Safety

Safety and Instructional Decals

|

Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. |

Installation

Determine the left and right sides of the machine from the normal operating position.

Preparing the Machine

-

Park the machine on a level surface.

-

Disengage the power takeoff and lower the attachments.

-

Engage the parking brake.

-

Shut off the engine and remove the key.

-

Wait for all movement to stop.

-

Allow machine components to cool.

Installing the Kit

Parts needed for this procedure:

| Sensor module | 1 |

| Bolt | 2 |

| Nut | 2 |

| Mounting bracket | 1 |

| Wire harness | 1 |

| Alarm | 1 |

| Plastic plug | 4 |

| Cable tie | 2 |

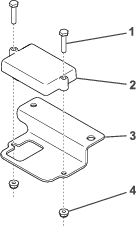

Installing the Sensor Module

-

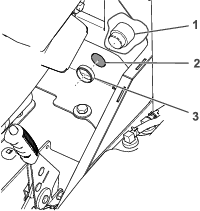

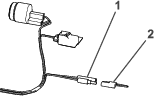

Secure the sensor module to the mounting bracket using 2 bolts and nuts (Figure 1).

-

Torque the fasteners to 4.2 N∙m (37 in-lb).

-

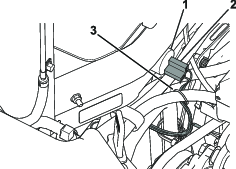

Remove and discard the plastic plugs securing the parking brake cover to the machine (Figure 2). Remove the parking brake cover.

Note: Use a putty knife or a plastic-fastener removal tool when removing the plastic plugs.

-

Raise the left side of the machine and remove the front left tire. Refer to Raising the Machine in the Operator’s Manual.

-

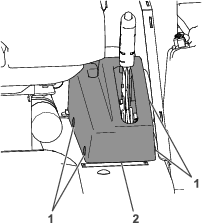

Remove the nuts shown in Figure 3.

Note: Do not remove the bolts from the machine.

-

Secure the mounting bracket to the machine using the bolts and nuts (Figure 3).

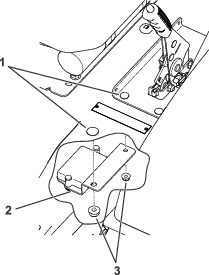

Installing the Alarm

-

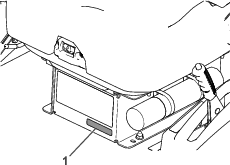

Remove the knockout from the panel behind the parking brake (Figure 4).

-

Remove the plastic nut from the alarm and use it to secure the alarm through the opening left by the knockout (Figure 4).

-

Install the previously removed parking brake cover using 4 new plastic plugs to secure it to the machine (Figure 2).

Note: You do not need to install the 2 outer plastic plugs on machines with cabs.

Routing the Wire Harness

-

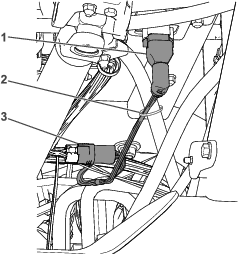

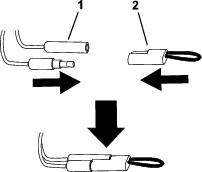

Plug the 90° connector into the bottom of the sensor module (Figure 5).

-

Route the wire harness back and plug the second connector into the machine wire harness (Figure 5).

-

Plug the very end of the wire harness into the previously installed alarm (Figure 6).

-

Secure the harness to the hydraulic tube with a cable tie as shown in Figure 5.

-

Secure the harness away from A/C compressor belt on cab units as shown in Figure 6.

Installing the Decal

Parts needed for this procedure:

| Decal | 1 |

-

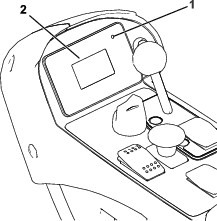

Install the decal on the machine as shown in Figure 7.

-

Install the front left tire, torque the lug nuts, and lower the machine. Refer to Installing the Front Tires in the Operator’s Manual.

Calibrating the Sensor

-

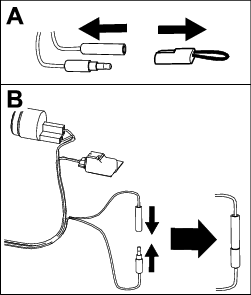

While on a flat surface, remove the plug from the calibration connectors (Figure 8).

-

Plug the calibration connectors together as shown in Figure 8.

-

Turn the ignition key to the ON position, but do not start the engine.

-

The displays shows Slope Sensor Calibrating.

Note: The LED light next to the display screen (Figure 9) is solid green as the sensor calibrates.

-

When the display shows Slope Sensor Calibrated, turn the ignition key to the OFF position.

-

Disconnect the calibration connectors and install the plug onto the connectors (Figure 10).

Operation

Using the Slope Sensor

The light and alarm indicates the severity of the slope:

-

Green light—normal operating conditions

-

Slow, flashing red light and B2713 displaying on the screen—moderate slope

-

Fast, flashing red light, audible alarm, and B2714 displaying on the screen—steep slope; proceed to a more shallow slope.

Warning

Slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death.

Use extreme caution when operating the machine on a slope.