Note: Determine the left and right sides of the machine from the normal operating position.

Installation

Preparing the Machine

-

Park the machine on a level surface.

-

Engage the parking brake.

-

Lower the cutting unit.

-

Shut off the engine and remove the key.

Drilling Holes for the Idler Assembly

Parts needed for this procedure:

| Template |

-

Open the hood.

-

Remove the tension on the belt and move the belt away from the installation area.

-

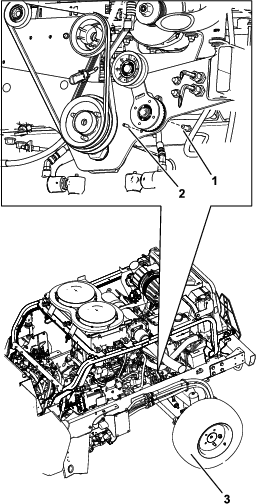

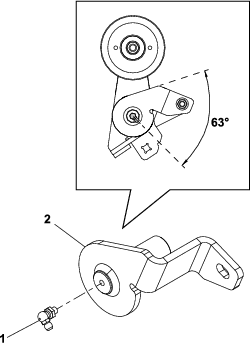

Remove the roll pin, bolt, and the existing idler pulley shown in Figure 1.

-

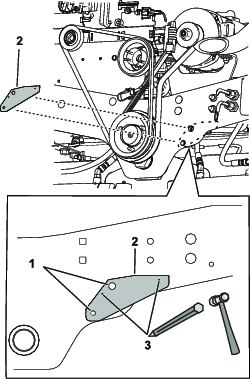

Align the template to the frame using the holes labeled 1 in Figure Figure 2.

-

Punch the location of the holes labeled 3 in Figure 2.

-

Remove the template.

-

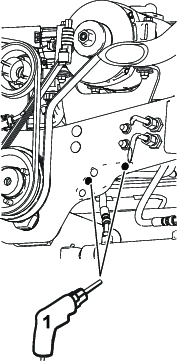

Drill 2 holes (13/32 inch) at the punched locations (Figure 3).

Installing the Idler Pulley

Parts needed for this procedure:

| Idler pulley | 1 |

| Idler arm | 1 |

| Idler support | 1 |

| Spring | 1 |

| Flange locknut (3/8 inch) | 1 |

| Bolt (1/2 x 1-3/4 inches) | 1 |

| Locknut (1/2 inch) | 1 |

| Spacer | 1 |

| Grease fitting | 1 |

| Bushing | 2 |

| Hex flange bolt (3/8 x 1-1/4 inches) | 2 |

-

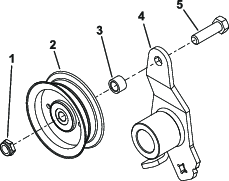

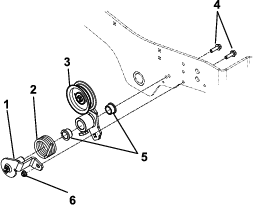

Install the idler pulley to the idler arm with a bolt (1/2 x 1-3/4 inches), spacer, and 1 locknut (1/2 inch); refer to Figure 4.

-

Install the grease fitting into the idler support as shown in Figure 5.

-

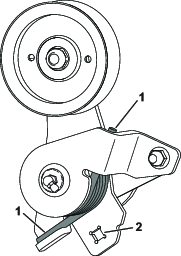

Install the idler support and idler arm to the frame of the machine with 2 bolts (3/8 x 1-1/4 inches), 2 bushings, a spring, and a nylon locknut (3/8 inch); refer to Figure 6.

-

Install the install the spring ends as shown in Figure 7.

-

Using a 3/8 inch ratchet in the square in the idler arm, rotate the idler arm and install the belt around the idler pulley (Figure 7).

-

Close the hood and secure it with the 2 hood latches.