Maintenance

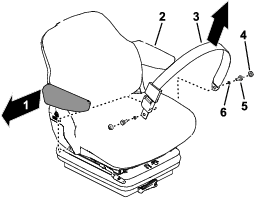

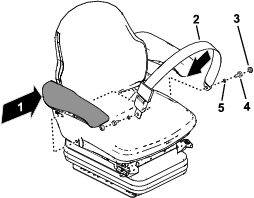

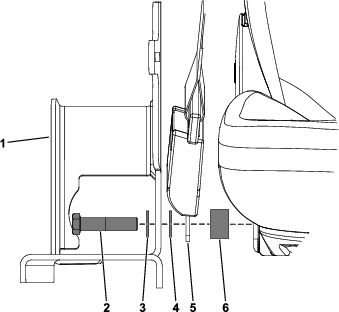

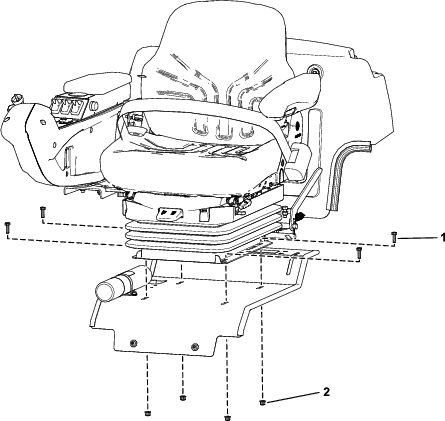

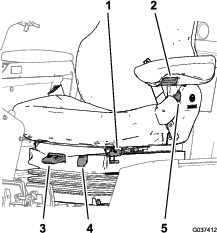

Greasing the Seat Suspension Mechanism

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Yearly |

|

-

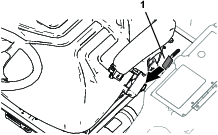

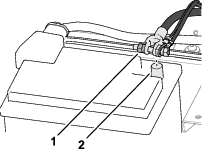

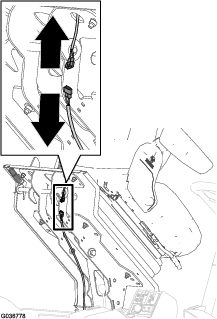

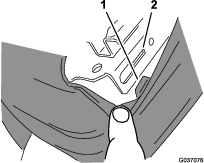

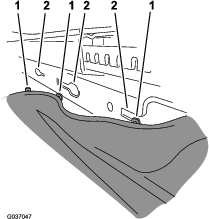

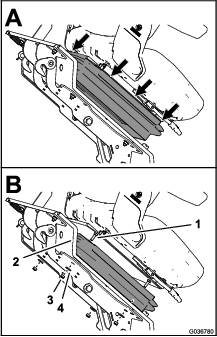

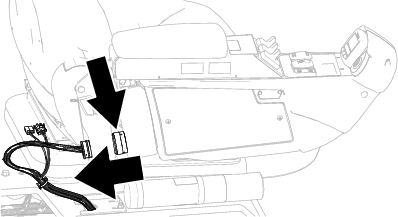

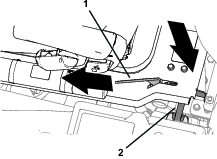

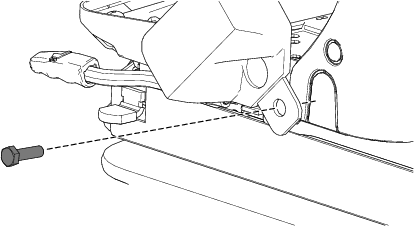

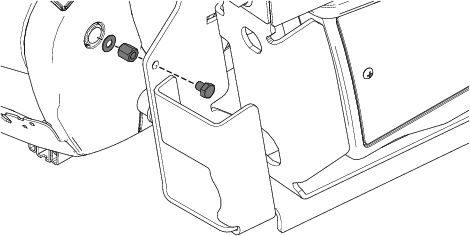

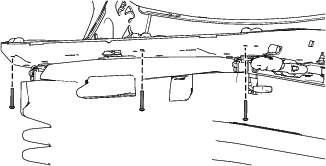

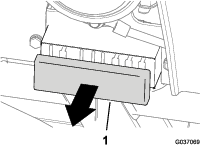

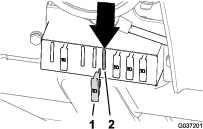

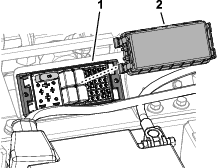

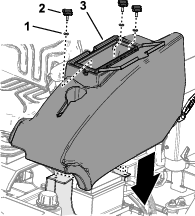

Pull back the rubber boot from the channel of the seat base.

-

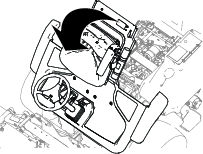

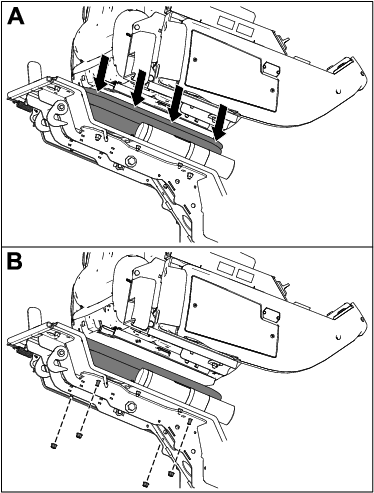

Apply good quality grease to all pivot points of the suspension mechanism.

-

Install the boot onto the channel of the seat base.

Maintaining the Seat Belt

There are no field-serviceable parts on the seat belt. If it shows signs of wear, damage, or malfunction, replace the seat belt assembly.

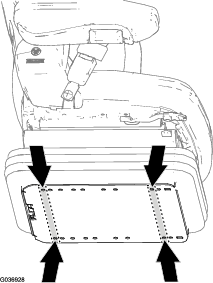

Cleaning the Seat

Important: Do not clean the seat with a pressure washer.

Note: Keep the surfaces of the operator's seat clean.

Caution

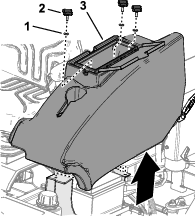

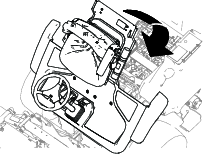

Use caution when cleaning the backrest—unintentionally moving backrest-tilt lever may cause the backrest to rotate forward unexpectedly and cause injury.

When cleaning the backrest cushion, firmly hold the backrest when operating the backrest-tilt lever.

-

You do not need to remove the upholstery from the seat frame for cleaning.

-

While cleaning the upholstery, do not allow cleaning solution to soak through the upholstery surfaces.

-

Use commercially available upholstery or plastic cleaning solution. Before using a new cleaning solution, test it for compatibility with the upholstery on a small concealed area of the seat.