Refer to the following table for the appropriate kit, traction unit, and traction-unit serial number combination:

| Kit Model Number | Traction Unit Model Number | Serial Number |

| 02945 | 02750 (T4240) | 405398421 and above |

| 30654 (CT2240) | 405623665 and above | |

| 31654 (CT2240) | All serial numbers | |

| 30657 (LT3340—cab equipped) | 405006390 and above | |

| 02946 | 30657 (LT3340) | 405006390 and above |

| 30659 (LT-F3000) | 404879018 and above | |

| 02947 | 30659 (LT-F3000—cab equipped) | 404879018 and above |

| 02949 | 02750 (T4240—cab equipped) | 405398421 and above |

| 02950 | 31050TE (PLH800) | 320000155 and above |

Safety

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Lower the cutting unit(s).

-

Shut off the machine and remove the key.

Installing the Kit

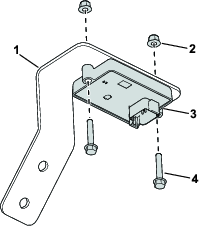

Parts needed for this procedure:

| Slope sensor | 1 |

| Slope-sensor mount (LTF/LT/CT only) | 1 |

| Slope-sensor mount (T4240 only) | 1 |

| Bolt (M6 x 35 mm) | 2 |

| Bolt (M6 x 25 mm—LTF/LT/CT only) | 2 |

| Flange nut (M6) | 4 |

| Bolt (M10—T4240 only) | 2 |

| Flange nut (M10—T4240 only) | 2 |

| LED indicator | 1 |

| Alarm | 1 |

| Wire harness | 1 |

| Cable tie | 6 |

| Slope sensor decal | 1 |

Installing the Kit

-

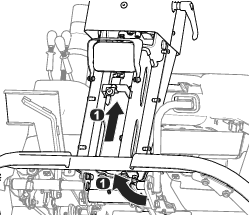

Release the operator platform; refer to your machine Operator’s Manual.

-

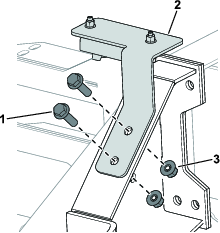

Use 2 bolts (M6 x 35 mm) and 2 flange nuts (M6) to secure the slope sensor to the slope-sensor mount.

-

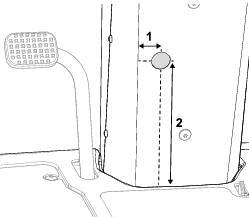

Use 2 bolts (M6 x 25 mm) and 2 flange nuts (M6) to secure the slope sensor mount to the chassis (Figure 3).

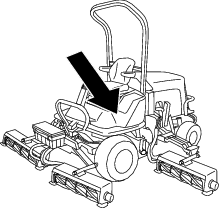

Note: Figure 2 shows the location of the chassis with the operator’s platform in the secured position. The chassis mounting position is under the operator’s platform.

-

Install the wire harness connector labeled P02 to the slope sensor (Figure 4).

-

Route the wire harness towards the control panel (Figure 4) and ensure that it is secured and away from moving parts or pinch points.

-

Coil any additional amount of wire harness to the left of the control panel (Figure 4).

-

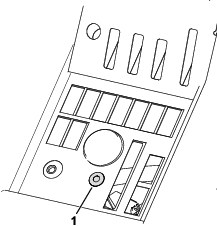

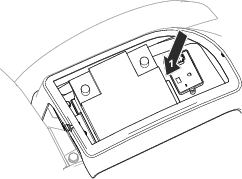

Remove the plug and install the LED light in the control panel as shown in Figure 5.

-

Connect the remaining wire-harness connectors as follows:

-

Wire harness connector labeled P01: Connect to one of the 6-pin sealed connectors located on the main harness below the control panel.

-

Wire harness connector labeled P08: Connect to the LED light.

-

Wire harness connector labeled P09: Connect to the alarm and position the alarm under the control panel.

Note: Ensure that the alarm does not obstruct any controls.

-

-

Secure the operator’s platform; refer to your machine Operator’s Manual.

-

Install the slope-sensor decal adjacent to the machine-stability decal on the operator’s platform (Figure 6).

Installing the Kit

-

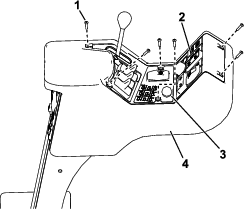

Remove the 6 screws securing the control panel to the control pod (Figure 7).

-

Carefully lift off the panel, ensuring that the connectors to the existing switches are not disturbed.

-

Remove the plug (Figure 7) from the console.

-

Insert the LED light into the console.

-

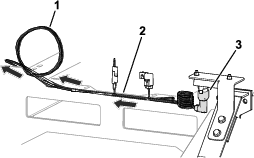

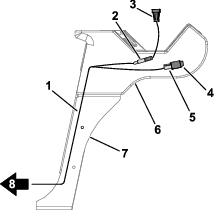

Install the wire harness as shown in Figure 8.

