Maintenance

Greasing the Platform

Grease all pivot joints every 8 operating hours and immediately after every washing.

Grease Type: General-purpose grease.

-

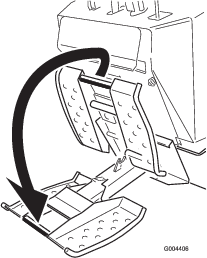

Lower the loader arms and stop the engine. Remove the key.

-

Clean the grease fittings with a rag.

-

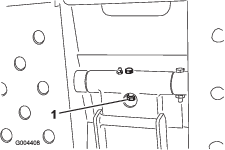

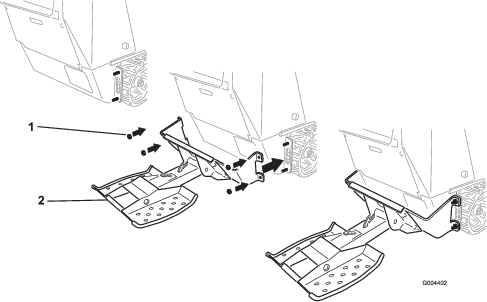

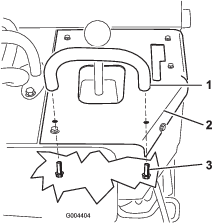

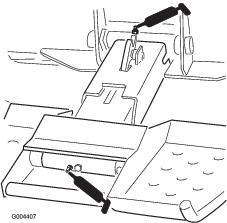

Connect a grease gun to each fitting (Figure 12).

-

Pump grease into the fittings until grease begins to ooze out (approximately 3 pumps).

-

Wipe up any excess grease.

Checking the Shear Bolt

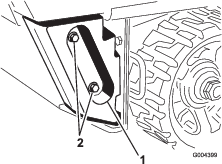

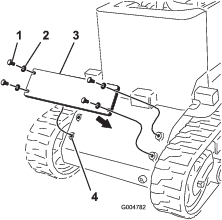

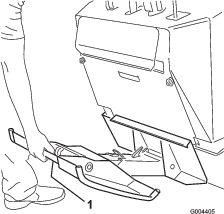

Check the shear bolt (Figure 13) for wear, cracks, or damage every 8 operating hours. Replace it if it is damaged.

Important: Use only a genuine Toro replacement shear bolt and nut. Other bolts will not function correctly and may lead to an unsafe condition.