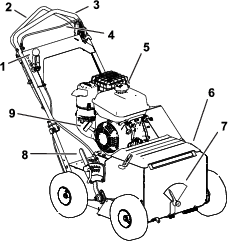

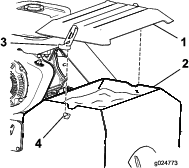

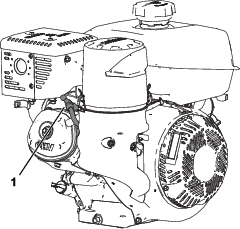

Before performing any maintenance on the engine, belt, or cutting blades, disconnect the spark-plug wire from the spark plug (Figure 15).

Lubrication

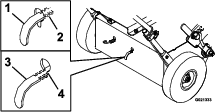

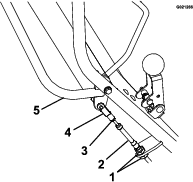

Lubricating the Slicer-Shaft Bearings

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire.

-

Engage the parking brake.

-

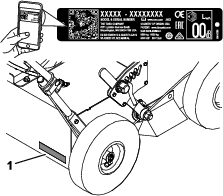

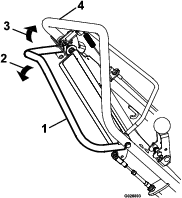

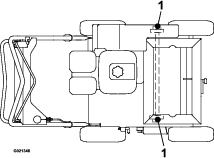

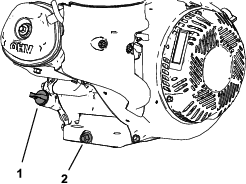

Lubricate the fittings (Figure 16) with 1 or 2 pumps of NLGI grade No. 2 multi-purpose grease.

Engine Maintenance

Engine Safety

-

Shut off the engine before checking the oil or adding oil to the crankcase.

-

Keep your hands, feet, face, clothing, and other body parts away the muffler and other hot surfaces.

Servicing the Air Cleaner

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

| Every 50 hours |

|

| Every 200 hours |

|

Important: Do not operate the engine without the air filter assembly; extreme engine damage will occur.

-

Shut off the engine and wait for all moving parts to stop; refer to Maintenance Safety.

-

Disconnect the wire from the spark plug; refer to Disconnecting the Spark-Plug Wire.

-

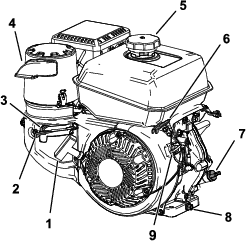

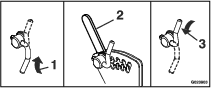

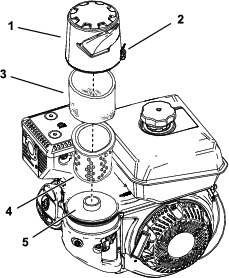

Unhook the latch that secures the air-cleaner cover ().

-

Remove the air-cleaner cover.

Note: Be careful to prevent dirt and debris from falling into the base.

-

Remove the foam and paper elements from the base ().

-

Remove the foam element from the paper element ().

-

Inspect the foam and paper elements, and replace them if they are damaged or excessively dirty.

-

Clean the paper element by tapping it gently to remove the dirt.

Note: Never try to brush dirt off the paper element; brushing forces the dirt into the fibers. Replace the element if tapping it fails to remove the dirt.

-

Clean the foam element in warm, soapy water or in a nonflammable solvent.

Note: Do not use gasoline to clean the foam element because it could create a risk of fire or explosion.

-

Rinse and dry the foam element thoroughly.

-

Wipe dirt from the base and the cover with a moist rag.

Note: Be careful to prevent dirt and debris from entering the air duct leading to the carburetor.

-

Install the air-cleaner elements and ensure that they are properly positioned.

-

Install the cover and hook the latch to secure it.

Servicing the Engine Oil

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| After the first 5 hours |

|

| Every 50 hours |

|

Toro Premium Engine Oil is available from your authorized Toro dealer.

Important: Use 4-cycle detergent engine oil that meets or exceeds the requirements for API service category SJ or higher.

