Maintenance

Lubricating the Machine

| Maintenance Service Interval | Maintenance Procedure |

|---|---|

| Every 100 hours |

|

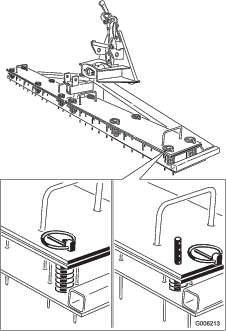

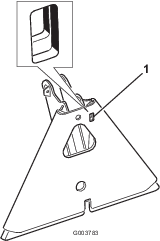

The nail drag has bushings that must be lubricated regularly. The bushings are located in the frame hub; lubricate the grease fitting immediately after every washing, regardless of the interval listed.

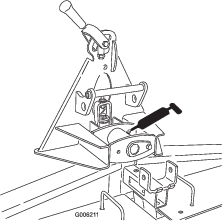

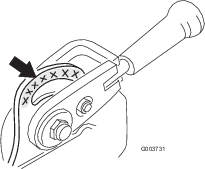

Greasing the Attachment Adapter

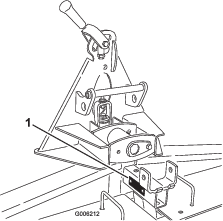

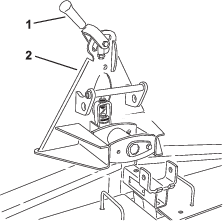

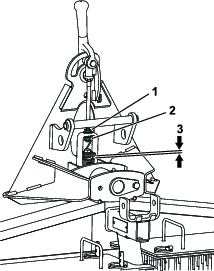

If the locking lever on the attachment adapter does not pivot freely and easily, apply a light coat of grease to the area shown in Figure 8.

Optional Equipment

| Quick-attach system groomer kit | Model No. 08762 |

| Automat kit (requires quick-attach system groomer kit, Model 08762) | Model No. 08763 |

| Manual drag mat kit | Model No. 130-7852 |