Maintenance

Service Screens

-

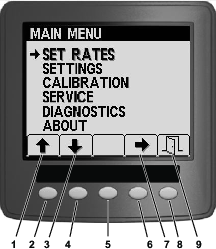

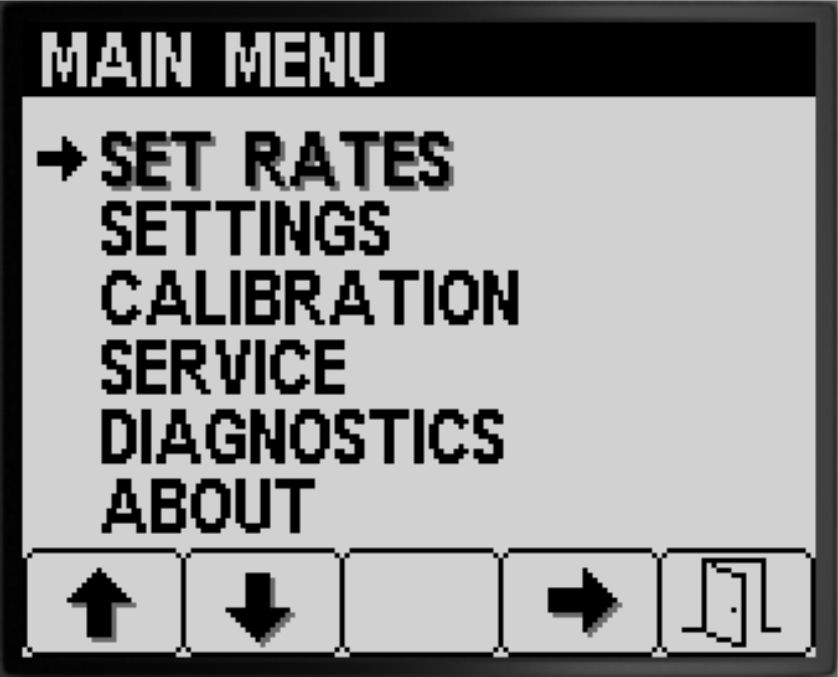

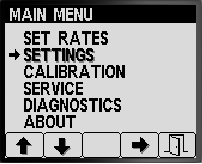

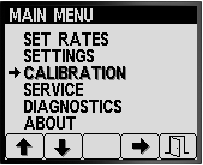

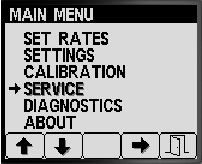

To access the Service screen press button 2 on the Main Menu screen to navigate to the SERVICE option (Figure 79); refer to Accessing the Main Menu Screen.

-

Press button 4 to select SERVICE sub-menu (Figure 79).

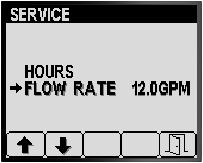

This screen displays and allows you to display hours and flow rate information.

Viewing the Service Hours

-

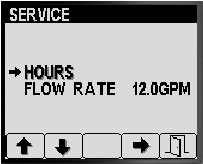

Press button 1 or 2 on the Service screen until you reach the HOURS option (Figure 80).

-

Press button 4 to select the Hours entry (Figure 80).

-

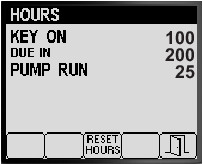

Use the counter information (Figure 81) displayed on the screen to determine the following:

-

The number of hours the key was in the ON position.

-

The number of until service is due.

-

The number hours the sprayer pump has run.

-

-

To reset the hours for all counter information, press button 3 (Figure 81).

-

Press button 5 to exit the HOURS screen, and return to the SERVICE screen (Figure 81).

Diagnostics Screens

-

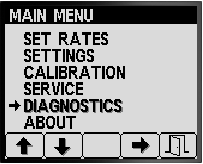

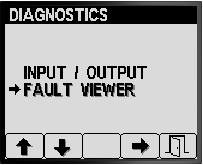

To access the Diagnostics screen press buttons 1 or 2 on the Main Menu screen to navigate to the DIAGNOSTICS option (Figure 83); refer to Accessing the Main Menu Screen.

-

Press button 4 to select DIAGNOSTICS sub-menu (Figure 83).

This screen displays and allows you to display input, output, and fault information.

Viewing the Input/Output Report

-

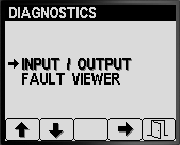

Press button 1 or 2 on the Diagnostics screen until you reach the INPUT/OUTPUT option (Figure 84).

-

Press button 3 to select the INPUT/OUTPUT entry (Figure 84).

-

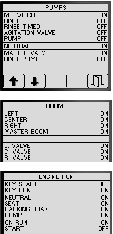

Use buttons 1 or 2 to navigate and review the state information for the inputs and outputs of the sprayer system (Figure 85).

-

Press button 5 to exit the INPUT/OUTPUT screen, and return to the DIAGNOSTIC screen (Figure 84).

Viewing the Sprayer System Faults

-

Press button 1 or 2 on the Diagnostics screen until you reach the FAULT VIEWER option (Figure 86).

-

Press button 3 to select the FAULT VIEWER entry (Figure 86).

-

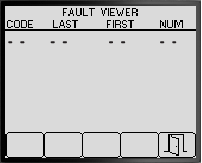

Review the fault viewer for sprayer system generated faults (Figure 87).

Note: If you see faults listed in the viewer, contact your Authorized Toro Service Dealer.

-

Press button 5 to exit the FAULT VIEWER screen, and return to the DIAGNOSTIC screen (Figure 87).

About Screens

-

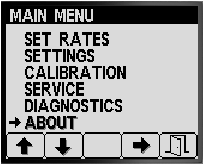

To access the About screen press buttons 1 or 2 on the MAIN MENU screen to navigate to the ABOUT option (Figure 88).

-

Press button 4 to select About sub-menu (Figure 88).

-

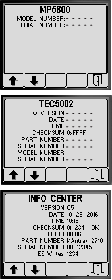

Press buttons 1 or 2 to scroll the machine information screen, the TEC controller information screen, or the InfoCenter information screen (Figure 89).

-

Press button 5 to exit the ABOUT screen, and return to the DIAGNOSTIC screen (Figure 87).