Crankcase Capacity: 1.1 L (44.7 fl oz)

Important: If the oil level in the crankcase is too low or too high and you run the engine, you may damage the engine. This type of damage is not covered by the warranty.

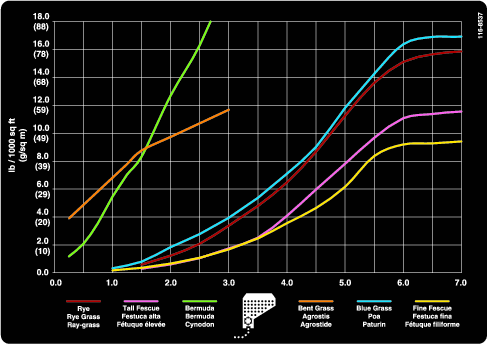

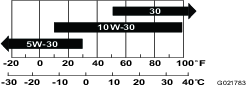

Note: Use SAE 10W-30 for general use. You can use the other viscosities shown in the chart when the average temperature in your area is within the indicated range (Figure 18).

Checking the Engine-Oil Level

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Stop the machine on a level surface, and ensure that the engine is level.

-

Disengage the cutting blades, shut off the engine, wait for all moving parts to stop, and turn the engine switch to the OFF position.

-

Allow the engine to cool.

-

Clean around the dipstick (Figure 19) so that dirt cannot fall into the fill hole and damage the engine.

-

Remove the dipstick, and wipe the end clean.

-

Insert the dipstick fully into the fill hole, but do not screw it in (Figure 19).

-

Remove the dipstick again and look at the end. If the engine-oil level is low, slowly pour only enough oil into the fill hole to raise the level to the Full mark on the dipstick (Figure 19).

Changing the Engine Oil

Warning

Oil may be hot after the engine has been run, and contact with hot oil can cause severe personal injury.

Avoid contacting the hot engine oil when you drain it.

-

Disengage the cutting blades, shut off the engine, turn off the engine switch, and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Raise the front wheels 5 to 8 centimeters (2 to 3 inches) off the ground, and place a pan under the drain plug to catch the oil.

-

Remove the drain plug (Figure 20).

-

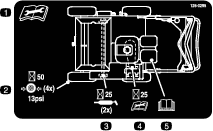

When the oil has drained completely, lower the front wheels to the ground, replace the drain plug, and torque the plug to 18 N⋅m (13 ft-lb).

Note: Dispose of the used oil at a certified recycling center.

-

Remove the dipstick, and slowly pour oil into the fill hole until the oil pours out of the fill hole.

-

Ensure that the oil is at the correct level on the dipstick; refer to Checking the Engine-Oil Level.

-

Replace and secure the dipstick.

-

Wipe up any spilled oil.

-

Connect the wire to the spark plug.

Servicing the Spark Plug

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

| Every 200 hours |

|

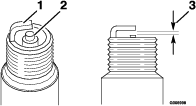

Spark plug specification: Champion RC12YC spark plug or equivalent.

-

Shut off the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Clean around the spark plug.

-

Remove the spark plug from the cylinder head.

Important: Replace a cracked, fouled, or dirty spark plug. Do not clean the electrodes, because grit entering the cylinder can damage the engine.

-

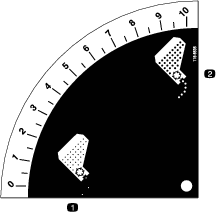

Set the gap on the plug to 0.76 mm (0.03 inch); refer to .

-

Carefully install the spark plug by hand (to avoid cross threading) until it is hand tight.

-

Tighten the spark plug an additional 1/2 turn if it is new; otherwise, tighten it an additional 1/8 to 1/4 turn.

Important: A loose spark plug can become very hot and can damage the engine; overtightening a spark plug may damage the threads in the cylinder head.

-

Connect the wire to the spark plug.

Checking the Spark Arrester

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

Note: A spark arrester is available as an option. If you require a spark arrester, contact your Authorized Service Dealer.Toro spark arresters are approved by the USDA Forestry Service.

Warning

If the engine has been running, the muffler will be hot.

-

Shut off the engine and wait for all moving parts to stop.