-

Connect the LED light to the wire-harness connector labeled P08 (Figure 8).

-

Connect the alarm to the wire-harness connector labeled P09 (Figure 8).

-

Route the remaining end of the wire harness down the control arm (Figure 8).

-

Use the previously-removed screws to secure the control panel to the control pod.

-

Raise the hood.

-

Route the wire harness along the machine chassis and up to the electrical panel.

-

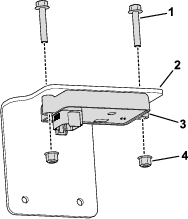

Use 2 bolts (M6 x 35 mm) and 2 flange nuts (M6) to secure the slope sensor to the slope-sensor mount (Figure 9).

-

Connect the wire-harness connector labeled P02 to the slope sensor.

-

Use 2 bolts (M6 x 25 mm) and 2 flange nuts (M6) to secure the slope sensor mount to the electrical panel (Figure 10).

-

Connect the kit-wire-harness connector labeled P01 to one of the 6-pin sealed connectors located below the relays on the electrical panel.

-

Use cable ties to secure the wire harness away from moving parts or pinch points.

-

Install the slope-sensor decal adjacent to the machine-stability decal on the storage-pod lid (Figure 11).

Installing the Kit

-

Remove the battery cover; refer to the electrical system maintenance section of your Operator’s Manual.

-

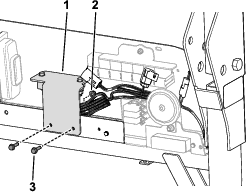

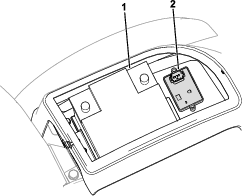

Use 2 bolts (M6 x 35 mm) and 2 flange nuts (M6) to secure the slope sensor on the mounting plate in front of the battery (Figure 12).

-

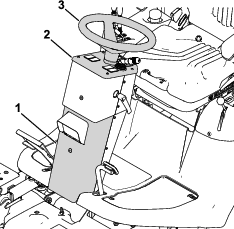

Remove the steering wheel, dashboard, and front panel (Figure 13).

Note: Carefully lift off the dashboard, ensuring that the connectors to the existing switches are not disturbed.

-

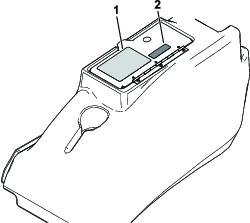

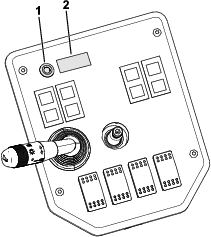

Remove the plug and install the LED light and the slope-sensor decal to the dashboard (Figure 14).

If a hole for the LED light is not present, drill a 19-mm hole in the location shown in Figure 15..

-

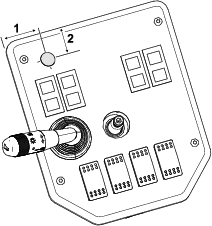

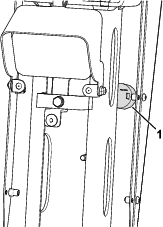

Remove the plug and install the alarm on the steering-column rear panel (Figure 16).

If a hole for the alarm is not present, drill a 30-mm hole in the location shown in Figure 17.

-

Connect the wire harness as follows:

-

Wire harness connector labeled P01: Connect to one of the 6-pin sealed connectors located on the main harness next to the grass chute on the right side of the machine.

-

Wire harness connector labeled P02: Connect to the slope sensor.

-

-

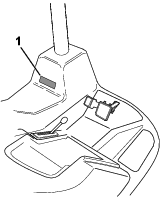

Route the wire harness under the platform with the machine wire harness and into the steering column (Figure 18).

-

Connect the remaining wire-harness connectors as follows:

-

Wire harness connector labeled P08: Connect to the LED light.

-

Wire harness connector labeled P09: Connect to the alarm.

-

-

Use a cable tie to coil together any additional amount of wire harness in front of the battery (Figure 19).

-

Use cable ties to secure the wire harness away from moving parts and pinch points.

-

Install the battery cover and the dashboard, steering wheel, and front cover.

Calibrating the Sensor

-

While the machine is on a flat surface, remove the plug from calibration connectors (labeled P05 and P06).

-

Plug the connectors together.

-

Turn the ignition key to the ON position, but do not start the engine.

Note: The LED light blinks as the sensor calibrates.

-

When the light no longer blinks, turn the ignition key to the OFF position.

-

Disconnect the calibration connectors and install the plug onto the connectors.

Operation

Using the Slope Sensor

When you start the machine, the LED light illuminates for 5 seconds to indicate that the sensor is functioning properly.

The light and alarm indicates the severity of the slope:

-

No light—normal operating conditions

-

Slow, flashing light—moderate slope

-

Fast, flashing light and audible alarm—steep slope; proceed to a more shallow slope.

Warning

Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death.

Use extreme caution when operating the machine on a slope.