-

Wait for the muffler to cool.

-

Remove the spark arrester from the exhaust outlet by removing the screws from the muffler cover and exhaust deflector.

-

If there are any breaks or holes in the screen, replace the spark arrester.

-

Use a brush to carefully remove carbon deposits from the spark-arrester screen.

-

Install the spark arrester on the exhaust outlet.

Fuel System Maintenance

Warning

Fuel-system components are under high pressure. The use of improper components can result in system failure, fuel leakage, and possible explosion.

Use only approved fuel lines and fuel filters.

Draining the Fuel Tank

-

Shut off the engine and wait for it to cool down. Engage the parking brake.

Note: Drain gasoline from a cold engine only.

-

Disconnect the wire from the spark plug.

-

Close the fuel shutoff valve.

-

Disconnect the fuel line by loosening the tube clamp at the carburetor.

-

Open the fuel valve by turning the lever to the open position.

-

Drain the gasoline completely from the tank and fuel line into an approved fuel container.

-

Close the fuel valve.

Drive System Maintenance

Note: The hydrostatic transmission is factory-filled and sealed. It does not require maintenance. For service, contact your Authorized Service Dealer.

Checking the Tire Pressure

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

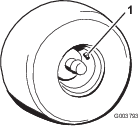

Maintain the air pressure in the tires as specified. To get the most accurate reading, check the tires when they are cold.

Pressure: 165 kPa (24 psi)

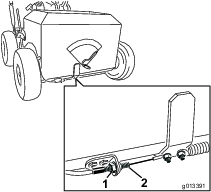

Adjusting the Self-Propel Drive

If the machine creeps either forward or rearward when the engine is on and the self-propel drive bail is in neutral, complete the following procedure:

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire.

-

Raise the cutting blades to the highest position.

-

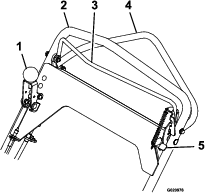

Squeeze the self-propel drive bail to the handle until the transmission is fully stroked.

-

If the bail contacts the handle, release the bail. If the bail does not contact the handle, then proceed to step 4.

-

Loosen the top adjustment nut 1 turn, and tighten the bottom adjustment nut.

-

Squeeze the bail to the handle.

-

Repeat this step until there is a gap of up to 3.2 mm (1/8 inch) between the self-propel drive bail and the handle.

-

Once the gap is achieved, proceed with step 4.

-

-

Remove the hairpin and rotate the turnbuckle clockwise 1 full turn.

-

Install the hairpin and rotate the jam nut against the turnbuckle.

-

Start the engine and test the adjustment, repeating this procedure as necessary.

Changing the Hydraulic-Transmission Fluid

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire. Engage the parking brake.

-

Remove the transmission from the machine.

-

Carefully clean the area around the expansion tank and oil-fill port.

Important: Do not allow any dirt or contamination to enter the hydraulic system.

-

Remove and retain the oil-fill port fitting, and position the transmission so that the oil drains completely out of the housing.

-

When all the oil has drained from the transaxle, remove and retain the #10-32 x 1/2 inch self-tapping screw and the ratchet fastener holding the expansion tank to the housing.

-

Remove the expansion tank, and drain the oil.

Note: Do not remove the vent cap from the tank.

Note: Do not remove the tank hose or the O-ring unless a replacement is needed.

-

Install the expansion tank by first inserting the hose into the tank. Place the tank opening over the O-ring, and push down to ensure a proper seal. Install the #10–32 x 1/2 inch self-tapping screw, and torque it to 25 in-lb (2.8 N⋅m).

-

Fill the transaxle at the oil-fill port until the oil level is between 1/2 and 1-1/4 inches (between 13 and 32 mm) below the top of the fill port.

Note: Toro Premium Hydro Oil is recommended. Mobil 1 15W-50 is an acceptable alternative.

-

Reinstall the oil-fill port fitting.

Belt Maintenance

Removing the Belt Guard

Installing the Belt Guard

-

Align the belt guard, capscrews, and flange-head bolts with the holes in the side frame plate and the spring bracket (Figure 25).

-

Assemble the belt guard to the machine with the 2 capscrews, and 2 flange-head bolts (Figure 25).

-

Torque the capscrews and flange-head bolts to 1378 to 2542 N∙cm (175 to 225 in-lb).

Checking the Condition of the Belts

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 25 hours |

|

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire. Engage the parking brake.

-

Remove the belt cover from the left side of the machine.

-

Check the belts for cracks, frayed edges, burn marks, or any other damage.

-

If a belt is damaged, replace it.

-

Check the drive-belt tension; refer to Adjusting the Self-Propel Drive-Belt Tension.

Adjusting the Self-Propel Drive-Belt Tension

If the self-propel drive belt squeals during operation (such as when moved from neutral to forward or reverse), tighten the belt as follows:

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire.

-

Raise the cutting blades to the highest position.

-

Remove and retain the 4 bolts, lock washers, and 2 spacers securing the belt cover to the left side of the machine, and remove the cover.

-

Check the tension of the belt. It should not flex more than a 6 mm (1/4 inch) with moderate finger pressure applied to the span just above the machine frame (Figure 26).

-

To tighten the belt, loosen the 4 mounting nuts and bolts securing the pulley carriage to the frame, and move the carriage to the left, tightening the belt; then secure the 4 mounting nuts and bolts (Figure 26).

-

Install the belt cover using the hardware retained in step 3.

Cutting Blade Maintenance

Checking and Replacing the Blades

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

When the cutting blades are worn down and no longer functioning properly, replace them as follows:

Important: Perform this procedure when the fuel tank is empty or nearly empty.

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire. Engage the parking brake.

-

Turn the fuel shutoff valve to the OFF position, and drain the fuel from the fuel tank; refer to Draining the Fuel Tank.

-

Remove the 4 bolts, lock washers, and 2 spacers securing the belt cover on the left side of the machine, and remove the cover.

-

Remove the blade drive belt from the machine.

-

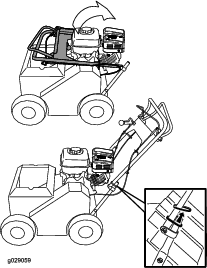

Tilt the machine rearward until the upper handle rests on the ground, and place a jack stand under the machine.

Note: If necessary, use 2 people to tilt the machine rearward.

Caution

Raising the machine and relying solely on mechanical or hydraulic jacks could be dangerous. The mechanical or hydraulic jacks may not provide enough support or may malfunction allowing the machine to fall, which could cause injury.

Do not rely solely on mechanical or hydraulic jacks for support. Use adequate jack stands or equivalent support.

-

Lower the cutting blades to the lowest position.

-

Spin the cutting blade assembly. It should spin freely. If it makes a grinding noise and is halting, the bearings are worn; replace them when the blades are replaced.

-

Inspect the blades for damage and wear, and replace them as required.

Danger

A worn or damaged blade can break. A piece of the blade could be thrown into the area of the operator or a bystander, resulting in serious personal injury or death.

-

Inspect the blade periodically for wear or damage.

-

Replace a worn or damaged blade.

-

-

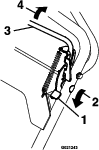

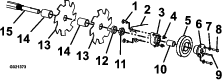

Remove the 4 carriage bolts and locknuts securing the cutting blade assembly (Figure 27), and remove it from the fork mounting bracket.

-

Remove the 2 bolts and washers attaching the pulley to the bearing. Loosen the setscrews on the bearing, and slide the key off the shaft (Figure 27). Remove the bearing and pulley by removing the bearing fasteners from the fork mounting bracket.

-

Loosen the 2 setscrews located on the flanged bearing, and slide the bearing off the shaft.

-

Loosen and remove the slicer-shaft nut and pulley spacer from the shaft.

-

Carefully slide the alternating blades and spacers off the shaft, and replace them as necessary.

-

Reverse the procedure to install the assembly.

Note: Rotate each blade 1/6 turn from the previous blade.

Warning

Incorrect installation of the blade or components used to retain the blade can be dangerous. Failure to use all original components and assembled as shown could allow a blade or blade component to be thrown out from under the deck resulting in serious personal injury or death.

Always install Toro blades, blade drivers, and blade bolts as shown.

-

Return the machine to the upright position.

-

Connect the wire to the spark plug.

Seed Gate Maintenance

Checking the Seed Gate

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Note: Trapped debris may prevent the seed gate from moving freely.

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire. Engage the parking brake.

-

Check to verify that the seed gate moves freely and is clear of debris.

-

If the seed gate does not open to the stop when the seeder-control lever is in the ON position, clean the gate assembly; refer to Cleaning the Seed Gate.

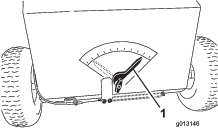

Adjusting the Seed-Gate Closed Position

If the seed gate is partially open when the seeder-control lever is in the OFF position, complete the following:

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire.

-

Raise the cutting blades to the highest position.

-

Pull the seeder-control lever to the OFF position.

-

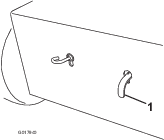

Loosen the nuts on the seed-gate control cable (see Figure 28).

-

Move the cable right to close the seed gate or left to open it.

Important: Do not tighten the cable to the point the seed gate is tight to the right with extreme tension on the cable as this will damage the gate and the cable. Only adjust it until the openings in the bottom of the seeder are closed.

-

Tighten the jam nuts and test the seeder-control lever to ensure that the seed gate opens and closes correctly.

Cleaning

Washing the Machine

Wash the machine as needed using water alone or with a mild detergent. You may use a rag when washing the machine

Important: Do not use brackish or reclaimed water to clean the machine.

Important: Do not use power-washing equipment to wash the machine. Power-washing equipment may loosen important decals or wash away necessary grease at friction points. Avoid excessive use of water near the control panel and engine.

Important: Do not wash the machine with the engine running. Washing the machine with the engine running may result in internal engine damage.

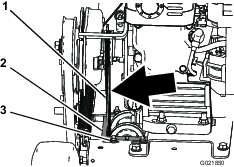

Cleaning the Engine Area

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

Caution

Excessive debris around engine and exhaust area can cause engine and exhaust area to overheat, which can create a fire hazard.

Clean all debris from engine and exhaust area.

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire.

-

Clean all debris from the engine air-intake screen and around the engine.

-

Wipe up any excessive grease or oil around the engine.

Cleaning the Bottom of the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Before each use or daily |

|

-

Shut off the engine, wait for all moving parts to stop, and remove the spark-plug wire.

-

To ensure the best performance, keep the underside of the machine clean.

Caution

The machine may dislodge material from under the housing.

-

Wear eye protection.

-

Stay in the operating position (behind the handle).

-

Do not allow bystanders in the area.

-

-

Turn the fuel shutoff valve to the OFF position, and drain the fuel from the fuel tank; refer to Draining the Fuel Tank.

-

Tilt the machine rearward until the upper handle rests on the ground, and place a jack stand under the machine.

Note: If necessary, use 2 people to tilt the machine rearward.

-

Remove the debris with a hardwood scraper or other suitable device. Avoid burrs and sharp edges.

-

Return the machine to the upright position.

-

Fill the fuel tank.

-

Connect the wire to the spark plug.

Cleaning under the Belt Cover

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 50 hours |

|

-

Shut off the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Remove and retain the 4 bolts, lock washers, and 2 spacers securing the belt cover to the left side of the machine.

-

Remove the cover, and brush out all the debris around the belt area.

-

Install the belt cover, and tighten all the hardware.

-

Connect the wire to the spark plug.

Cleaning the Seed Gate

-

Shut off the engine and wait for all moving parts to stop.

-

Disconnect the wire from the spark plug.

-

Drain the fuel from the fuel tank; refer to Draining the Fuel Tank.

-

Tilt the machine rearward until the upper handle rests on the ground, and place a jack stand under the machine.

Note: If necessary, use 2 people to tilt the machine rearward.

-

Clean the debris between the frame and the seed gate.

-

Lubricate the sliding surface between the frame and seed gate with a dry lubricant.

-

Return the machine to the upright position.

-

Fill the fuel tank.

-

Connect the wire to the spark plug.